System for taking exhaust gas samples from internal combustion engines

A technology of internal combustion engine and exhaust gas, which is applied in the direction of internal combustion engine testing, sampling, engine testing, etc., and can solve problems such as the inability to use manifold gasoline engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

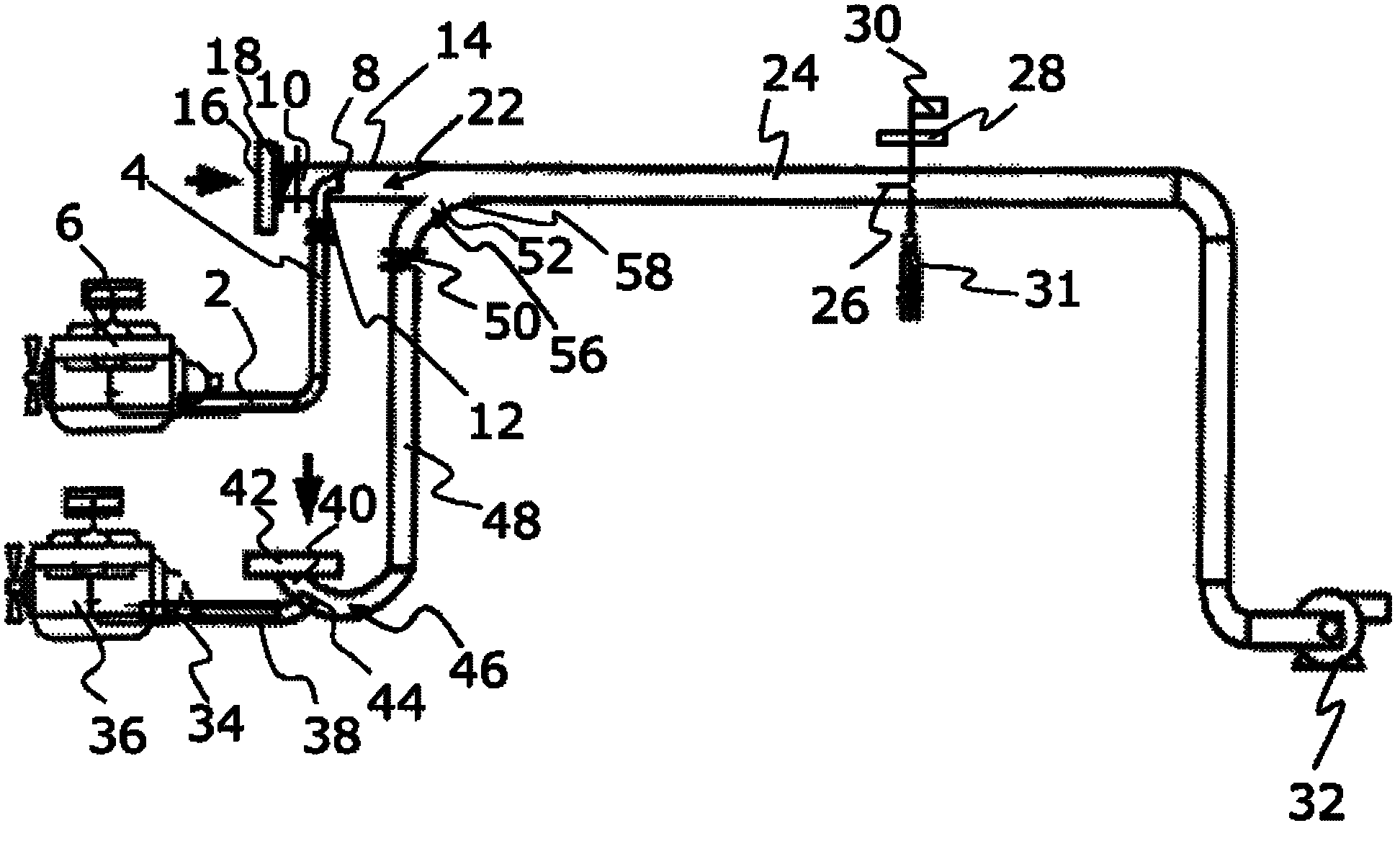

[0023] The device according to the invention for extracting exhaust gas samples from internal combustion engines is used in diesel engines and gasoline engines, the device comprising a first exhaust gas inlet 2, through which a first exhaust gas channel 4 is in fluid communication with an exhaust gas source 6, which The exhaust gas source is constituted by the diesel engine of the motor vehicle.

