Impact-resistant ceramic insulator and manufacturing method thereof

A technology for ceramic insulators and manufacturing methods, applied in the field of impact-resistant ceramic insulators and their manufacturing, can solve the problems of low impact strength, no toughening treatment, poor comprehensive mechanical properties, etc., achieve fracture toughness and impact strength, and comprehensive mechanical properties Excellent performance and the effect of improving impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

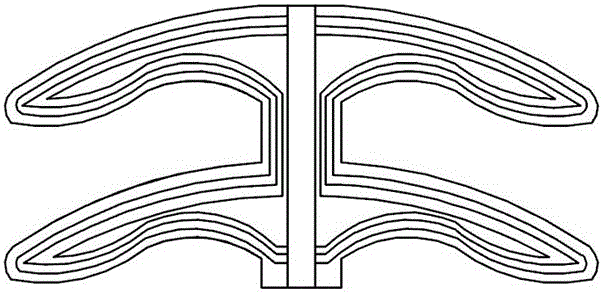

[0027] Such as figure 1 The insulator shown is graded according to the three-dimensional size of the outline, every 4mm is a grade, and the maximum effective diameter of the innermost layer is Φ8mm. Parts, 20 parts of silicon carbide powder with a particle size of 3 μm, 5 parts of calcium fluoride powder, 2 parts of carbon powder, 2 parts of molybdenum silicide, 1 part of ethyl orthosilicate, 1 part of absolute ethanol, 10 parts of purified water, thermoplastic phenolic 4 parts resin.

[0028] The manufacturing method of the impact-resistant ceramic insulator comprises the following steps:

[0029] 1) Raw material preparation

[0030] ①Prepare 6 parts by weight of aluminum borate whiskers, 70 parts of aluminum nitride micropowder with a particle size of 3 μm, 20 parts of silicon carbide micropowder with a particle size of 3 μm, 5 parts of calcium fluoride powder, 2 parts of carbon powder, and 2 parts of molybdenum silicide , 1 part of ethyl orthosilicate, 1 part of absolute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com