Cold straightening process for high-strength thin plate

A high-strength plate, cold straightening technology, applied in the field of steel rolling, can solve the problem of inaccessibility of the steel plate, and achieve the effect of improving the qualification rate of straightening, improving the straightness and uniform internal stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

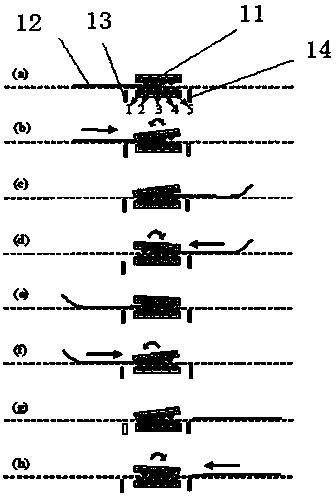

[0022] A straightening process for wear-resistant steel with a 5mm yield strength of 1200MPa. The roll diameter and roll distance of the straightener used in this process are 180mm and 240mm respectively. This process requires four straightening passes (two heavy pressing, one medium pressing , a light pressure), heavy pressure entrance roll gap is -30mm, exit roll gap is 5mm, medium pressure entrance roll gap is -18mm, exit roll gap is 5mm, light pressure entrance roll gap is -9mm, exit roll gap is 5mm ;In the process of heavy pressure biting, the method of driving the steel plate first and then setting the roll gap is adopted to prevent the collision between the steel plate head and the work roll; Too heavy bending causes reverse straightening to fail to bite in, realizing the large reduction straightening of the steel plate through the plate; after straightening, the straightness of the plate through the plate is less than 3mm / 2m.

[0023] In this embodiment, a piece of 5mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com