Low-temperature pyrolysis method for pulverized coal and oil shale powder and external heating vertical type descending low-temperature pyrolysis furnace

A technology of oil shale powder and low temperature pyrolysis, which is applied in the field of coal pyrolysis to achieve the effects of rapid pyrolysis treatment, good quality and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

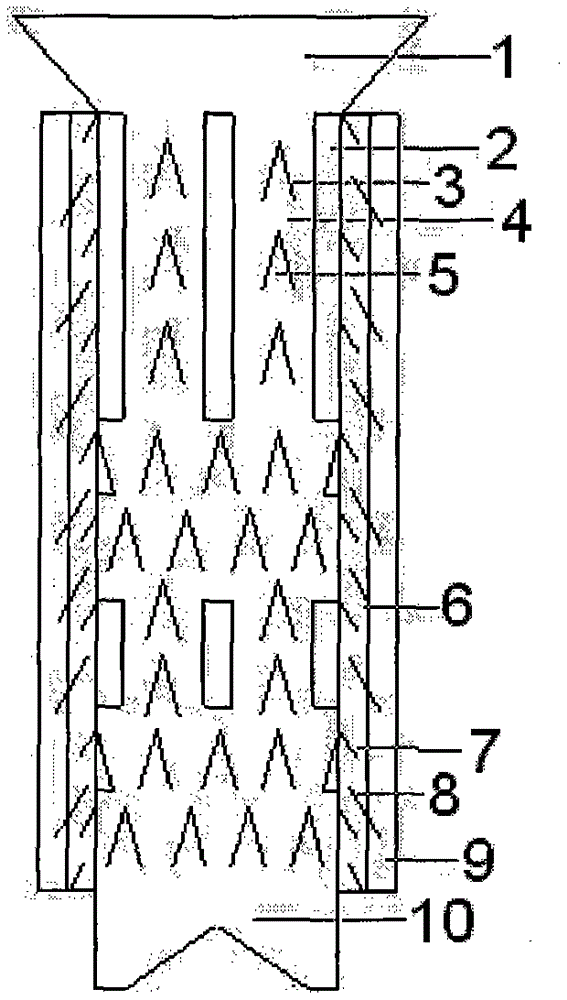

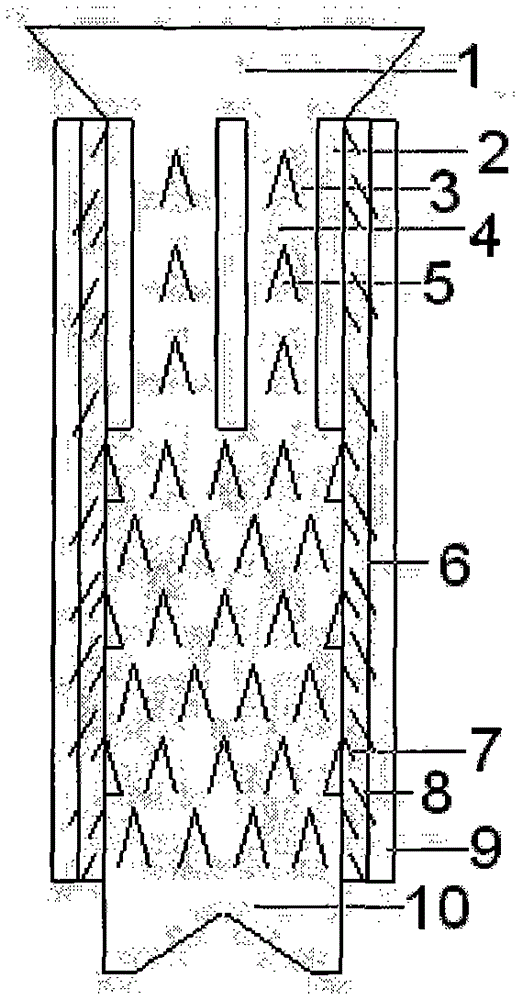

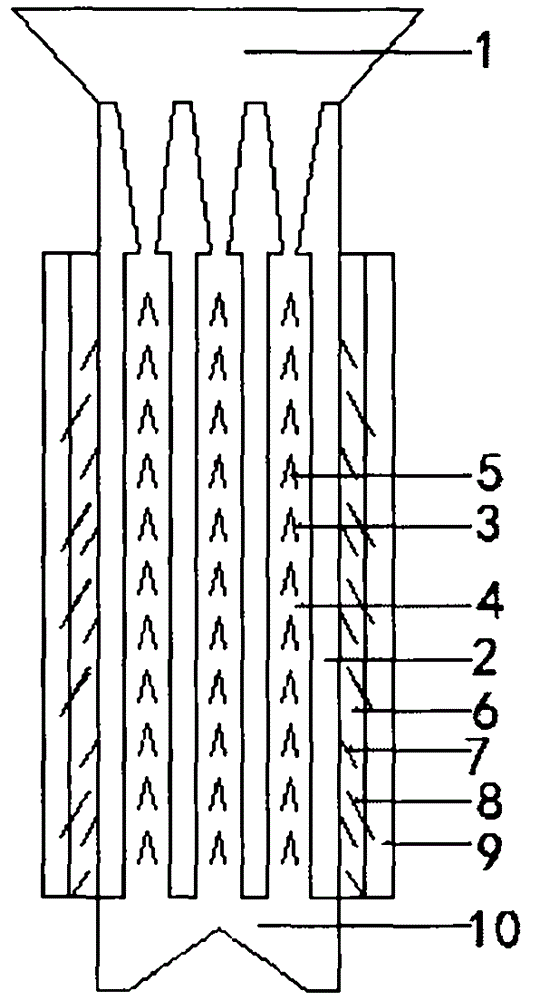

Image

Examples

Embodiment Construction

[0058] The low-temperature pyrolysis method of pulverized coal and oil shale powder of the present invention is to use a drying system to dry and preheat pulverized coal or oil shale powder with a diameter below 0.6cm to 200°C; The preheated pulverized coal or oil shale powder is indirectly heated to 550-600°C to decompose and separate semi-coke, oil gas and hot gas; then use the dust removal system to remove the dust in the oil gas and hot gas; finally use the oil and gas separation system to separate Clean gas and coal tar; finally, use the inert gas generated by the drying system and the coke quenching system to quench the semi-coke produced by the heating and pyrolysis system.

[0059] Specifically, the drying system can alternatively receive and screen pulverized coal or oil shale powder, send pulverized coal or oil shale powder with a diameter of less than 0.6cm into the dryer, and use the tail gas discharged from the heating and pyrolysis system to carry out Drying, ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com