Alloy guide plate treated with precoated sand

A technology of alloy plate and coated sand, which is applied in the direction of fluidized bed combustion equipment, burning fuel in molten state, combustion method, etc., can solve the problems of deflector stain deposition and other problems, and achieve effective bonding length extension and compressive strength The effect of improving and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

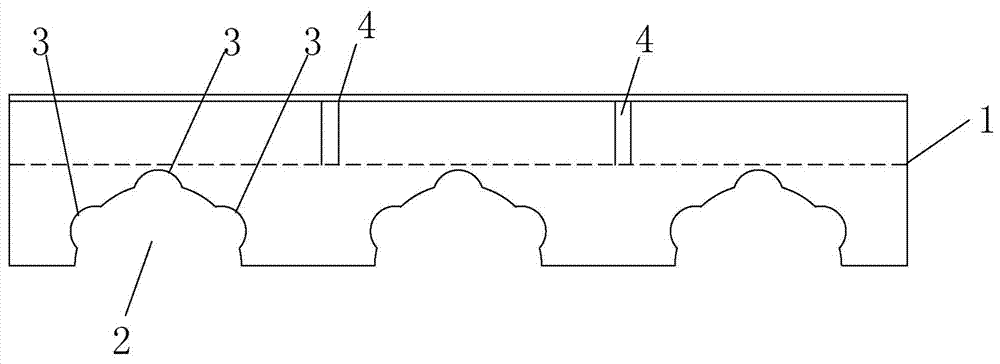

[0045] Such as figure 1 and 2 As shown, the diversion alloy plate of the present invention includes an alloy plate body 1, the upper surface of the alloy plate body 1 is composed of a horizontal plane and an inclined plane, and the end of the inclined plane away from the plane is lower than the plane; one side of the horizontal plane faces the membrane wall, There is at least one inner groove 2 corresponding to the outer diameter of the membrane wall tube, a first diversion groove 3 is provided on the inner circular surface of the inner groove 2 facing the membrane wall, and a first guide groove 3 is provided on the inclined surface. There is a second diversion groove 4, and a coated sand layer is added to the surface of the alloy plate body 1 through a coated sand process.

[0046] The coated sand process of the diversion alloy plate comprises the following steps,

[0047] 1) Design: Coating temperature testing, coating process simulation, and coating thermophysical paramet...

Embodiment 2

[0061] Embodiment 2 is basically the same as Embodiment 1, the difference is that

[0062] The coated sand includes the following raw materials in mass percentage: 92% of raw sand, 2.5% of binder, 1% of curing agent, 1% of coupling agent, 1% of lubricant, 1.5% of fireproof and wear-resistant particles, and 0.5% of surface cleaner % and lignin fiber 0.5%; the original sand is made of 80 parts of quartz sand, 30 parts of chromite sand and 25 parts of high-temperature cement, and the particle size of the original sand is 150 mesh; the binder is phenolic resin nano modified The preparation method is as follows: 2 parts, 4 parts, 6 parts and 8 parts of modified montmorillonite, caprolactam, formaldehyde solution and oxalic acid are sequentially added to the reaction kettle by weight, and after fully stirring, Add 75 parts by weight of phenol, slowly heat up to 85°C, stop heating, add 5 parts of oxalic acid, wait for the reaction system to automatically heat up to boiling, and reflu...

Embodiment 3

[0069] Embodiment 3 is basically the same as Embodiment 1, the difference is that

[0070] The coated sand includes the following raw materials in mass percentage: 91% of raw sand, 3.4% of binder, 0.5% of curing agent, 1% of coupling agent, 1.5% of lubricant, 2% of fireproof and wear-resistant particles, and 0.3% of surface cleaner % and lignin fiber 0.3%; the original sand is made of 75 parts of quartz sand, 25 parts of chromite sand and 20 parts of high-temperature cement, and the particle size of the original sand is 135 mesh; the binder is phenolic resin nano modified The preparation method is as follows: 2 parts, 4 parts, 6 parts and 8 parts of modified montmorillonite, caprolactam, formaldehyde solution and oxalic acid are sequentially added to the reaction kettle by weight, and after fully stirring, Add 75 parts by weight of phenol, slowly heat up to 85°C, stop heating, add 5 parts of oxalic acid, wait for the reaction system to automatically heat up to boiling, and ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com