High-performance titanium joint seal ring for deep-sea oil drilling and production equipment and processing method thereof

A technology for oil drilling and sealing rings, which is applied to mechanical equipment, flange connections, engine sealing, etc. It can solve problems such as poor seawater corrosion resistance, uneven internal stress of components, and short service life, and achieve internal stress distribution Uniformity, easy replacement or maintenance, and improved mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the titanium connection sealing ring and its processing method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

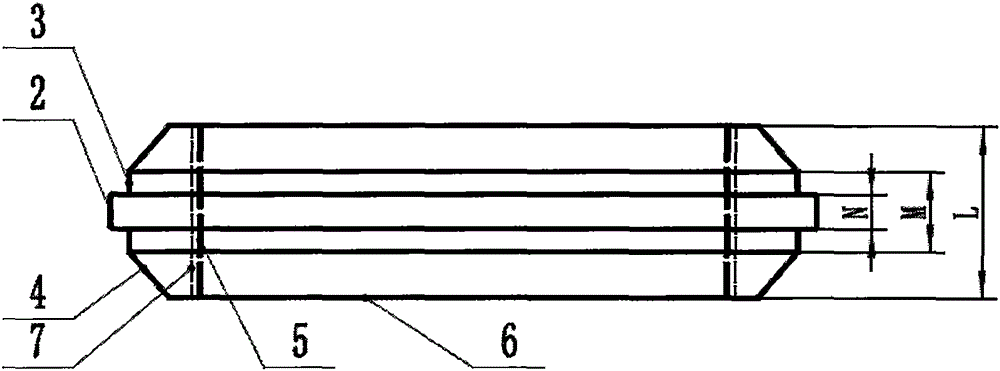

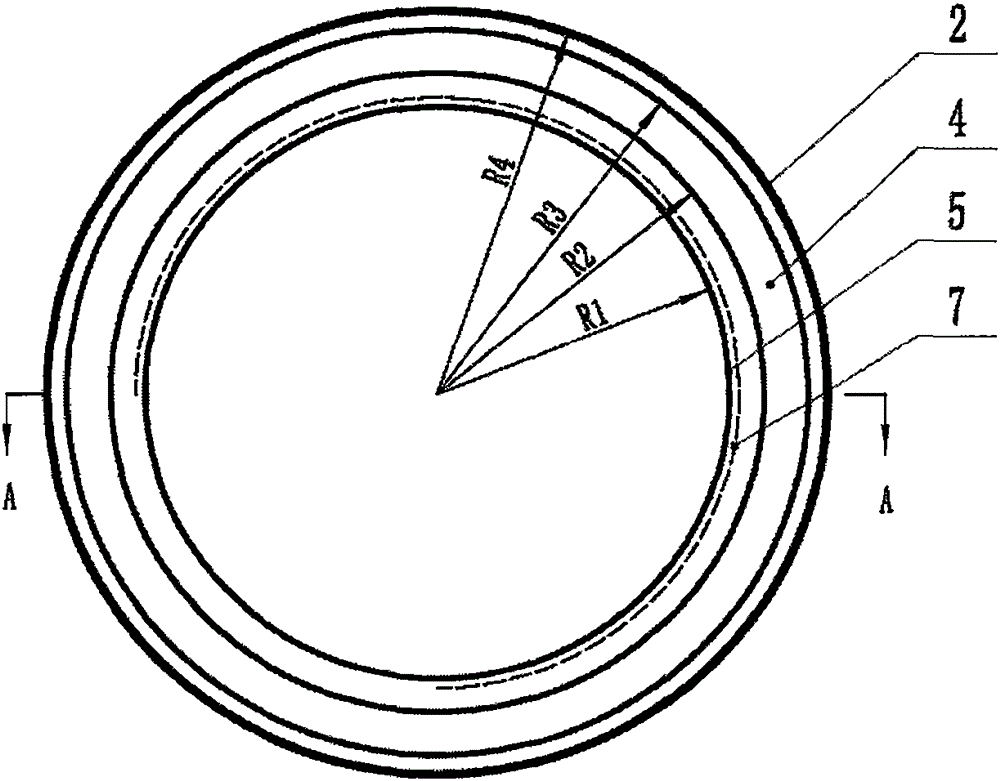

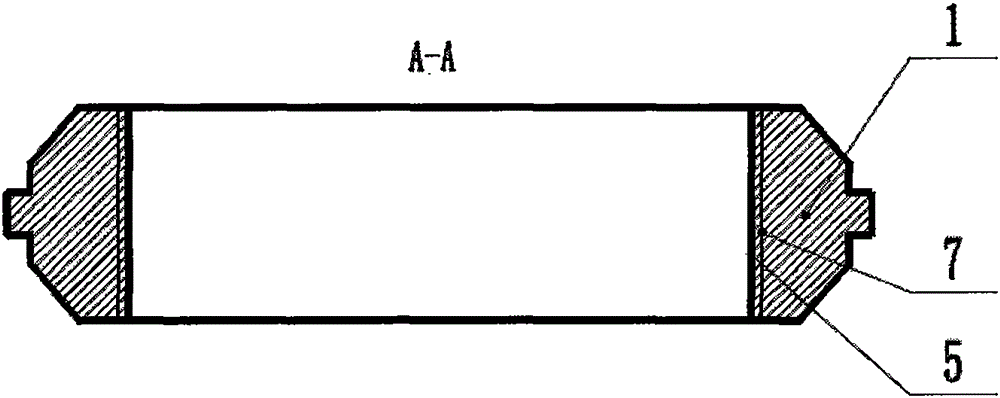

[0035] 1. First, if Figure 1 ~ Figure 3 Shown is the front view, top view and A-A sectional view of the top view of the high-performance titanium connection seal ring for deep-sea oil drilling equipment of the present invention. Among them, L—the axial width of the titanium connecting sealing ring, N—the axial width of the boss, M—the sum of the axial widths of the boss 2 and two adjacent platforms 3 . The ring body 1 of the present invention is a hollow cavity structure symmetrical to the boss 2 . The inner surface of the hollow body is an inner circumferential surface 5 , and its outer surface is also a circumferential surface, and has a boss 2 , a platform 3 , and an inclined end surface 4 . Such as figure 1 and image 3As shown, along the up or down direction of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com