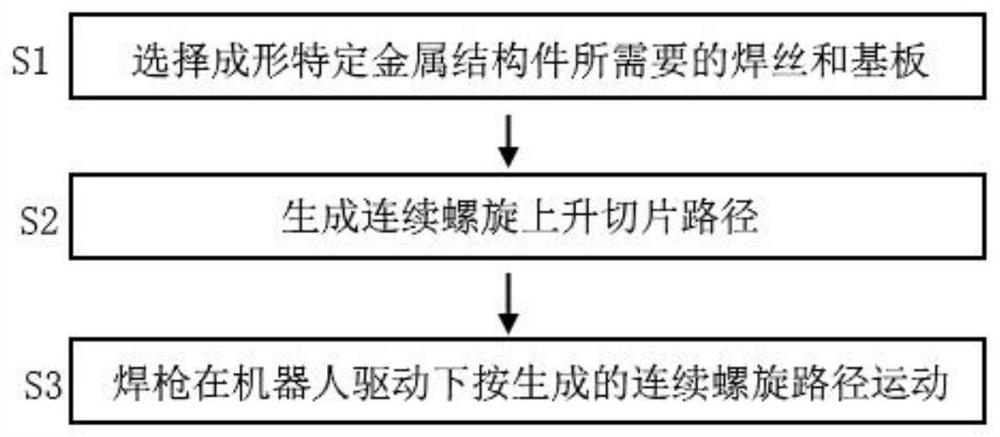

Method and system for multilayer single-channel continuous arc additive manufacturing of metal structural parts

A metal structure, multi-layer and single-pass technology, applied in the field of additive manufacturing, can solve the problems of discontinuous additive process, uneven chemical composition, insufficient strength, etc., to shorten the development cycle, reduce the number of processing technology steps, and achieve mechanical properties. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

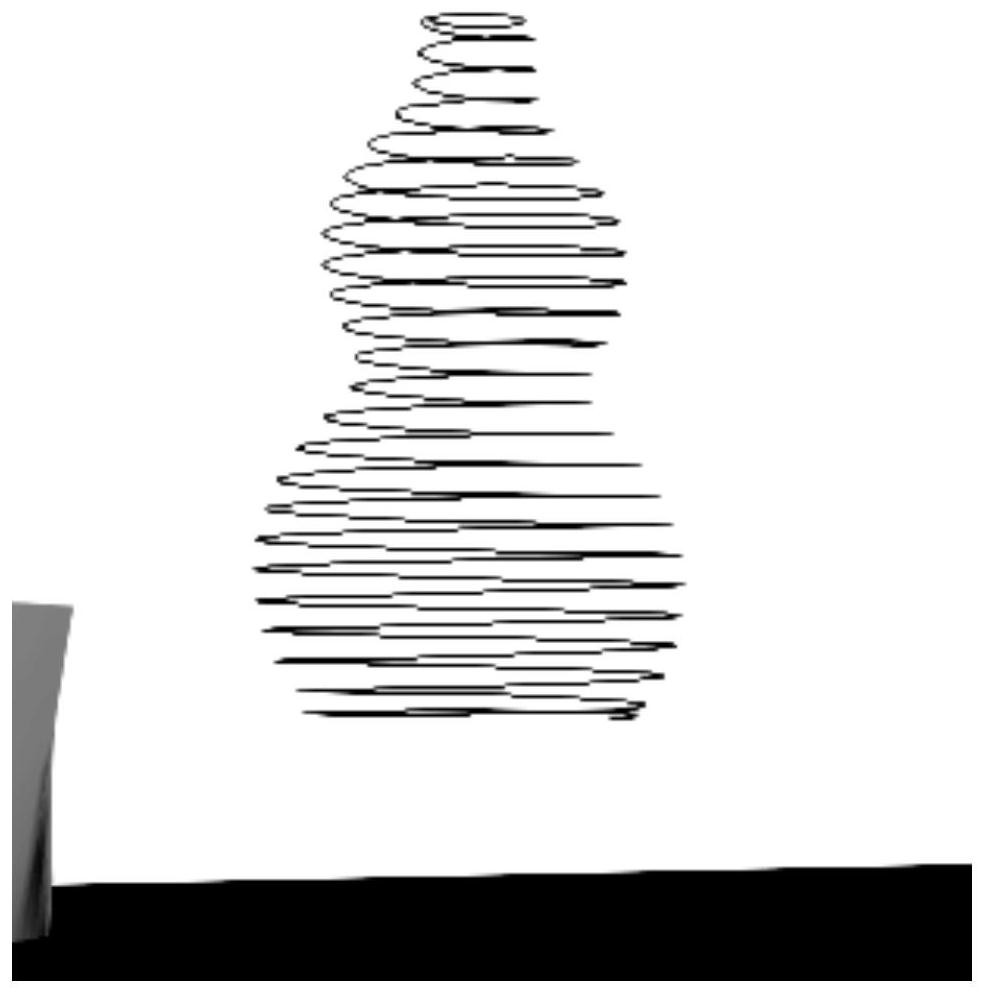

[0119] Example 1: 4mm thick 4043 aluminum alloy ring-shaped regular structural part multi-layer single-channel arc additive manufacturing

