Manufacturing method of arc additive of titanium alloy structural part

A technology for additive manufacturing and structural parts, applied in the field of rapid prototyping, can solve problems such as difficulty in meeting the schedule requirements of rapid development of new products and mass production, difficulty in machining, affecting processing procedures, etc., and achieve reduction of technical procedures and good forming. The effect of high quality and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

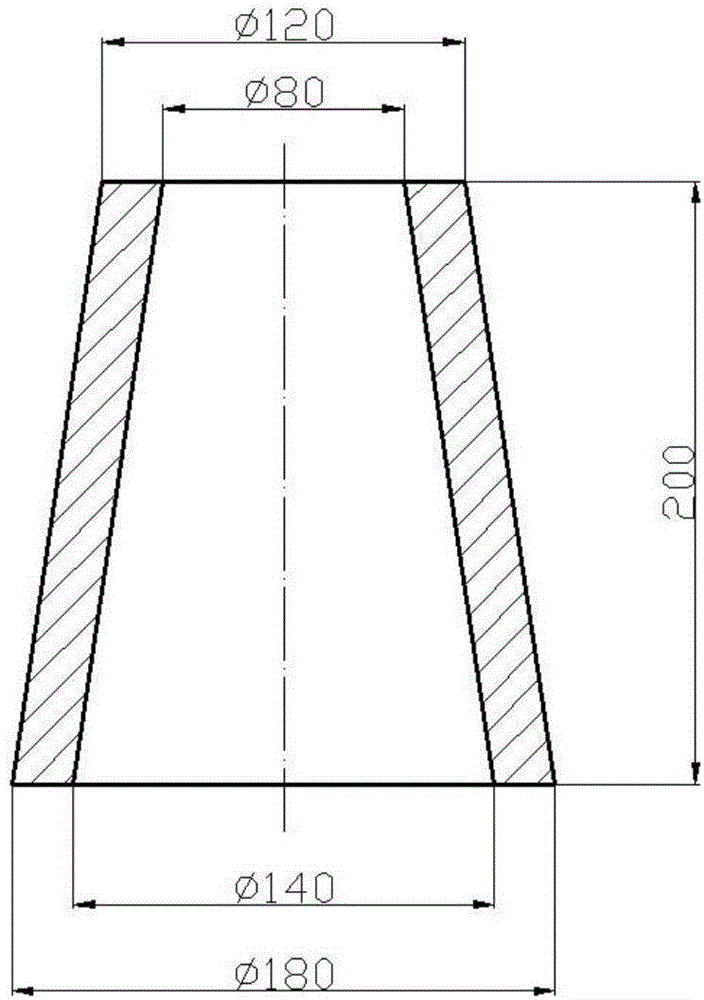

[0028] Such as figure 2 As shown, the height of the titanium alloy structural part is 200mm, the wall thickness is 20mm, and it is formed by surfacing welding of 200 layers of ring parts, and the height of each layer of ring parts is 1mm. It is manufactured using the arc additive method for titanium alloy structural parts described in the present invention. Specifically:

[0029] The arc additive manufacturing method is used to weld each layer of ring parts, that is, the wire feeding device feeds the welding wire, the welding torch melts the welding wire for welding, and the inner to outer ring welds are overlapped to form a layer of ring parts; then the welding torch increases a layer thickness , repeat the above welding method to form another layer of ring parts, and so on, and finally form a titanium alloy structural part by superimposing 200 layers of ring parts.

