Functional film prepared by functionalized organic powder, low-temperature non-damaging manufacturing method and application

An organic powder and manufacturing method technology, applied in the field of functional membranes, can solve problems such as difficulty in manufacturing functional organic membranes, affecting membrane material ion conductivity, environmental pollution, etc., and achieve excellent ion conductivity, high molecular weight, and long chain segments Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

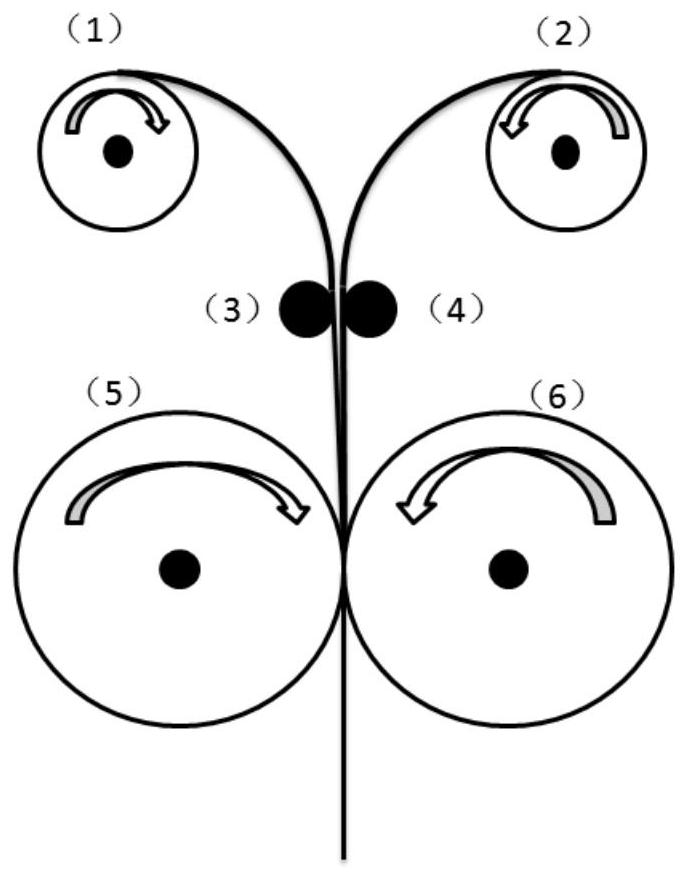

Method used

Image

Examples

Embodiment 1

[0035] Mix the pre-lithiated polyvinylidene fluoride (PVDF) powder and PTFE powder according to the weight percentage of 92%:8%. 2 hours until powder A is obtained evenly. Powder A is ground in a stainless steel closed chamber with dry compressed air whose air velocity reaches supersonic speed, and the air is preheated before contacting the powder, and the temperature reaches 45°C to prepare mixed powder B, and the ground powder B Exhausted with air flow and collected. The powder B extruder removes the gas in the powder to form a continuous cake-shaped broadband, and then rolls it into a functional film C by a hot roller press. The temperature of the hot pressing film is 100°C, and the film thickness is about 90 microns. The functional film C is wound up. Two or more sheets of film C are combined by hot pressing to form a composite film D. The thermal lamination temperature is 85°C, and the film thickness can reach about 60 microns. The lithium ion conductivity of the prep...

Embodiment 2

[0037] Mix the pre-lithiated polyphenylene sulfide (PPS) powder and PTFE powder according to the weight percentage of 90%:10%, in a VC type high-efficiency asymmetric mixer, and in a low-temperature refrigerator at 5°C, mix for 2 hour to obtain powder A uniformly. Powder A is ground in a stainless steel closed chamber with dry compressed air whose air velocity reaches supersonic speed, and the air is preheated before contacting the powder, and the temperature reaches 45°C to prepare mixed powder B, and the ground powder B Exhausted with air flow and collected. Powder B is made into a continuous cake-shaped broadband through the extruder to remove the gas in the powder, and then rolled into film C by using a hot roller press. The hot pressing temperature is 90°C, and the film thickness can reach about 100 microns. Film C is wound up. Two or more sheets of film C are combined by hot pressing to form a composite film D. The thermal lamination temperature is 85°C, and the film ...

Embodiment 3

[0039] Mix the pre-lithiated polyimide (PI) powder and PTFE powder according to the weight percentage of 93%:7%, in a VC type high-efficiency asymmetric mixer, and in a low-temperature refrigerator at 5°C, mix for 2 hour to obtain powder A uniformly. Powder A is ground in a stainless steel closed chamber with dry compressed air whose air velocity reaches supersonic speed, and the air is preheated before contacting the powder, and the temperature reaches 45°C to prepare mixed powder B, and the ground powder B Exhausted with air flow and collected. The powder B is made into a continuous cake-shaped broadband through an extruder to remove the gas in the powder, and then rolled into a film C by a hot roller press. The hot pressing temperature is 120°C, and the film thickness can reach about 80 microns. The functional film C is wound up. Two or more sheets of film C are combined by hot pressing to form a composite film D. The thermal lamination temperature is 90°C, and the film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com