Patents

Literature

58results about How to "Large amount of gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PVC (polyvinyl chloride) foam material for sole and preparation method of PVC foam material

InactiveCN105440505AImprove temperature resistanceGood weather resistanceSolesWeather resistanceFoaming agent

The invention relates to the technical field of PVC materials, in particular to a PVC (polyvinyl chloride) foam material for a sole and a preparation method of the PVC foam material. The PVC foam material for the sole comprises raw materials in parts by weight as follows: 80-120 parts of PVC resin, 40-60 parts of a plasticizer, 20-30 parts of a filling agent, 6-10 parts of a wear-resistant modifier, 4-8 parts of a thermal stabilizer, 2-4 parts of a foaming agent, 0.8-1.2 parts of a lubricant and 1-2 parts of a processing aid. The raw materials are adopted for preparation of the PVC foam material for the sole, the weight proportion of the raw materials is controlled strictly, the performance of the prepared PVC foam material for the sole exceeds the national standards, and the PVC foam material is environment-friendly and has good temperature resistance and weather resistance, high strength, excellent anti-impact performance, good flame-retardant effect, good processing performance and excellent comprehensive performance.

Owner:广东祺龙科技有限公司

Method for producing coal gasification formed coke

InactiveCN101440295AHigh mechanical strengthUniform particle sizeSpecial form destructive distillationPolyvinyl alcoholCarbonization

The invention relates to a method for manufacturing coal gasification type coke. Blind coal is used as a main material, is added with a caking agent and is pressurized to form type coal; the type coal is subjected to middle-temperature carbonization and high-temperature oxygen-isolated carbonization to manufacture type coke, wherein raw material coal comprises 75 to 90 percent of blind coal, 3 to 10 percent of one-third coking coal, 5 to 12 percent of fat coal and 2 to 10 percent of graphite; the composite caking agent is made from a mixture of hydrochloric acid and sodium hydroxide accounting for 0.1 to 0.5 percent of the weight pulverized coal, a polyvinyl alcohol modified solution accounting for 7 to 10 percent of the weight the pulverized coal, weathered coal accounting for 5 to 10 percent of the weight the pulverized coal and high aluminium powder accounting for 0.5 to 3 percent of the weight the pulverized coal according to proportion. The manufactured product has high fixed carbon and high heating power, can substitute for the blind coal or the coke to produce water gas, does not need to make any reconstruction on the prior gas generating furnace, can reduce the production cost of the water gas, improve the economic value of the pulverized coal of the blind coal, can be widely applied to fertilizer, metallurgy, building materials and other industries, and has good market application prospect.

Owner:福建龙耀煤业科技有限公司

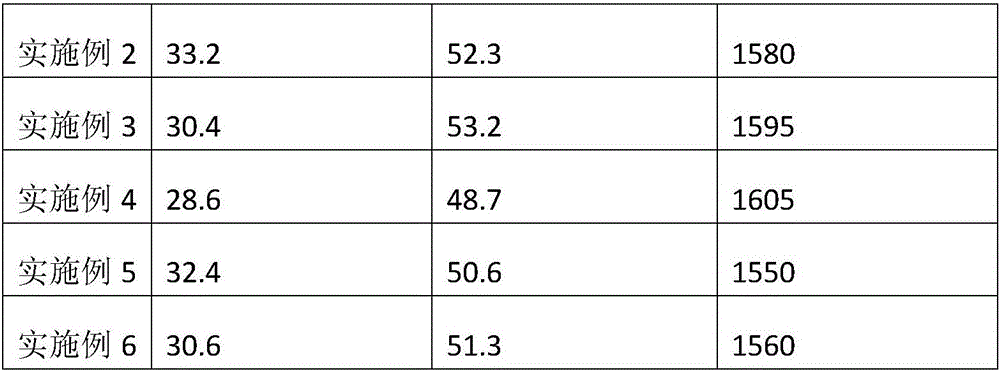

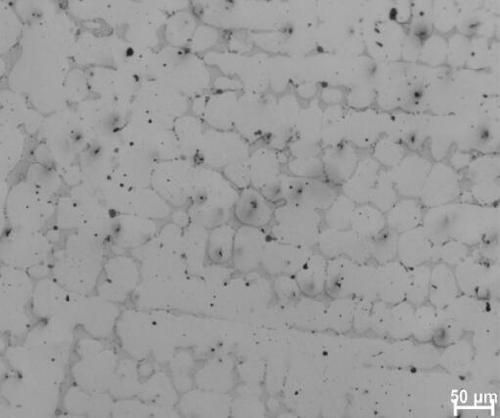

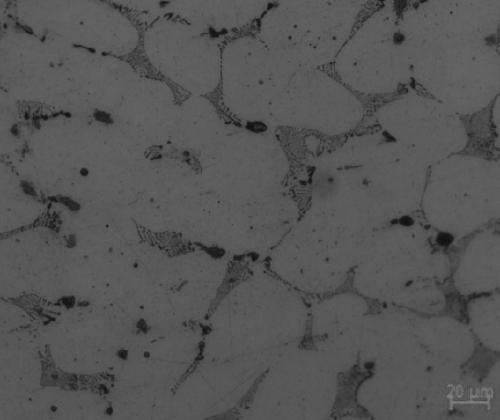

Homo-polypropylene/carbon fiber/montmorillonite composite material and preparation method thereof

The invention relates to a homo-polypropylene / carbon fiber / montmorillonite composite material and a preparation method of the homo-polypropylene / carbon fiber / montmorillonite composite material. The homo-polypropylene / carbon fiber / montmorillonite composite material is prepared from the following raw materials in parts by weight: 85 to 95 parts of homo-polypropylene, 5 to 10 parts of carbon fibers, 2 to 3 parts of organic montmorillonite, and 3 to 5 parts of foaming masterbatches, the foaming masterbatches are prepared from the following raw materials in parts by weight: 60 to 70 parts of polyethylene, 20 to 30 parts of foaming agents, 1 to 3 parts of foam stabilizers, 3 to 5 parts of nucleating agents, 0.5 to 1.5 parts of zinc oxide, 0.5 to 1 part of a titanate coupling agent NDZ-201, 3 to 5 parts of PE wax and 0.5 to 1 part of zinc stearate. According to the homo-polypropylene / carbon fiber / montmorillonite composite material disclosed by the invention, the mechanical properties are excellent, the tensile strength reaches 36.9 MPa, the impact strength reaches 55.1 kJ / m<2>, and the flexural modulus reaches 1590 MPa. The foaming material has best foaming and biggest cell density, the cell density reaches 2.3*10<7> / cm3, and the porosity of the foaming material is 17.7%.

Owner:GUANGZHOU JUZHU GENERAL TECH INST CO LTD

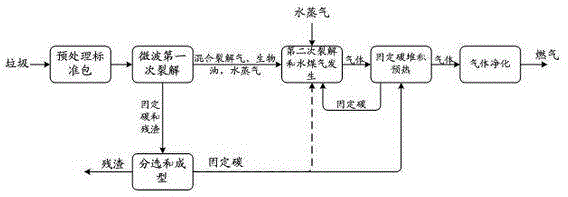

Process for preparing gas by microwave carbon pyrolysis of municipal solid waste

ActiveCN102719279ALarge amount of gasPromote lysisSolid waste disposalSpecial form destructive distillationWater vaporMaterials science

The invention relates to a process for preparing gas by the microwave carbon pyrolysis of municipal solid waste and belongs to the technical field of environmental protection. The process comprises the following steps of: removing dust from municipal solid waste which is accumulated for a certain time, press-packing, and feeding into microwave heating equipment for pyrolysis; separating fixed carbon and residue which are generated by the pyrolysis, and making the fixed carbon into a shape which is loose and through which gas can conveniently pass; continuously heating the fixed carbon, and fully cracking incomplete pyrolysis gas and biological oil to generate combustible gas; reacting water vapor and thermofixed carbon to generate water gas; and performing purification treatment such as desulfurization and dephosphorization on the gas to obtain harmless combustible gas. By the process, the yield of the gas is high, the calorific value is high, the energy is equal to or higher than the energy consumed by the process, and the operation cost is low; and toxic and substances with peculiar smell such as dioxin are eradicated while a large amount of harmless combustible gas is obtained, so that the environment is effectively protected.

