Fan assembly

a technology of fan assembly and fan body, which is applied in the direction of non-positive displacement fluid engine, pump components, piston pumps, etc., can solve the problems of deformation of the blower efficiency, so as to improve the blower efficiency of the fan assembly and prevent the effect of thermal deformation of the impeller portion breaking or cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

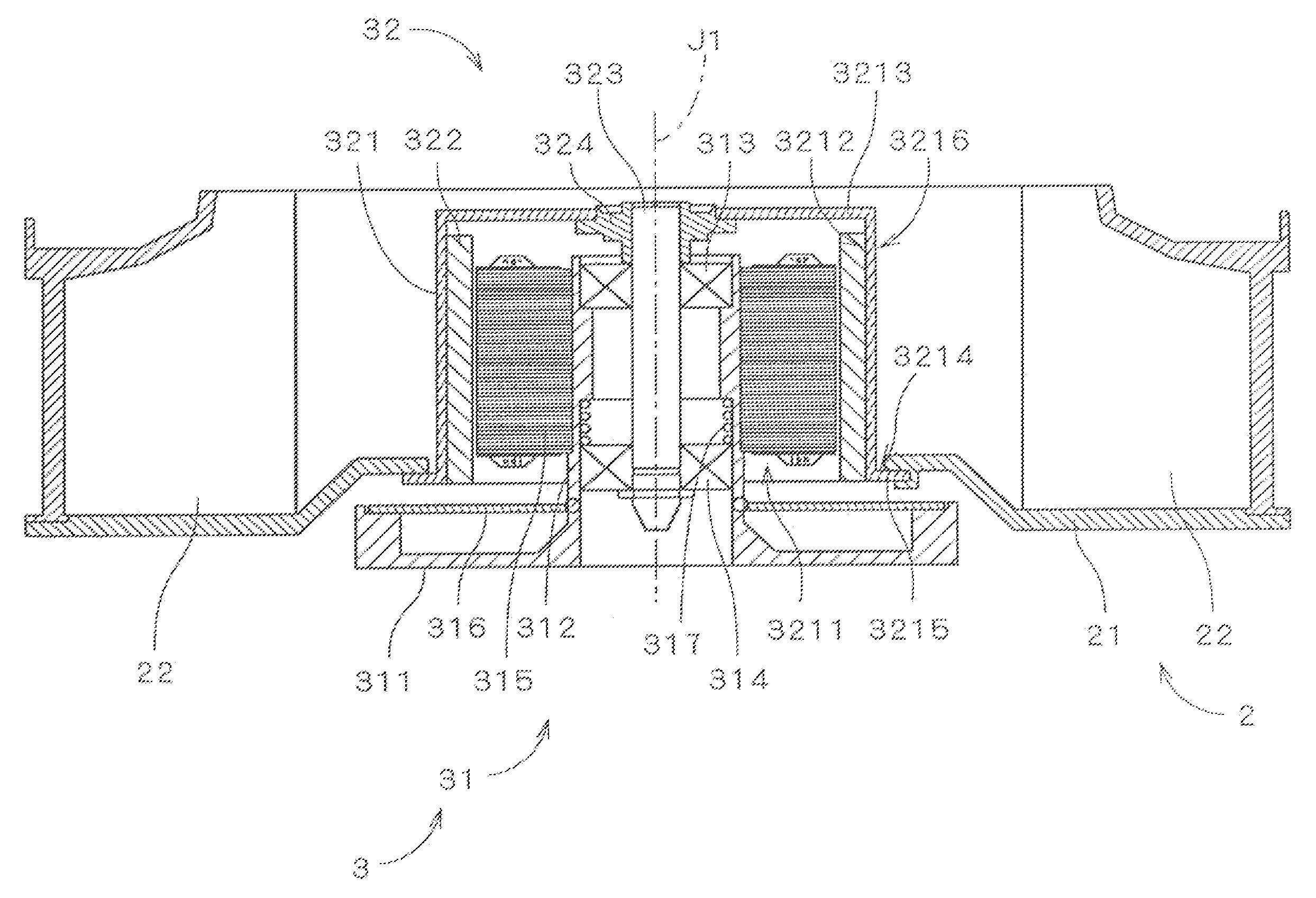

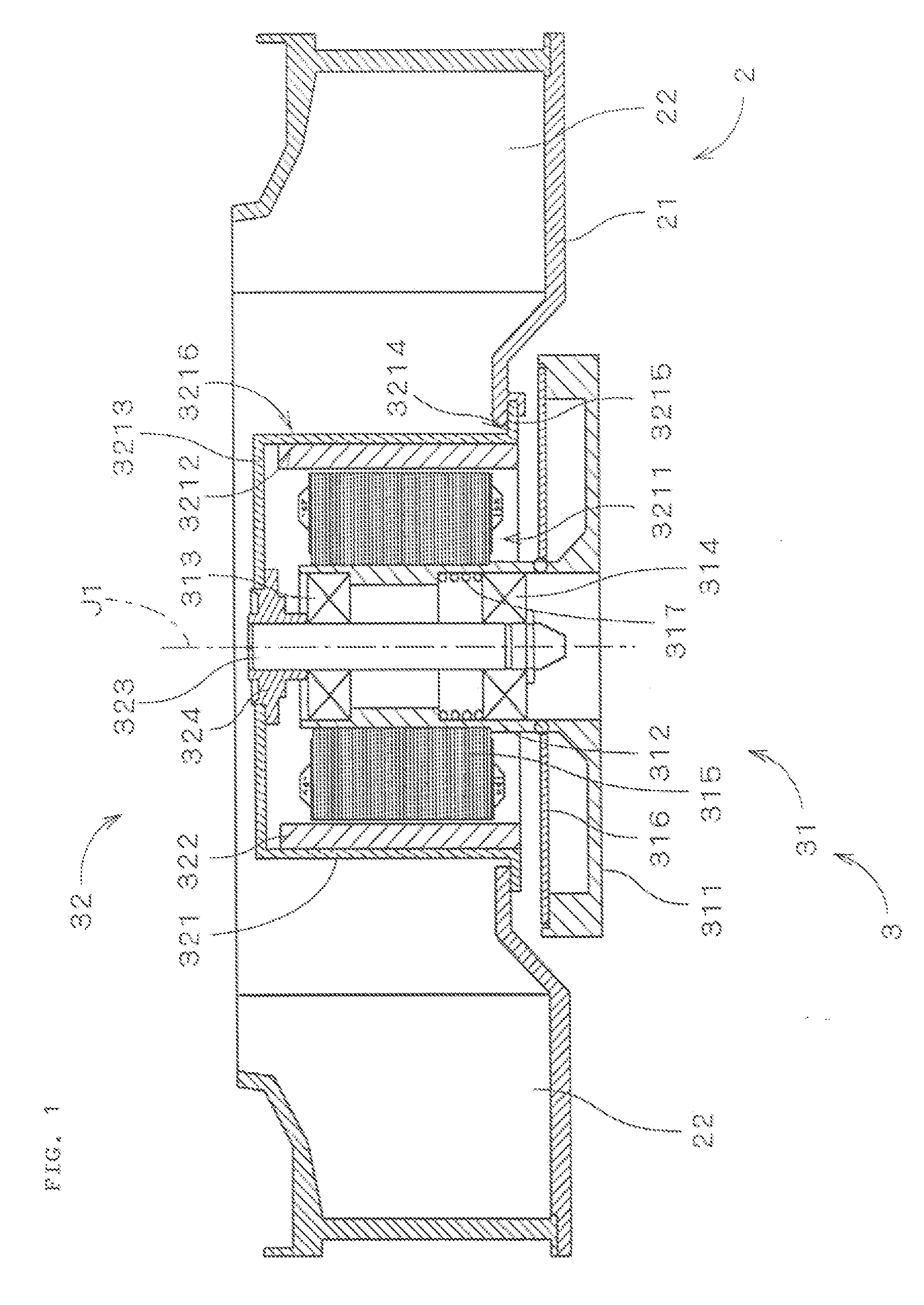

