Pyrolysis and biomass gas catalytic reforming reactor and application thereof

A reforming reactor, pyrolysis and gasification technology, applied in the direction of chemical modification of combustible gas, combustible gas purification/transformation, gasification process, etc., to achieve the effect of promoting pyrolysis and improving the conversion efficiency of pyrolysis and gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention will be further described.

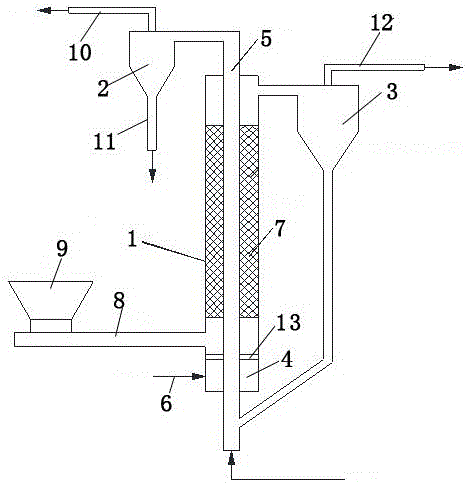

[0029] Such as figure 1 Shown, a pyrolysis and biomass gas catalytic reforming reactor, including:

[0030] Pyrolysis and gasification furnace 1, the pyrolysis and gasification furnace 1 is vertically arranged, and the pyrolysis and gasification furnace 1 is a tubular structure, the first reaction zone, the second reaction zone and the In the third reaction zone, the pyrolysis gasification furnace 1 is longitudinally penetrated with several internal heat pipes 5, between the internal heat pipes 5 and the internal heat pipes 5, and between the internal heat pipes 5 and the tubular structure are filled with integral metal fillers 7;

[0031] A flue gas cyclone separator 2, the flue gas cyclone separator 2 communicates with the top of the inner heat pipe 5, the bottom of the inner heat pipe 5 passes into the air blown in by the fan, and the top of the flue gas cyclone separator 2 is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com