Tower for flue gas desulfurization in homogeneous air-humidifying method

A desulfurization tower, rheumatism technology, applied in separation methods, chemical instruments and methods, calcium/strontium/barium sulfate, etc., can solve the problem of uneven distribution of gas-liquid two-phase flow velocity, increased pressure drop in the tower, and reduced desulfurization efficiency and other problems, to achieve the effect of reducing operating costs, reducing consumption, and uniform flow field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

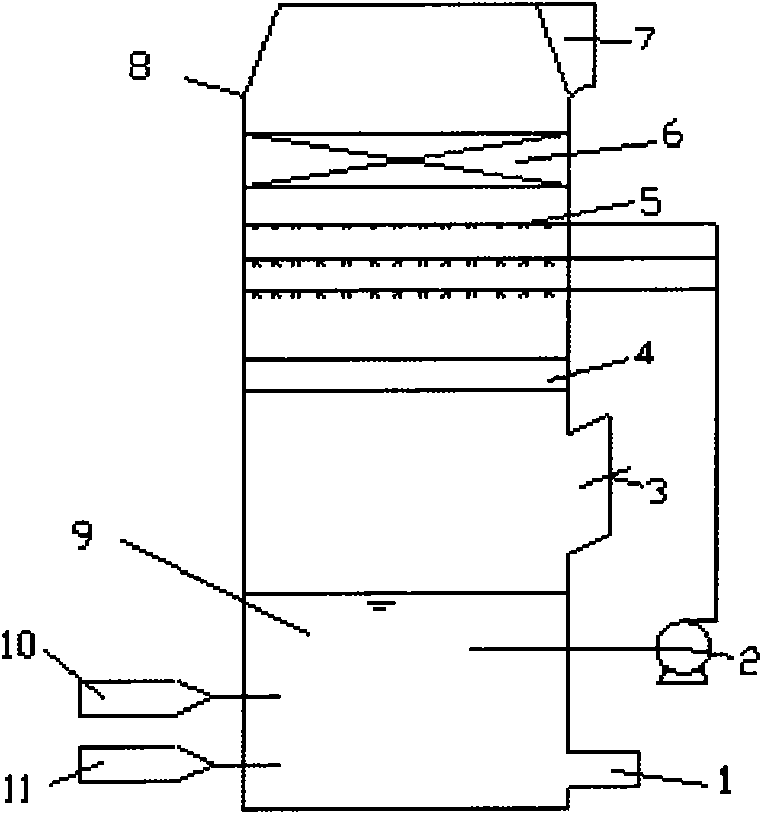

[0036] Such as figure 1 The uniform air distribution flue gas desulfurization tower shown

[0037] A flue gas desulfurization tower device of evenly distributed rheumatic method, comprising a desulfurization tower 8, said desulfurization tower 8 comprising a flue gas inlet 3, a flue gas outlet 7, a desulfurization product slurry outlet 1, a slurry spray area 5, and a demister Zone 6, desulfurizer slurry pool 9, limestone slurry external supply device 10, oxidation air system 11, slurry circulation pump 2 and Venturi diversion tube zone 4;

[0038] The flue gas outlet 7 is opened at the top of the desulfurization tower 8, and the desulfurizer slurry pool 9 is arranged at the bottom of the desulfurization tower 8,

[0039] There is a desulfurization product slurry outlet 1 on the bottom side of the desulfurization agent slurry pool 9;

[0040] Limestone slurry external supply device 10 and oxidation air system 11 are respectively connected with desulfurizer slurry pool 9;

[...

Embodiment 2

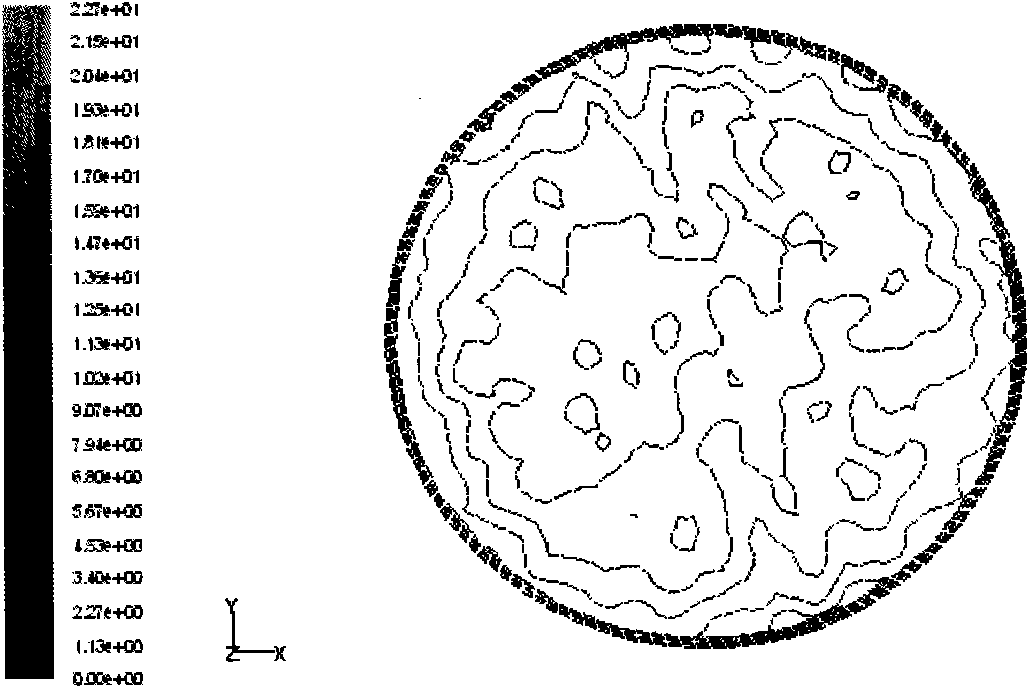

[0046] Use traditional flue gas desulfurization towers with non-uniform air distribution for desulfurization

