Production technology for quickly synthesizing polycrystalline diamond

A polycrystalline diamond and production process technology, applied in the application of ultra-high pressure process, etc., can solve the problems of unsteady control of product quality, low production efficiency, high cost, etc., achieve small internal stress, improve service life, and internal The effect of uniform stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiments.

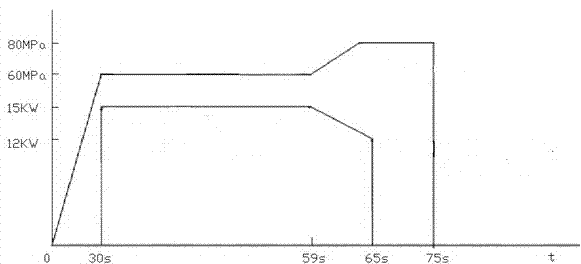

[0016] Such as figure 1 shown, including the following steps:

[0017] 1) Assemble the synthetic block with catalyst and raw materials, and bake at 200°C-230°C for 12-14 hours;

[0018] 2) Put the synthetic block into the press, and the starting pressure rises to 60MPa;

[0019] 3) Start heating after 30 seconds, the heating power is 15KW, and the heating current is 4000A;

[0020] 4) After heating for 29 seconds, raise the pressure to 80MPa;

[0021] 5) After continuing to heat for 6 seconds, the heating power suddenly drops to 12KW, and the heating stops after the heating current is 3150A;

[0022] 6) Continue to keep the pressure, the pressure is 80MPa;

[0023] 7) After 6-10 seconds, stop pressurization and synthesize polycrystalline diamond. The optimal solution is 10 seconds.

[0024] The technical solution of the present invention is not limited to the limitati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com