Wood fireproof glue and manufacturing process of fireproof plate

A technology of fireproof glue and fireproof board, which is applied in the direction of manufacturing tools, wood processing appliances, and the joining of wooden veneers to achieve the effect of small heat generation, no residue, and increased coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

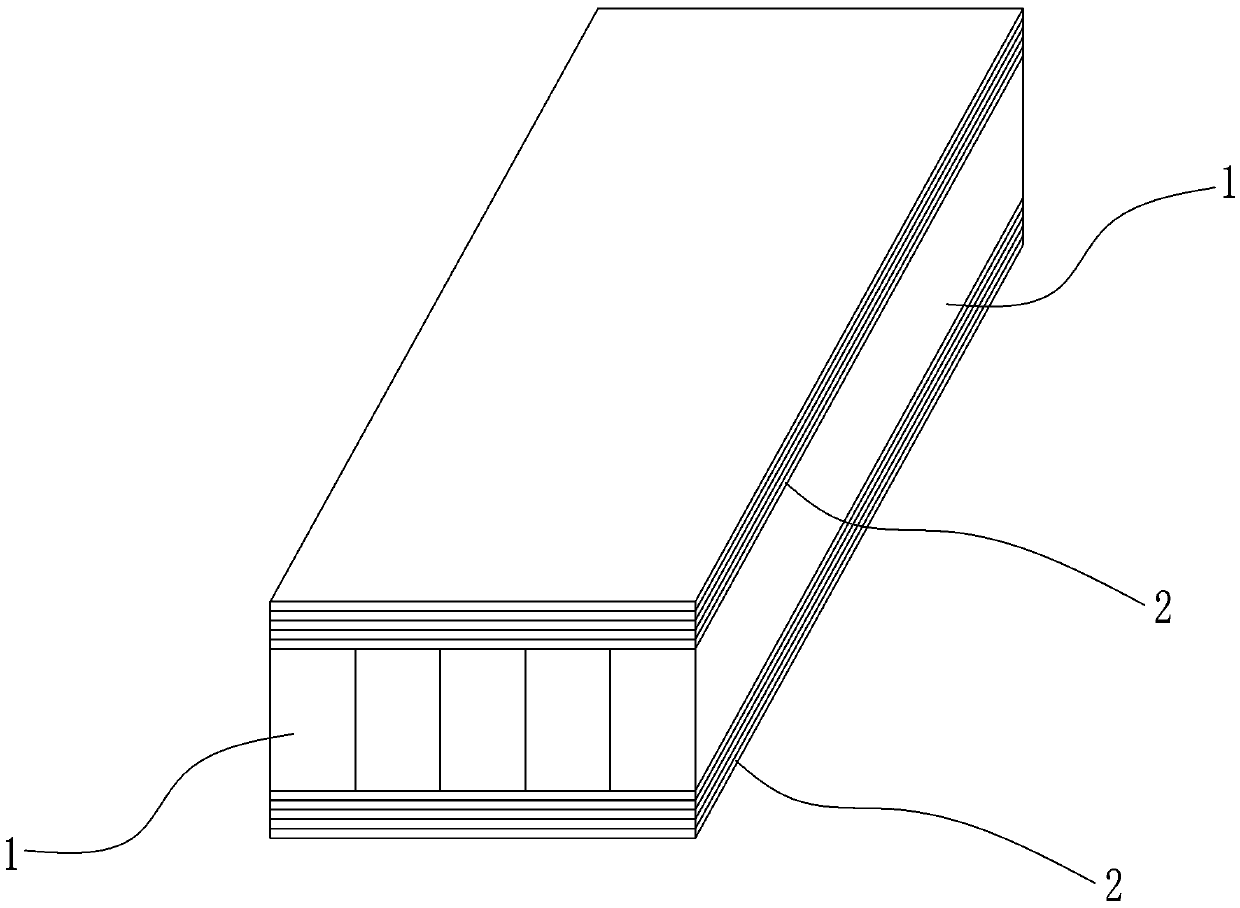

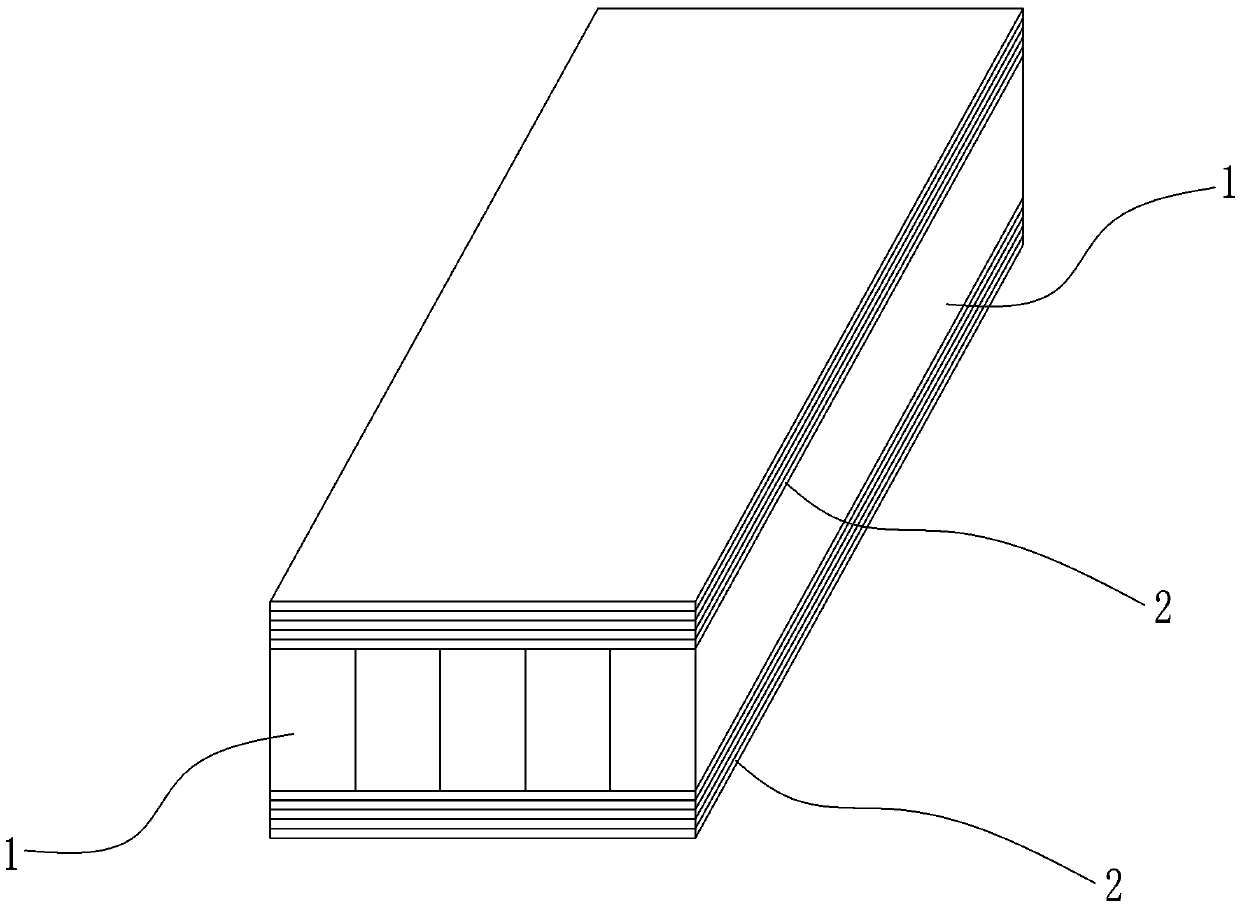

Image

Examples

Embodiment 1

[0039]The invention provides a wood fireproof glue, which is made of magnesium chloride, polyvinyl alcohol, magnesium sulfate and water in a reaction kettle after being stirred and heated up so that the magnesium chloride and magnesium sulfate destroy the hydrogen bond of polyvinyl alcohol and react to form an intermediate material. The intermediate material It is formed due to the strong electronic interaction between the magnesium ions after magnesium chloride and magnesium sulfate are dissolved in water and the oxygen atoms in the hydroxyl groups on the polyvinyl alcohol molecular chain. The intermediate material is mixed with additives under the action of stirring to obtain the Described wood fireproof glue, wherein, the weight component of the raw material that prepares described intermediate material is magnesium chloride 35 parts, polyvinyl alcohol 8 parts, magnesium sulfate 3.5 parts, water 95 parts; Described auxiliary agent comprises the magnesium oxide 10 parts of wei...

Embodiment 2

[0049] The invention provides a wood fireproof glue, which is made of magnesium chloride, polyvinyl alcohol, magnesium sulfate and water in a reaction kettle after being stirred and heated up so that the magnesium chloride and magnesium sulfate destroy the hydrogen bond of polyvinyl