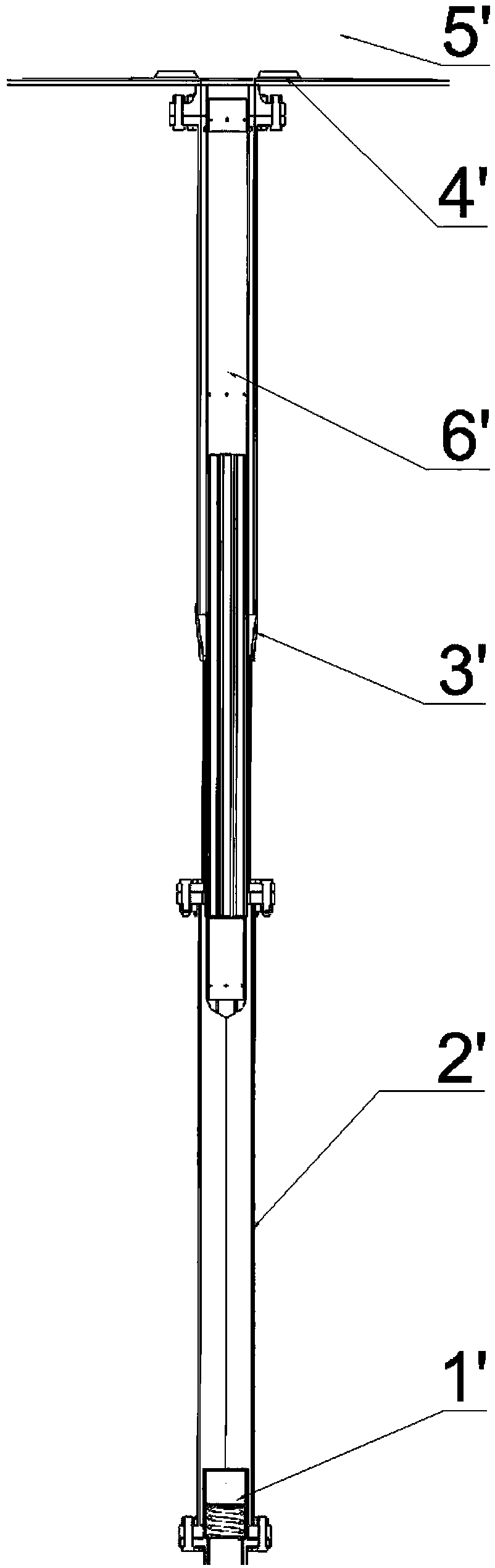

Hydraulic buffer structure for hydraulic suspension passive shutdown experimental device

A technology of buffer structure and experimental device, which is applied in the direction of reactor, nuclear power generation, nuclear reaction control, etc., can solve the problems of large influence of suspension stability of control rod, increased uncertainty of experimental data measurement, unfavorable test section and centrifugal pump safety, etc. , to achieve the effect of improving suspension stability, uniform coolant velocity distribution, and reducing rod drop time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

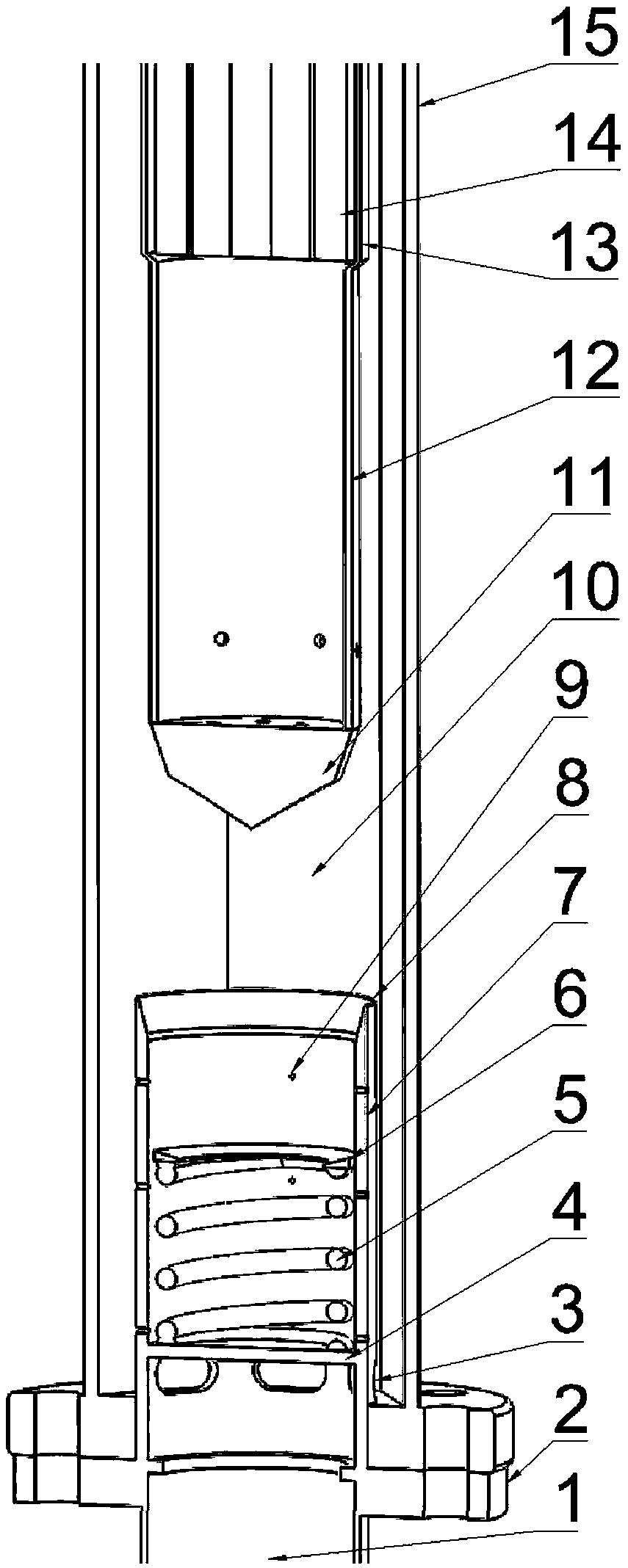

[0030] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0031] refer to figure 2 , a hydraulic buffer structure for a hydraulic suspension type passive shutdown experimental device according to the present invention, comprising an inlet pipe flange 2, a water inlet hole 3, a compression spring base baffle plate 4, a cylindrical compression spring 5, Buffer gasket 6, hydraulic buffer cylinder 7, tapered through hole 8, pressure relief hole 9, lower end cover 11, damping block 12, passive shutdown rod model middle sleeve 13 and visualization sleeve 15.

[0032] figure 2 Shown is the structural representation of the hydraulic buffer and supporting parts of the present invention, the hydraulic buffer cylinder 7 is vertically welded on the center of the upper end face of the inlet pipe flange 2, and the hexagona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com