Patents

Literature

33results about How to "Enhanced geometric stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Control method of asymmetric deformation of deep mine roadway surrounding rock

ActiveCN104265322AHigh compressive strengthImprove stress resistanceUnderground chambersTunnel liningSteel tubeCoal mining

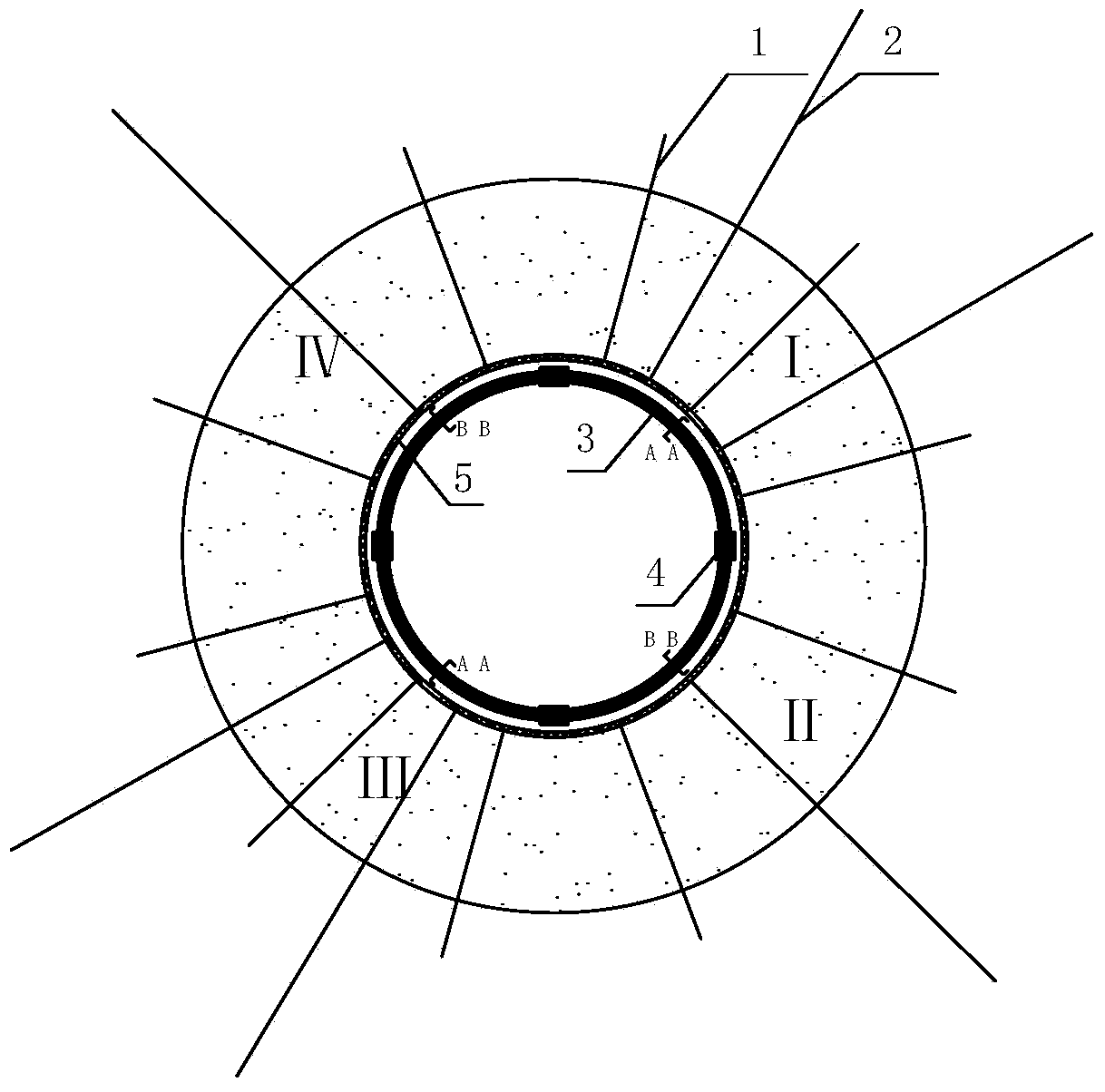

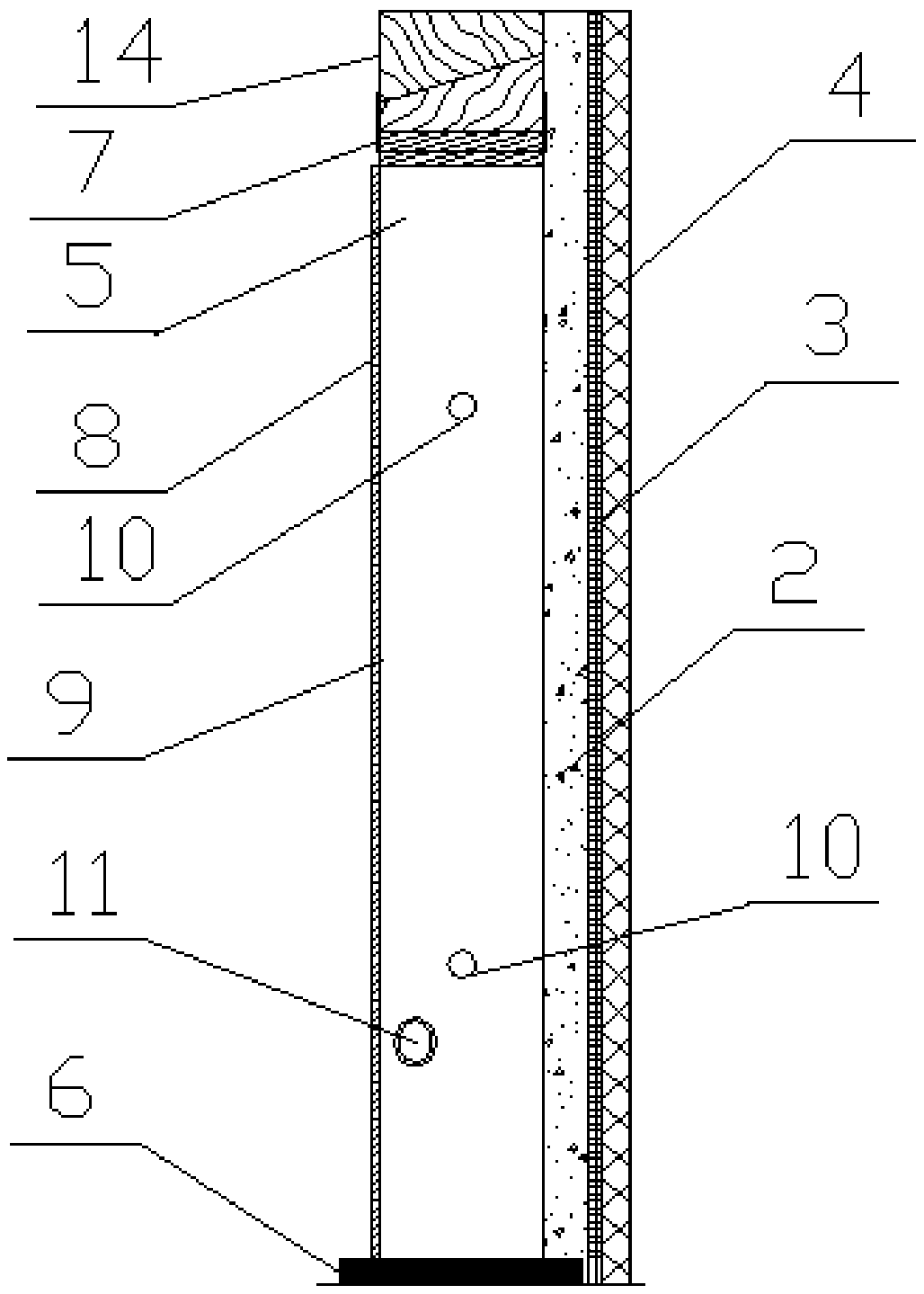

The invention discloses a control method of asymmetric deformation of deep mine roadway surrounding rock and belongs to the technical field of coal mining roadway support. The control method comprises digging the cross section of the deep mine roadway surrounding rock into a round or arc shape and then clockwise and evenly dividing the cross section of the roadway into a plurality of zones; laying wire meshes around the surrounding rock, sequentially mounting anchor rods and anchor cables in the corresponding area of the cross section of the deep mine roadway and forming concrete coating through spraying to form an anchor-mesh-coating primary support structure; lastly, performing secondary support on the roadway surrounding rock of the primary support structure through a steel tube concrete support frame. According to the control method of the asymmetric deformation of the deep mine roadways surrounding rock, by means of the composite support method of combining the primary support with the secondary support and by adding high-prestress anchor rods in relatively large key zones and increasing the support density of the anchor cables and the wall thickness of the support frame, the support strength of a support body can be enhanced, and the asymmetric deformation of the deep mine roadway surrounding rock can be effectively controlled.