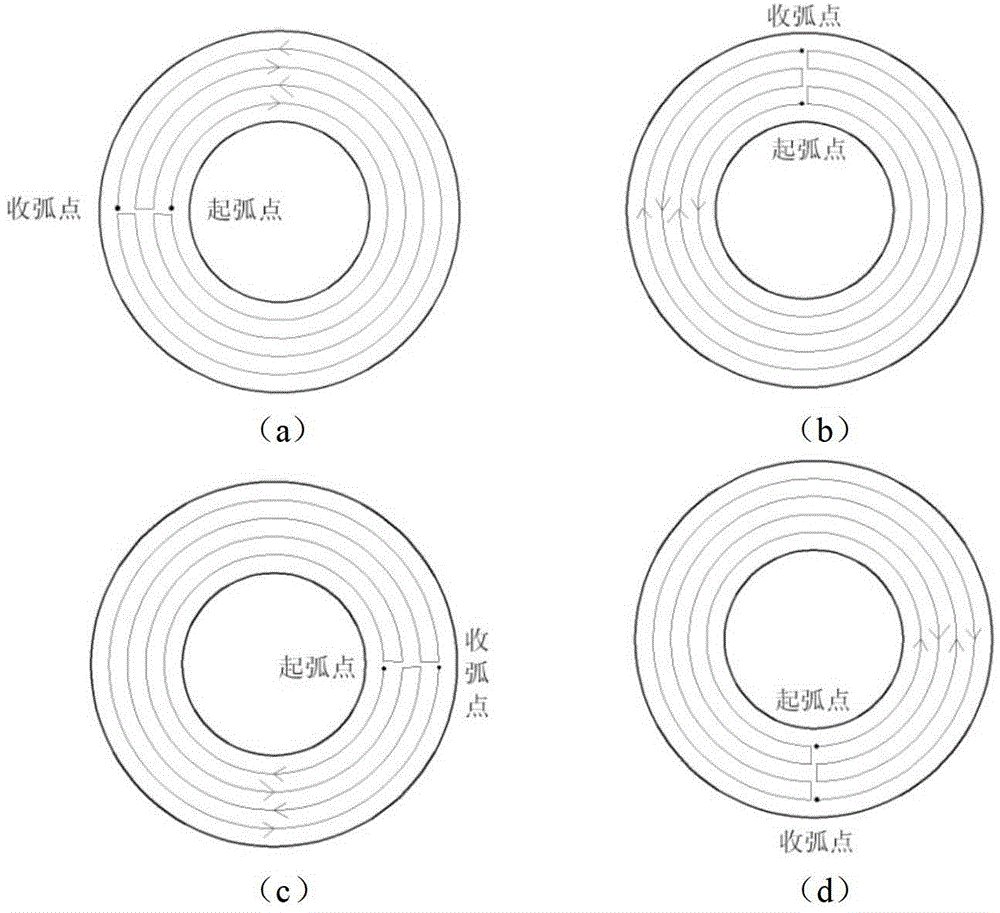

[0030] Adjacent annular welds are welded in opposite directions during welding, and the welding arc starti...

Embodiment 2

[0032] Such as figure 2 As shown, the height of the titanium alloy structural part is 200mm, the wall thickness is 20mm, and it is formed by surfacing welding of 200 layers of ring parts, and the height of each layer of ring parts is 1mm. It is manufactured by the arc additive method of titanium alloy structural parts according to the present invention, such as figure 1 As shown, the specific steps are:

[0033] (1) Select the arc starting point on the Q235 carbon steel substrate, and start the clockwise welding of the first ring on the first layer;

[0034] (2) After the first layer of the first ring welding is completed, the welding torch moves 1.4mm to the outside of the ring, and the counterclockwise welding of the first layer and the second ring is started, and the welds overlap by 0.6mm;

[0035] (3) After completing the second ring welding of the first layer, repeat step (2), and then complete another 13 ring welding, and the adjacent ring welding of the same layer a...

Embodiment 3

[0043] The height of the titanium alloy structural part is 100mm, and the wall thickness is 15mm. It is formed by surfacing welding of 50 layers of ring parts, and the height of each layer of ring parts is 2mm. It is manufactured by the arc additive method of titanium alloy structural parts according to the present invention, such as figure 1 As shown, the specific steps are:

[0044] (1) Select the arc starting point on the Q235 carbon steel substrate, and start the counterclockwise welding of the first ring on the first layer;

[0045] (2) After the first layer of the first ring welding is completed, the welding gun moves 1mm to the outside of the ring, and starts the clockwise welding of the first layer of the second ring, with 0.5mm of overlap between the welds;

[0046] (3) After completing the second ring welding of the first layer, repeat step (2), and then complete another 13 ring welding, and the adjacent ring welding of the same layer adopts the opposite direction; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com