Multiblade fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]Exemplary embodiments of the present invention are described in detail below with reference to the accompanying drawings. The present invention is not limited to the exemplary embodiments. Elements of the embodiments include all equivalents that do not depart from the spirit and scope of the invention in its broadest form. The plurality of modifications of the embodiments mentioned below can be arbitrarily combined within the range that will occur to those skilled in the art.

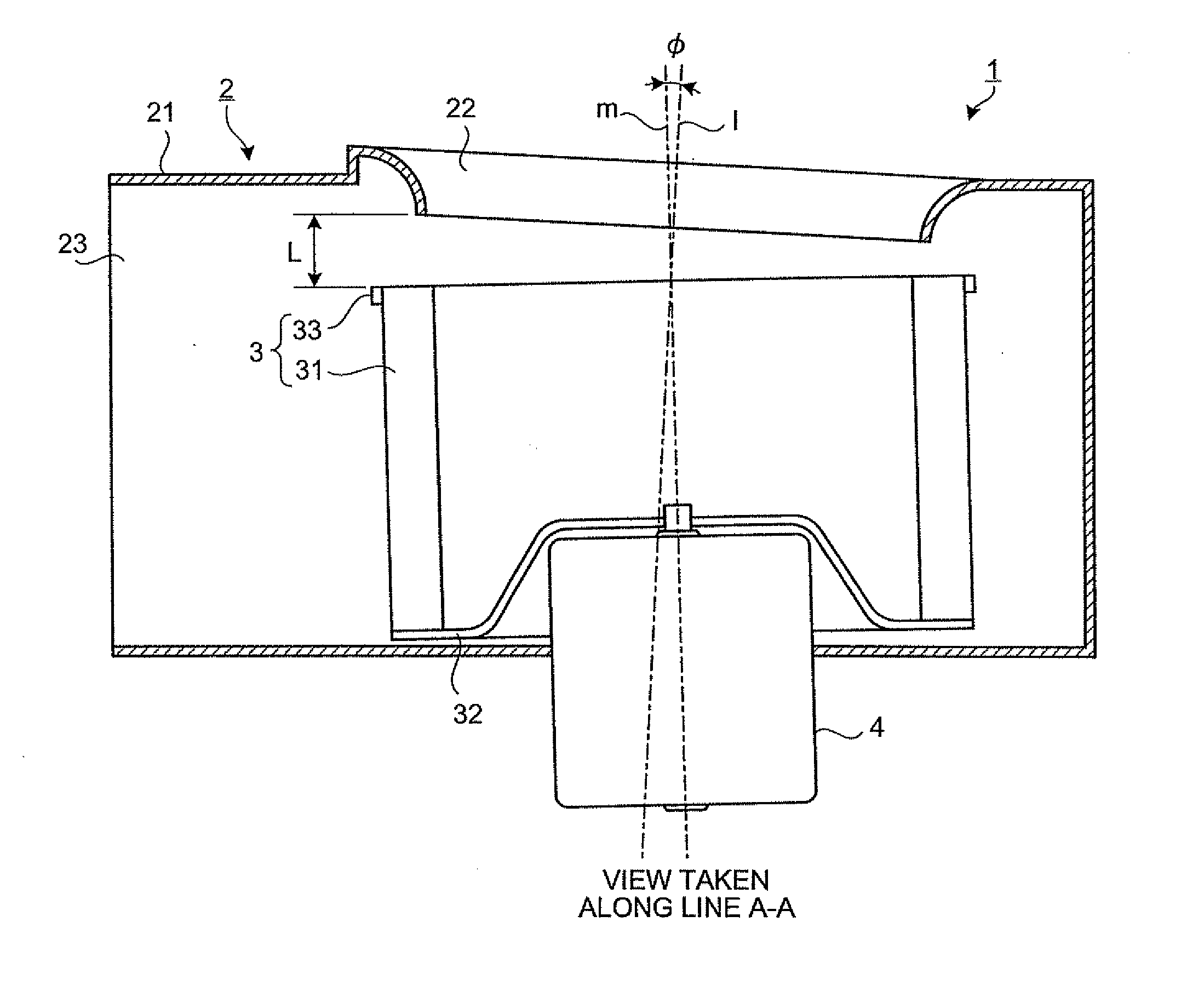

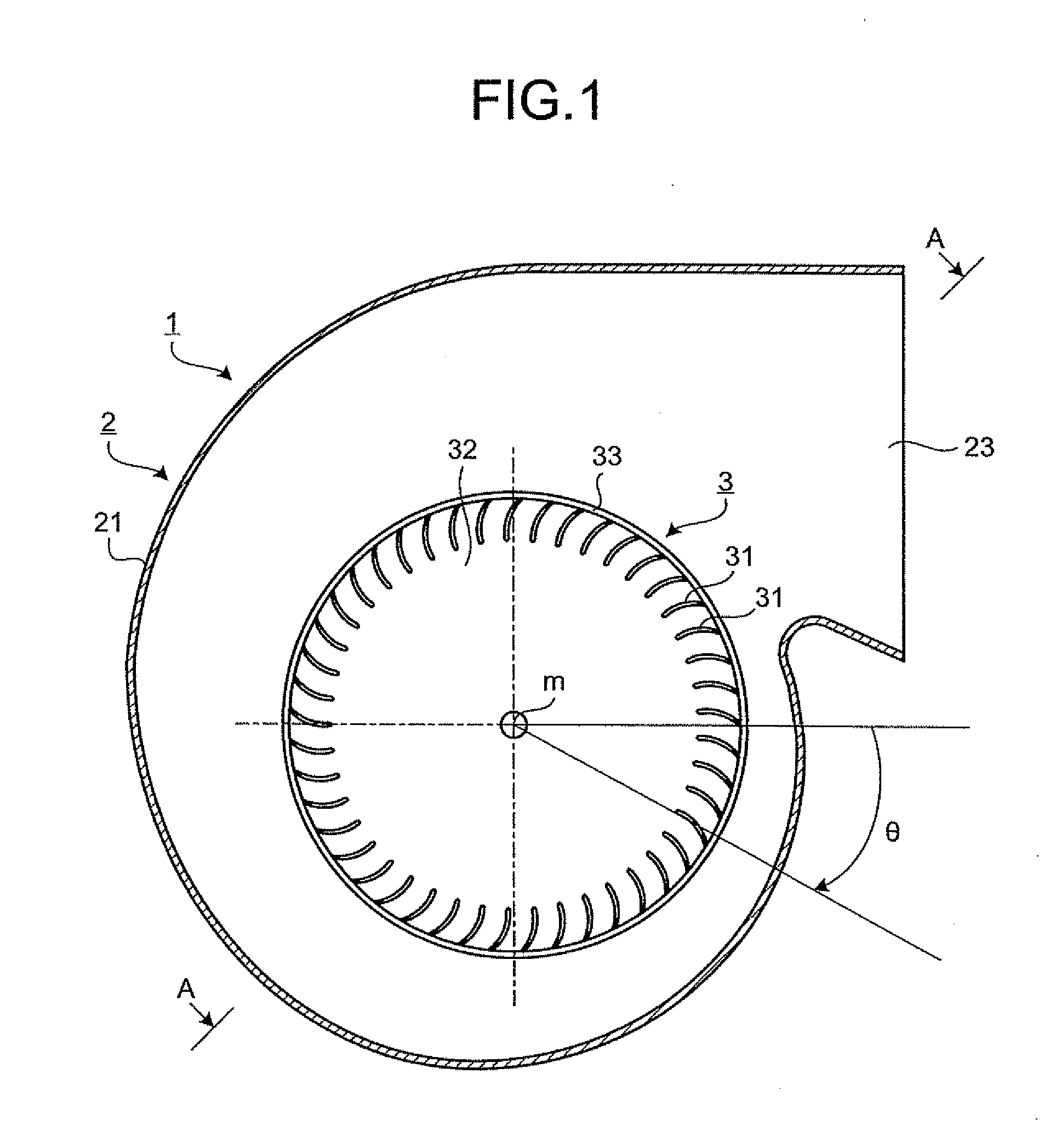

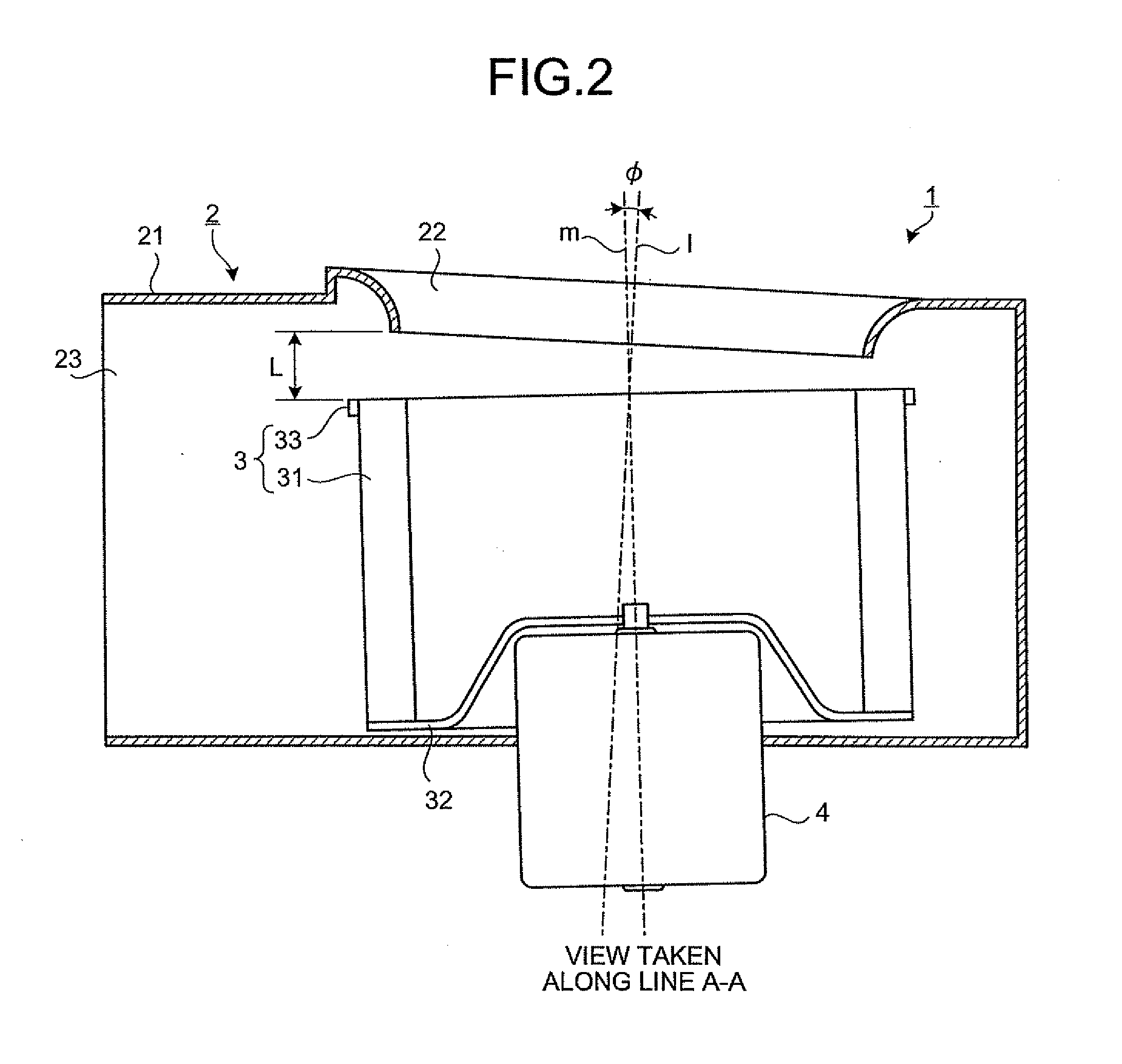

[0027][Multiblade Fan]

[0028]A multiblade fan 1 is a blower that includes a multibladed wheel (sirocco fan). The multiblade fan 1 is applied to, for example, an air conditioning system, a duct fan, and a ventilating fan. The multiblade fan 1 can be of a single inlet type or a double inlet type. In the present embodiment, the multiblade fan 1 of a single inlet type will be described as an example.

[0029]The multiblade fan 1 includes a casing 2, an impeller 3, and a drive motor 4 (see FIG. 1 and FIG. 2).

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com