alcohol and react to form an intermediate material. The intermediate material It is formed due to the strong electronic interaction between the magnesium ions after magnesium chloride and magnesium sulfate are dissolved in water and the oxygen atoms in the hydroxyl groups on the polyvinyl alcohol molecular chain. The intermediate material is mixed with additives under the action of stirring to obtain the Said wood fireproof glue, wherein, the weight component of the raw material that prepares described intermediate material is magnesium chloride 47 parts, polyvinyl alcohol 11 parts, magnesium sulfate 7 parts, water 110 parts; Described auxiliary agent comprises the magnesium oxide 15 parts of weight ...

Embodiment 3

[0059] The invention provides a wood fireproof glue, which is made of magnesium chloride, polyvinyl alcohol, magnesium sulfate and water in a reaction kettle after being stirred and heated up so that the magnesium chloride and magnesium sulfate destroy the hydrogen bond of polyvinyl alcohol and react to form an intermediate material. The intermediate material It is formed due to the strong electronic interaction between the magnesium ions after magnesium chloride and magnesium sulfate are dissolved in water and the oxygen atoms in the hydroxyl groups on the polyvinyl alcohol molecular chain. The intermediate material is mixed with additives under the action of stirring to obtain the The wood fireproof glue, wherein, the weight component of the raw material for preparing the intermediate material is 38 parts of magnesium chloride, 8.5 parts of polyvinyl alcohol, 4.0 parts of magnesium sulfate, and 98 parts of water; the auxiliary agent includes 12 parts of magnesium oxide by weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com