A kind of manufacturing method of titanium forged flange tee

A manufacturing method and block technology, which is applied in the field of titanium metal processing and the manufacture of titanium forged flange tees, can solve the problems of insufficient compression resistance of titanium welded tees, and achieve easy replacement and maintenance, uniform internal stress distribution, and easy use. Effect of life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

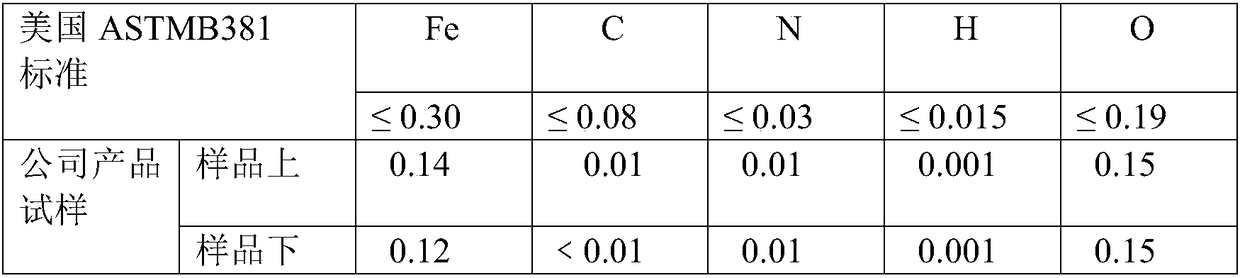

[0073] According to the capacity of the press tank, O grade sponge titanium is used as the raw material, and the oxygen bag is made of ≤0.07% iron and ≤0.2% oxygen;

[0074] The titanium sponge and the oxygen pack are placed in layers in the press tank, pressed under a 4500 press to form an electrode block, and then welded into an electrode by argon arc welding;

[0075] Place the obtained electrode in a vacuum electric arc furnace for secondary melting treatment to obtain titanium ingots. The first melting: use a crucible with a diameter of ф480~ф560mm, the arcing current is 2200A, the voltage is 27V, and the vacuum degree is 6.8E- 0. The melting current is 6000A, the voltage is 33V, the vacuum degree is 1.5E·1, the arc stability is 3, the cooling time is 2.5h, and the water temperature is below 60°C; the second melting: use a crucible with a diameter of ф560~ф640mm, The arc starting current is 2.2KA, the voltage is 27V, the vacuum degree is 6.8E-0, the melting current is 8KA...

Embodiment 2

[0082] According to the capacity of the press tank, O grade sponge titanium is used as the raw material, and the oxygen bag is made of ≤0.07% iron and ≤0.2% oxygen;

[0083] The titanium sponge and the oxygen pack are placed in layers in the press tank, pressed under a 4500 press to form an electrode block, and then welded into an electrode by argon arc welding;

[0084] Place the obtained electrode in a vacuum electric arc furnace for secondary melting treatment to obtain titanium ingots. The first melting: use a crucible with a diameter of ф480mm~ф560mm, the arcing current is 2800A, the voltage is 28V, and the vacuum degree is 4.3E- 0. The melting current is 7500A, the voltage is 34V, the vacuum degree is 1.5E·1, the arc stability is 6, the cooling time is 4h, and the water temperature is below 60°C; the second melting: use a crucible with a diameter of ф560mm~ф640mm, starting The arc current is 2.8KA, the voltage is 28V, the vacuum degree is 4.3E-0, the melting current is 1...

Embodiment 3

[0091] According to the capacity of the press tank, O grade sponge titanium is used as the raw material, and the oxygen bag is made of ≤0.07% iron and ≤0.2% oxygen;

[0092] The titanium sponge and the oxygen pack are placed in layers in the press tank, pressed under a 4500 press to form an electrode block, and then welded into an electrode by argon arc welding;

[0093] Place the obtained electrode in a vacuum electric arc furnace for secondary melting treatment to obtain titanium ingots. The first melting: use a crucible with a diameter of ф480mm~ф560mm, the arcing current is 3500A, the voltage is 30V, and the vacuum degree is 1.4E- 0. The melting current is 9000A, the voltage is 35V, the vacuum degree is 5.0E·0, the arc stability is 8, the cooling time is 5.5h, and the water temperature is below 60°C; the second melting: use a crucible with a diameter of ф560mm~ф640mm, The arc starting current is 3.5KA, the voltage is 30V, the vacuum degree is 1.4E-0, the melting current is...

PUM

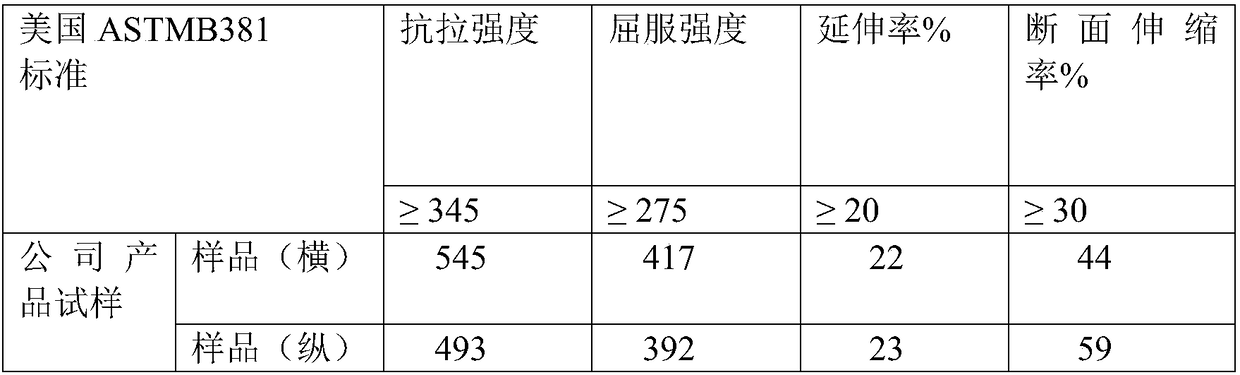

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com