Radial injecting mixer for mixing exhaust gas and reducing agent fluid

A technology for injecting mixers and reducing agents, which is applied in exhaust treatment, exhaust devices, machines/engines, etc., can solve the problems of easy air leakage and increased space occupied by mixers, and achieves increased uniformity and reduced pressure. drop, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific drawings and embodiments.

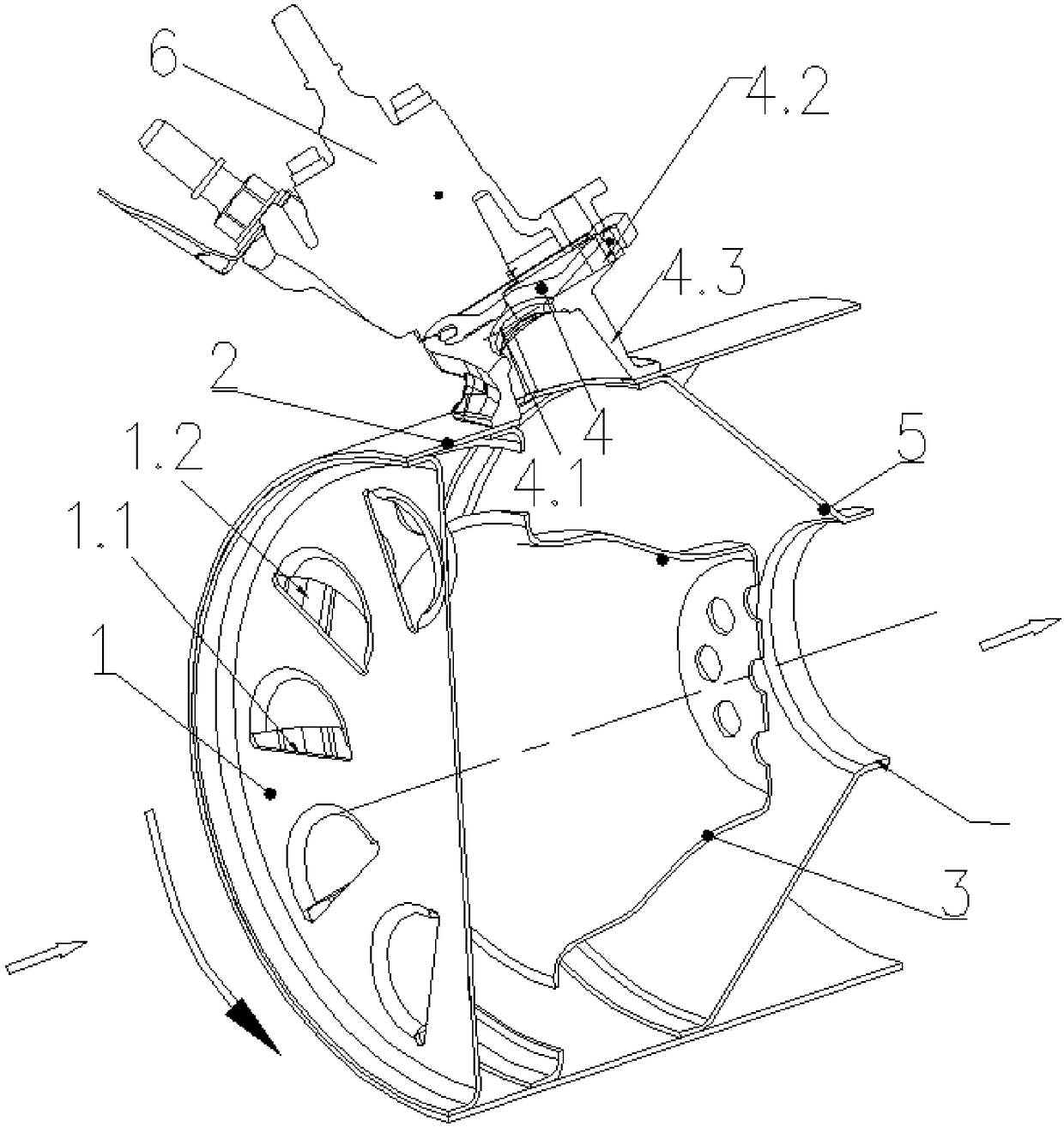

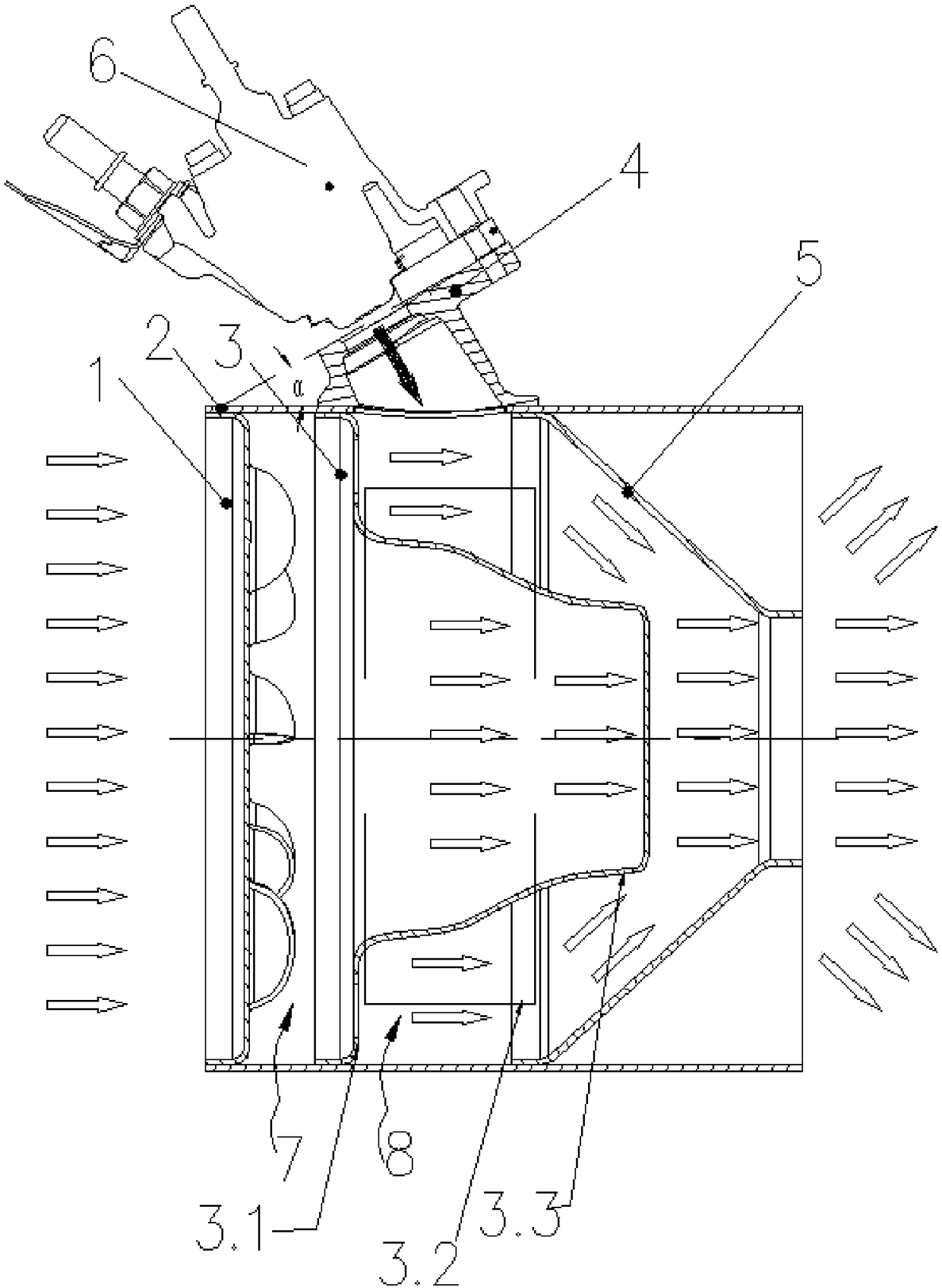

[0024] Such as Figure 1-2 Shown: a radial jet mixer for mixing exhaust gas and reducing agent fluid, including a cylindrical cylinder 2, the outer wall of the cylinder 2 is provided with a reducing agent injection base 4, and the cylinder enters The gas end is provided with a first swirl partition 1, and the first swirl partition 1 is provided with a plurality of semicircular through holes 1.1, and on the inner wall of the first swirl partition 1, each through hole The lower end is provided with a hemispherical wall plate 1.2;

[0025] At the rear end of the swirl partition 1, a second swirl partition 3 is provided along the inner wall of the cylinder, and the second swirl partition 3 includes a first part 3.1, a second part 3.2, and a third part 3.3 , the first part is cylindrical and is arranged close to the inner wall of the cylinder, the second part is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com