An arch bridge type motion platform for X-ray detection device

A technology of detection device and motion platform, applied in the field of motion platform, can solve the problems of low resonance frequency of five-axis motion platform, easy to be excited by external environment vibration, poor anti-interference ability, etc. The effect of ease of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

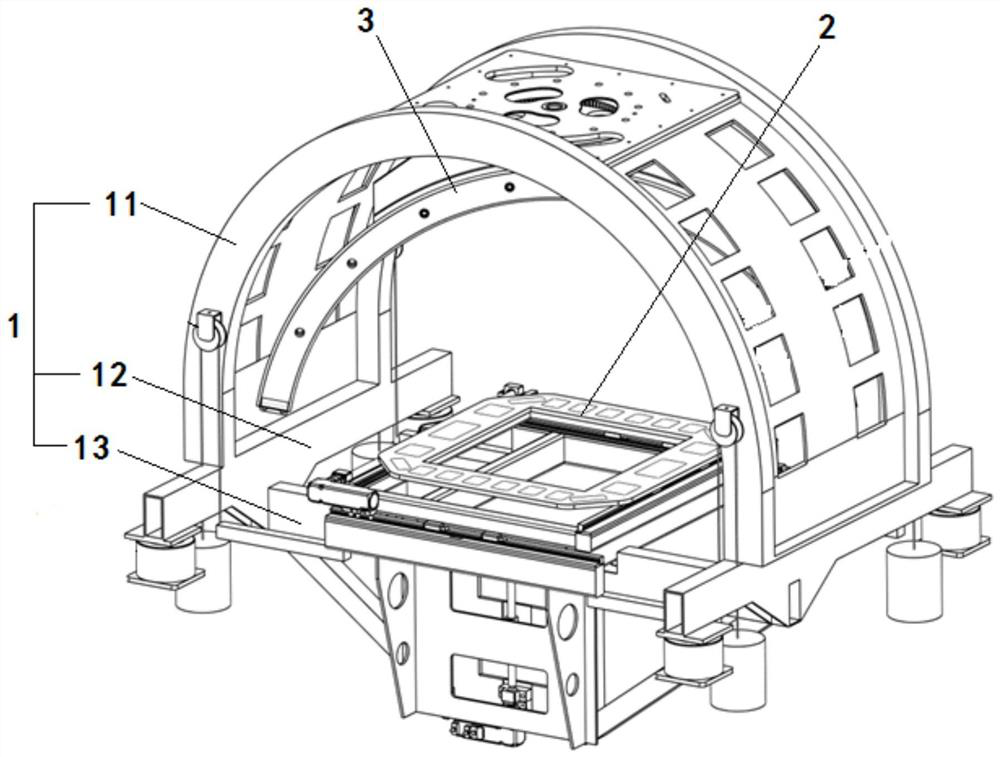

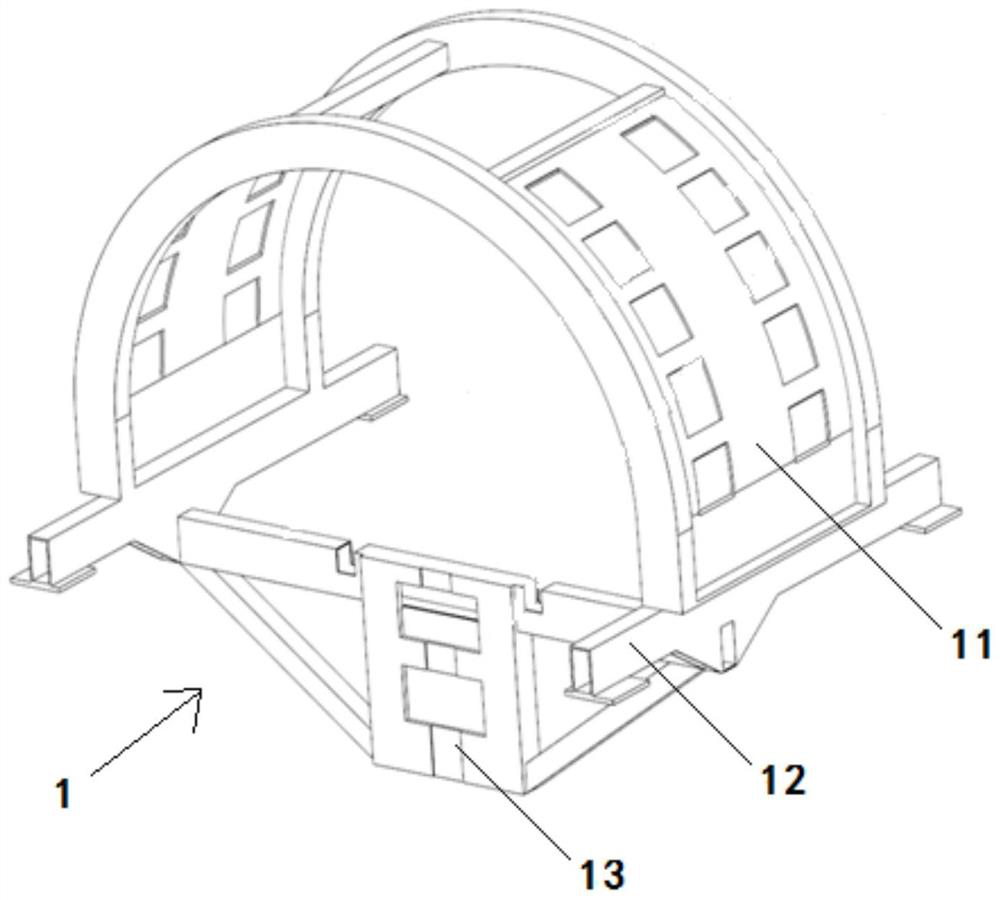

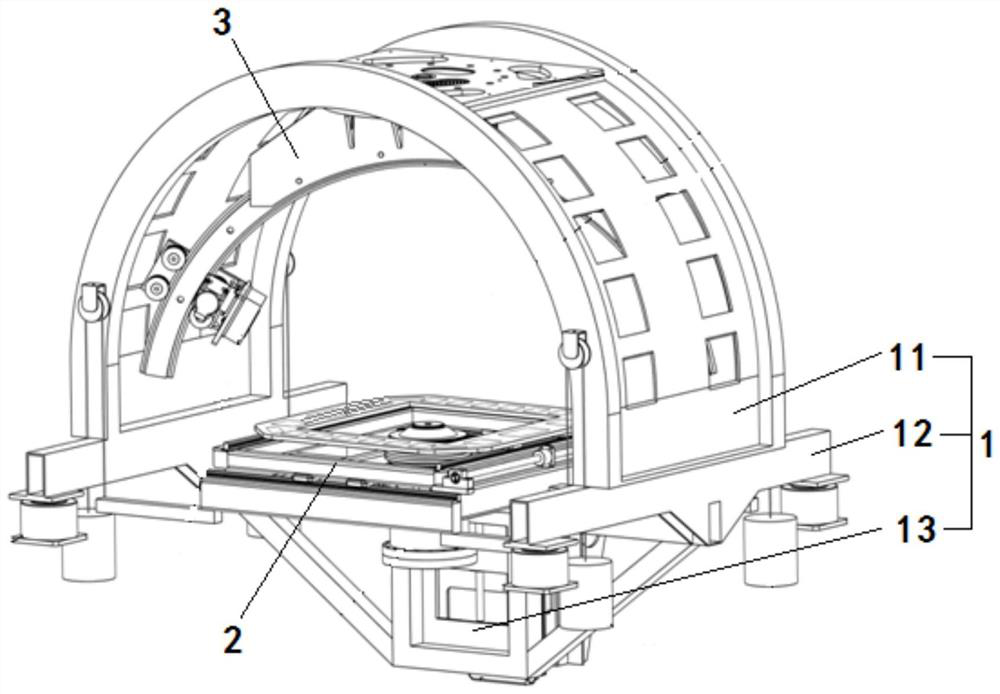

[0049] like figure 1 , figure 2 As shown, this embodiment discloses an arch bridge type motion platform for an X-ray detection device, including a platform support frame 1, a three-axis linear motion mechanism 2 and a two-axis rotary motion mechanism 3; the platform support frame 1 includes an arch bridge Type frame 11, horizontal support frame 12 and vertical support frame 13; Described horizontal support frame 12 is provided with two, and described horizontal support frame 12 upper walls are respectively fixed with described arch bridge type frame 11 two ends; Said horizontal support frame A vertical support frame 13 is arranged between the two side walls of the frame 12 and its side wall is fixed to both ends of the vertical support frame 12; the vertical support frame 13 is a frame structure of "inverted trapezoidal shape";

[0050] like image 3 As shown, the X-ray source assembly is fixed at the middle of the top of the vertical support frame 13; the three-axis linear...

Embodiment 2

