Multi-channel mixed gas burner

A technology of mixing gas and burner, applied in the direction of gas fuel burner, burner, combustion method, etc., can solve the problems of inability to achieve combustion effect, affect the quality of cement, low calorific value, etc., and achieve improved ignition conditions, complete combustion, The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

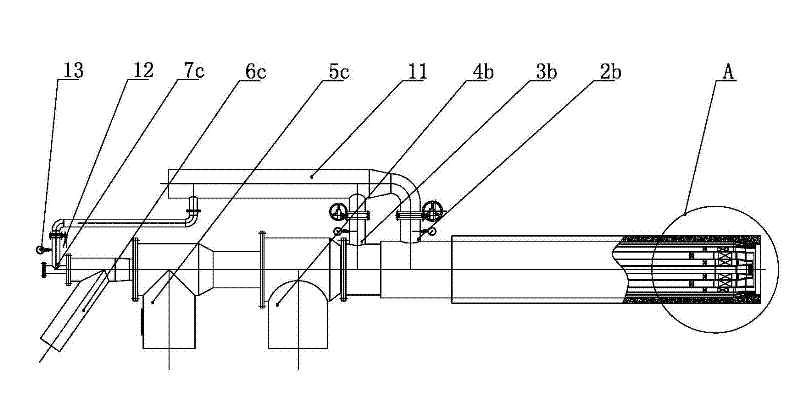

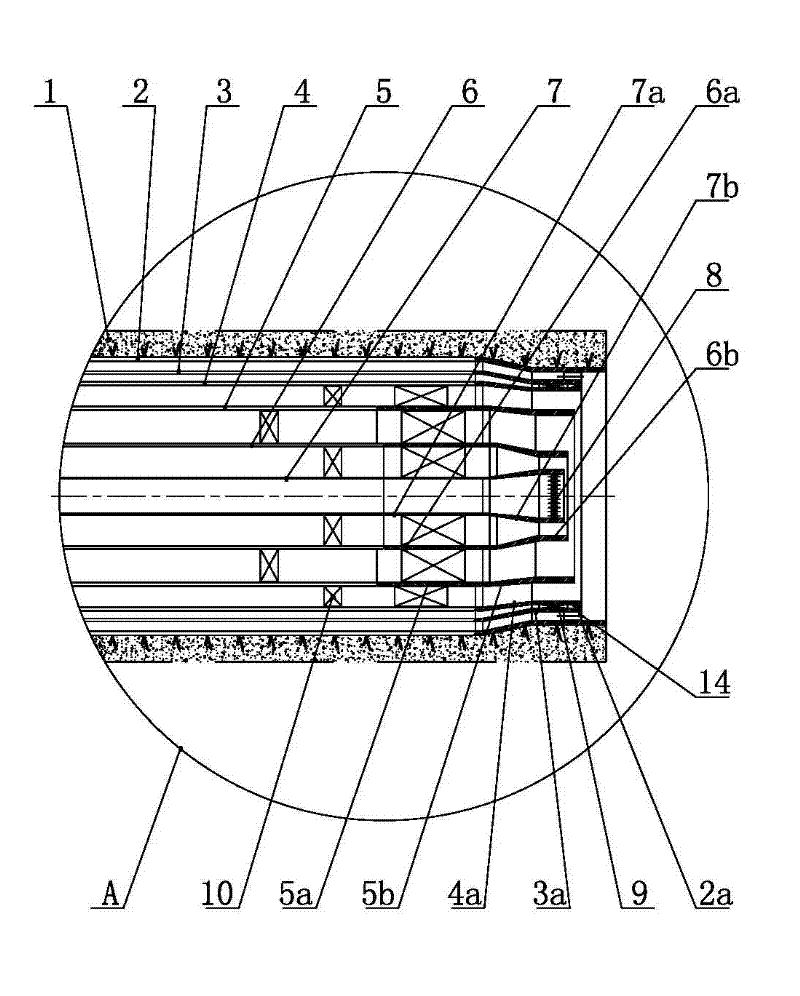

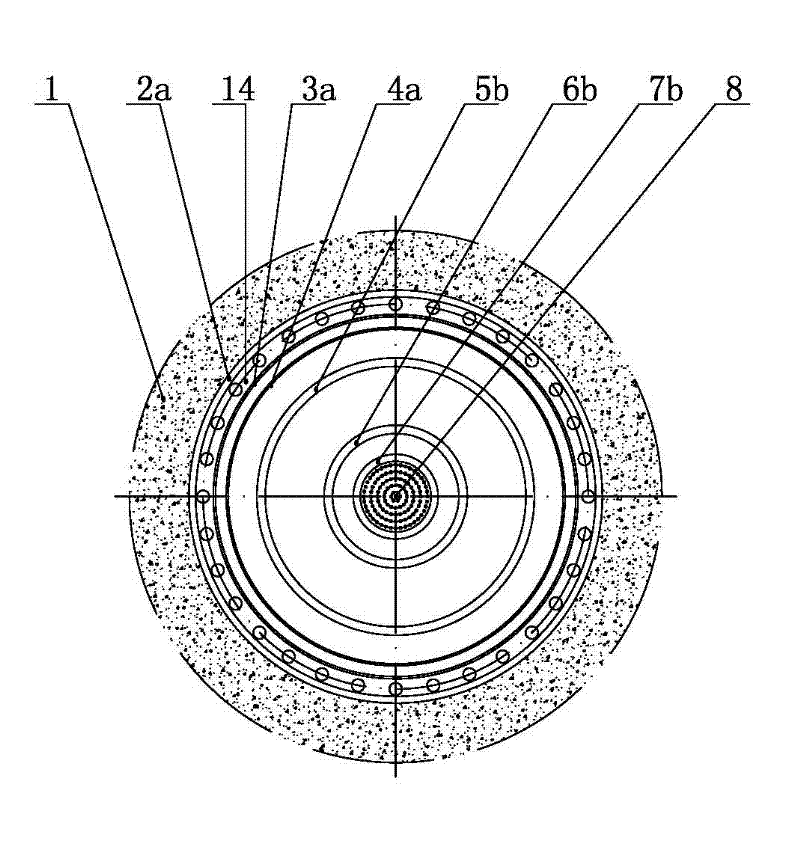

[0026] As shown in the figure, a multi-channel mixed gas burner includes an inner air pipe 7 and a coke oven gas pipe 6, a converter gas pipe 5, and a blast furnace gas pipe 4, which are coaxially sleeved from the inside to the outside of the inner air pipe 7, The cyclone pipe 3, the outer air pipe 2, and the air outlet end of the inner air pipe 7 are connected to one end of the coke oven gas cyclone 7a. The other end of the coke oven gas cyclone 7a is connected with an internal air nozzle 7b and an internal air nozzle 7b From the inside to the outside, a coke oven gas nozzle 6b, a converter gas nozzle 5b, a blast furnace gas nozzle 4a, a cyclone nozzle 3a, and an outside air nozzle 2a are sequentially set from the inside to the outside. The air outlet end of the coke oven gas pipe 6 corresponds to one end of the converter gas cyclone 6a. Connection, the other end of the converter gas cyclone 6a is connected with a coke oven gas nozzle 6b, the outlet end of the converter gas pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com