Centrifugal Compressor

a centrifugal compressor and compressor technology, applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problem of difficult to measure the internal flow of airflow flowing within the diffuser passage, and achieve the effect of reducing the surge flow rate and widening the compressor operation rang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]Hereunder an embodiment of a centrifugal compressor according to the present invention is described, based on the drawings.

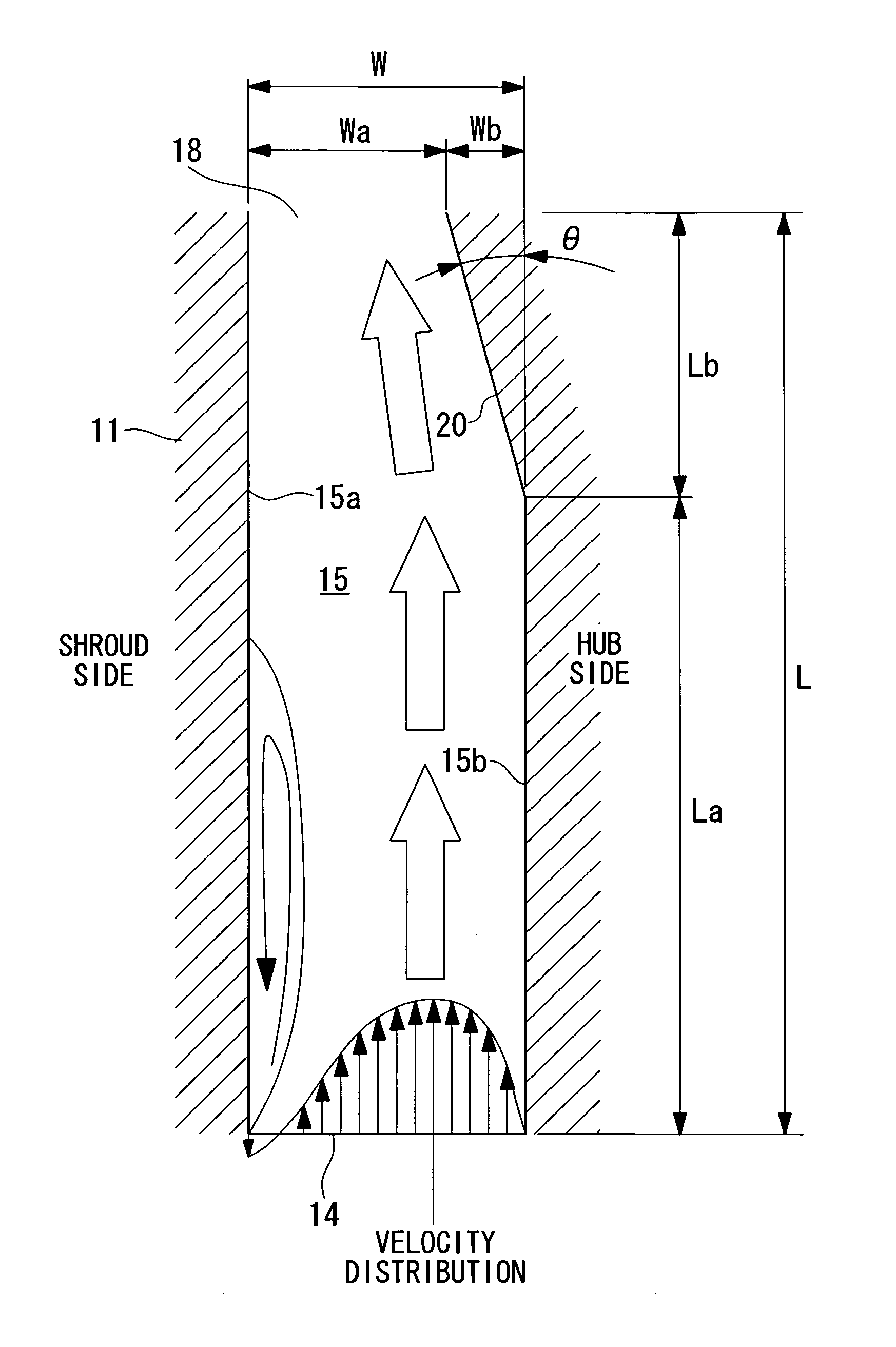

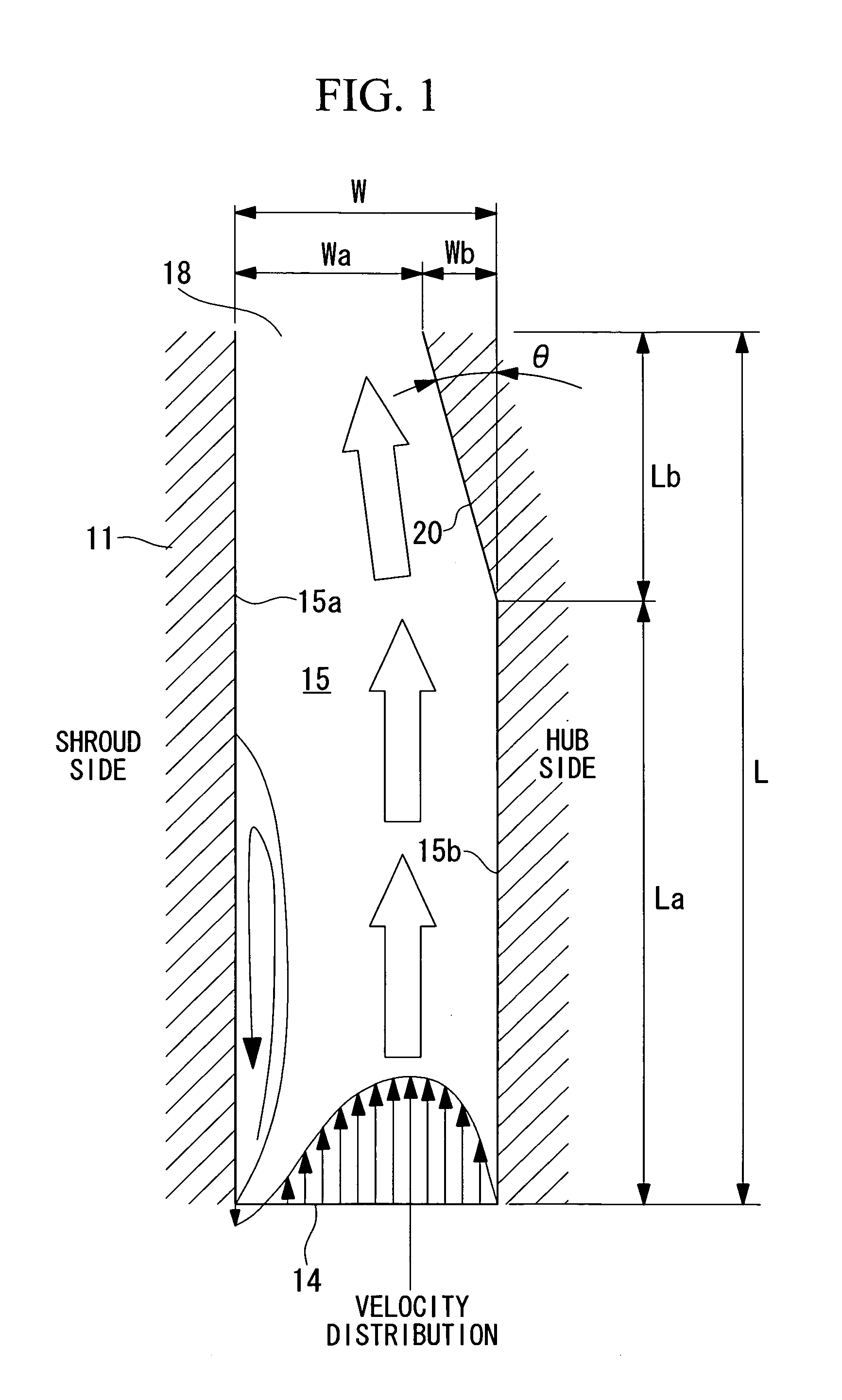

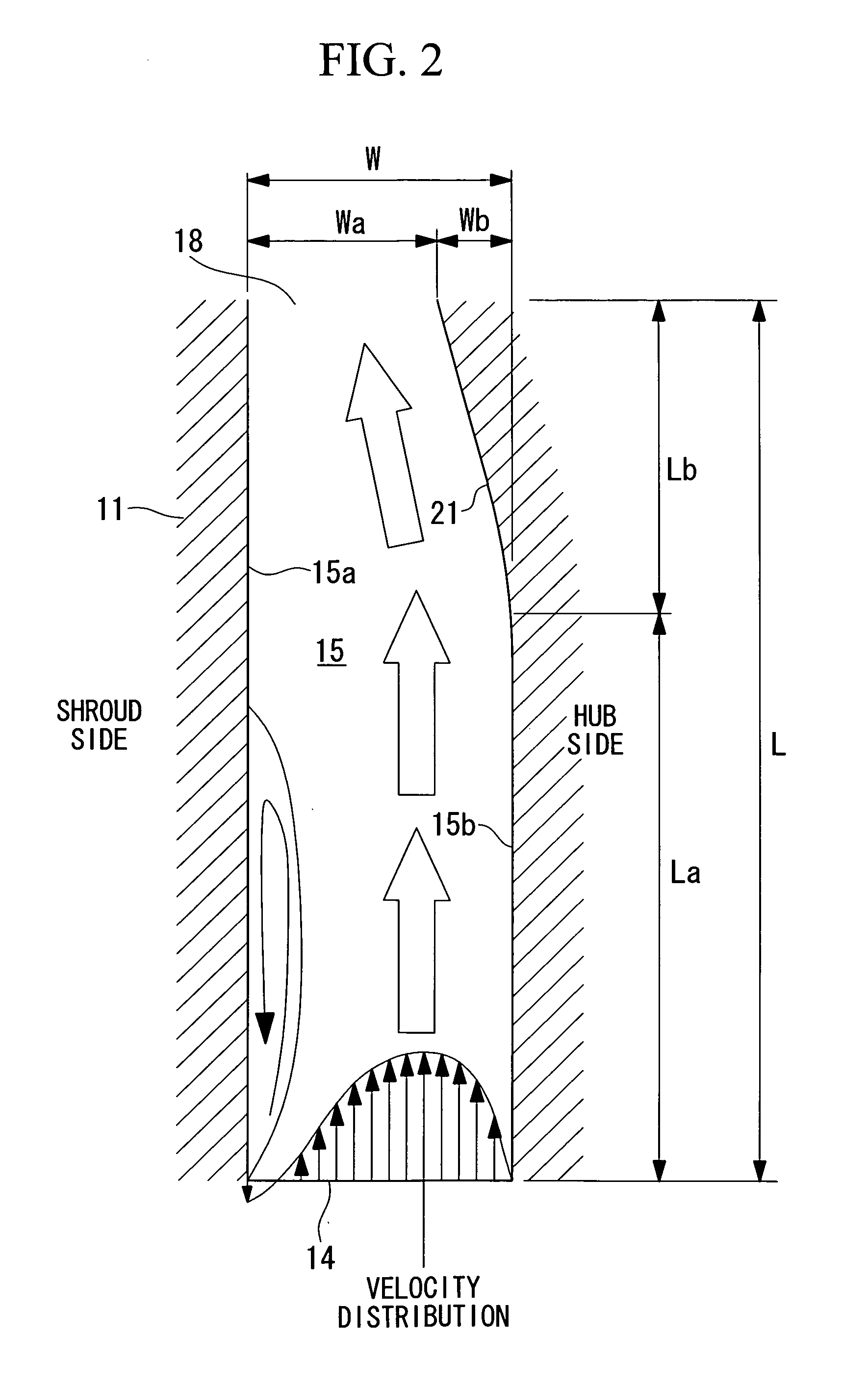

[0044]As shown in FIG. 5A, a centrifugal compressor 10 is provided with a diffuser passage 15 that recovers static pressure by reducing the velocity of a discharged air from an outer circumferential end of an impeller 13 that rotates within a housing 11. The diffuser passage 15 is provided so as to connect between an impeller exit (diffuser entry) 14 and a scroll 16, and is formed in between a pair of opposing wall surfaces that comprise a shroud side wall surface 15a and a hub side wall surface 15b.

[0045]FIG. 1 is a sectional view of the diffuser passage 15 showing a first embodiment. This diffuser passage 15 introduces from the diffuser entry 14, the discharged air (indicated with white arrows in the drawing) from the outer circumferential end of the impeller 13, and allows the airflow guided to the passage between the shroud side wall surface 15a and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com