Owner:SICHUAN HOPE MICROWAVE SCI & TECH

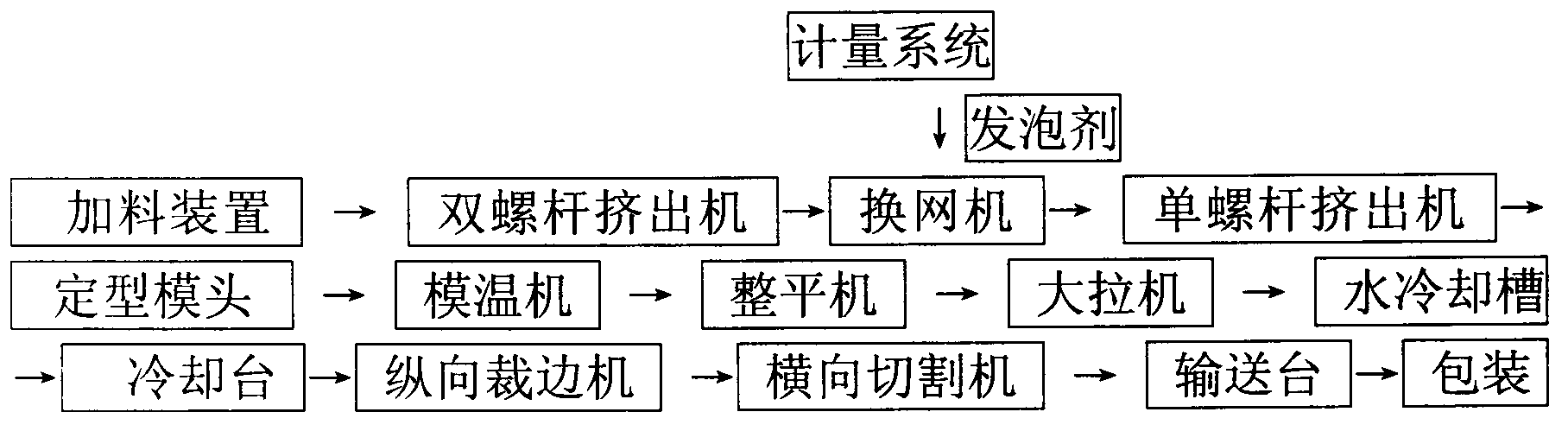

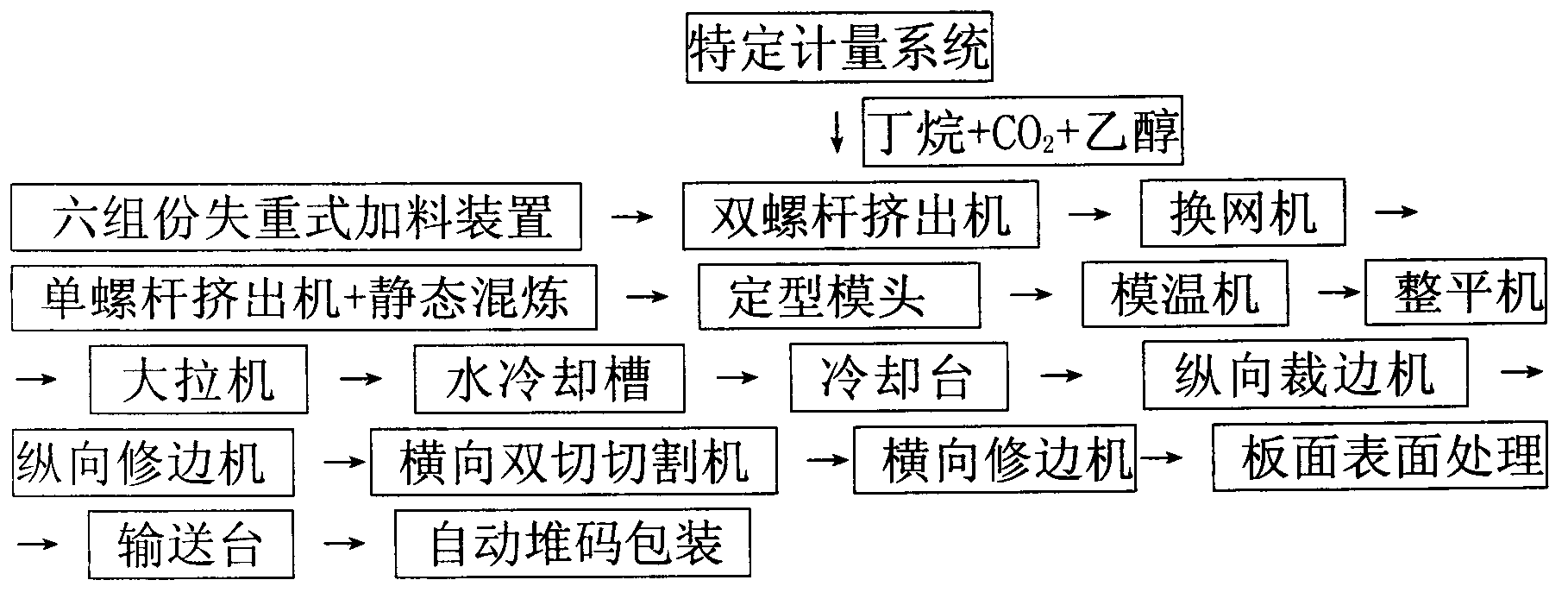

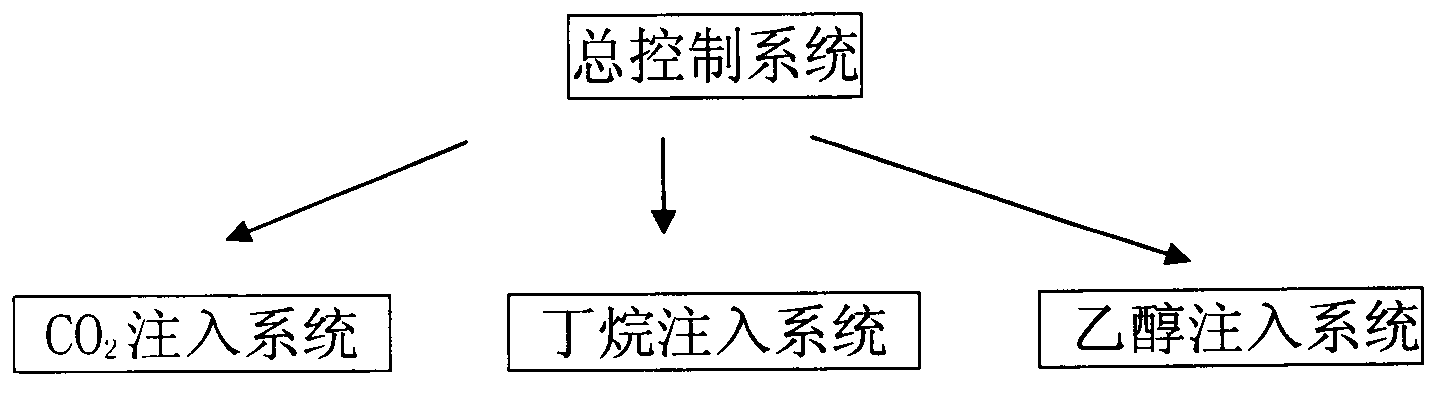

Process for production of extruded polystyrene foam plate by CO2 foaming

Relating to the technical field of extruded polystyrene foam plates, the invention provides a process for production of an extruded polystyrene foam plate by CO2 foaming. The production technology process includes: adding raw materials into a double-screw extruder through a six-component weight loss type feeding device, injecting butane, CO2 and ethanol into the double-screw extruder to conduct foaming through a specific metering system; extruding the foamed material to a net change machine by the double-screw extruder, conveying the material to a single screw extruder by the net change machine and conducting static mixing, letting the single screw extruder to extrude the mixed material to a shaping mold head, shaping a foam plate on the shaping mould head by a mold temperature controller, leveling the shaped foam plate by a leveling machine, stretching the leveled foam plate by a heavy drawing machine, cooling the stretched foam plate by a cooling stage and conveying it to the cooling stage. The process provided by the invention has the advantages of production cost reduction, time saving, accurate control, convenient operation, and ensures process stability.

Owner:上海新兆塑业有限公司

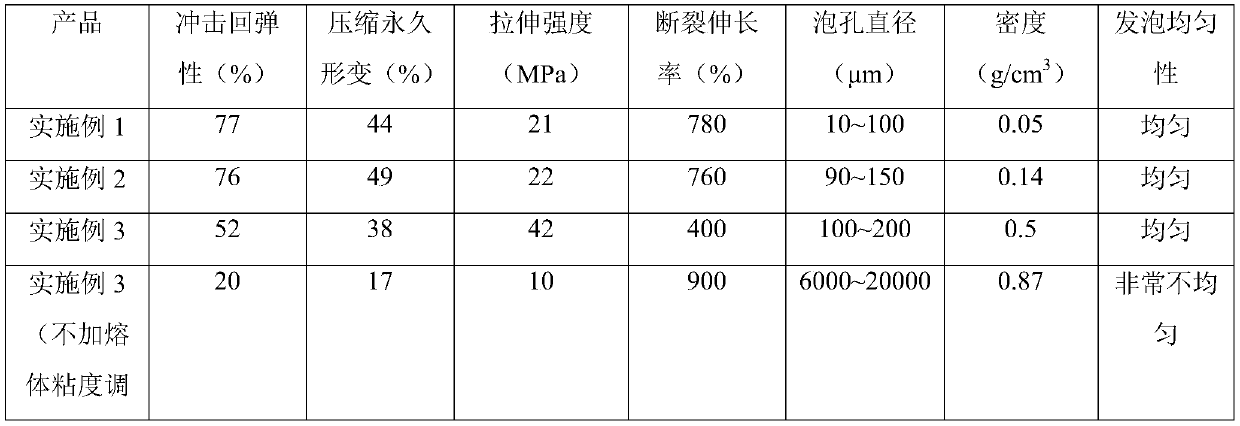

Thermoplastic polyamide elastomer physical and chemical combined foam material and preparation method thereof

The invention discloses a thermoplastic polyamide elastomer physical and chemical combined foam material and a preparation method thereof. The preparation method comprises the following steps: (1), extruding a mixture of polyamide elastomer, a melt viscosity regulator, a cell nucleating agent and a foaming aid by an extruder to obtain foaming particles; (2), mixing the foaming particles, a surfactant and a chemical foaming agent in a reactor, heating the mixture in an inert atmosphere, starting stirring and keeping the temperature; heating the mixture continuously, adding a physical foaming agent to pressurize the reactor, performing pressure relief after heat preservation and pressure keeping, and performing cooling and shaping to obtain the product. The foam material has the advantages of good rebound resilience, uniform cell size, low foam material density, good foam effect and the like; besides, aiming at the characteristics of low melt viscosity and melt strength and difficult foam of the polyamide elastomer, a melt viscosity regulator is introduced to improve melt viscosity and strength to facilitate foaming, and the foam material is suitable for popularization and application. Furthermore, chemical and physical foaming methods are used, gas evolution is large, and controllability is high.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

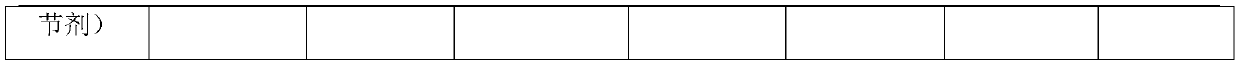

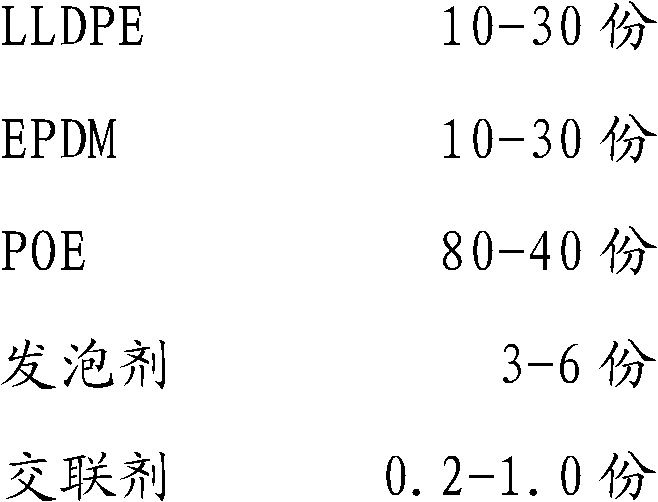

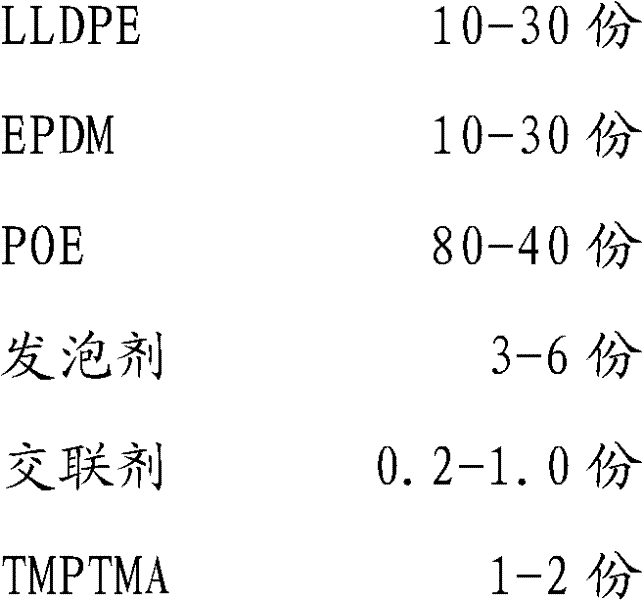

PP foaming composite additive

The invention discloses a PP foaming composite additive, which comprises the following raw materials by weight: 10-30 parts of LLDPE, 10-30 parts of EPDM, 80-40 parts of POE, 3-6 parts of foaming agent, 0.2-1.0 part of cross-linking agent, 1-2 parts of TMPTMA, 0.2-1.0 part of nano zinc oxide; PP enables a rapid degradation while crosslinking foaming, the TMPTMA is taken as a crosslinking auxiliary agent which effectively increases the crosslinking speed, meanwhile, a reactivity reaction is generated between the crosslinking and degrading of PP, and the crosslinking speed is greater than degradation speed. The speed for decreasing the PP melt-strength is alleviated which is beneficial to ideal foaming of PP, in addition, bubble strength and uniformity can be increased by adding nano zinc oxide, and the reaction process can be accelerated, the crosslinking temperature of the cross-linking agent can be reduced, the heat transfer and the crosslinking degree can be increased, the composite additive is benefit for harmless degradation, recovery and treatment of waste PP foaming plastics.