Owner:SHANDONG UNIV OF SCI & TECH

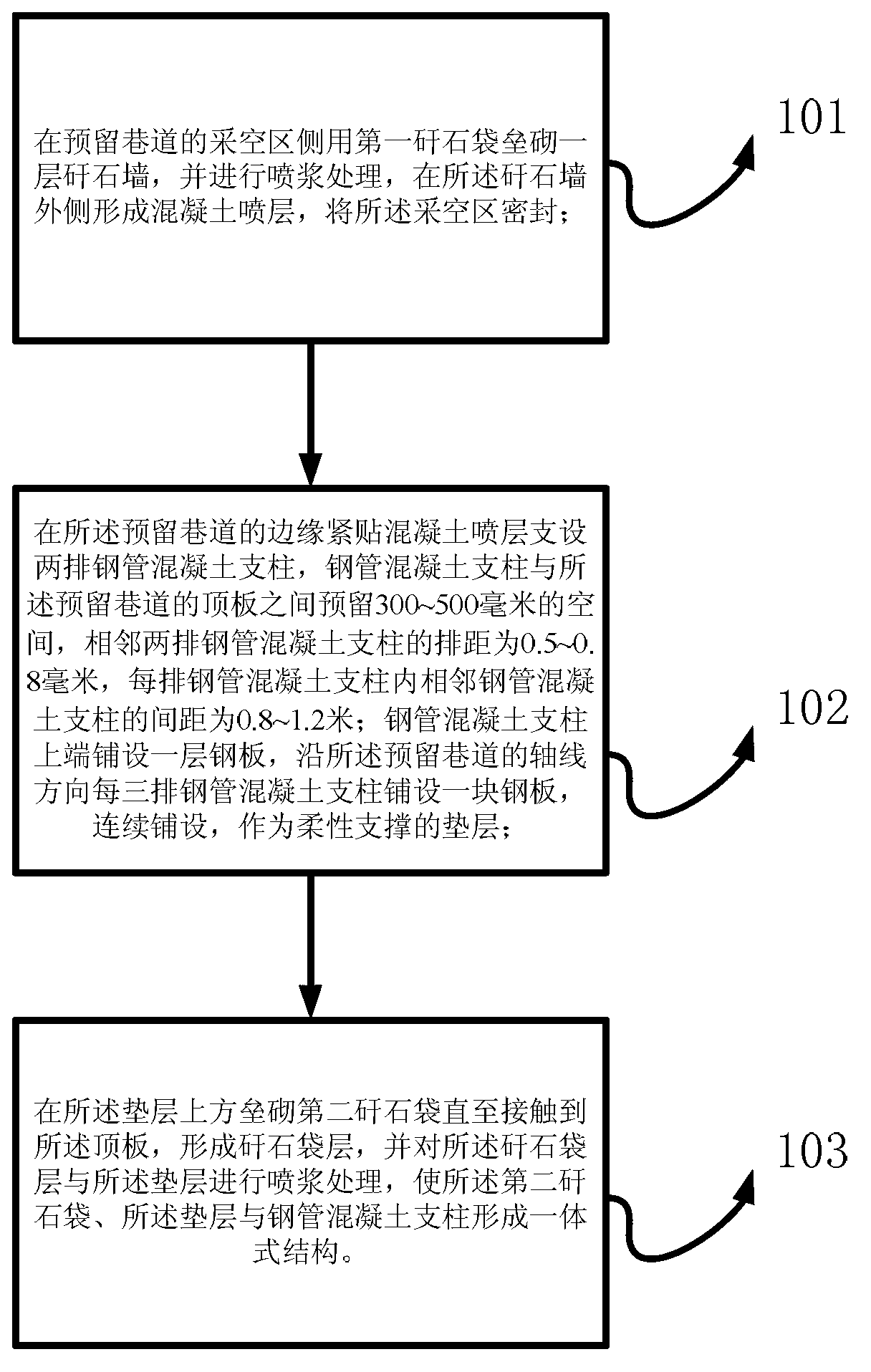

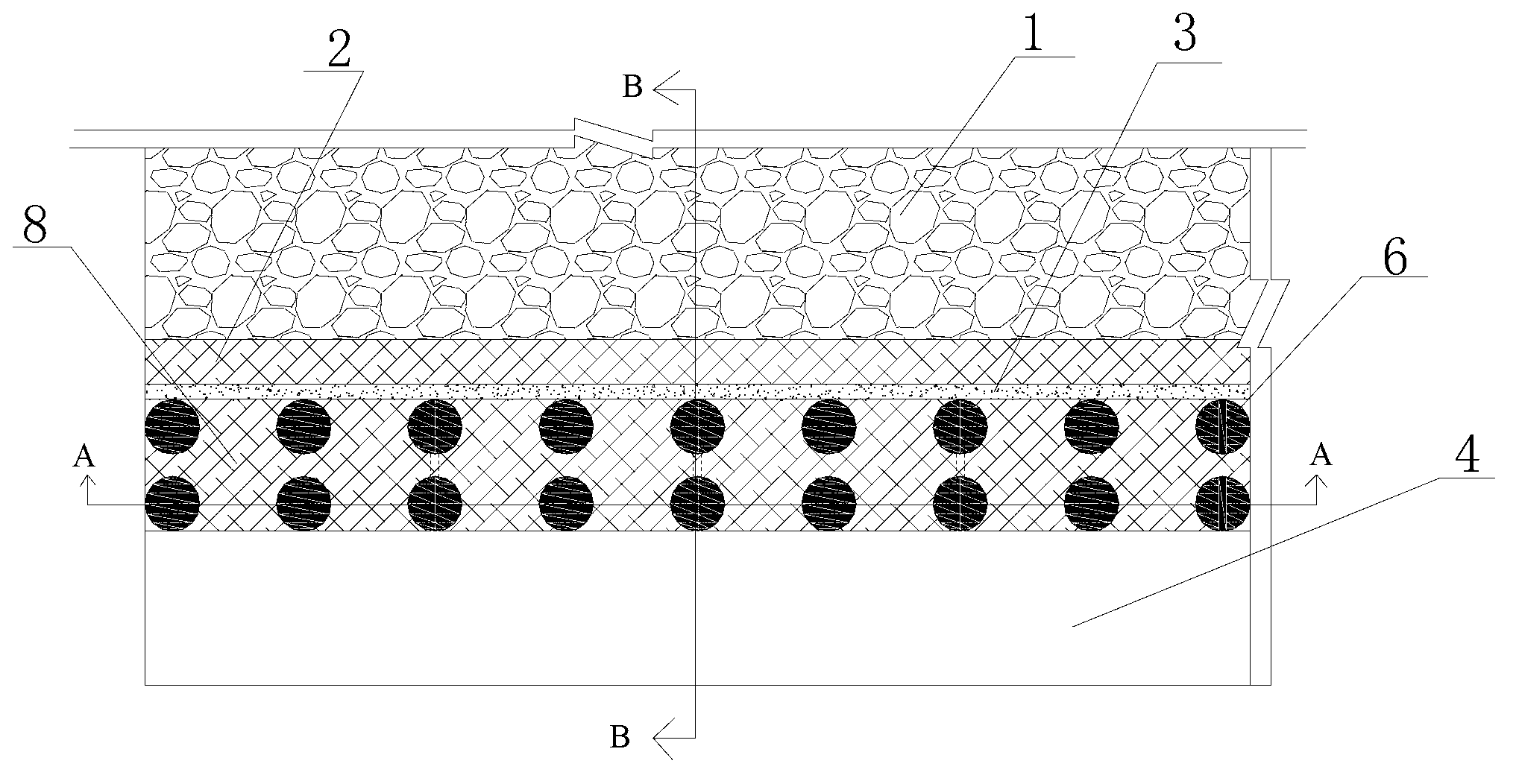