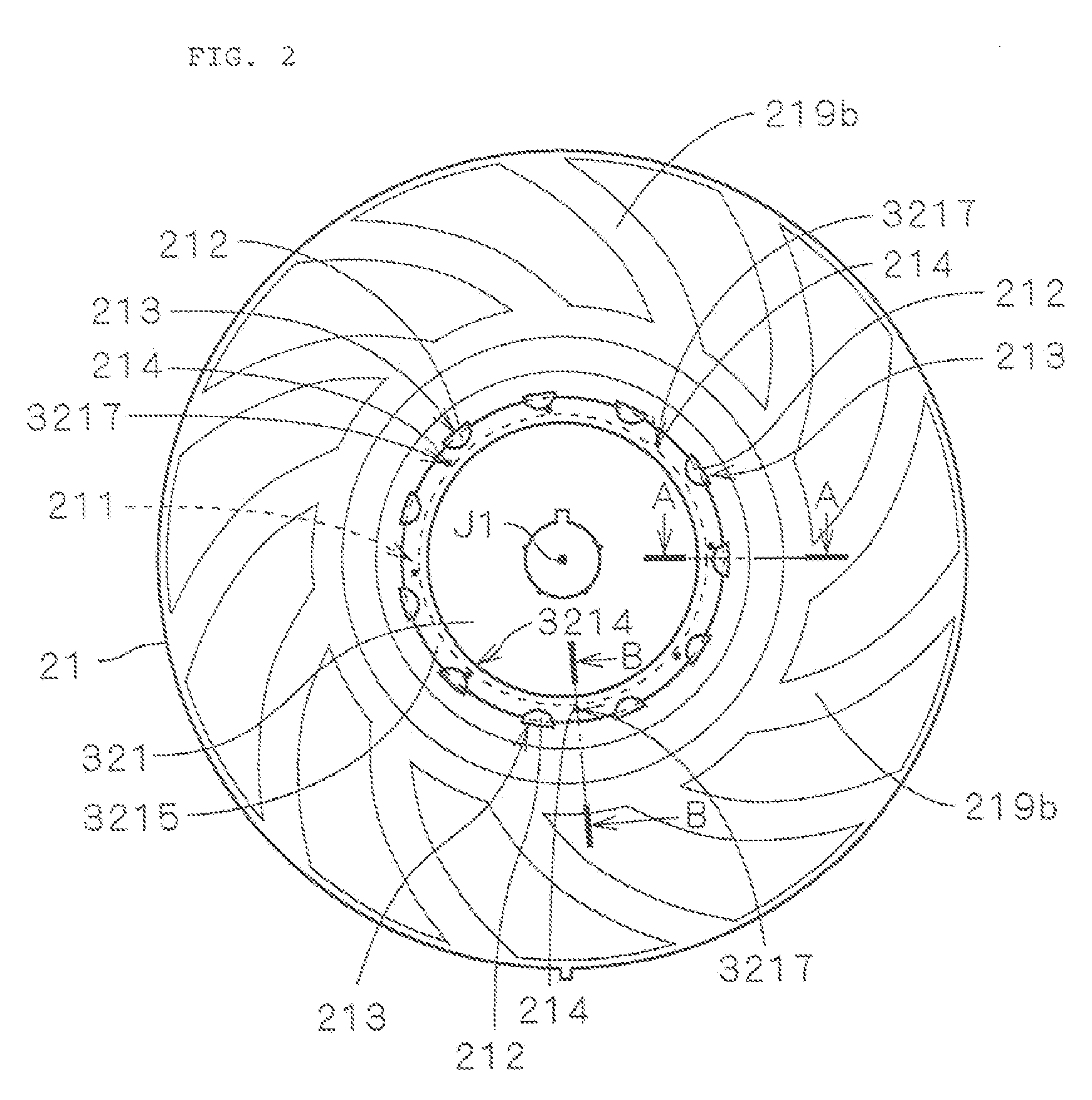

[0027]FIG. 1 is a vertical sectional view of a fan assembly 1 along a plane including a center axis J1, illustrating a configuration of the centrifugal type fan assembly 1 according to a first preferred embodiment of the present invention. As shown in FIG. 1, the fan assembly 1 includes an impeller portion 2 and a motor 3. The impeller portion 2 is attached to the motor 3 and generates air flow by rotation thereof. The motor 3 rotates impeller 2 about a center axis J1. The fan assembly 1 is accommodated within a housing (not shown) which defines a passage of air flow. In other words, the housing controls the air flow generated by the rotation of the impeller and sends the air outside of the housing. The fan assembly 1 is, for example, used as an air cooling fan for an electronic device.

[0028] The motor 3 is an outer rotor type motor, including a stator portion 31 which is a stationary assembly and a rotor portion 32 which is a rotary assembly. The rotor portion 32 is supported rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com