Artificial surface plasmon-based miniaturized low-pass filter

An artificial surface plasmon, low-pass filter technology, applied in the field of filters, can solve the problem that the wave vector transmission conversion efficiency cannot meet the ideal requirements, and achieves the effect of strong innovation, good technical foresight, and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

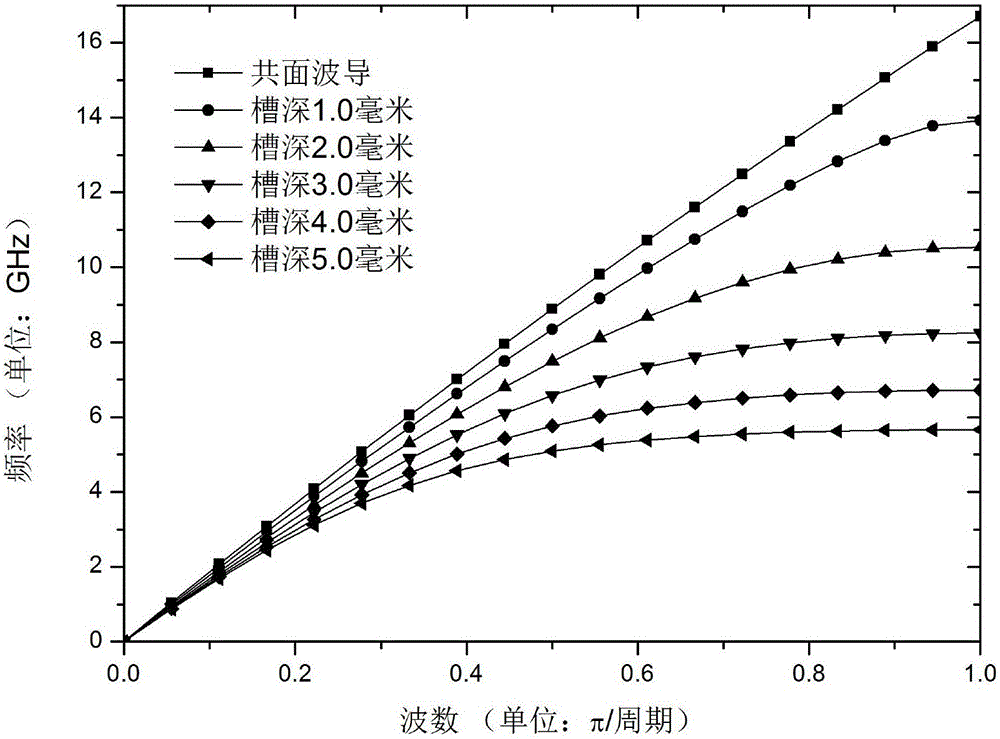

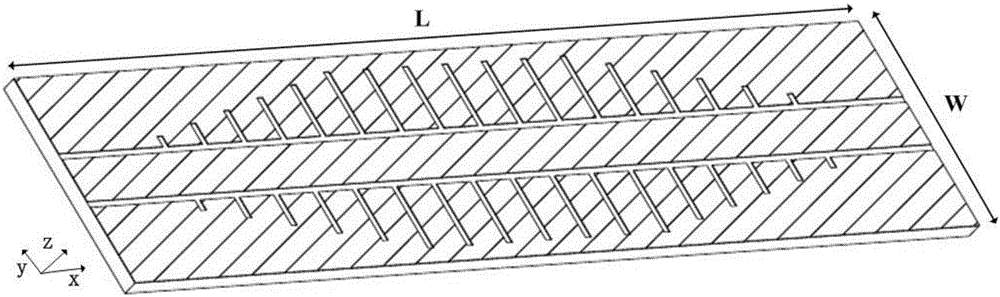

[0028] Such as image 3 As shown, the structure of the present invention is based on the coplanar waveguide, and its two metal grounding strips are etched with a rectangular structure slot unit array periodically distributed along the coplanar waveguide length direction (x direction), and the slot unit array is about the coplanar waveguide The width direction (y direction) is left-right symmetrical, and the two slot unit arrays are vertically symmetrical with respect to the central conductor strip. The depth of the slot unit (that is, the height in the y direction) increases uniformly from both sides to the middle in the x direction to form a pattern matching section, and the depth of the slot unit in the middle remains unchanged to form the SSPPs transmission section, and the number of slot units with gradually changing depths on both sides and the depth in the middle remain unchanged The number of slot units is set according to the transmission requirements of the guided wav...

Embodiment 2

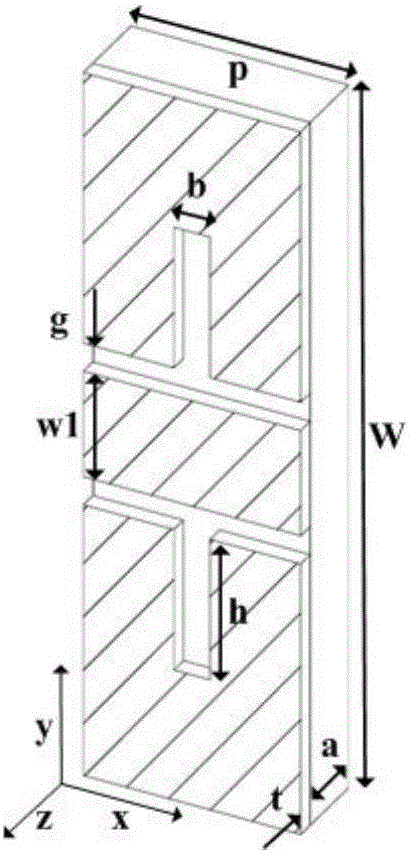

[0034] Such as Figure 6 As shown, it is consistent with the basic structure of Embodiment 1, the difference is that the groove unit of this embodiment adopts a T-shaped structure, the length of the overall structure is L=100mm, the width is W=20mm, the thickness of the dielectric substrate a=1.0mm, and the thickness of the metal layer t = 0.018mm.

[0035] Such as Figure 7As shown, the coplanar waveguide signal line width w1=3mm, and the distance between the signal line and the ground g=0.8mm is used to construct the port impedance of 50ohm. In this embodiment, the width of the transverse branch and the vertical branch of the T-shaped slot unit is equal to b=0.5mm, and the width of the transverse branch and the vertical branch can also be unequal. It is set according to the transmission requirements of the guided wave signal, and the period along the x direction is p= 4mm distribution. The length of the branches of the T-shaped groove unit in the x direction remains const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com