Owner:HUAQIAO UNIVERSITY

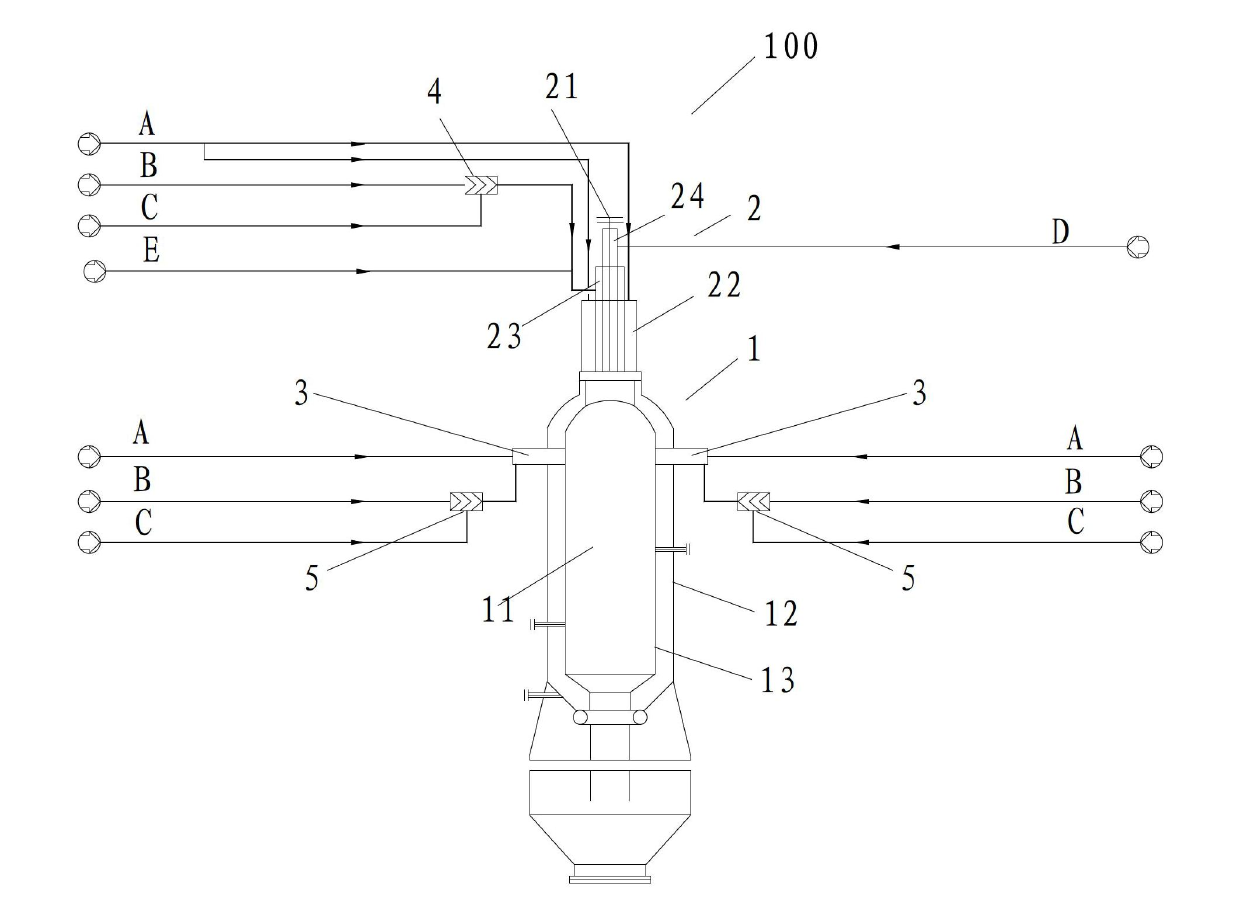

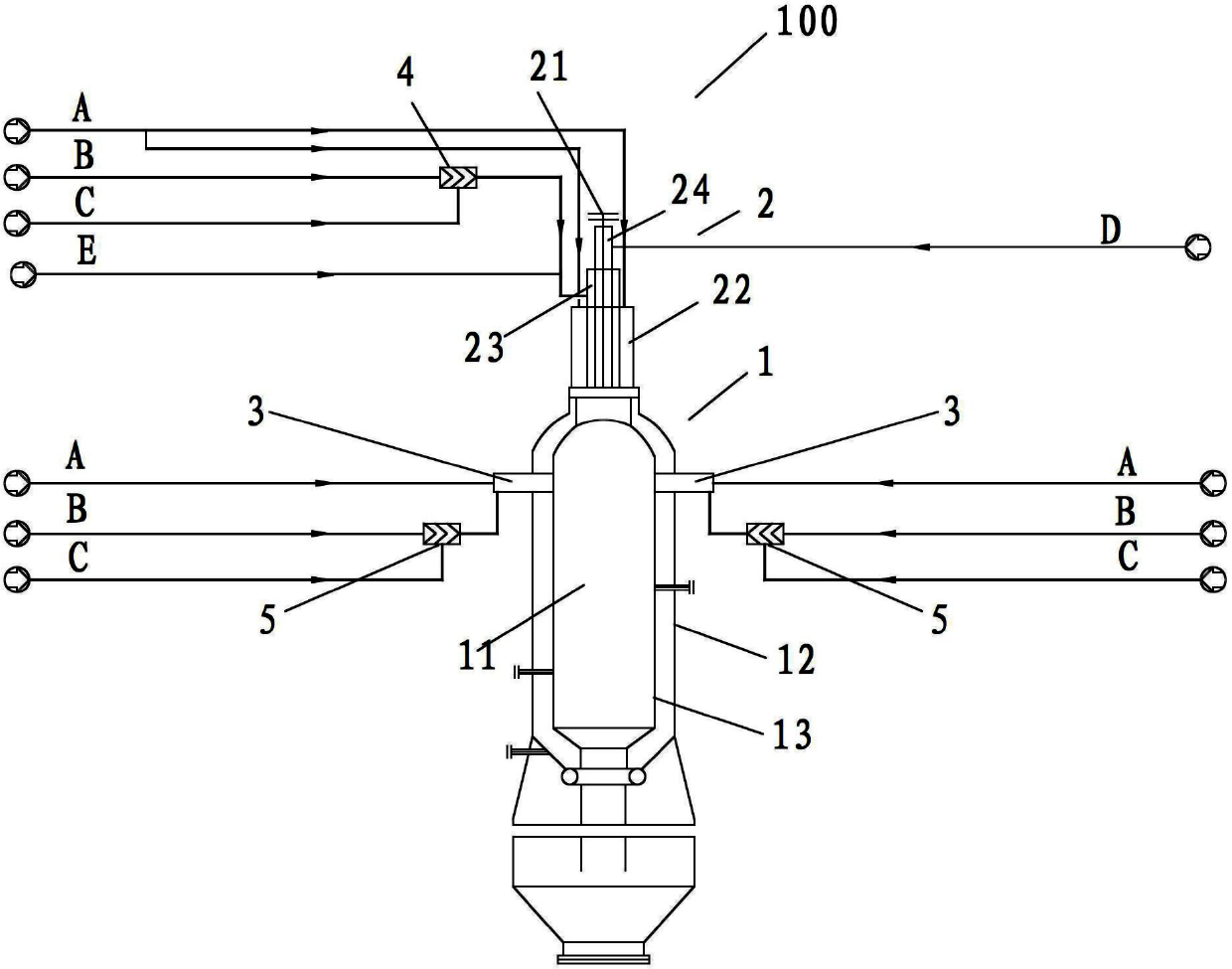

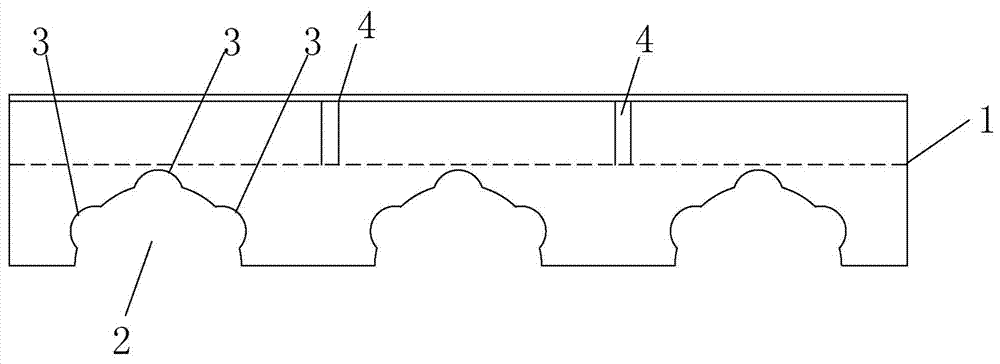

Dry powder gasification furnace

InactiveCN102676228AIncrease transfer rateImprove conversion rateGranular/pulverulent flues gasificationDecompositionWater vapor

The invention discloses a dry powder gasification furnace which comprises a furnace body, a top nozzle and a side nozzle, wherein the furnace body is internally provided with a vaporizing chamber; the top nozzle is arranged at the top of the furnace body, and is used for injecting pulverized coal, oxygen, steam and fuel gas into the vaporizing chamber from the top of the vaporizing chamber; the top nozzle is internally provided with an ignition rod; and the side nozzle is arranged at the side of the furnace body, and is used for injecting pulverized coal, oxygen and steam into the vaporizing chamber from the side of the vaporizing chamber. According to the dry powder gasification furnace, the carbon conversion rate is higher than 99%, and the decomposition rate of water vapor is higher than 80%; therefore, the dry powder gasification furnace has remarkable gasification efficiency and can be widely applied to the field of the existing coal gasification technology.

Owner:BEIJING YINGDE QINGDA TECH

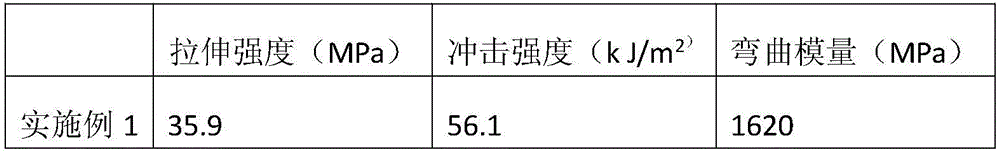

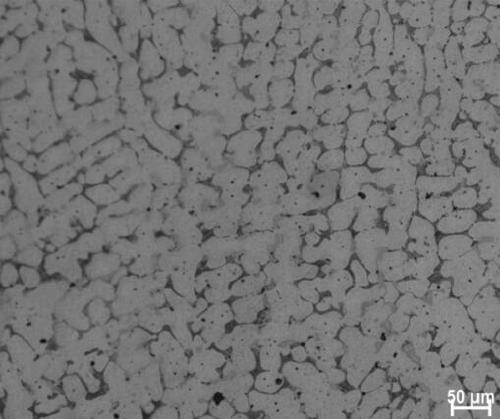

Polypropylene microcellular foam composite material and preparation method thereof

The invention relates to a polypropylene microcellular foam composite material and a preparation method thereof. The polypropylene microcellular foam composite material is prepared from, by weight, 85-95 parts of polypropylene, 5-10 parts of carbon fibers and 3-5 parts of foaming masterbatch, wherein the foam masterbatch is prepared from, by weight, 60-70 parts of polyethylene, 20-30 parts of a foaming agent, 3-5parts of a nucleating agent, 0.5-1.5 parts of zinc oxide, 0.5-1 part of a titanate coupling agent NDZ-201, 3-5 parts of PE wax and 0.5-1 part of zinc stearate. According to the polypropylene microcellular foam composite material prepared through the method, the mechanical property is superior, the tensile strength reaches 35.9 MPa, the impact strength reaches 56.1 kJ / m<2>, and the bending modulus reaches 1,620 MPa.

