Support plate stabilizer with gas mixing function and integrated afterburner

A stabilizer and support plate technology, applied in the combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of insufficient combustion, increased difficulty in ignition and flame stabilization, achieve full combustion, improve fuel distribution uniformity, The effect of reducing flow obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings.

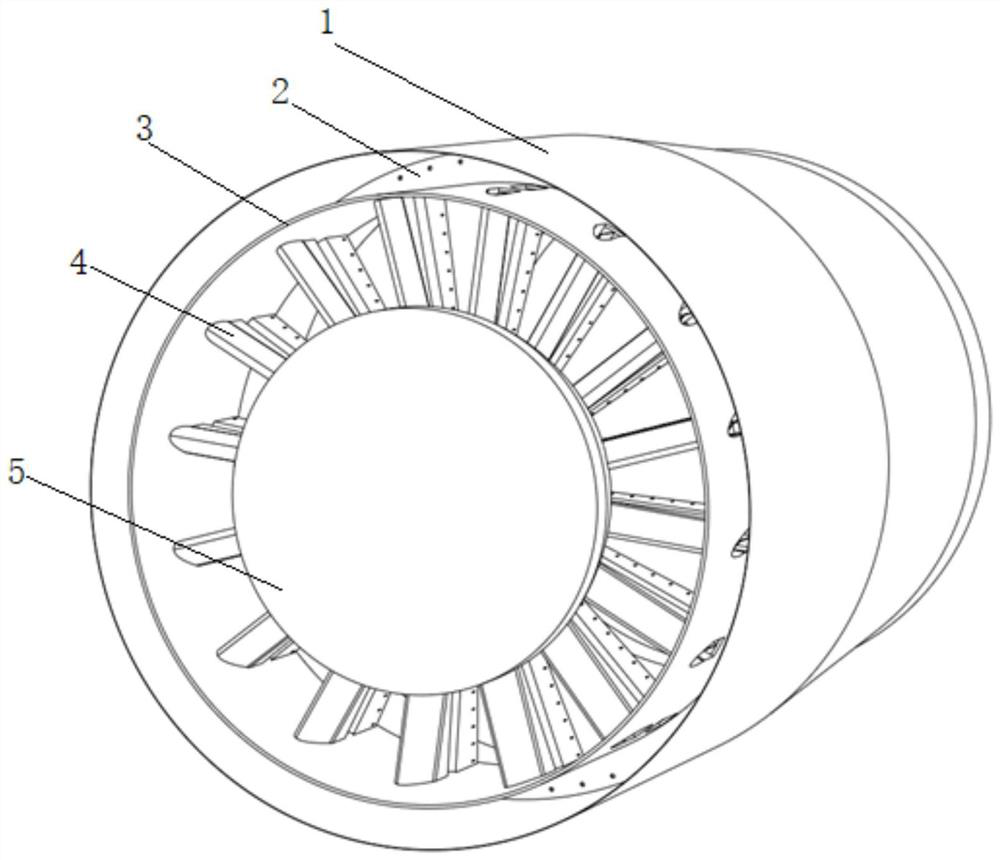

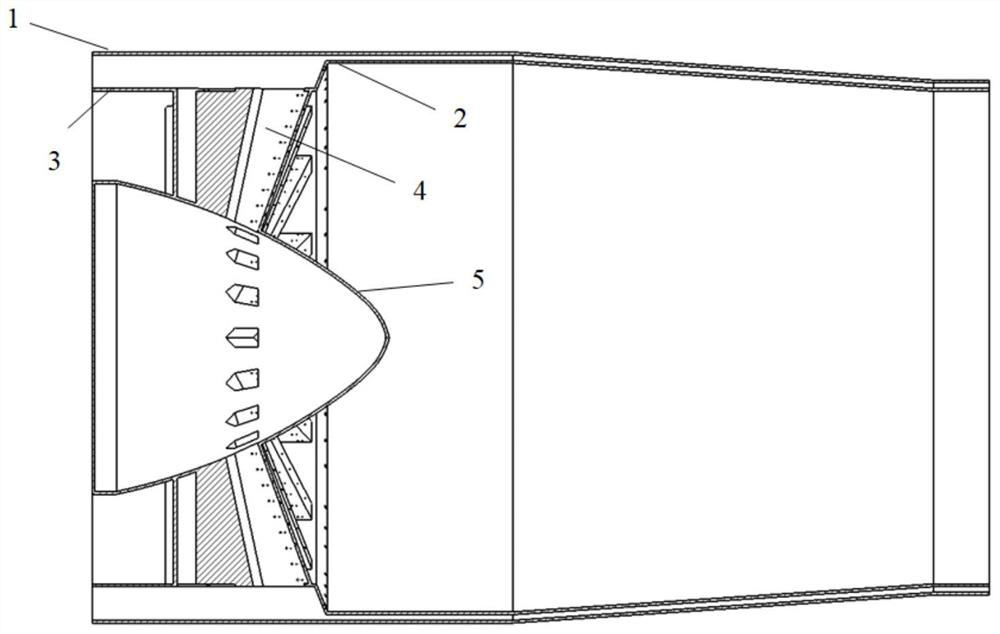

[0033] like Figure 1-3 As shown in the figure, the afterburner provided by the present invention, which integrates the mixer and the support plate stabilizer, includes an afterburner cylinder 1, a rear ducted ejector 3, and a