Desulphurization method for circulating fluidized bed boiler with superfine desulfurizing agent granules

A circulating fluidized bed and desulfurizing agent technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of small specific surface area, low desulfurization efficiency, large diameter of desulfurizing agent particles, etc., and achieve large specific surface area , reduce waste, easy to promote the effect of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

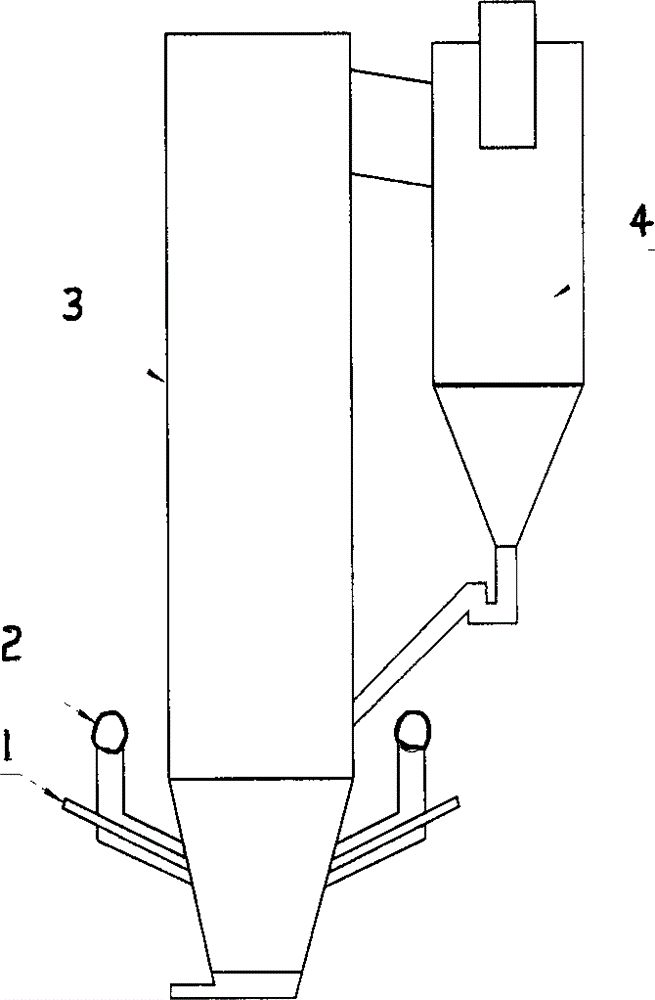

[0012] Embodiment: The accompanying drawing is a schematic diagram of a circulating fluidized bed boiler ultrafine particle desulfurization agent desulfurization method implementation diagram, the circulating fluidized bed boiler includes a desulfurizer injection pipe (1), a lower secondary air pipe (2), and a furnace (3) , cyclone separator (4). The desulfurizer powder (particle diameter: 50-75 μm) is sprayed into the furnace (3) through the desulfurizer injection pipe (1) by means of gas delivery, and the calcium-sulfur ratio is kept at 1.8-2.5. A desulfurizer injection pipe (1) is installed in each lower secondary air pipe (2) of the boiler. Under the action of the secondary air, the desulfurizer quickly diffuses into the flue gas and combines with the SO2 in the flue gas. Reacts to form sulfates or sulfites. The unreacted desulfurizer is captured by the cyclone separator (4) and circulated with the material to the furnace (3) for secondary reaction. The furnace temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com