a flame stabilizer

A technology of flame stabilizer and jet device, which is applied in the direction of combustion method, lighting and heating equipment, continuous combustion chamber, etc., can solve the problems of large pressure loss, poor flame stabilization effect, narrow combustion stability boundary, etc., and achieve fluid resistance and total The effect of small pressure loss, relief of cold and heat stress deformation, and wide combustion stability boundary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

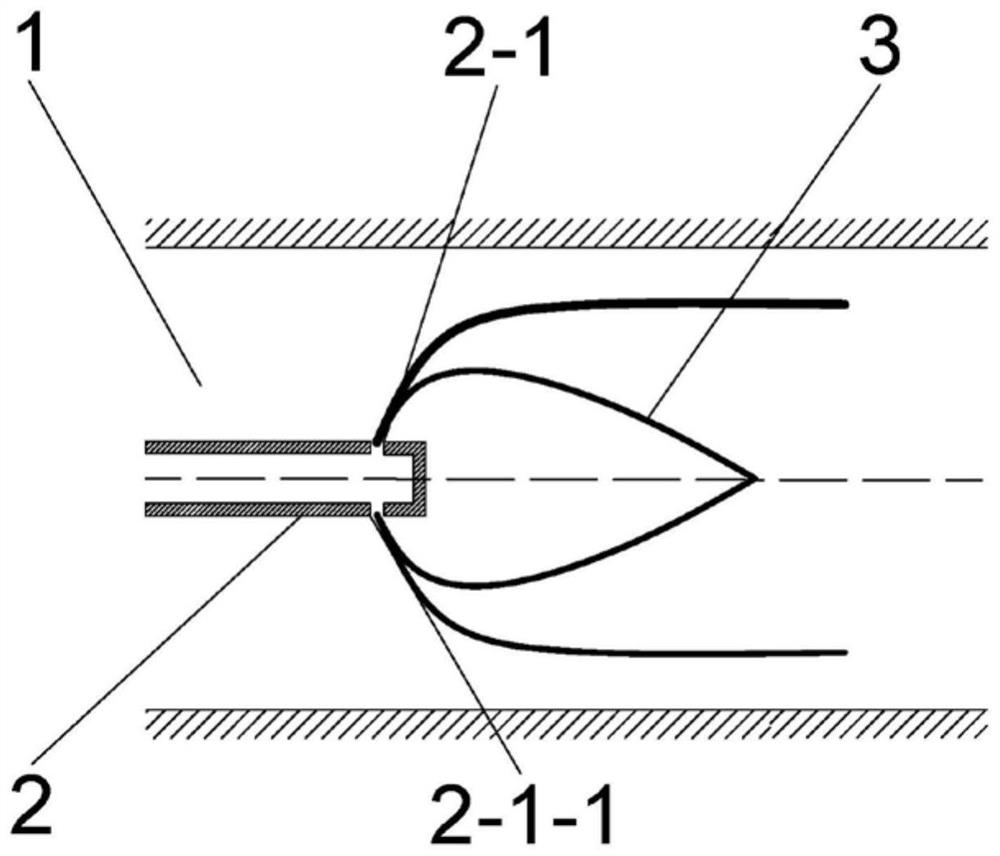

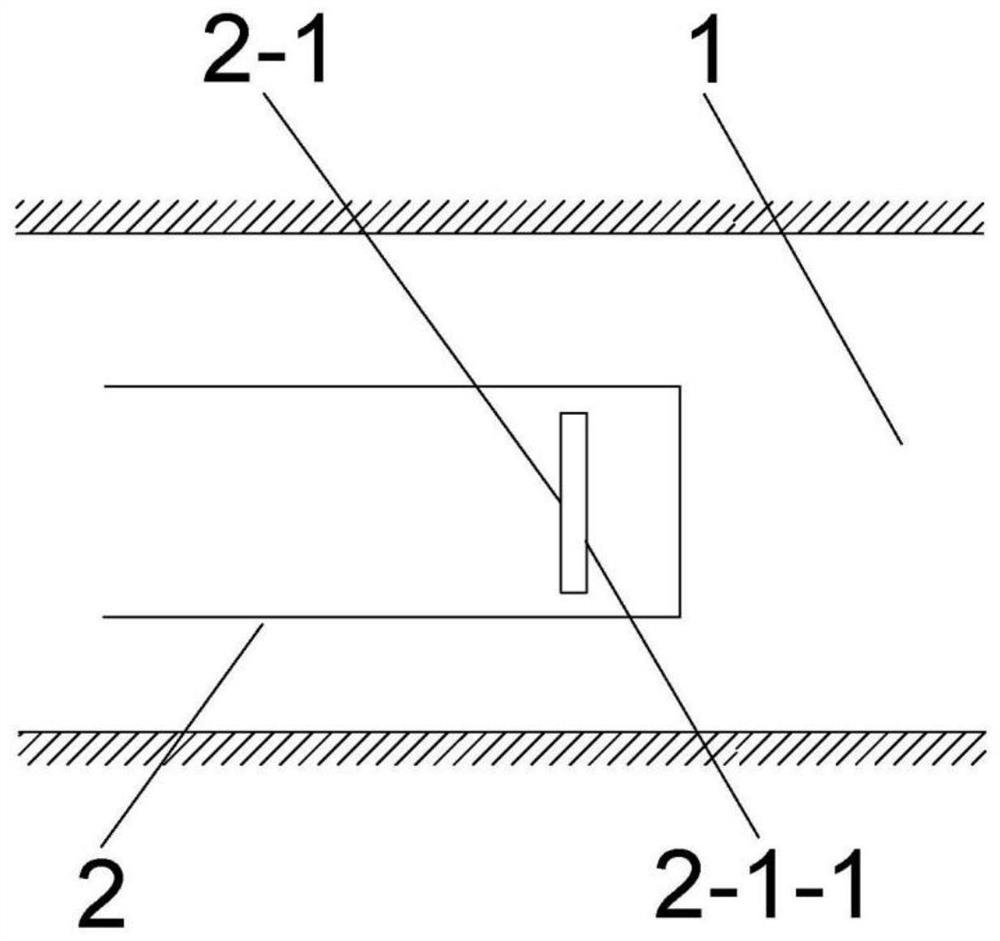

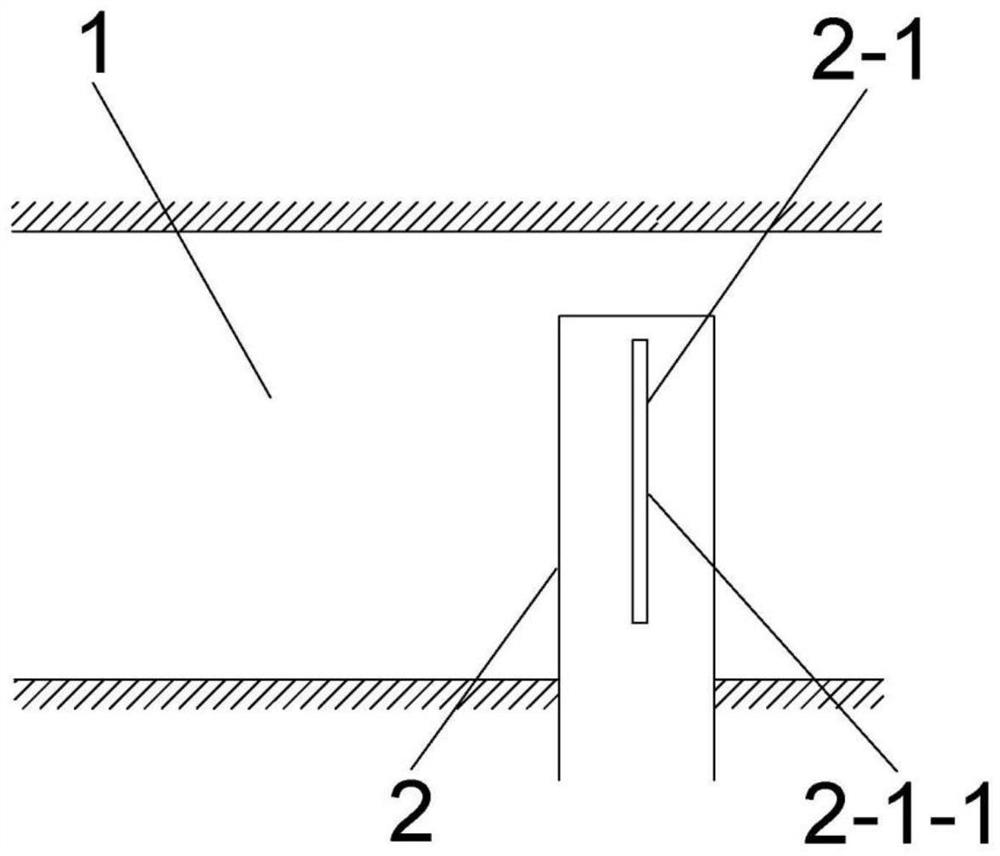

[0065] like Figure 1 to Figure 27 As shown, the present invention provides a flame stabilizer. The flame stabilizer includes a jet device 2 installed in the main flow channel 1. The jet device 2 is provided with an injection port 2-1. The shape of the injection port 2-1 is a slit shape. Mouth 2-1-1; Or, the shape of injection port 2-1 is circular hole shape, and this injection port 2-1 is circular hole shape injection port 2-1-2, and circular hole shape injection port 2-1-2 has A plurality of circular hole-shaped injection ports 2-1-2 are at least divided into two groups, and each group of circular hole-shaped injection ports 2-1-2 is distributed along the circumferential direction or the length direction of the jet device 2; two adjacent groups of circular holes The injection ports 2-1-2 are distributed in a staggered manner.

[0066] When the length direction of the jet device 2 is parallel to the main flow direction, the circular hole-shaped injection ports 2-1-2 are dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com