Suction and exhaust device

An exhaust device and air technology, which is applied in the direction of pipeline layout, shielding with air flow, and household stoves/stoves, etc., can solve the problems of difficulty in dispersing the air flow pressure, disordered blowing flow, and inability to generate a rotating flow with flow velocity distribution. Uniform flow velocity distribution to achieve the effect of exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

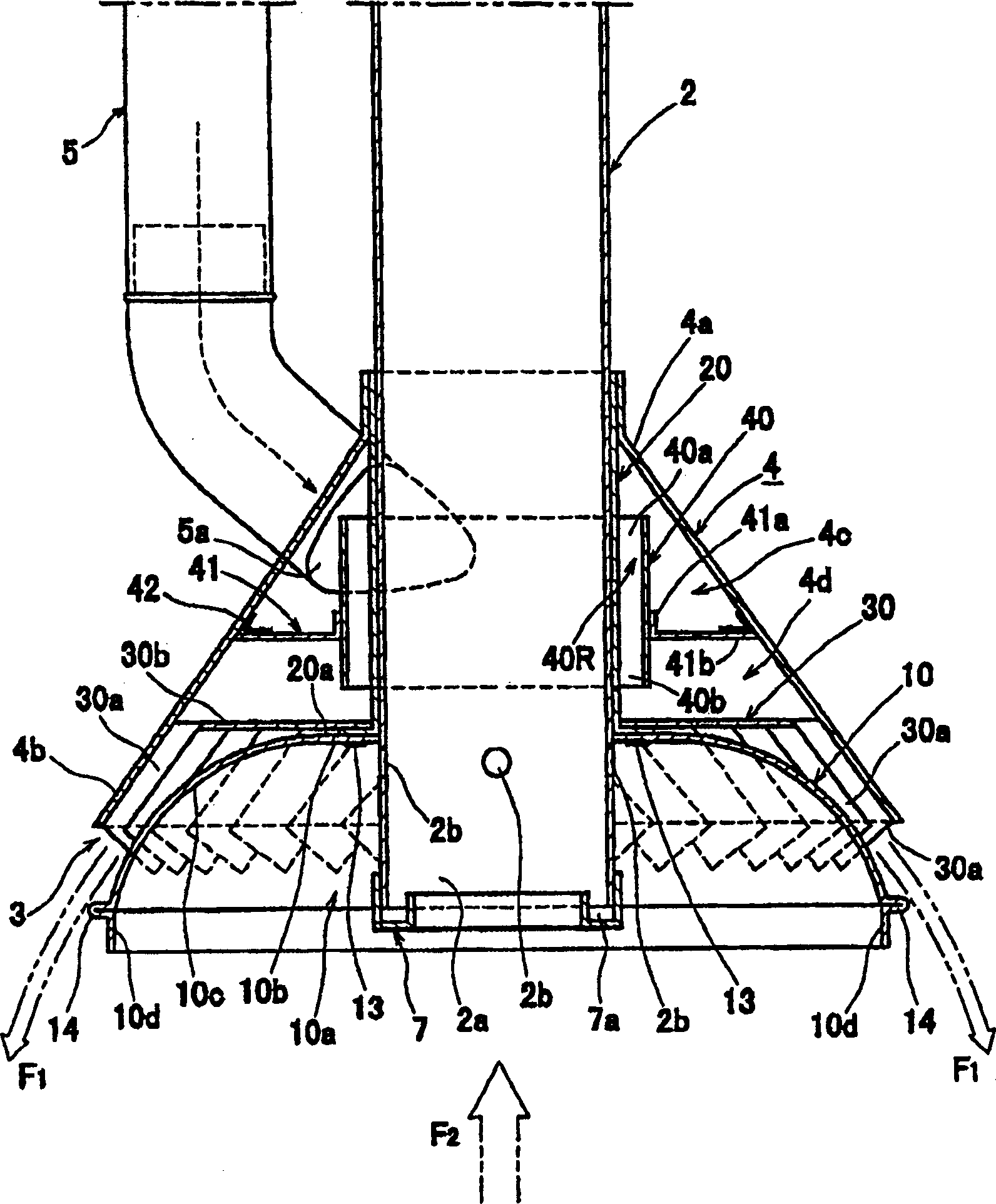

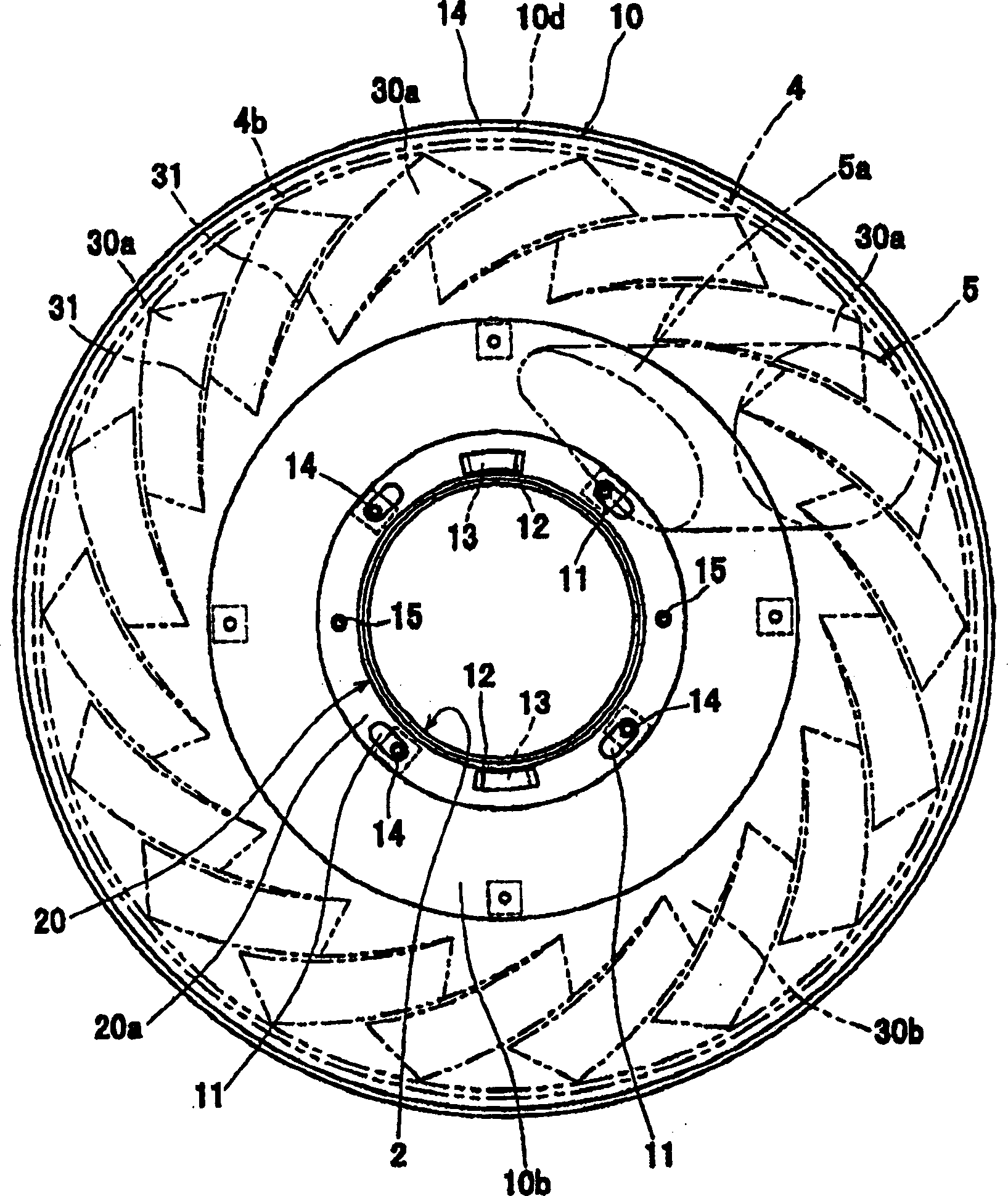

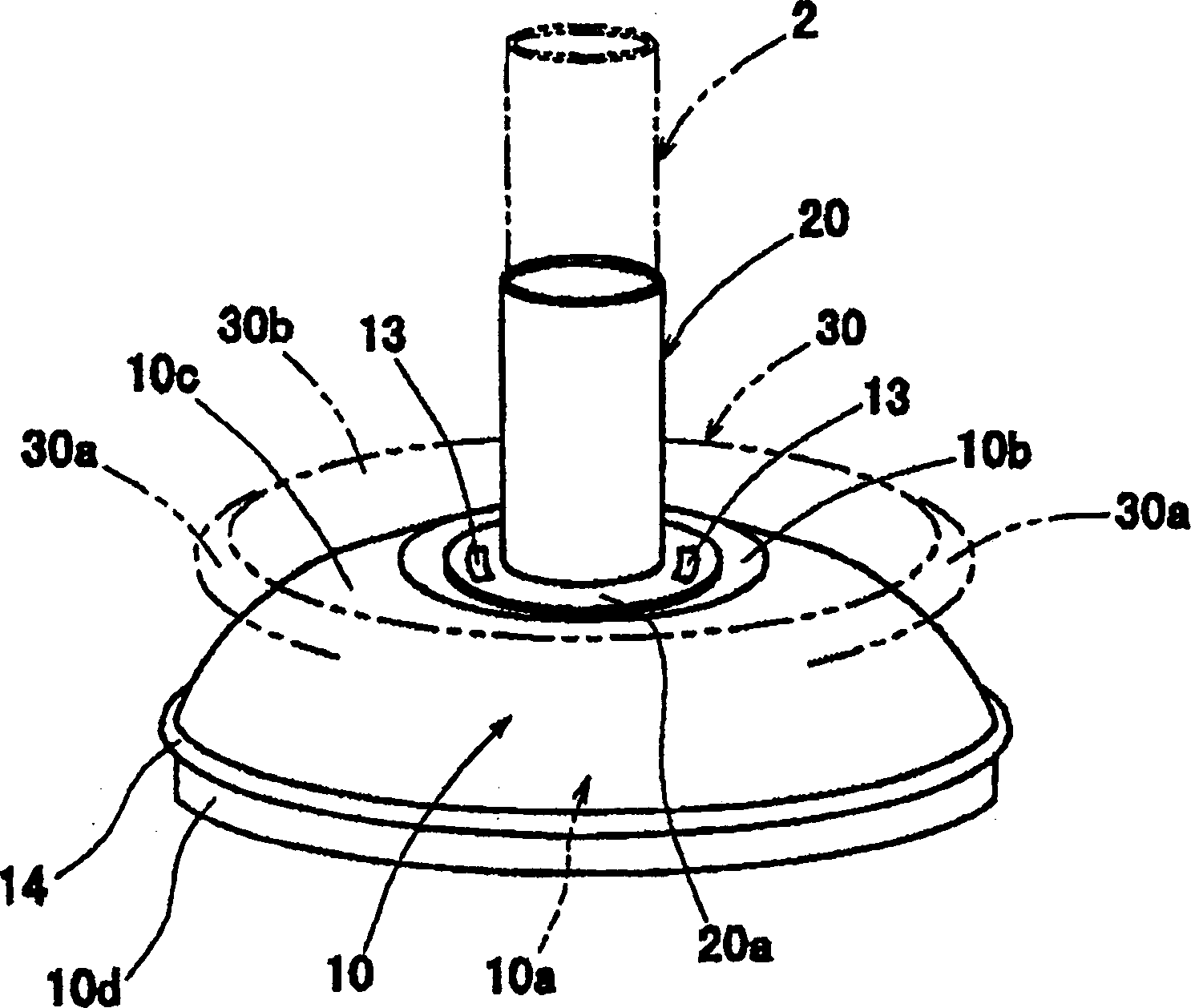

[0056] Figure 1 to Figure 8 Shown is the structure of the cyclone type local ventilation device formed by the air supply and exhaust device according to Embodiment 1 of the present invention.

[0057] The cyclone-type local ventilation device is installed on the upper part of the heating tableware in a predetermined local area such as a gas stove in a general household kitchen or a business kitchen of a restaurant, etc. F1 encloses the heating tableware in an air curtain shape, and the spiral swirling vortex F1 utilizes the external air introduced from the outside to pass through the inner center of the spiral