Thermoplastic polyamide elastomer physical and chemical combined foam material and preparation method thereof

A thermoplastic polyamide and polyamide elastomer technology, which is applied in the field of thermoplastic polyamide elastomer physical and chemical combined foaming materials and their preparation, can solve the problem of low viscosity of materials and inability to encapsulate air bubbles, air bubbles merging or bursting, and difficulty in foam molding. problems, to achieve the effect of improving melt viscosity and strength, low density of foamed materials, and good foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

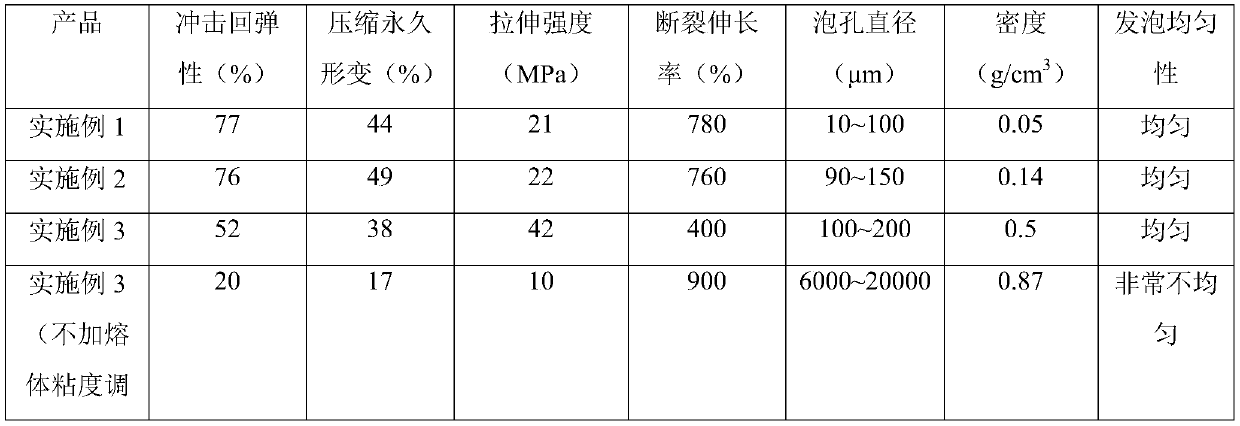

Examples

Embodiment 1

[0038] Mix 1000g of polyamide elastomer (polyamide 1212 and polytetrahydrofuran ether glycol copolymerized elastomer, the mass ratio of the two is 20:80), 50g of polyamide 6, 5g of nano-calcium carbonate, 20g of antioxidant 1010, and 20g of stearic acid Uniform, then put into the twin-screw extruder, control the screw speed of the extruder to 100 rpm, control the working temperature of the extruder at 160°C, extrude and granulate, and prepare small foaming particles that meet the requirements, with a diameter of 1mm.

[0039] Add the small foaming particles prepared above, 5g of sodium lauryl sulfate, and 200g of azodicarbonamide into the autoclave, fill with nitrogen to replace the air in the autoclave, raise the temperature to 150°C and start stirring, and control the stirring rate to 200 Turn per minute, keep warm for 20 minutes; then raise the temperature to 200°C, and at the same time introduce carbon dioxide to make the pressure in the kettle reach 5MPa, continue to stir...

Embodiment 2

[0041] 1000g polyamide elastomer (polyamide 66, polyamide 1010 and polypropylene glycol copolymerized elastomer, the mass ratio of the three is 7:15:78), 100g polypropylene, 20g nano-montmorillonite, 10g antioxidant 1010, 10g Unsaturated fatty acid zinc is mixed evenly, and then added to the twin-screw extruder, the screw speed of the extruder is controlled at 50 rpm, and the working temperature of the extruder is controlled at 220°C, extruded and granulated to prepare foam that meets the requirements Small particles, 3mm in diameter.

[0042] The small foaming particles prepared above, 15g of sodium lauryl sulfate, 60g of azodicarbonamide and 40g of 4,4-oxobisbenzenesulfonylhydrazide were added to the autoclave, and the air in the autoclave was replaced by nitrogen gas. Raise the temperature to 120°C and start stirring, control the stirring rate to 400 rpm, and keep the heat for 30 minutes; then raise the temperature to 180°C, and at the same time feed in chloro(substitute)pr...

Embodiment 3

[0044]1000g polyamide elastomer (polyamide 1012 and polycarbonate diol copolymerized elastomer, the mass ratio of the two is 20:80), 300g polyamide 66, 200g acrylonitrile-butadiene-styrene copolymer, 50g nano Silicon dioxide and 2g of antioxidant 1098 are mixed evenly, and then added to a twin-screw extruder, the screw speed of the extruder is controlled at 150 rpm, and the working temperature of the extruder is controlled at 200°C, extruded and granulated to prepare Small foaming particles that meet the requirements, with a diameter of 5mm.

[0045] Add the small foaming particles prepared above, 30g Pingpingjiao, 25g azodicarbonamide and 25g 2,2'-azobisisobutyronitrile into the autoclave, replace the air in the autoclave with nitrogen gas, and raise the temperature Start stirring at 130°C, control the stirring rate at 300 rpm, and keep warm for 25 minutes; then raise the temperature to 190°C, and at the same time feed carbon dioxide to make the pressure in the kettle reach 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com