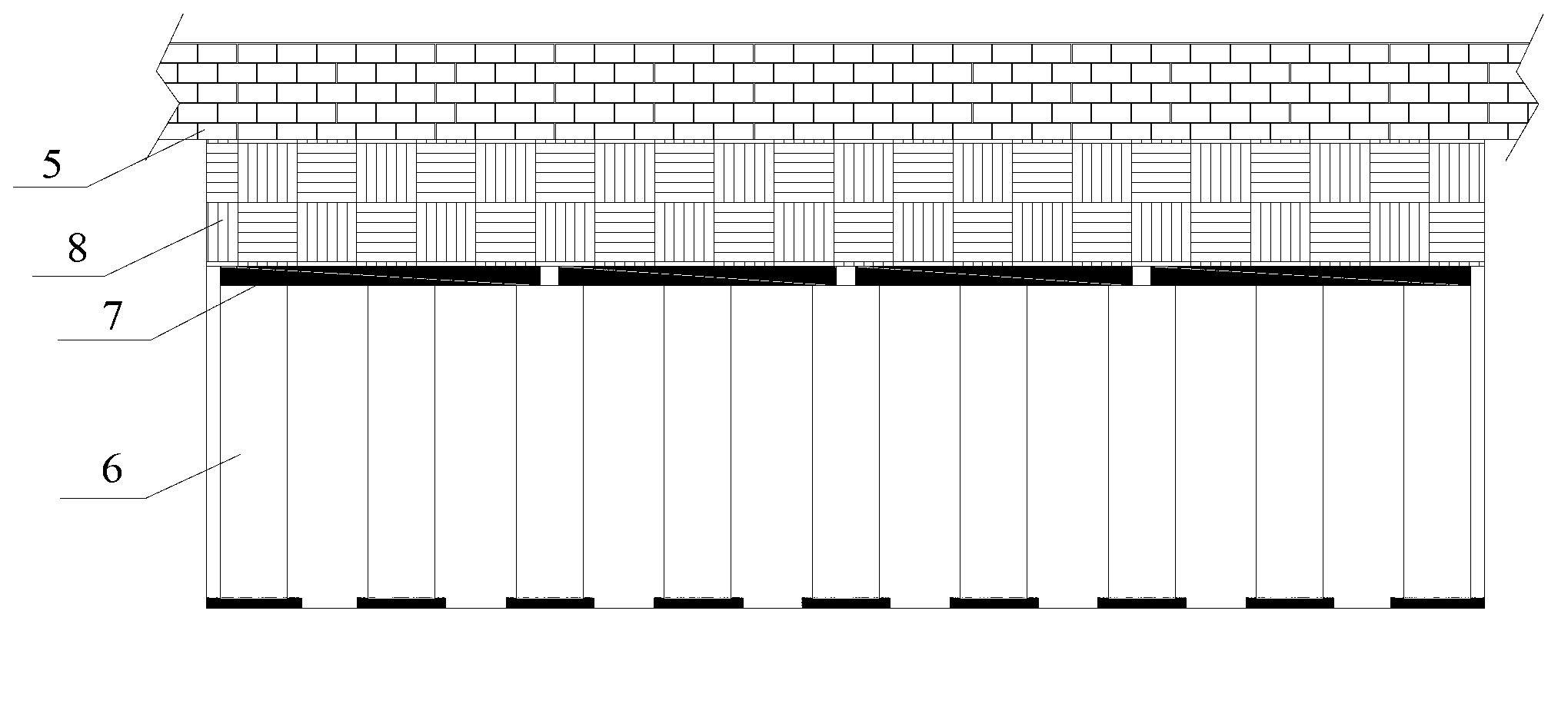