swirling vortex F1 acting on the air curtain and toward the suction direction. The suction negative pressure makes the tornado-shaped suction swirling vortex F2 generated upward in the air-curtain-shaped spiral swirling vortex F1, and the tornado-shaped rising swirling vortex F2 can efficiently attract the gas from the above-mentioned predetermined local area. Exhaust ...

Embodiment 2

[0081] under Figure 9 and Figure 10 The structure of the cyclone type local ventilation device constituted by the air supply and exhaust device according to the second embodiment of the present invention is shown.

[0082] In the structure of the cyclone-type local ventilator of the above-mentioned Embodiment 1, in this embodiment, the upper end side opening (inflow port) 40a side and the lower end side opening (outflow port) 40b side of the flow rectification passage 40 are provided respectively. The straightening plates 43, 44 having a plurality of small holes 43a, 43a, . . . , 44a, 44a, . These rectifying plates 43, 44 adopt a structure such as a punched plate.

[0083] In this way, if rectification plates 43, 44 are respectively provided on the upper end side opening (inflow port) 40a side and the lower end side opening (outflow port) 40b side of the rectification passage 40R that completes the above-mentioned rectification action, in the inflow rectification passage 4...

Embodiment 3

[0090] under Figure 11 and Figure 12 Shown is the structure of the cyclone type local ventilation device constituted by the air supply and exhaust device according to Embodiment 3 of the present invention.

[0091] In the structure of the cyclone-type local ventilator in the above-mentioned embodiment 1, in this embodiment, the rectification passage 50R is provided on the outer peripheral side of the rectification passage 40R to form two sets of rectification passages that are curved in the vertical direction, continuous, and arranged side by side in the radial direction. The channel is characterized by further improving the rectification effect.

[0092] That is, in this structure, by leaving a predetermined interval on the outer peripheral side of the first cylindrical wall 40 forming the rectifying passage 40R of the first embodiment, and further providing the large-diameter second cylindrical wall 50 forming the second rectifying passage 50R, And leave the second cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com