Liquid forging process for main reduction gear used for automobile transmission

A technology of automobile gearbox and liquid die forging, which is applied in metal material coating process, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting forging efficiency, easy to block forging molds, etc., and achieve high efficiency and high corrosion resistance. , Reasonable effect of process step design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the manufacturer's conditions, and the unspecified implementation conditions are usually conventional experimental conditions.

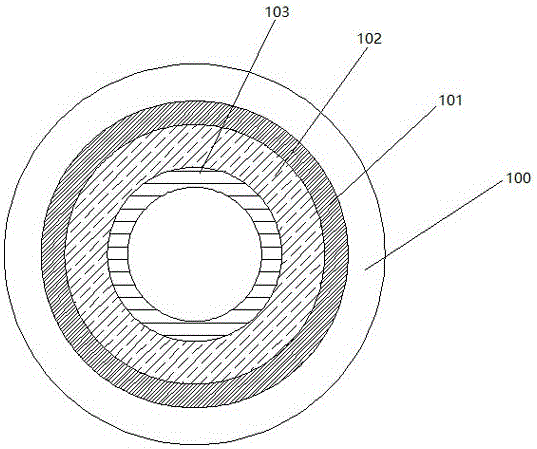

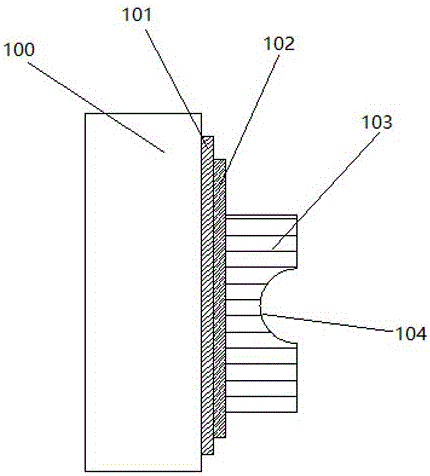

[0046] see figure 1 and figure 2 , the main reduction gear obtained by the liquid die forging process of a main reduction gear for automobile transmission provided by the present invention includes a circular ring 100, and the surface of the circular ring 100 is successively provided with a first protruding ring 101, a second protruding ring 102, and a second protruding ring 102. The protruding ring 102 is internally connected with a tube body 103, the circular ring 100, the first protruding ring 101, the second protruding ring 102 and the tube body 103 are arranged in a ladder shape and arranged concentrically and coaxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| bending fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com