Owner:GUANGZHOU JUZHU GENERAL TECH INST CO LTD

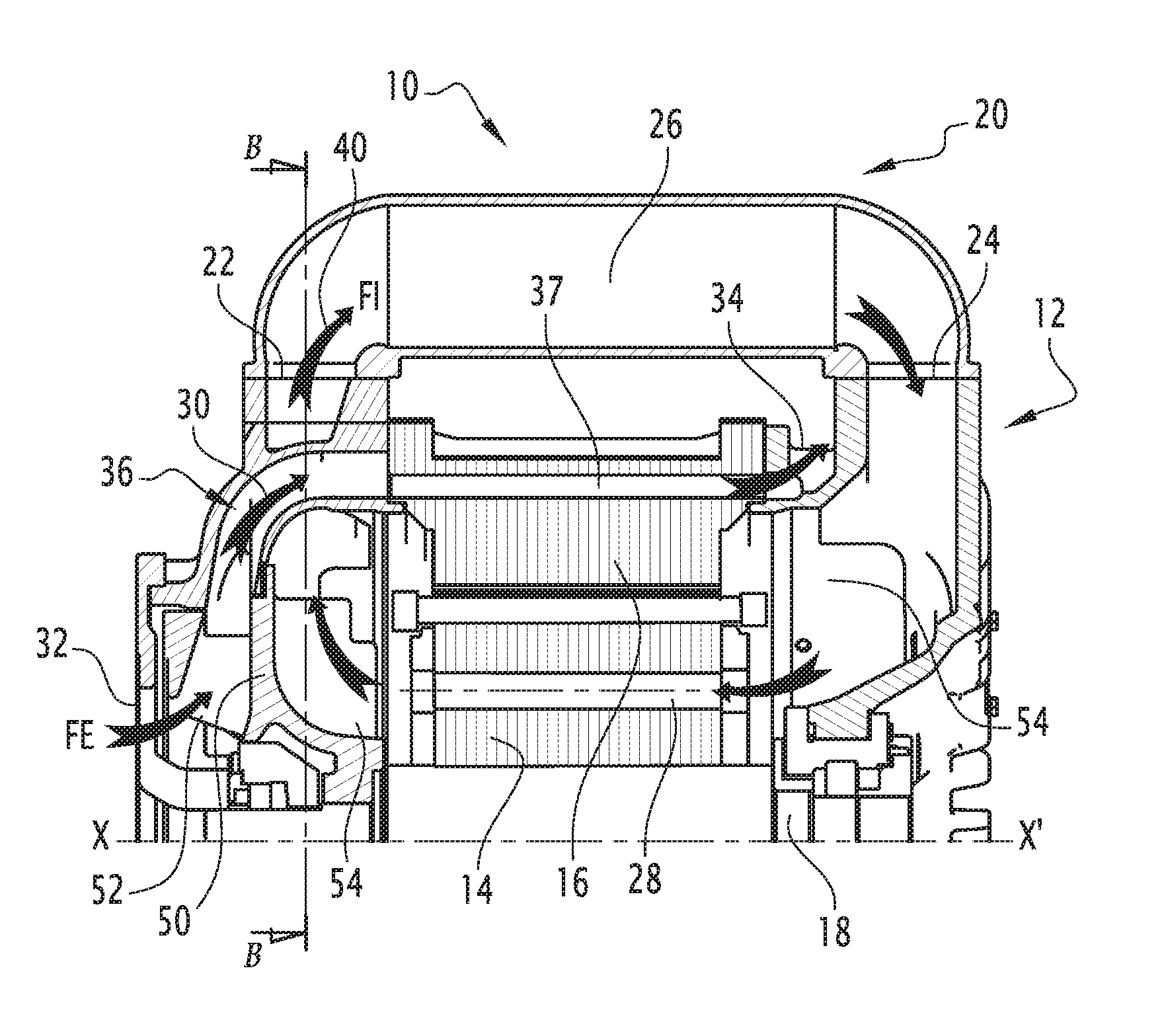

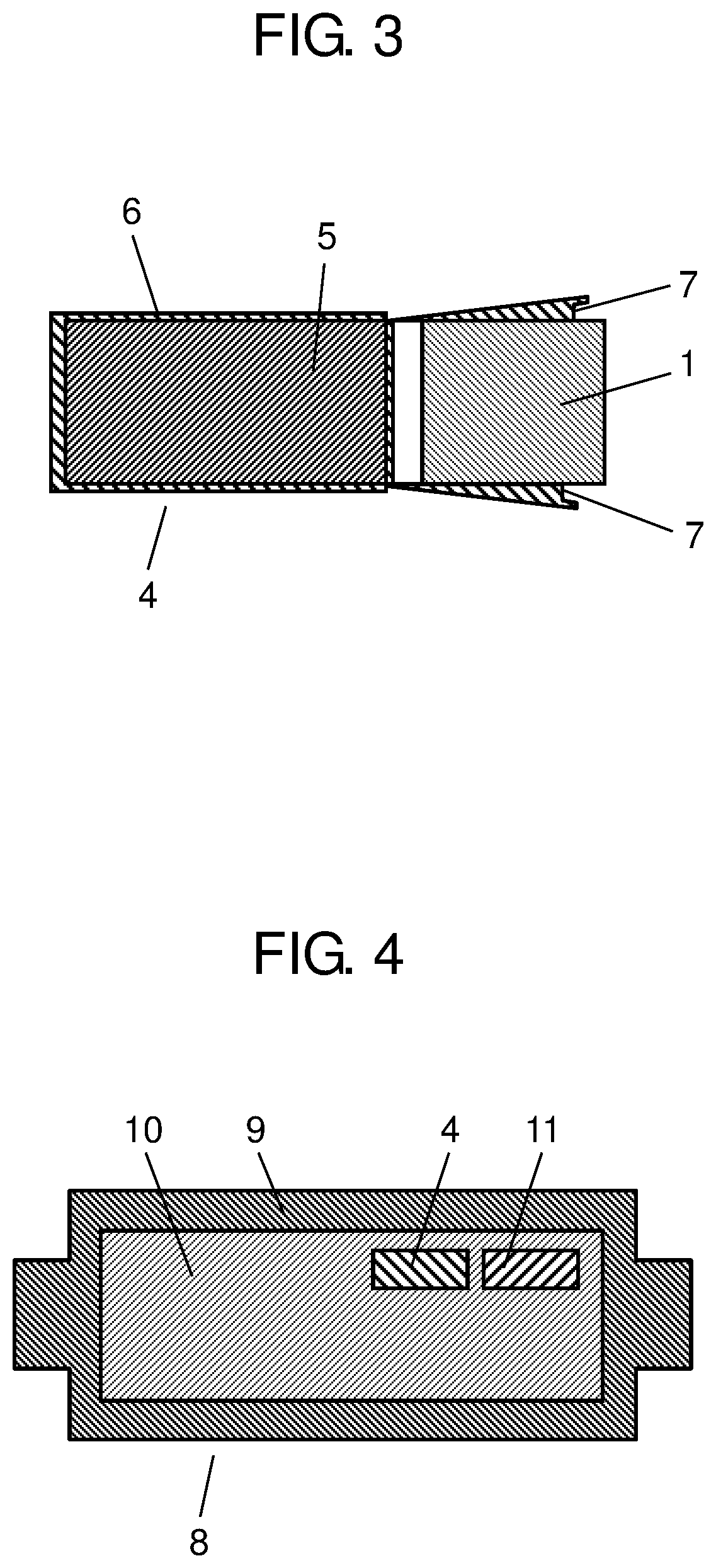

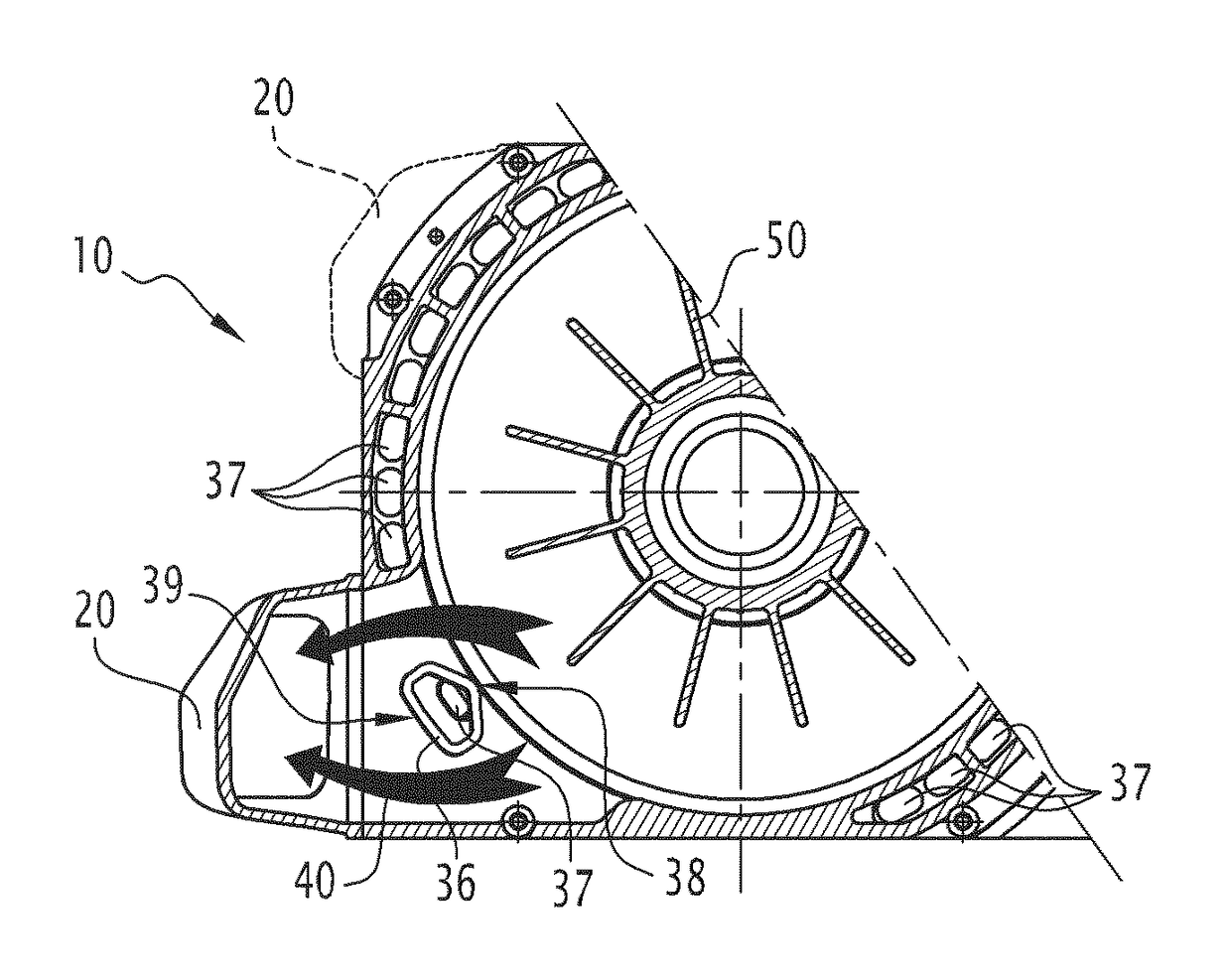

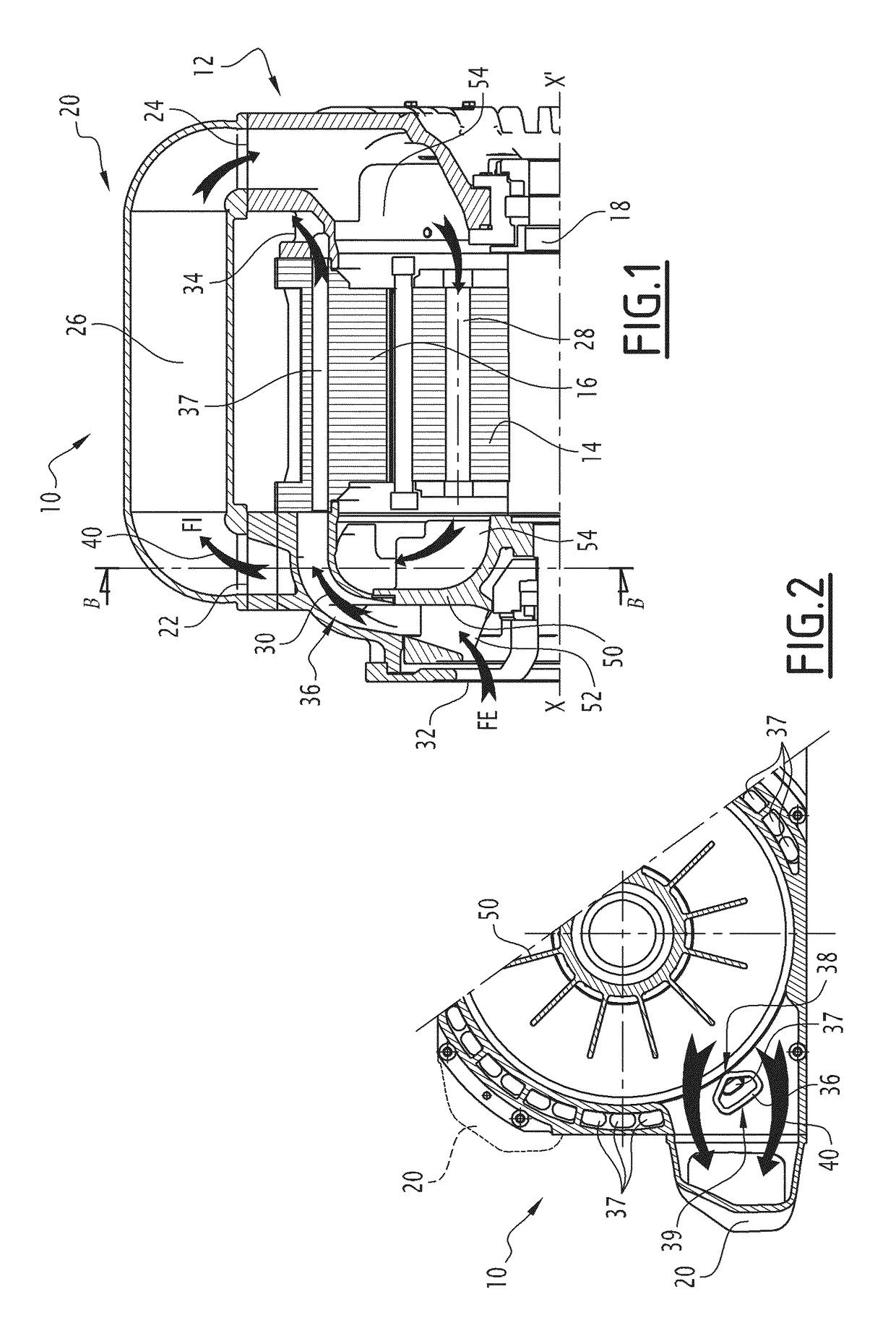

Electric motor with outer radiator and two separate cooling circuits

ActiveUS20160233743A1Efficient simple coolingEfficient and simple coolingMagnetic circuit stationary partsCooling/ventillation arrangementHeat spreaderElectric motor

A motor includes a frame defining an internal volume in which are housed a rotor and a stator; at least one cooling circuit, which includes a primary inlet and a primary outlet in fluidic communication with the outside of the frame; at least one cooling device outside the frame, which includes a secondary air inlet and a secondary air outlet, and a conduit; at least one secondary cooling circuit, separate from the primary circuit, crossing the rotor and in fluidic communication with the secondary inlet and the secondary outlet of the cooling device. The secondary cooling circuit is crossed by a channel of the primary cooling circuit supplying the stator with the gas fluid from the outside of the frame.

Owner:ALSTOM TRANSPORT TECH SAS

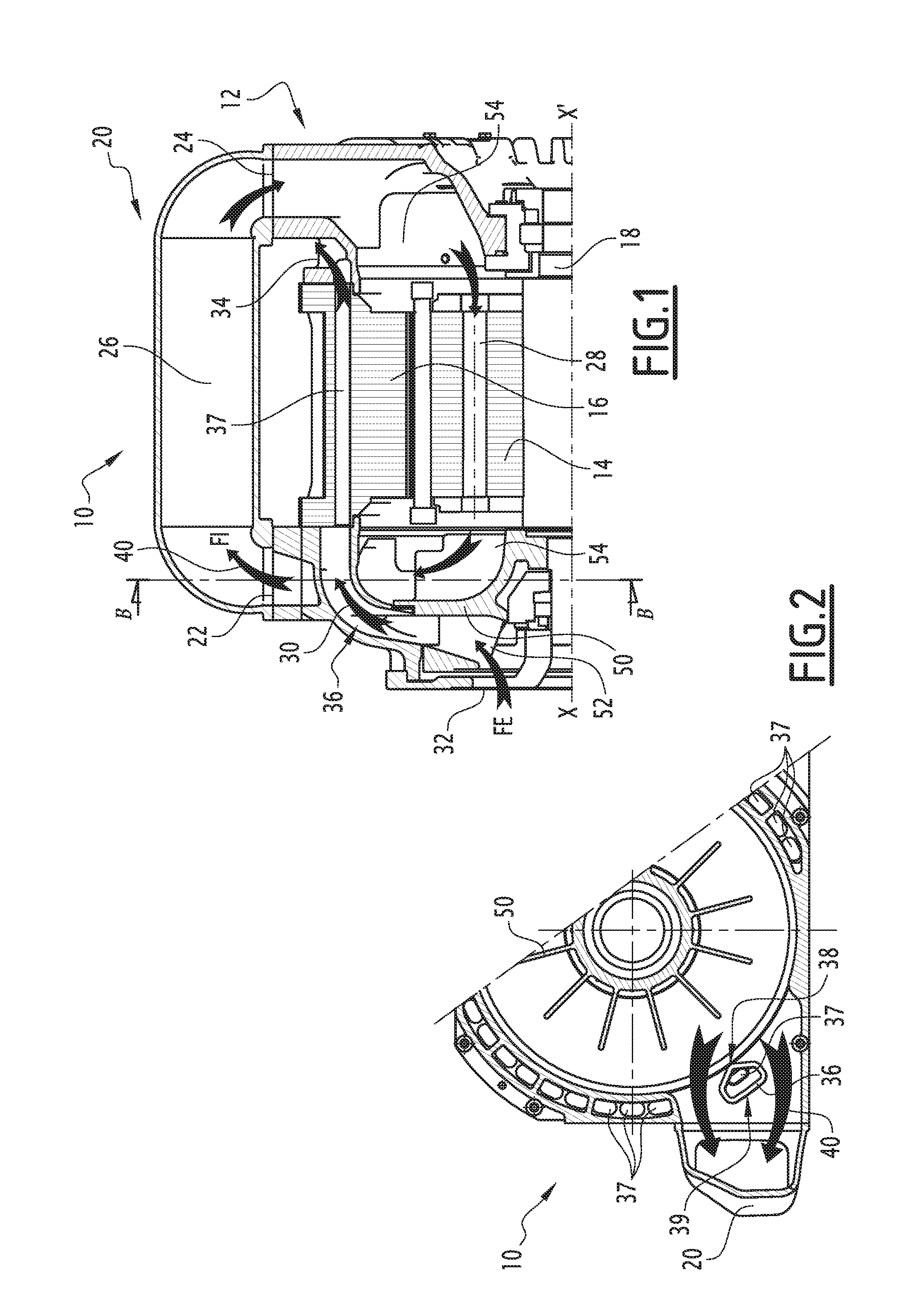

EVA nanometer composite foam rubber and plastic combined inner tire preparation method

InactiveCN106147037AExtended service lifeSolve the substantive defects such as piercing, puncture, tire leakage repair and inflationPolymer scienceMolding machine

EVA / EPDM / CPE / MMT nano-composite closed-cell micro-cellular foam rubber-plastic combined inner tube belongs to the scientific and technological field of nano-composite foam rubber and plastic products. The method is to mix and shear the EVA nanocomposite base material and other filler additives according to the weight of the preferred formula to make EVA blended foam material, put it into the molding machine, heat it at high temperature for foaming, and then you can get high-performance Molecular EVA nano-composite rubber and plastic products. The invention solves the versatility of the combined tire inner tubes of various vehicles, airplanes and bicycles, and obtains a substantive breakthrough in new material products that are not afraid of being punctured and not inflated, high in quality and low in price, can be recycled and utilized.