[0066] like Figure 8 As shown, the difference between this embodiment and the first embodiment is that it also includes a counterweight mechanism 4, and the counterweight mechanism 4 includes a leveling counterweight assembly 41 and a gravity compensation counterweight assembly 42; the leveling counterweight assembly 41 and the gravity compensation counterweight assembly 42 are provided with two groups, and the leveling counterweight assembly 41 of the two groups is symmetrically arranged on the front side walls at both ends of the frame body of the arch bridge type frame 11; the gravity compensation counterweight assembly of the two groups 42 are symmetrically arranged on the front and rear walls of the two ends of the arch bridge frame 11;

[0067] like Figure 9 , Figure 11 As shown, the leveling counterweight assembly 41 includes a first pulley 411, a first traction rope 412, a first connecting rod 413 and a first counterweight 414; the first pulley 411 is symmetricall...

Embodiment 3

[0072] like Figure 8 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that this embodiment is also provided with a vibration isolator 5, and the vibration isolator 5 is air-floating vibration isolation or rubber vibration isolation, and the vibration isolator 5. It is fixedly arranged at the bottoms of the front and rear ends of the two vertical support frames 13; through the effect of the vibration isolator 5, the modal vibration amplitude of the arch bridge frame 11 can be effectively reduced, reducing the impact of environmental vibration on the motion platform. Impact.

[0073] The vertical support frames 13 of the present embodiment can also be arranged as two groups, and the two groups of vertical support frames 13 are symmetrically fixed between the two horizontal support frames 12, and the two sides of the three-axis linear motion mechanism 2 are respectively vertical to the two groups. The support frame 12 is fixed, and the stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com