EVA nanometer composite foam rubber and plastic combined inner tire preparation method

A nano-composite and combined technology can solve the problems of high cost, tire puncture, short service life, etc., and achieve the effect of overload service life, long service life, high quality and low price and renewable utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

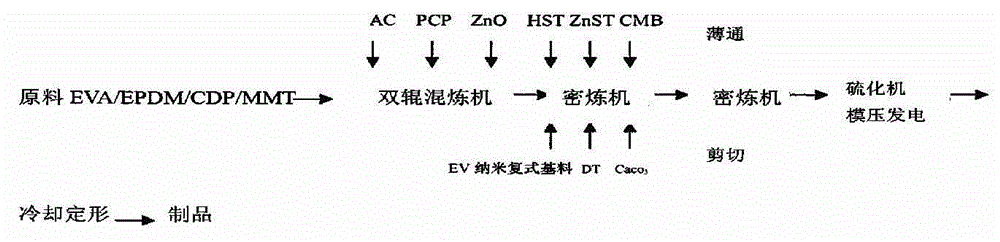

[0010] Realize the invention of the EVA / EPDM / CPE / MMT nano-composite closed-cell microcellular foam rubber-plastic combined inner tube, which is mainly prepared from the following raw materials, and its formula ratio (by mass parts) is EVA VA content 14%-21%, MFI1 .5-2.5, azodicarbonamide (AC) 1-3.5, dicumyl peroxide (DCP) 0.2-0.8, zinc oxide (ZnO) 0.2-1, stearic acid (Hst) 0.1-1, hard Zinc fatty acid (Znst) 0.1-1, EPDM 8%-50%, chlorinated polyethylene (CPE) 5%-40%, clay (MMT) 0.2%-10%, talcum powder ( DT) 5%-40%, heavy calcium carbonate (Caco 3 ) 5%-40%, color eye material (CMB) 1%-6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com