Owner:吕钟舟

Processing method of sponge rubber

Relating to the processing field of rubber materials, the invention discloses a processing method of sponge rubber. The method includes the following seven steps of rubber drying, rubber cutting, rubber breaking, plastication, mixing, molding and vulcanization, and shrinkage treatment, etc. Crude rubber is placed in a drying room for heating so as to decrease hardness and melt crystals, thus facilitating cutting and making moisture volatilized at the same time. Before plastication, a well cut rubber block is subjected to rubber breaking by a rubber breaking machine, thus improving the production efficiency of sponge rubber, ensuring the quality of sponge rubber and production equipment safety. By adopting multi-stage plastication glue, the plastication temperature is low, the plasticization effect is good, and arbitrary plasticity requirement can be met. The rubber has good aging resistance and fatigue resistance, and low thermogenesis under a dynamic condition.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

A thin-wall heat-resistant steel exhaust manifold casting method

The invention discloses a thin-walled heat resistant steel exhaust gas manifold casting method, and belongs to the technical field of heat resistant steel exhaust gas manifold casting. The casting method comprises the following steps of core manufacturing, modeling, smelting, pouring and sand shakeout. Through the reasonable design of the amount of molten iron entering a pouring channel and the section ratio of each unit in a pouring system and strict control of the iron mold sand covering layer thickness, the mold cavity exhaust gas system and pouring temperature and the sand shankout box opening time, the thickness of the prepared exhaust gas manifold is 3.2-3.6mm, the wall is thin, the grain size level is 5.5, and the technical property reaches the required index. The prepared exhaust gas manifold has the thin wall and low weight, is stable in property, solves the problem that a common wet sand technology is difficult to form, effectively lowers the integral weight, and achieves light-weight design of an engine.

Owner:西峡飞龙特种铸造有限公司 +1

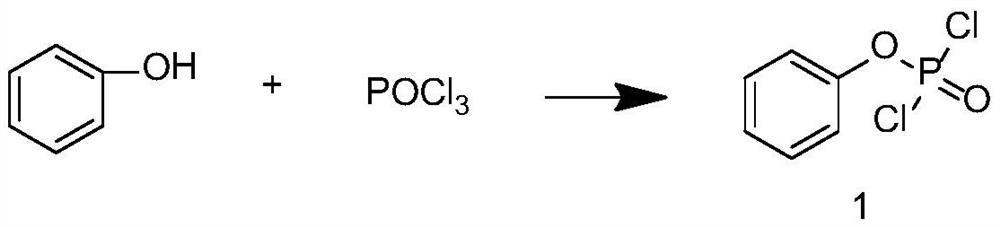

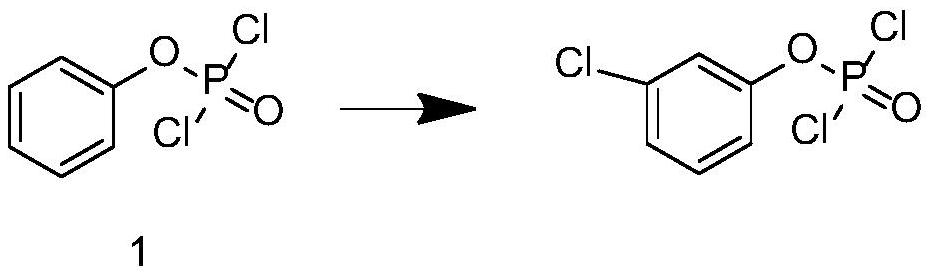

Monocomponent foaming agent and preparation method thereof

InactiveCN103242501AOvercome flammableOvercome the disadvantage of being explosiveToxic gasPolyester

The invention provides a monocomponent foaming agent and a preparation method thereof. The monocomponent foaming agent is prepared from the following raw materials in parts by weight: 20 to 30 parts of isocyano polyacid ester, 25 to 30 parts of polyester polyol, 3 to 8 parts of polyether polyol, 30 to 40 parts of methylene dichloride, 0.5 to 2 parts of catalyst and 3 to 5 parts of fireproof and high-temperature resistant filling agent. The preparation method comprises the following steps: adding the polyether polyol into a vessel and dehydrating in the vacuum environment; sequentially adding polyester polyol, isocyano polyacid ester and the catalyst and stirring evenly; adding the fireproof and high-temperature resistant filling agent and stirring at a high speed; adding methylene dichloride; and then standing for 24 hours, thereby obtaining the monocomponent foaming agent. The monocomponent foaming agent has the beneficial effects of overcoming the flammable and explosive defects of the traditional foaming agent and being safer and more convenient to store and use. The monocomponent foaming agent has the characteristics of being large in gas generation volume, small in residue volume, high in reaction speed and uniform in gas generation. In addition, the monocomponent foaming agent is simple in production process, low in cost, safe and environmental-friendly and cannot generate toxic gas.

