Atomic beam generation method and apparatus for atomic chipset

A technology of atomic chips and generating devices, applied in phonon exciters, masers, circuits, etc., can solve the problems of low atomic density, low longitudinal velocity, and low transverse velocity, and achieve increased atomic density and velocity distribution Uniform, low transverse velocity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

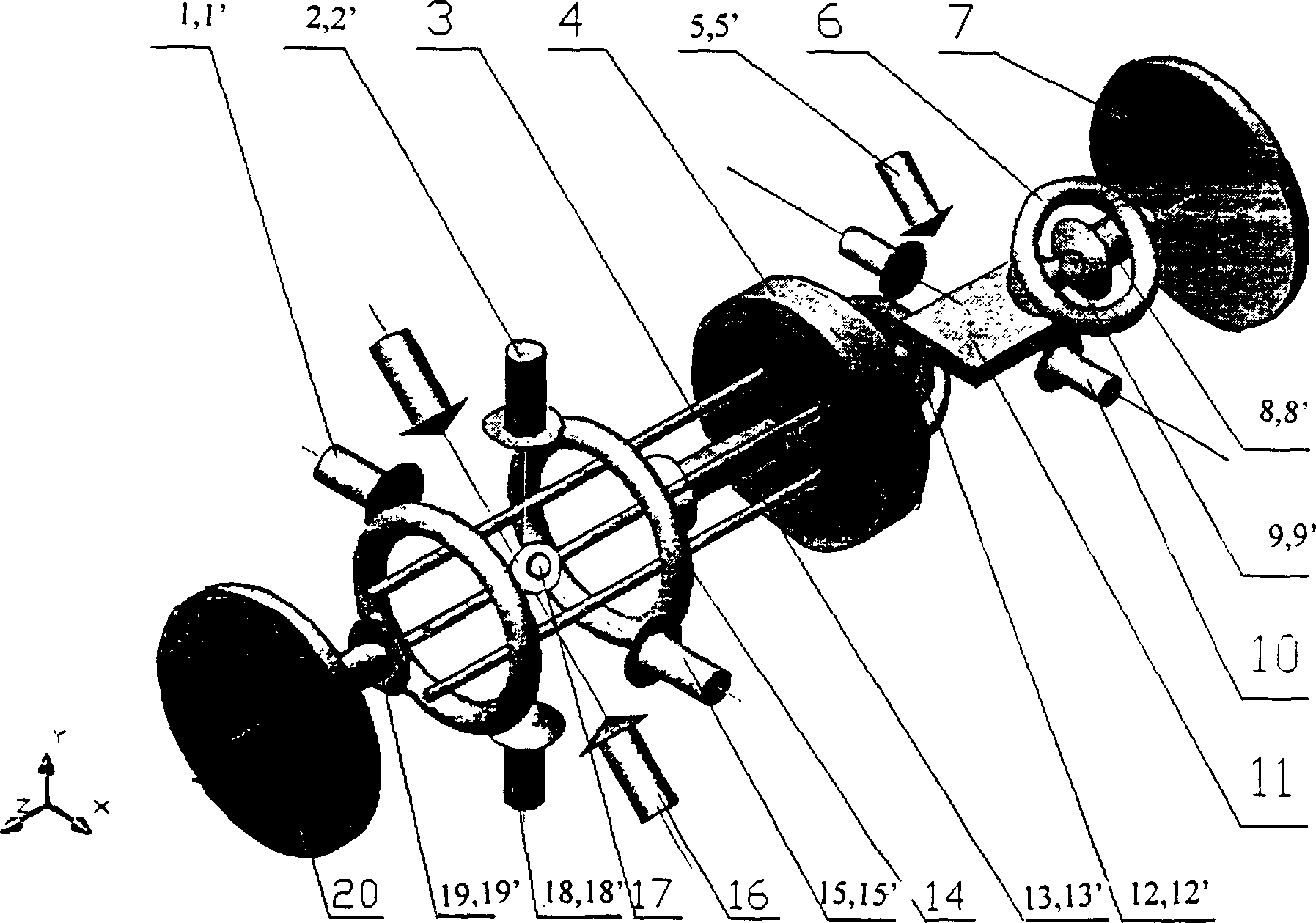

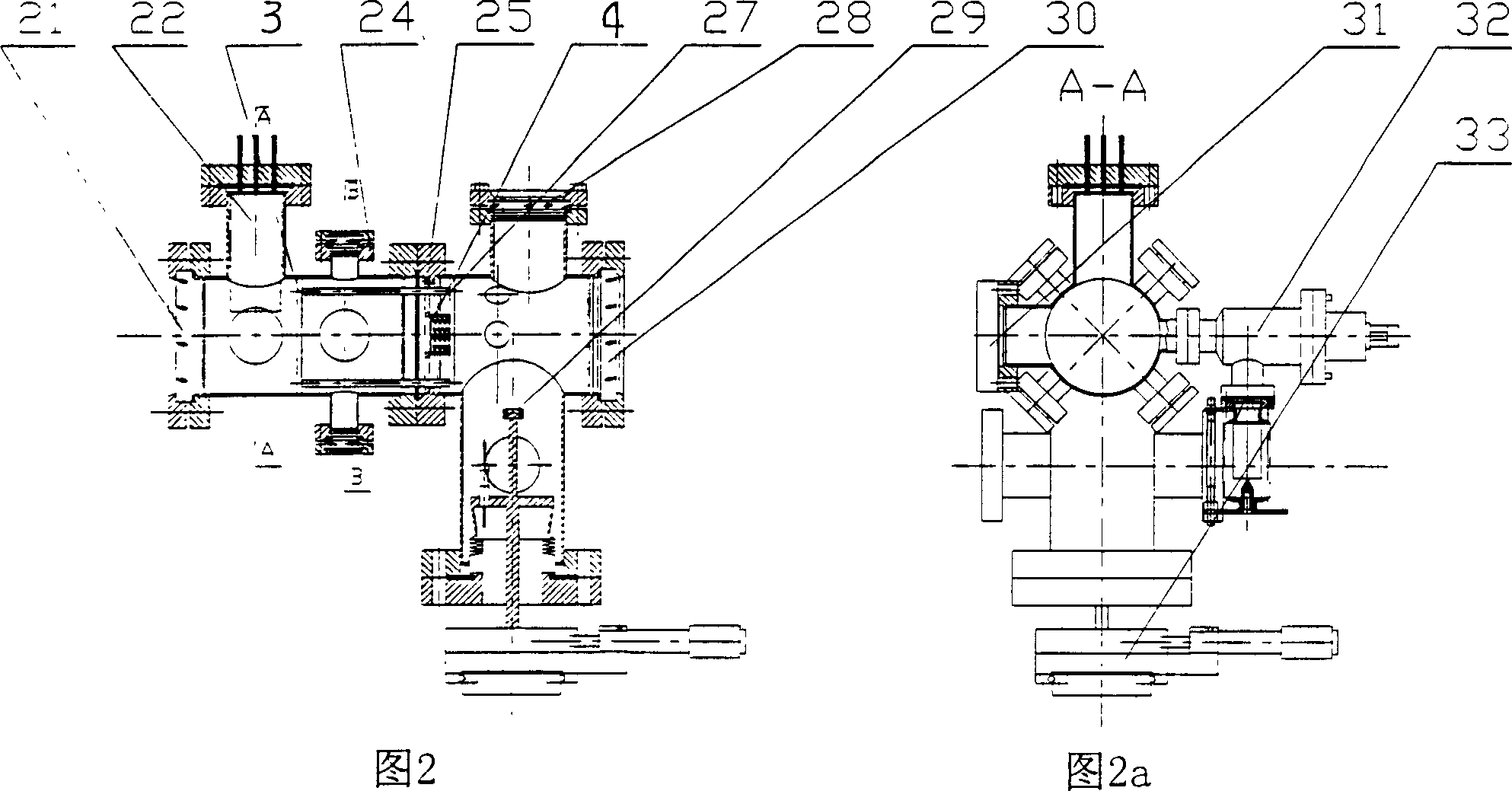

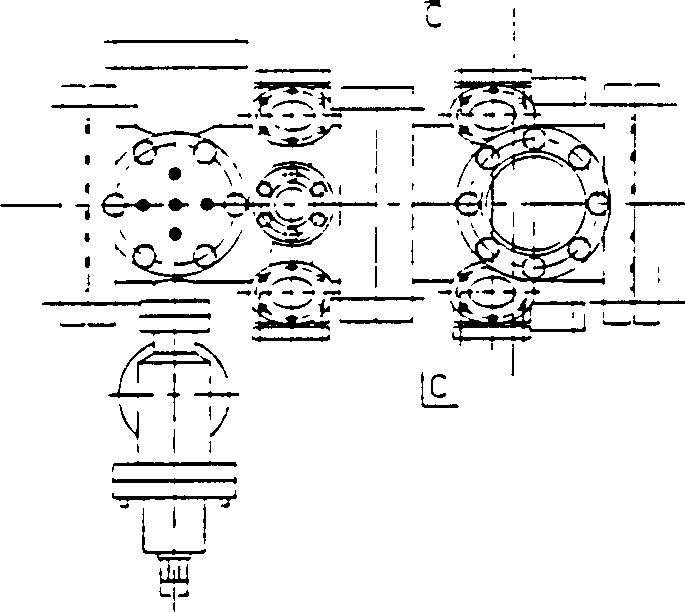

[0089] The atomic beam generating device for an atomic chip provided by the present invention includes an atomic source, a vacuum chamber, a two-dimensional fine-tuning table, a magnet (permanent magnet or magnetic field coil) and an internal and external optical system.

[0090] Such as figure 1 As shown, the three-dimensional magneto-optical trap formed by cooling lasers 1, 2, 13, 15, 18, 19 and the second pair of anti-Hertz coils 14 captures and cools the atom source steam beam 17 ejected from the hot atom source nozzle, Wherein the cooling laser 15 is that the cooling laser 1 passes through a 1 / 4 wave plate positioned outside the vacuum chamber and a mirror ( figure 1 Not shown in ) the reflected cooling laser that obtains, cooling laser 18 is that cooling laser 2 passes through a 1 / 4 wave plate and a mirror ( figure 1 not shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com