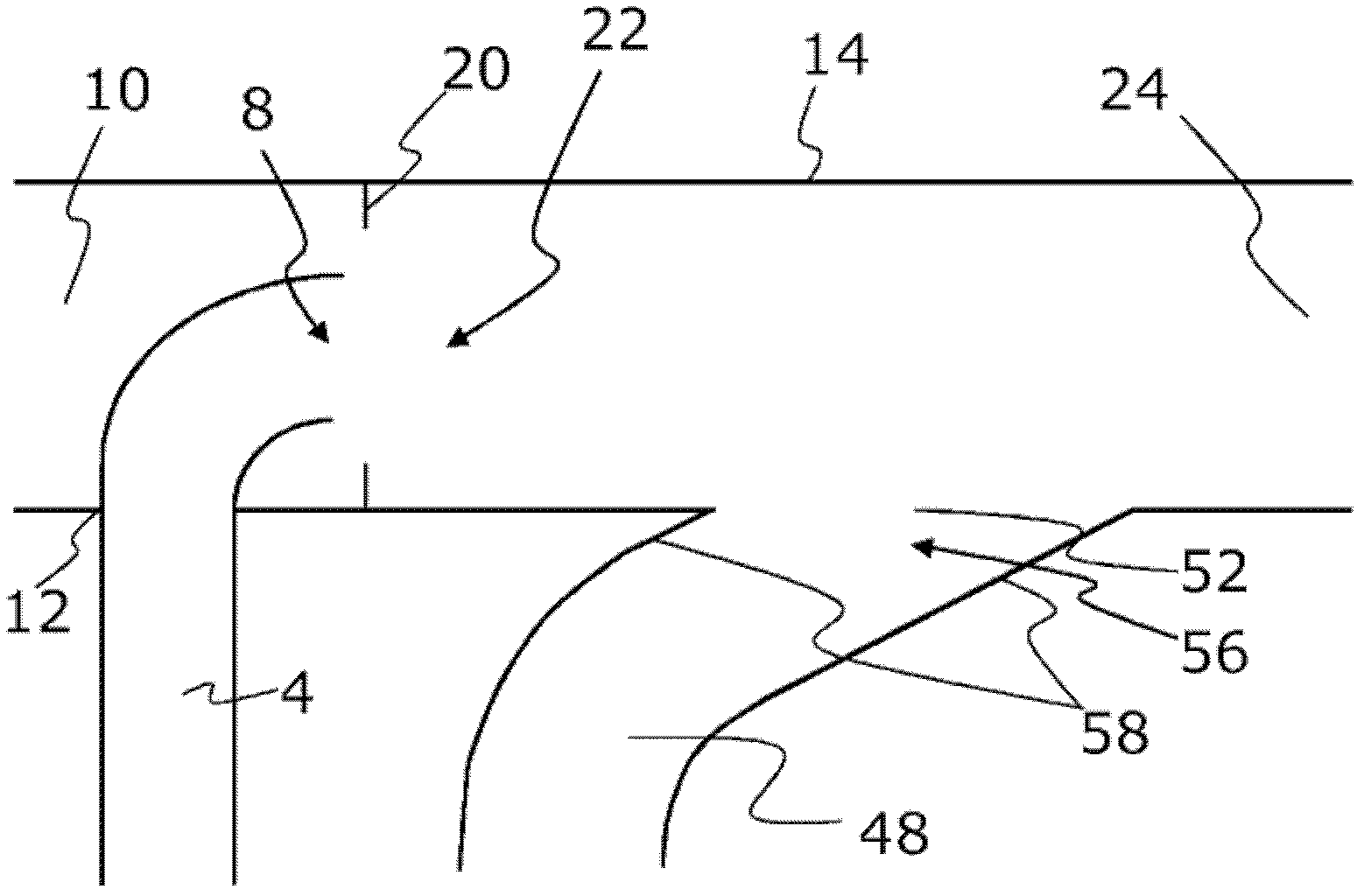

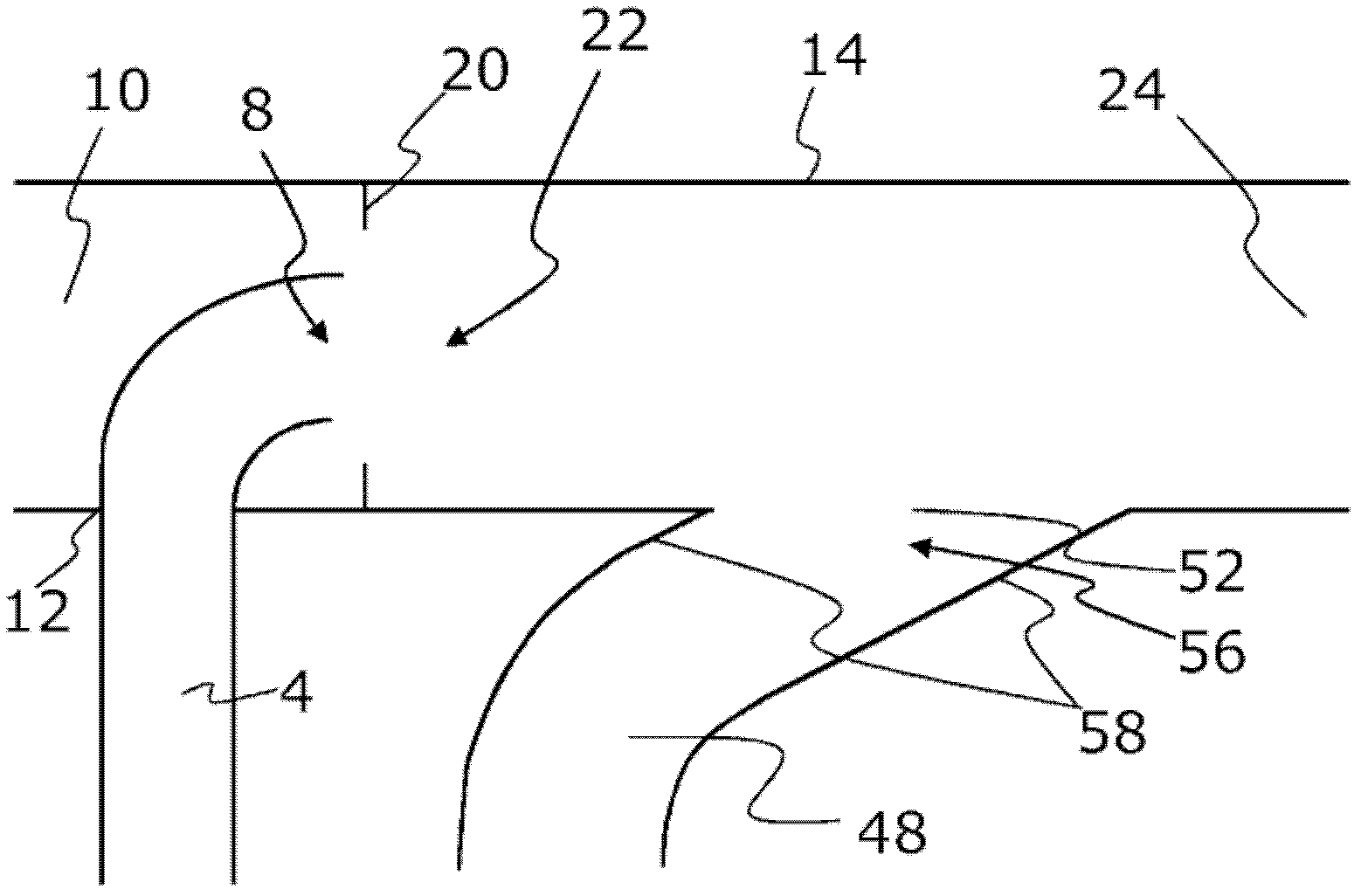

[0024] The exhaust gas channel 4 has a pipe end 8 which opens concentrically into the interior of the first air channel 10 . For this purpose, the first air channel has in its boundary wall 14 a hole 12 through which the exhaust gas channel 4 projects vertically into the air channel 10 . In order to open concentrically into the air duct 10 , the exhaust gas duct 4 has a 90° bend.

[0025] At the beginning of the air channel 10 there is a first air filter 16 , usually consisting of three filters, through which air can be drawn into the air channel 10 . The first regulating valve 18 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com