Owner:天津鼎鑫防火材料科技有限公司

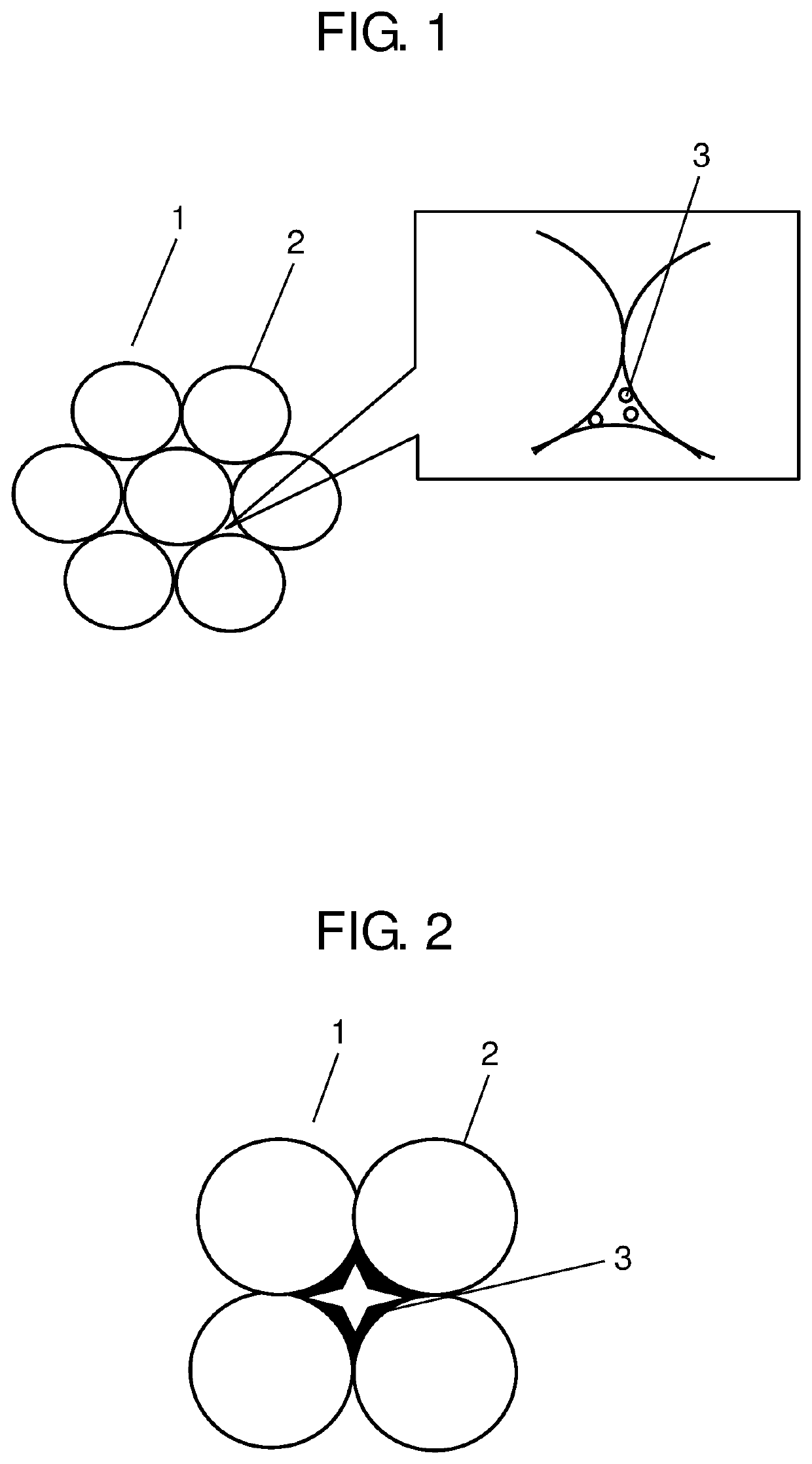

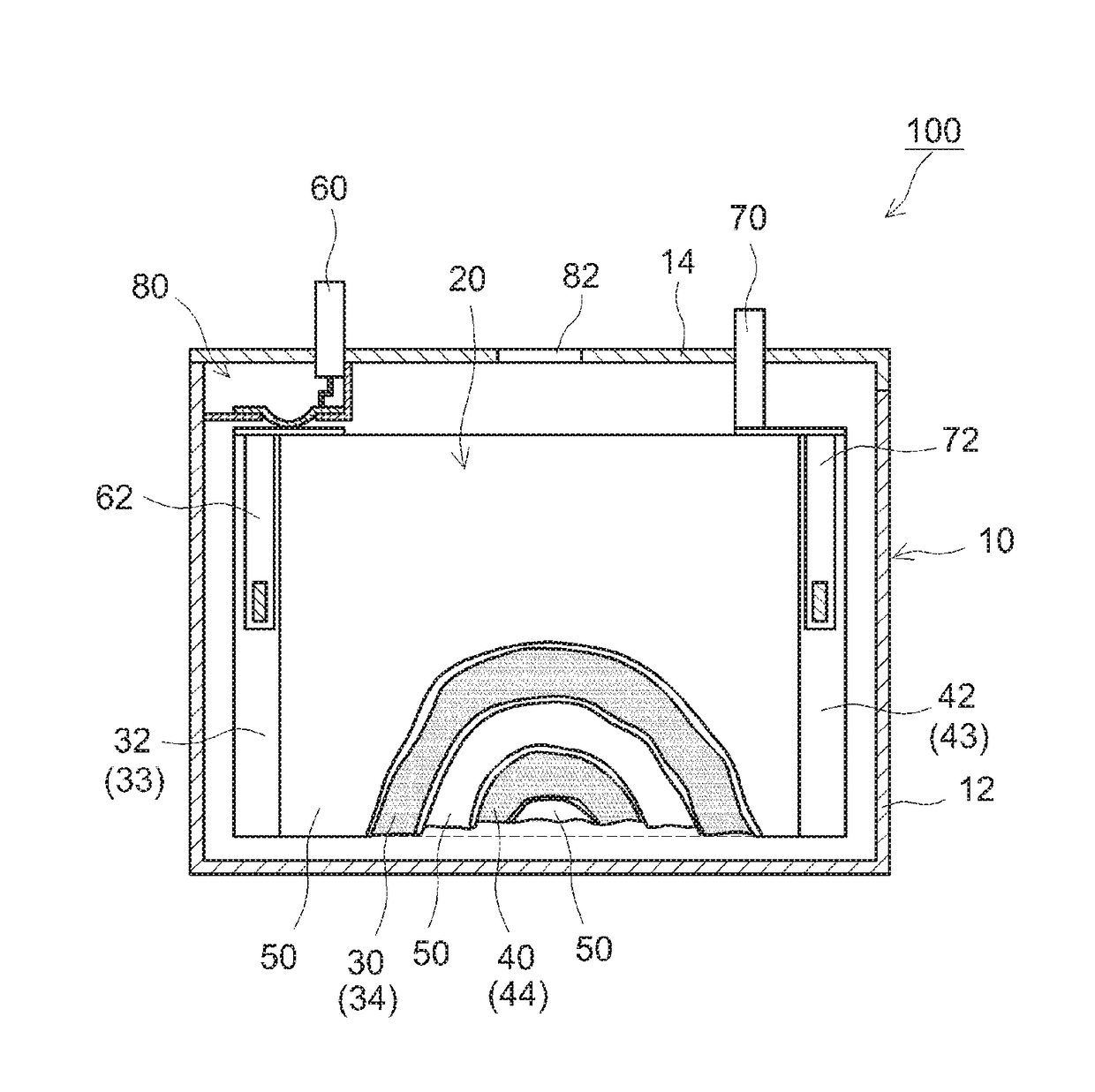

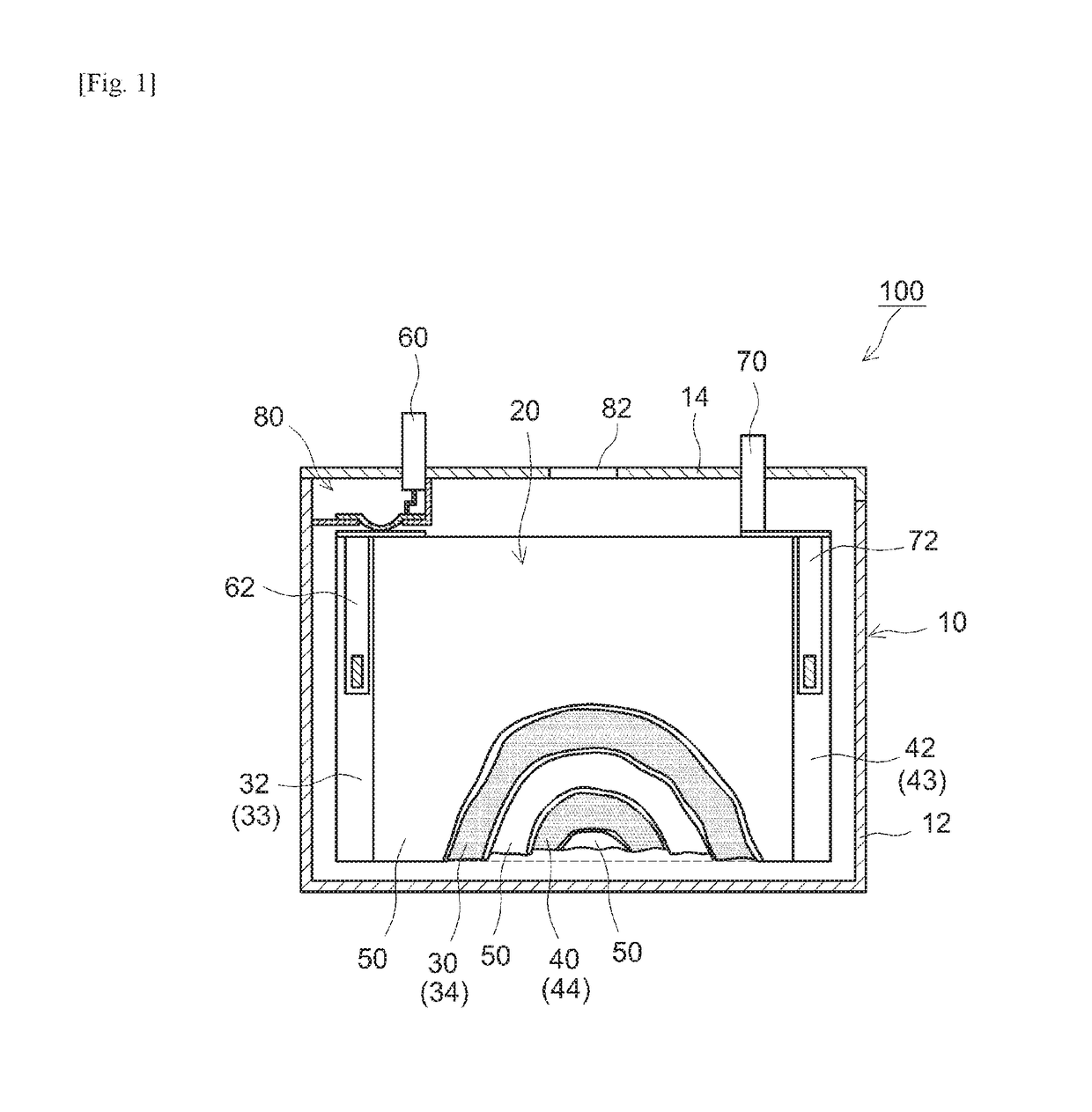

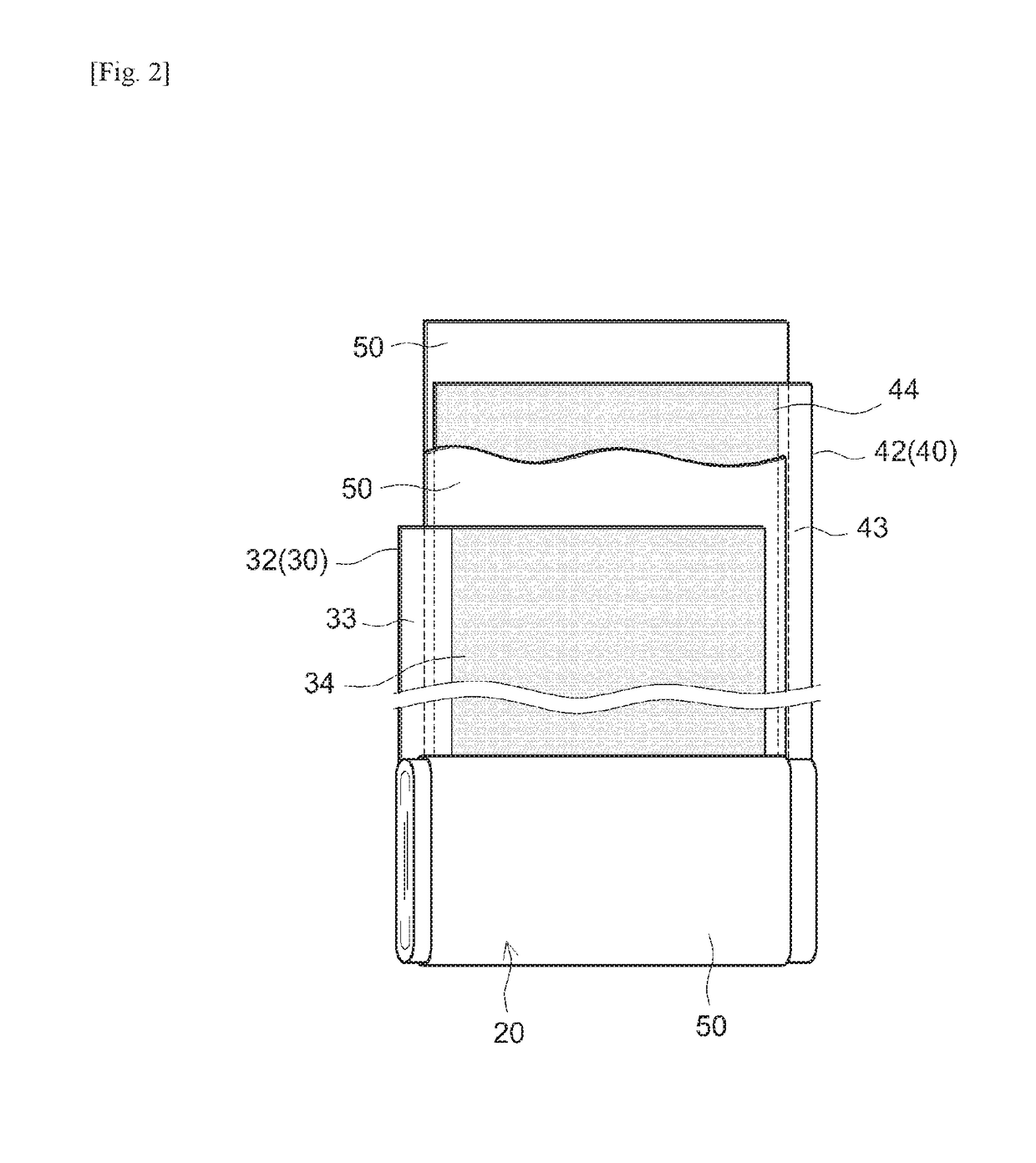

Filter, gas adsorption device using filter, and vacuum heat insulator

InactiveUS20210283546A1Reduce sizeLow melting pointOther chemical processesThermal insulationWater vaporPhysical chemistry

A filter has a primary structure composed of a first material with a relatively high melting point; a secondary structure composed of a second material with a lower melting point than the first material; and voids. This configuration provides the filter with controllable breathability. A gas-adsorption device including the filter can control the gas permeability rate. A vacuum insulation material including the gas-adsorption device enables the gas adsorber to selectively adsorb non-condensable gas from water-vapor-containing gas. As a result, the vacuum insulation material can be maintained at low pressure for a long period of time, thereby maintaining high insulation performance.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Resin old sand recovering and utilizing method

InactiveCN100500325CReduce the amount addedPrevent oxidationMould handling/dressing devicesPolyresinCoal

The present invention discloses a method for recycling a resin old sand, which is characterized in that: firstly the resin old sand is broken and screened, and is added into wet clay sand as new supplemental sand; under the precondition of ensuring the lowest coal powder content in the wet clay sand is no less than 0.3%, the addition quantity of the coal powder needing to be reduced is calculated according to the addition quantity of the resin old sand; the corresponding fomula is as follows: DeltaWcp is equal to WrsrxGrs / Gcp; wherein DeltaWcp is the addition quantity of the coal powder reduced; the unit is ml / g, Gcp is the gas content of the coal powder, unit is ml / g. Compared with adding the original sand into the wet type clay sand, the application effect of the molding sand in the invention which adopts the method of adding the resin old sand recycled into the wet type clay sand is not affected, the aim of recycling resin old sand is achieved. The invention has the advantages of excellent treating effect, low energy consumption and low costs.

Owner:SHANGHAI INST OF TECH

3DP sand mold casting process suitable for ZL205A aluminum alloy complex thin-wall component

ActiveCN113042685AImprove casting qualityReduce casting defectsAdditive manufacturing apparatusFoundry moulds3d printPtru catalyst

The invention discloses a 3DP sand mold casting process suitable for a ZL205A aluminum alloy complex thin-wall component, and belongs to the technical field of 3DP sand mold casting processes. The 3DP sand mold casting process comprises the steps that firstly, a pouring system of a casting is designed through three-dimensional drawing software, a three-dimensional structure of a casting mold is obtained, and 3D printing slicing data of the casting mold are obtained; then according to the slicing data, silica sand with the mesh number of 70-140 is used, furan resin serves as a binder, p-toluene sulfuric acid serves as a catalyst, and 3DP sand mold printing is carried out through a 3D printer; printing parameters are set, wherein the thickness of a printing layer is 0.28 mm, and the resin content is 1.5 wt.%; then sand cleaning, drying and mold assembling are carried out on a 3DP sand mold, the inner wall of the 3DP sand mold is coated with a layer of water-based zircon powder coating, drying is carried out 2.5-3 hours at the temperature of 120-130 DEG C, and furnace cooling is carried out; finally, a ZL205A alloy is smelted, the temperature is reduced to 725 + / -5 DEG C, and casting is carried out; and after the casting is solidified, cleaning is carried out to obtain the casting. According to the process, through the reasonable 3DP sand mold printing process and the casting process, the casting defects are reduced and the casting quality is improved through the sand mold preparation process and the casting process.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Lithium ion secondary battery

ActiveUS20170373352A1Quick buildLower internal resistanceFinal product manufactureCell electrodesInternal resistancePhysical chemistry

Provided is a lithium ion secondary battery which has a low internal resistance in a low-SOC region and a sufficiently large amount of gas generated during overcharge. The lithium ion secondary battery disclosed herein includes an electrode body having a positive electrode and a negative electrode, and a nonaqueous electrolytic solution. The lithium ion secondary battery further includes a pressure-type safety mechanism. The nonaqueous electrolytic solution includes a gas generating agent. The positive electrode has a positive electrode active material layer including a positive electrode active material. The positive electrode active material includes a lithium transition metal composite oxide represented by LiNiaCobMncO2 wherein a, b and c satisfy the following conditions: 0.35≦a≦0.45, 0.15≦b≦0.25, 0.35≦c≦0.45, and a+b+c=1, and a lithium transition metal composite oxide represented by LiNixCoyMnzO2 wherein x, y and z satisfy the following conditions: 0.35≦x≦0.45, 0.45≦y≦0.55, 0.05≦z≦0.15, and x+y+z=1, and the mass ratio of the oxides is 60:40 to 85:15.

Owner:TOYOTA JIDOSHA KK

Nanometer artificial leather and production method thereof

ActiveCN106367984ALower decomposition temperatureHigh strengthCoatingsTextiles and paperCalcium carbonateEpoxidized soybean oil

The invention discloses a nanometer artificial leather. The artificial leather is produced through adding a high-strength slurry by adopting a calendering technology, and the high-strength slurry is produced through blending, by weight, 100 parts of PVC resin powder, 5-15 parts of a composite nanomaterial, 10-40 parts of epoxidized soybean oil, 2-20 parts of color master batches, 3-7 parts of a stabilizer and a foaming agent and 20-40 parts of heavy calcium carbonate. The artificial leather has the advantages of good mechanical performances, good air permeability and good antibacterial characteristic.