[0120] Such as figure 2 As shown, the aluminum alloy structure has a height of 200 mm and a wall thickness of 6 mm. It is formed by 181 layers of continuous spiral welding arc additive manufacturing, and the height of each layer of welding seam is 1.1 mm. It is manufactured by a multi-layer single-pass electric arc additive method for metal structural parts described in the present invention. Specifically:

[0121] Print the selected 6061 aluminum alloy sheet with a substrate thickness of 15mm. The welding wire used is 4043 aluminum alloy welding wire with a diameter of 1.2mm. First, calculate the heat input through the optimal temperature required for workpiece forming, so as to obtain a set of suitable forming process parameters: select The welding process is CMT+P and CMT Advance, the welding current is 59A, the wire feeding speed is...

Embodiment 2

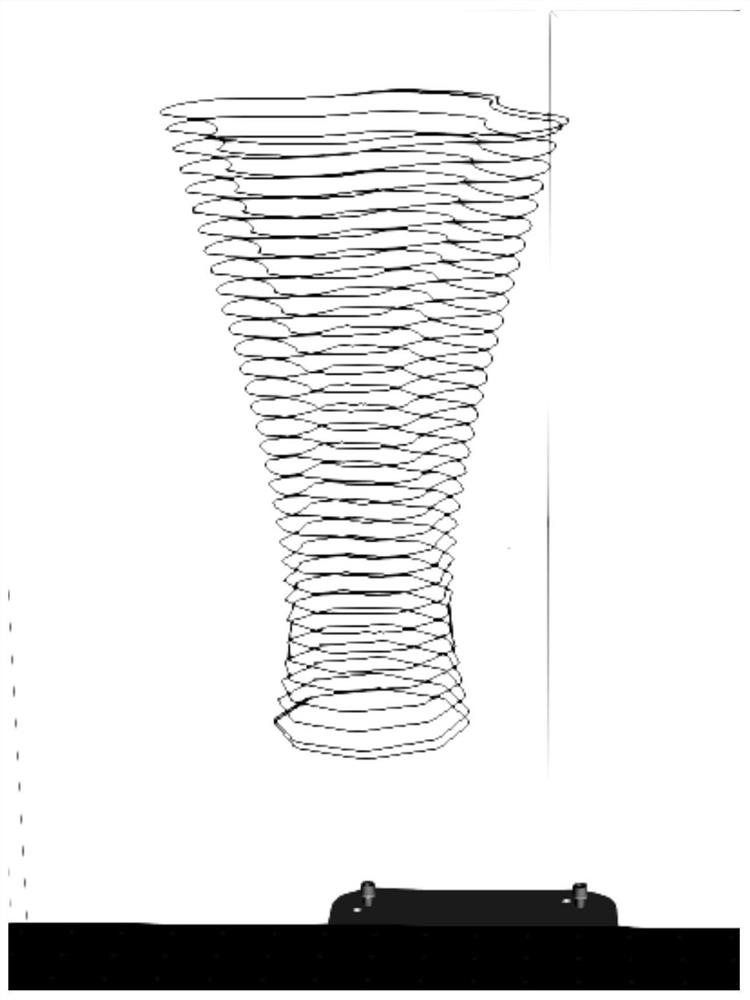

[0125] Example 2: 8mm thick 4043 aluminum alloy twisted polygon ring structure multi-layer single-channel arc additive manufacturing

[0126] The difference from Example 1 is:

[0127] Such as image 3 As shown, the aluminum alloy structure has a height of 500 mm and a wall thickness of 8 mm. It is formed by 556 layers of continuous spiral welding arc additive manufacturing, and the height of each layer of welding seam is 0.9 mm. It is manufactured by a multi-layer single-channel continuous arc additive method for metal structural parts described in the present invention. Specifically:

[0128] Print the selected 6061 aluminum alloy sheet with a substrate thickness of 16mm. The welding wire used is 4043 aluminum alloy welding wire with a diameter of 1.2mm. First, calculate the heat input through the optimal temperature required for workpiece forming, so as to obtain a suitable set of forming process parameters: select welding The process is CMT+P, the welding current is 90A...

Embodiment 3

[0132] Example 3: Multi-layer single-pass arc additive manufacturing of 6mm thick stainless steel regular structure

[0133] Such as Figure 4 As shown, the height of the stainless steel structural part is 420 mm, the wall thickness is 6 mm, and it is formed by 323 layers of continuous spiral welding arc additive manufacturing, and the height of each layer of welding seam is 1.3 mm. It is manufactured by a multi-layer single-channel continuous arc additive method for metal structural parts described in the present invention. Specifically:

[0134] Print the selected Q235 carbon steel substrate with a thickness of 16mm. The welding wire used is 308L stainless steel welding wire with a diameter of 0.8mm. First, calculate the heat input through the optimal temperature required for workpiece forming, so as to obtain a set of suitable forming process parameters: Selective welding The process is CMT, the welding current is 90A, the wire feeding speed is 8.5m / min, the welding speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com