[0047] Flue gas discharged from the boiler, where SO 2 The concentration is 1500mg / m 3 , after being dedusted by the electrostatic precipitator, the flue gas flow rate is selected to be 6785m through the booster fan 3 / L is sent into the desulfurization tower 8 through the flue gas inlet 3 of the desulfurization tower 8. The flue gas is divided into two paths, respectively forming a clockwise and a counterclockwise vortex to flow upward, and continue to flow upward, passing through the staggered arrangement in the desulfurization In the upper spray area 5 of the tower 8, the limestone slurry in the slurry pool 9 passes through the limestone slurry circulation pump 2 at a flow rate of 67.85m 3 / L is continuously transported to the spray area 5, sprayed out through the nozzle, and contacts with the flue gas countercurrently, thereby completing the desulfurization. Si...

Embodiment 3

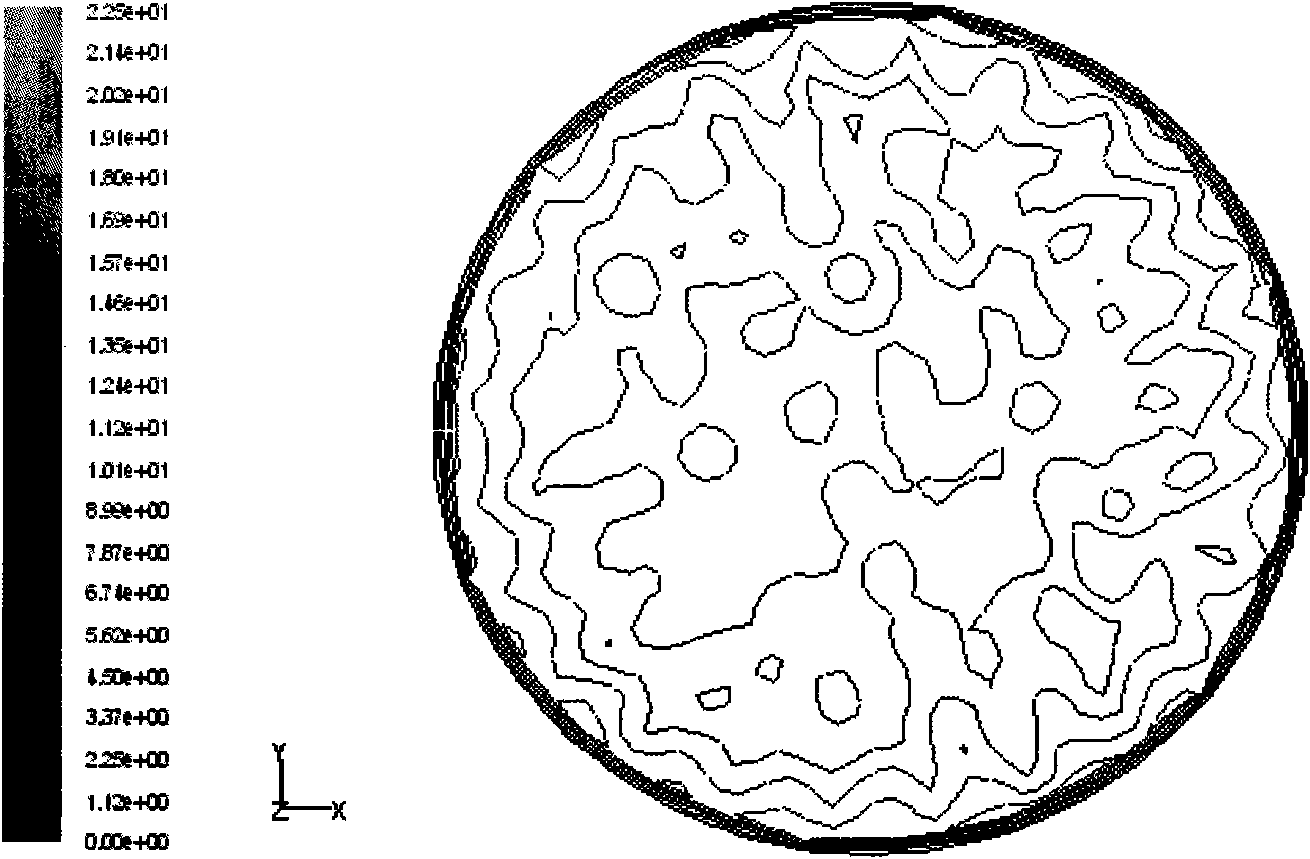

[0050] The flue gas desulfurization tower adopting uniform air distribution of the present invention performs desulfurization

[0051] Flue gas discharged from the boiler, where SO 2 The concentration is 1500mg / m 3 , after being dedusted by the electrostatic precipitator, the flue gas flow rate is selected to be 6785m through the booster fan 3 / L is sent into the desulfurization tower 8 through the flue gas inlet 3 of the desulfurization tower 8. The flue gas is divided into two paths, respectively forming a clockwise and a counterclockwise vortex to flow upward, and is rectified by the Venturi guide tube 4 to form a uniform distribution. The flue gas is turbulent and continues to flow upwards, passing through the spray area 5 staggeredly arranged above the middle of the desulfurization tower 8, and the limestone slurry in the slurry pool 9 passes through the limestone slurry circulation pump 2 at a flow rate of 67.85m 3 / L is continuously transported to the spray area 5, sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com