support plate stabilizer 4, which are arranged coaxially from the inside to the outside. and center cone 5. An outer duct is formed between the afterburner cylinder 1 and the rear duct ejector 3 . An inner channel is formed between the rear bypass ejector 3 and the central cone 5 . One end of the support plate stabilizer 4 is connected with the rear duct ejector 3 , and the other end is connected with the center cone 5 . A heat shield 2 is also arranged between the forcing cylinder 1 and the support plate stabilizer 4 . Gap, which is used for the passage of extraneous airflow.

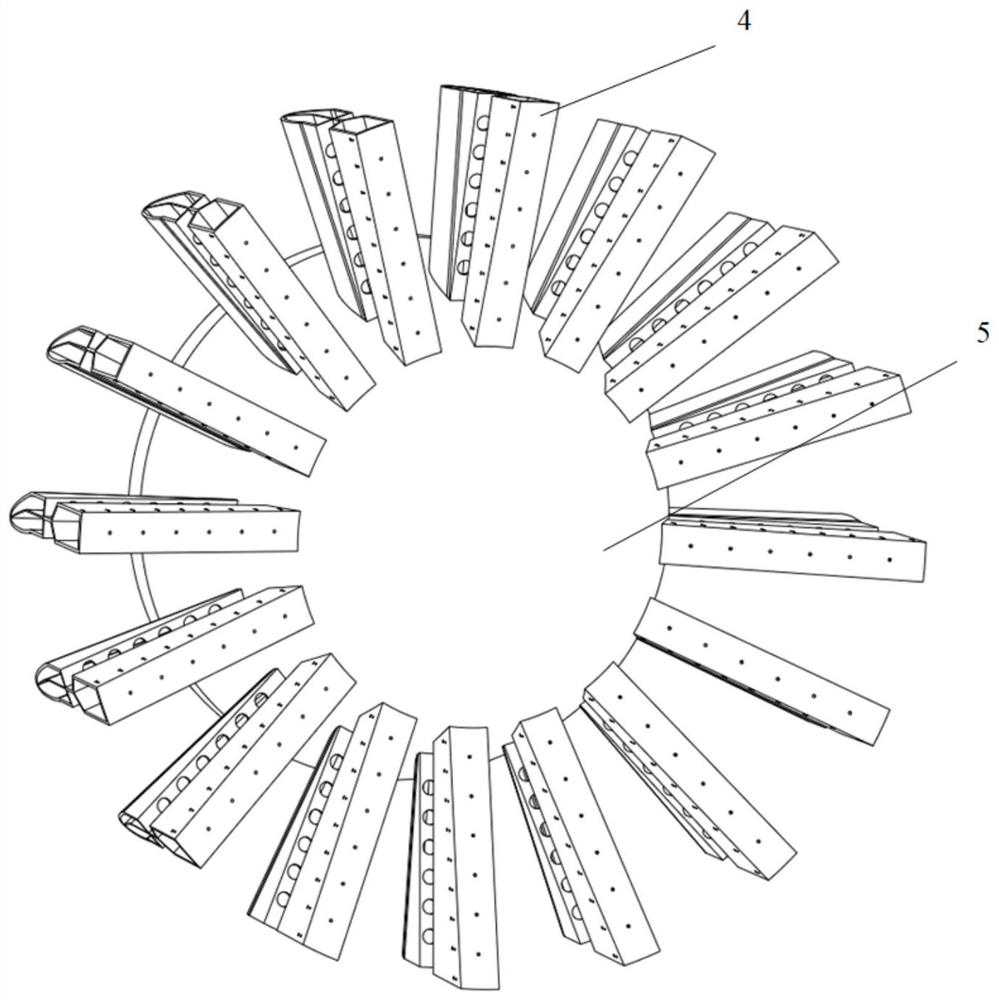

[0034] like Figure 4As shown, there are a plurality of support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com