Method for rolling and forming low-oxygen-content pure-titanium precise thin strip coiled material

A technology with low oxygen content and forming method is applied in the field of rolling processing of pure titanium precision thin strip coils, and achieves the effects of high efficiency, simple and easy production method and no anisotropy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

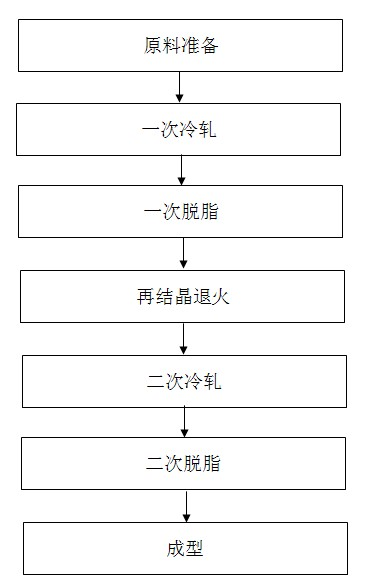

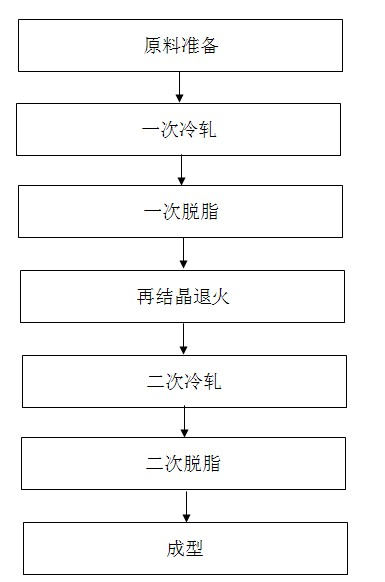

[0022] Such as figure 1 Shown, is process flow diagram of the present invention. A rolling forming method of low-oxygen content pure titanium precision thin strip and coil material: the TA2 pure titanium thin coil material with a cold-rolled 2B surface of 1.5mm in thickness is used as a raw material, rolled by a 20-high rolling mill, lye degreased, Recrystallization annealing, secondary cold rolling in 20-high mill, secondary lye degreasing, tension straightening, slitting / cross-cutting, inspection, packaging and warehousing and other processes.

[0023] Among them, the surface roughness of the work rolls in the primary rolling of the 20-high rolling mill is Ra0.7μm, and the pass deformation rate is 40%. The degreasing agent is an alkaline solution with a pH of 10. The recrystallization annealing temperature is 650°C, the holding time is 15 minutes, the argon atmosphere is protected, and the air is rapidly cooled. The surface roughness of the work rolls in the secondary col...

Embodiment 2

[0025] The TA1 pure titanium strip with a thickness of 2mm is used as the raw material, and it is rolled by a 20-roll mill, degreased with lye, recrystallized annealed, cold-rolled twice by a 20-roll mill, degreased with lye, It is made by tension straightening, slitting / cross-cutting, inspection, packaging and warehousing.

[0026] Among them, the surface roughness of the work rolls in the primary cold rolling of the 20-high rolling mill is Ra0.7μm, the pass deformation rate is 50%, the degreasing agent is an alkaline solution with a pH of 10, the recrystallization annealing temperature is 620 ° C, and the holding time is 15 minutes. Argon atmosphere protection, rapid air cooling. The surface roughness of the work rolls in the secondary cold rolling of the 20-high mill is Ra0.50μm, and the deformation rate of each pass is 20%; the surface of the low-oxygen content pure titanium precision thin strip coil has no surface pollution such as an oxygen-rich layer Layer, uniform int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com