Owner:JIANGSU GUOXIN SYNTHETIC LEATHER

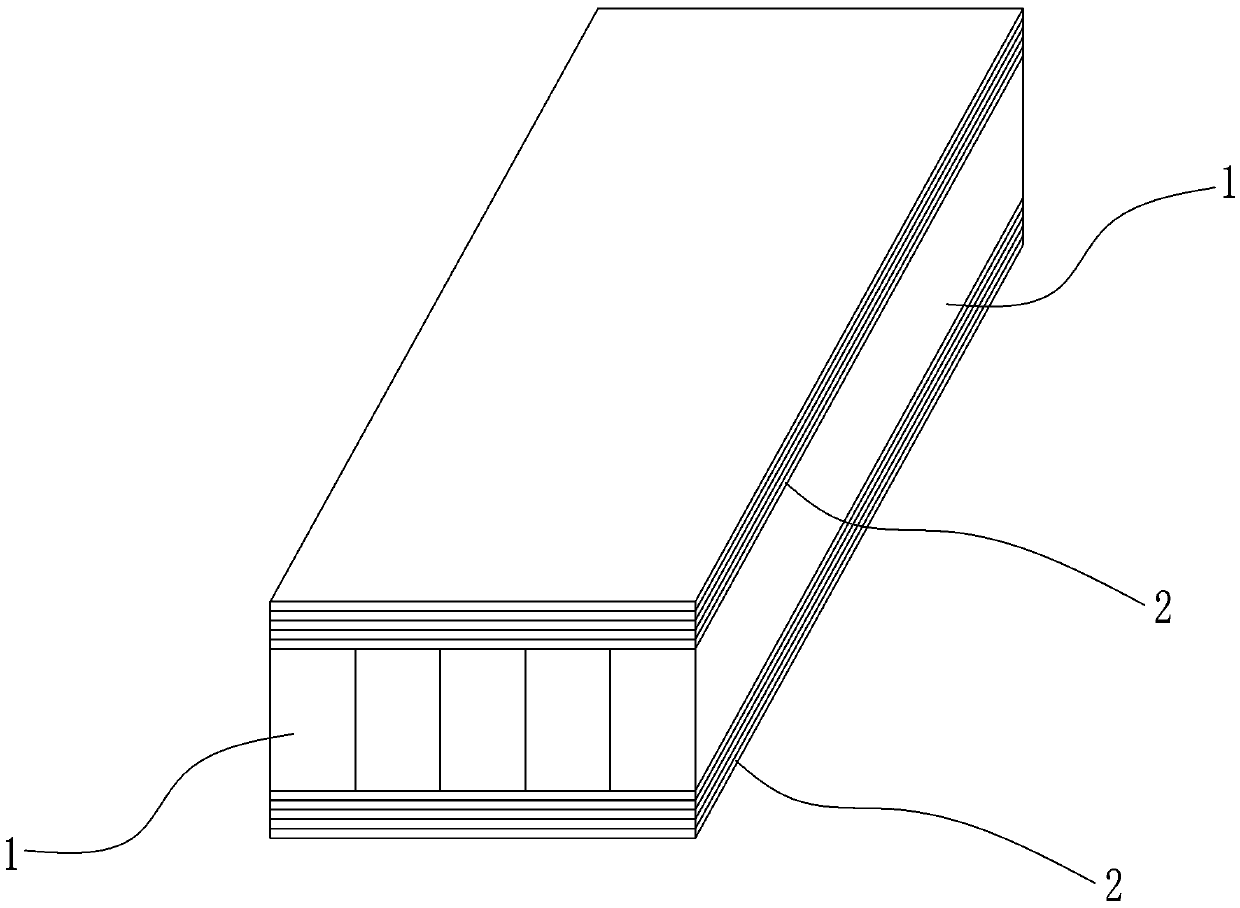

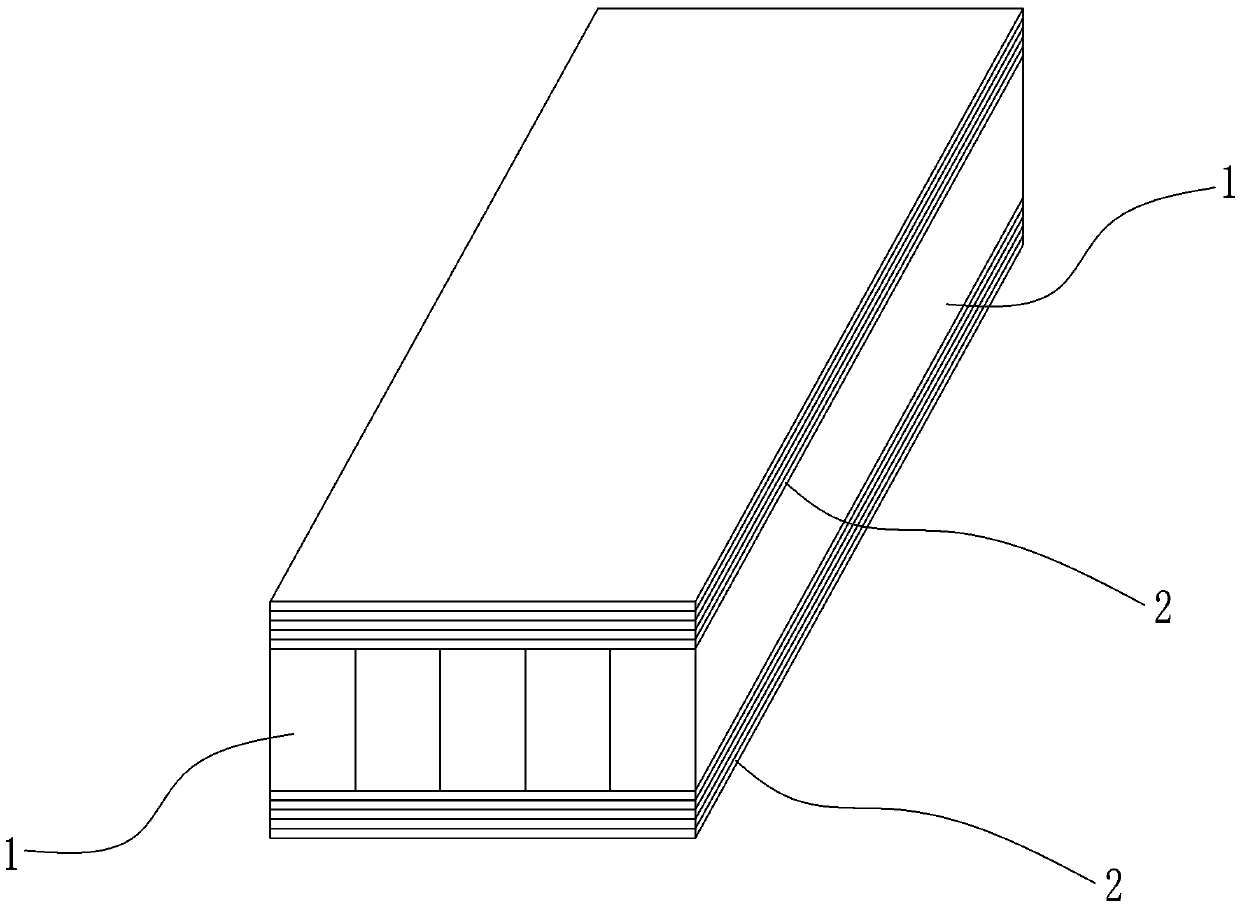

Wood fireproof glue and manufacturing process of fireproof plate

ActiveCN109837041AHigh strengthImprove wettabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesSolid woodPolyvinyl alcohol

The invention discloses wood fireproof glue, which is prepared by the following steps: stirring and heating magnesium chloride, polyvinyl alcohol, magnesium sulfate and water in a reaction vessel, reacting to generate a fireproof glue intermediate material, adding an auxiliary agent into the intermediate material while stirring to prepare the wood fireproof glue. The invention also discloses a fireproof plate prepared from the wood fireproof glue and a manufacturing process thereof. The fireproof plate comprises a fireproof plate sandwich layer composed of multiple solid wood blocks which aresuccessively distributed from left to right. Upper and lower sides of the fireproof plate sandwich layer are respectively provided with a fireproof wood chip layer which is formed by crisscrossed lamination of multiple wood chips according to the wood grain. Between the fireproof wood chip layer and the fireproof plate sandwich layer, between two adjacent solid wood blocks and between two adjacentwood chips is coated with the wood fireproof glue. The fireproof plate is prepared by steps of wood turning, final trimming, coating with the wood fireproof glue, cold pressing, drying, sanding and hot pressing.

Owner:东莞市宏晟木业有限公司

Electric motor with outer radiator and two separate cooling circuits

ActiveUS9768667B2Efficient and simple coolingExtended service lifeMagnetic circuit stationary partsCooling/ventillation arrangementEngineeringHeat spreader

A motor includes a frame defining an internal volume in which are housed a rotor and a stator; at least one cooling circuit, which includes a primary inlet and a primary outlet in fluidic communication with the outside of the frame; at least one cooling device outside the frame, which includes a secondary air inlet and a secondary air outlet, and a conduit; at least one secondary cooling circuit, separate from the primary circuit, crossing the rotor and in fluidic communication with the secondary inlet and the secondary outlet of the cooling device. The secondary cooling circuit is crossed by a channel of the primary cooling circuit supplying the stator with the gas fluid from the outside of the frame.

Owner:ALSTOM TRANSPORT TECH SAS

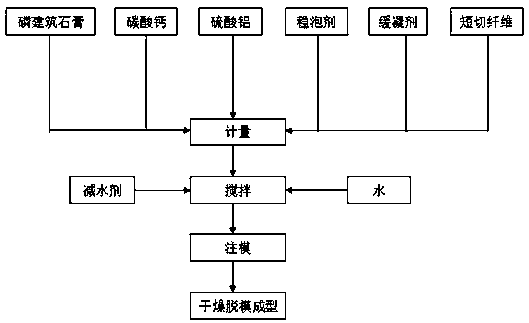

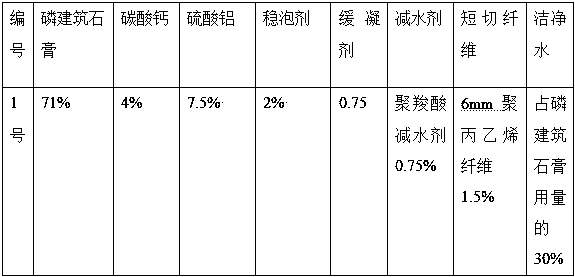

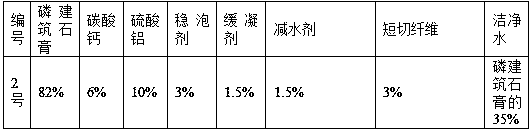

Aerated phosphorus building gypsum heat preservation block and preparation method thereof

The invention discloses an aerated phosphorus building gypsum heat preservation block and a preparation method thereof. The aerated phosphorus building gypsum heat preservation block is prepared fromthe following raw materials by mass percent: 71-82% of phosphorus building gypsum, 4-6% of calcium carbonate, 7.5-10% of aluminum sulfate, 2-3% of a foam stabilizer, 0.75-1.5% of a retarder, 0.75-1.5%of a water reducing agent and 1.5-3% of chopped fiber. The aerated phosphorus building gypsum heat preservation block prepared by the invention is excellent in the aspects of mechanical property andlight-weight heat preservation, accumulated industrial byproduct gypsum is utilized to produce the aerated phosphorus building gypsum heat preservation block, a block body material, which is good in heat preservation effect and light in self-weight and has good compression resistance and crack resistance, is produced when the utilization of solid waste and environmental protection are simultaneously solved, the material has a positive meaning in the aspects of resource saving and environmental protection, a large quantity of phosphorus building gypsum can be utilized for the material, and thematerial can be recycled, thereby being more environmentally friendly.

Owner:KUNMING UNIV OF SCI & TECH

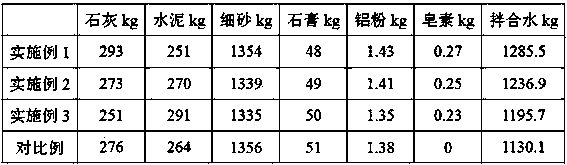

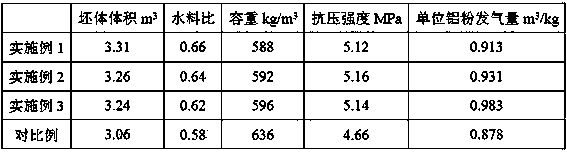

B06-grade autoclaved sand aerated concrete block prepared by adding saponin air entraining agents

ActiveCN104129953AHigh utilization factor of masonry strengthIncreased durabilityCeramicwareHydration reactionCompressive resistance

The invention provides a B06-grade autoclaved sand aerated concrete block prepared by adding saponin air entraining agents. The autoclaved aerated concrete block is prepared by using cement, lime and sand as main raw materials, doping gas generating agents, regulating agents and air entraining agents, and carrying out hydration reaction, mold forming by pouring, blank forming by procuring, forming by cutting, autoclaved curing and out-kettle processing. The dry density, compressive strength, mean pore diameter and percent of pass of the product are respectively less than 596kg / m<3>, more than 5.12MPa, less than 0.45mm and more than 97%. By adding a small quantity of saponin concrete air entraining agents, the ratio of water to material, unit aluminium powder gas evolution and pouring stability in the production process and the volume, strength and quality of the product can be obviously increased. The block is novel in conception, rich in raw materials, simple in process and low in cost, is convenient to implement and has greater generalization performance. The block is an environment-friendly and energy-saving wall material and can be applied to processing and construction of non-load-bearing walls, wallboards and roofing boards of buildings.

