3DP sand mold casting process suitable for ZL205A aluminum alloy complex thin-wall component

A technology of ZL205A and thin-walled components, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of increased gas generation in sand molds, affecting dimensional tolerances, and increasing printing costs, so as to achieve excellent casting quality and improve casting quality. Quality, the effect of reducing casting defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, casting of ZL205A pitch seat casting:

[0033] (a) Taking a certain type of pitch seat as an example, its structural features are complex and its size is relatively large. Its horizontal plane size is 997mm×636mm, its height is 627mm, and its mass is about 52kg. The ZL205A alloy pitch seat has a large number of variable cross-section structures, the thinnest part of which is only 6mm thick, and the cross-section ratio is nearly 1:15. There are two shell components with complex shapes and structures in the vertical direction, and their cross-sectional dimensions change frequently. There is only a horizontal bracket with a minimum wall thickness of 6mm and a maximum wall thickness of 15mm between the two shell parts, and the length of the horizontal bracket is 420mm, accounting for nearly half of the overall length of the pitch seat casting, which is very prone to deformation. These structural features make the pitching seat castings have special characteri...

Embodiment 2

[0039] Embodiment 2, casting of ZL205A pitch frame casting:

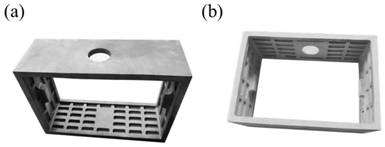

[0040] (a) Take a pitching frame as an example, its structural feature is a frame structure, its horizontal plane size is 415mm×286mm, its height is 156mm, and its mass is about 7.5kg. The pitching frame is a frame structure as a whole, and the outer wall presents a large area of thin walls as a whole, with a wall thickness of 9mm. The wall is a multi-place rib structure, and the wall thickness here is 14mm. There are two bosses on the inner wall, the wall thickness of which is 32mm. During the solidification process, the thin-walled structure may have problems such as insufficient pouring, shrinkage cavities, and feeding difficulties. The uneven thickness may cause excessive thermal stress and cracks in the casting during the cooling process. Pitch frame castings show a "large size effect" during the filling process and solidification process, and cracks are prone to occur at the corners of the casting due to li...

example 3

[0046] Example 3, casting of ZL205A small cabin castings:

[0047] (a) Taking a certain type of small cabin as an example, the external dimensions of the cabin are: the small end diameter is 240mm, the large end diameter is 340mm, the height is 263mm, the minimum wall thickness is 7mm, and the mass is about 12.7kg. There are 5:1 and 3:1 variable cross-section structures between bosses and wall thicknesses on the inner wall of the cabin. There are six large bosses at one end of the cabin, with a height of 40mm and a thickness of 37mm. The internal structure of the cabin is complex, and there are many There are two irregular windows, the wall thickness of the cabin is not uniform, and there are many variable cross-section structures. It is easy to form casting heat joints and defects in these parts with large wall thickness differences. The multiple bosses of the casting may cause insufficient pouring during filling, and defects may also occur due to insufficient feeding during ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com