Aerated phosphorus building gypsum heat preservation block and preparation method thereof

A technology of phosphorus building gypsum and building gypsum, which is applied in the field of aerated phosphorus building gypsum insulation blocks and its preparation, which can solve the problems of small size of ordinary clay bricks, affect the performance of houses, and poor recycling of waste, and achieve low price , easy construction, less water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

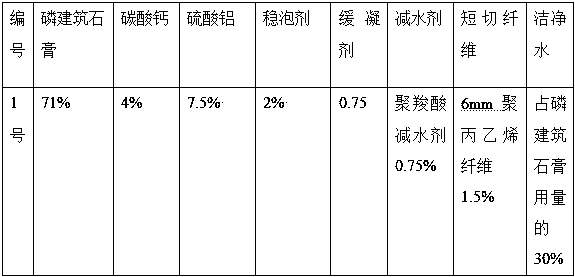

[0030] Embodiment 1: In this embodiment, the phosphorus building gypsum taken by a phosphate fertilizer factory in Yunnan is used as raw material to prepare the aerated phosphorus building gypsum insulation block. The ratio is as follows:

[0031]

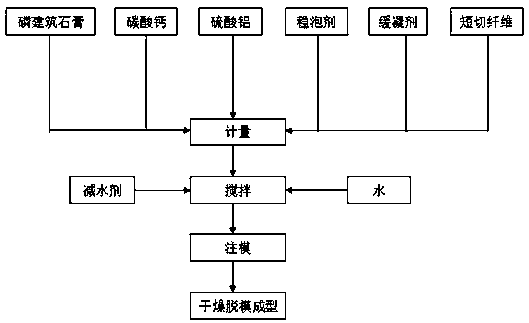

[0032] like figure 1 Shown: the concrete steps of preparation method are as follows:

[0033] (1) First, mix 30% water, 0.75% polycarboxylate superplasticizer, and 0.75% retarder citric acid of the amount of phosphorus building gypsum and stir evenly, then add 71% phosphorus building gypsum to the solution, and use 90r After stirring at a rotating speed of 290r / min for 25s, and then stirring at a rotating speed of 290r / min for 25s, a mixed solution I was obtained;

[0034] (2) Add 4% calcium carbonate and 7.5% aluminum sulfate successively to the mixed solution in step (1), then stir at a speed of 90r / min for 30s, and then stir at a speed of 290r / min for 25s to obtain a mixed solution II ;

[0035] (3) Add 2% foam stabilizer ...

Embodiment 2

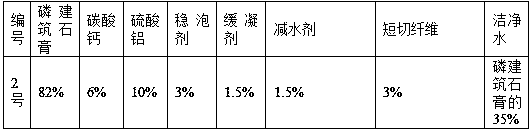

[0039] Embodiment 2: Take the phosphorus construction gypsum taken by a phosphate fertilizer factory in Yunnan as raw material,

[0040] The matching ratio is as follows:

[0041]

[0042] The concrete steps of preparation method are as follows:

[0043] (1) First, mix 35% water, 1.5% polycarboxylate superplasticizer, and 1.5% retarder citric acid of the amount of phosphorus building plaster and stir evenly, then add 82% phosphorus building plaster to the solution, and use 110r After stirring at a rotating speed of 310r / min for 35s, and then stirring for 35s at a rotating speed of 310r / min, a mixed solution I was obtained;

[0044] (2) Add 6% calcium carbonate and 10% aluminum sulfate successively to the mixed solution in step (1), then stir at a speed of 110r / min for 45s, and then stir at a speed of 310r / min for 35s to obtain a mixed solution II ;

[0045] (3) Add 3% foam stabilizer silicone resin polyether emulsion to the mixed solution II in step (2), and stir at a sp...

Embodiment 3

[0049] Embodiment 3: take the phosphorus construction gypsum that a certain phosphate fertilizer factory in Yunnan gets as raw material,

[0050] The matching ratio is as follows:

[0051]

[0052] The concrete steps of preparation method are as follows:

[0053] (1) First, mix 32% water, 1% polycarboxylate superplasticizer, and 1% retarder tartaric acid of the amount of phosphorus building gypsum and stir evenly, then add 80% phosphorus building gypsum to the solution at 100r / After stirring for 30s at a rotating speed of 300r / min, stirring for 30s at a rotating speed of 300r / min, a mixed solution I was obtained;

[0054](2) Add 5% calcium carbonate and 8% aluminum sulfate successively to the mixed solution in step (1), then stir at a speed of 100r / min for 40s, and then stir at a speed of 300r / min for 30s to obtain a mixed solution II ;

[0055] (3) Add 2.5% foam stabilizer silicone resin polyether emulsion to the mixed solution II in step (2), and stir at a speed of 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com