Owner:FUZHOU UNIV

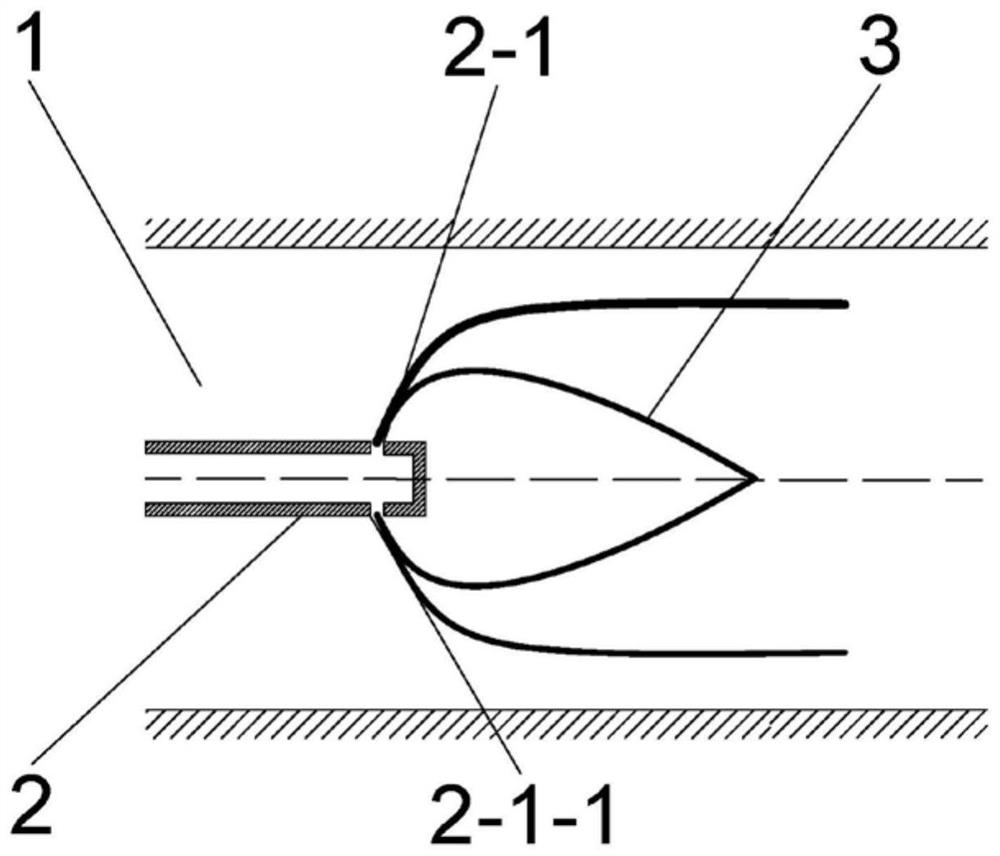

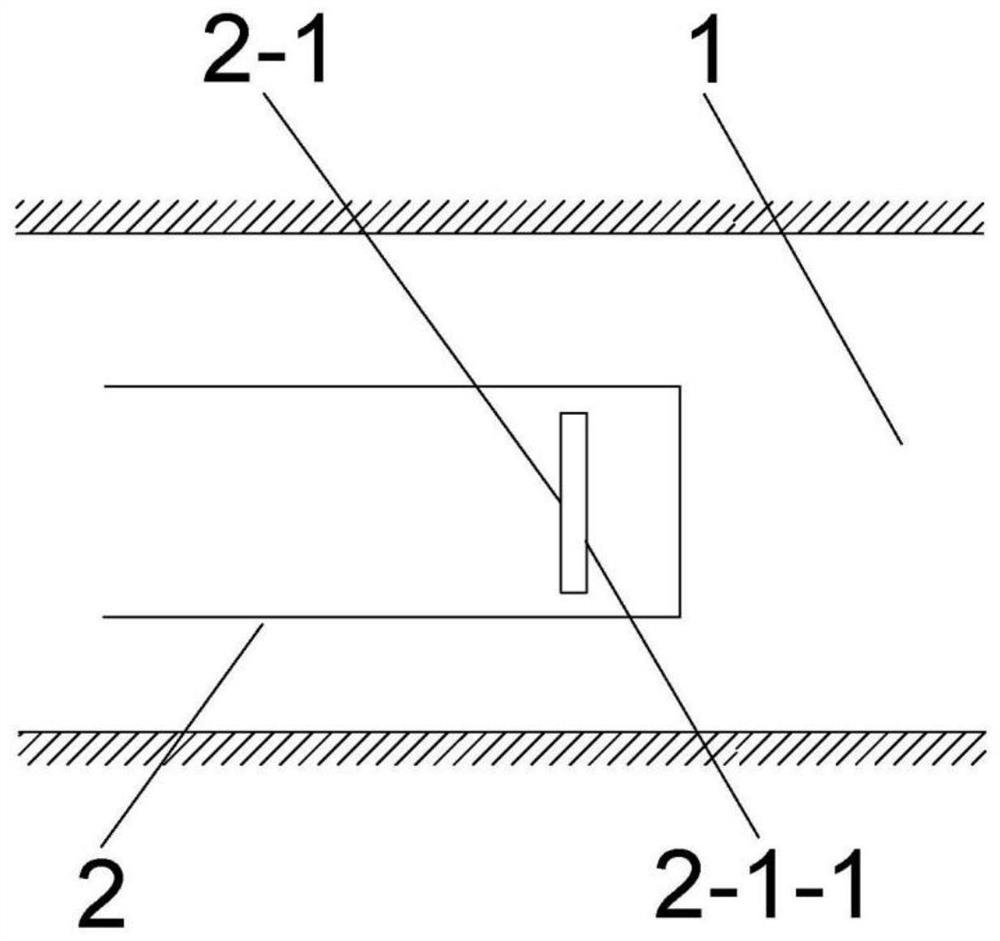

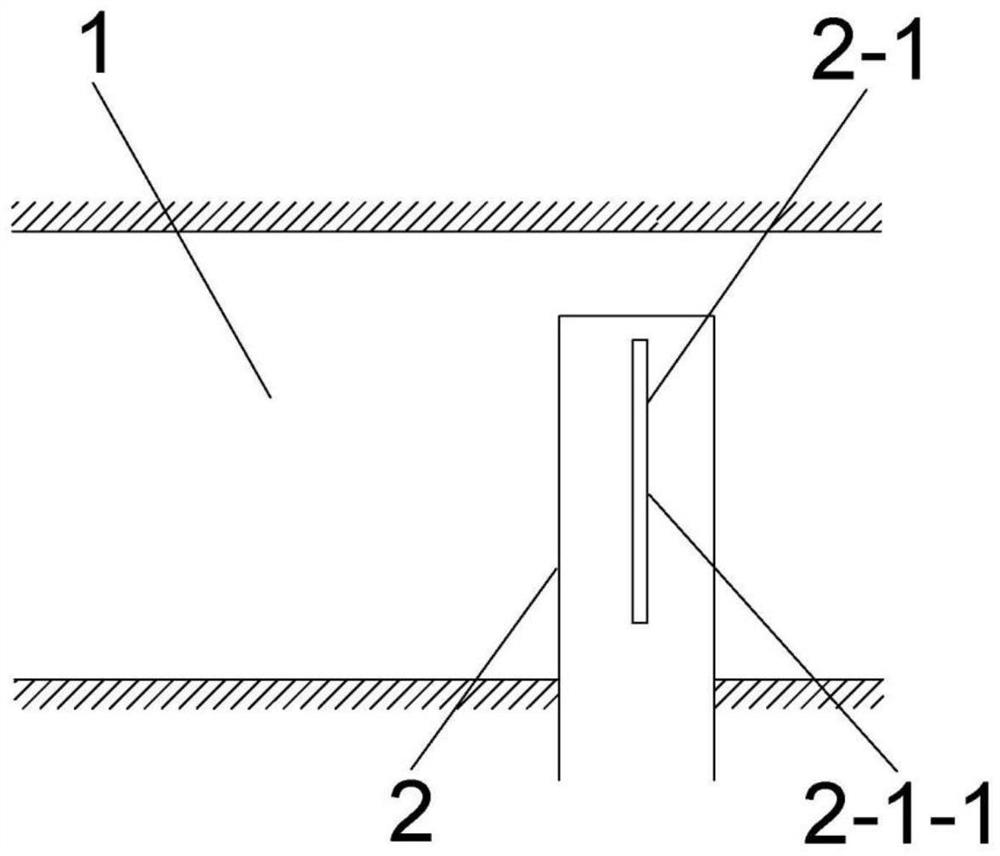

a flame stabilizer

ActiveCN109579052BIncreased recirculation zoneImprove flame stabilityContinuous combustion chamberAviationCombustion chamber

The invention discloses a flame stabilizer which can be used for an aero-engine afterburner and the like, comprising a jet device installed in a mainstream channel, wherein the jet device is providedwith injection ports, and the shape of the injection port is in a slot shape; alternatively, the shape of the injection port is a circular hole shape, the plurality of circular hole-shaped injection ports are divided into at least two groups, each group of circular hole-shaped injection ports is distributed perpendicular to the direction of the main flow direction, and the adjacent two groups of circular hole-shaped injection ports are staggered. The flame stabilizer sprays continuous jet at a certain angle in the mainstream through the jet device, and the jet forms an aerodynamic barrier in the mainstream, and then forms a return zone after the aerodynamic barrier. The return zone can effectively stabilize the flame, so the flame stabilizer is also called a jet flame stabilizer. The flamestabilizer has the advantages of high temperature resistance and deformation resistance, high combustion efficiency, low pressure loss, weak infrared radiation, continuous, effective and stable aerodynamic barrier, large return zone, good flame stabilization effect and wide combustion stabilization boundary.

Owner:李子万

Alloy guide plate treated with precoated sand

ActiveCN107327836AReduce washoutImprove protectionFluidized bed combustionApparatus for fluidised bed combustionAlloyOptimal treatment

The invention discloses an alloy guide plate treated with precoated sand. The alloy guide plate treated with the precoated sand comprises an alloy plate body. The upper surface of the alloy plate body is composed of a horizontal plane and a slope, and the end, away from the plane, of the slope is lower than the plane. At least one inner groove corresponding to a membrane wall pipe in external diameter is formed in one side of the horizontal plane and faces the membrane wall. First guide grooves are formed in the inner circular surface, facing the membrane wall, of each inner groove. The slope is provided with second guide grooves. A precoated sand layer is arranged on the surface of the alloy plate body. The optimal treatment is conducted on the surface of the alloy guide plate through a precoated sand technique, so that the alloy guide plate has the characteristics of abrasion resistance, corrosion resistance, high-temperature resistance, adhesion resistance and the like, deposition of stains like coal ash on the surface of the alloy guide plate is reduced advantageously, and the service life is prolonged.

Owner:上海炳晟机电科技有限公司

Polyvinyl butyral foamed material

Owner:LUOHE IRON HORSE RUBBER PROD CO LTD

High-temperature flame-retardant foaming agent and preparation method thereof

The invention discloses a high-temperature flame-retardant foaming agent. The foaming agent is prepared from, by weight, 20 to 30 parts of azodicarbonamide, 10 to 15 parts of gelatin, 0.1 to 0.3 part of alkaline protease, 8 to 10 parts of flame-retardant mesoporous silicon dioxide and 15 to 25 parts of deionized water. The invention also discloses a preparation method of the high-temperature flame-retardant foaming agent. The azodicarbonamide and a protein type foaming agent are compounded according to a proper compatibility ratio, the defect that the foam stability of the azodicarbonamide is poor is effectively overcome, the composite organic foaming agent is loaded in the carrier mesoporous silica and can be uniformly dispersed in a polymer matrix, and the composite organic foaming agent is used as a bubble nucleation point to make particles of the foaming agent refined, so the problems that foam holes of a foam material prepared by the foaming agent are not uniform and the density of the foam holes is low are solved, and the foaming agent has flame retardance and high temperature resistance, so that the foaming agent has a certain application prospect and market value.

Owner:嘉善县纤明新材料有限公司

low temperature gas generating agent

A low-temperature gas generating agent comprises the following components in percentage by mass: 40 to 60% of guanidine nitrate, 25 to 55% of a combustion temperature regulator, 3 to 15% of a combustion rate regulator and 0.5 to 3% of a binder. The combustion temperature regulator can be oxamide, ammonium oxalate, ammonium sulfate, Oxalic dihydrazide and azodicarbonamide; the combustion rate regulator can be bistetrazole ammonium salt, zinc oxide and a copper and iron oxide, and the binder can be clay, paraffin and modified cellulose. The low-temperature gas generating agent has the characteristics of low combustion temperature, fast combustion rate, low solid residue content, and the like, and can meet the requirement of rapid inflating of a sealed capsule.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Method for producing quicklime by calcination of small particle size limestone

The invention discloses a method for producing quicklime through forging small-sized limestone. The method has the quicklime productivity of 14-14.5 t / h and can control the quicklime granularity to be 30-60 mm. The method provided by the invention has the following advantages: normal forging of small-sized limestone in a lime kiln is realized, in-furnace limestone with the granularity of 40 mm or below accounts for 80%, the granularity of quicklime is effectively reduced, the quicklime underfiring rate is lowered, the operation condition of a calcium carbide furnace can reach a higher level, and the power consumption during calcium carbide production is reduced.

Owner:中盐吉兰泰氯碱化工有限公司

Air-generating agent for air-entrained concrete and its application method

An air-generating agent for air-entrained concrete and its application method belong to the technical field of building materials. The gas generating agent of the present invention is composed of ferrosilicon powder with a silicon content ≥ 95%, and its fineness is 45um, and the sieve residue is 2-8%. At present, most of the air-generating agents used in aerated concrete are aluminum powder or aluminum paste air-generating agents with aluminum as the main component. Air concrete manufacturer. The ferrosilicon powder gas-generating agent with silicon as the main component provided by this invention solves the above-mentioned difficulties, and uses the technical principle that silicon can undergo a chemical reaction to generate hydrogen under alkaline conditions, and the chemical properties of silicon are more stable than aluminum, and can be used at normal temperature and pressure. It does not chemically react with air, which simplifies the production process, storage conditions and other issues. The price of silica fume in the market is also lower than that of aluminum, which can greatly reduce production costs. It has a great application prospect in the production of aerated concrete. .

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com