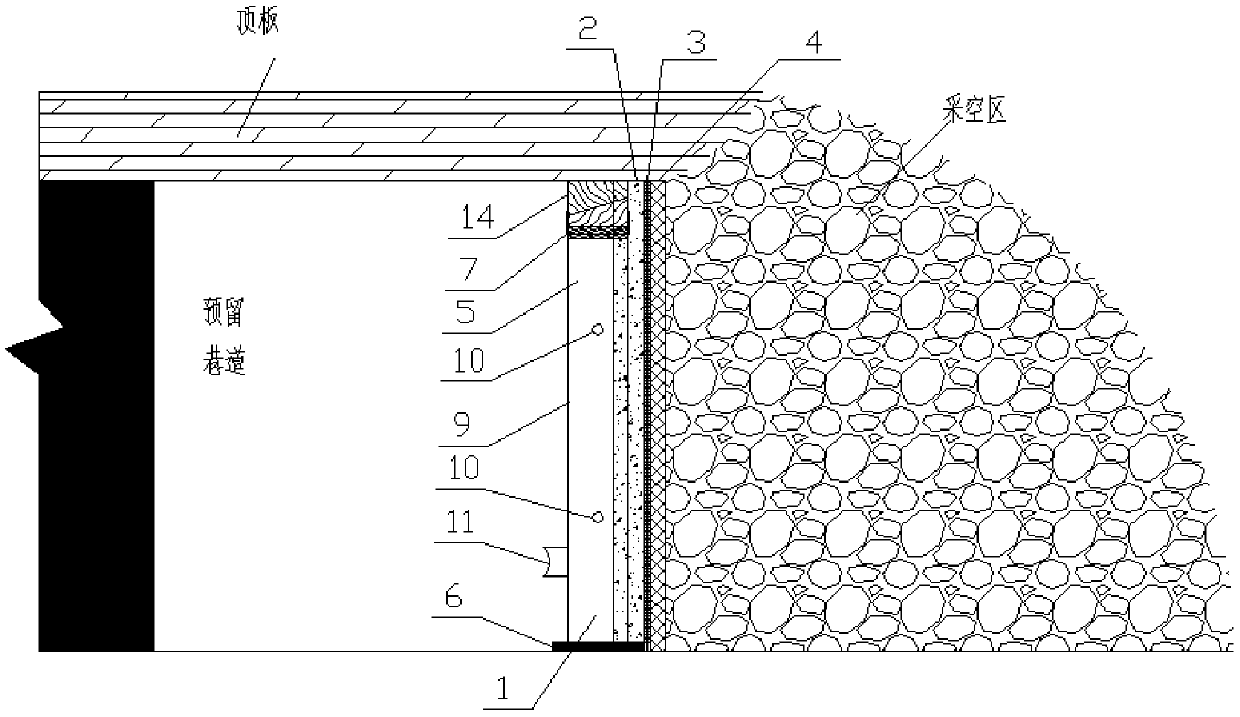

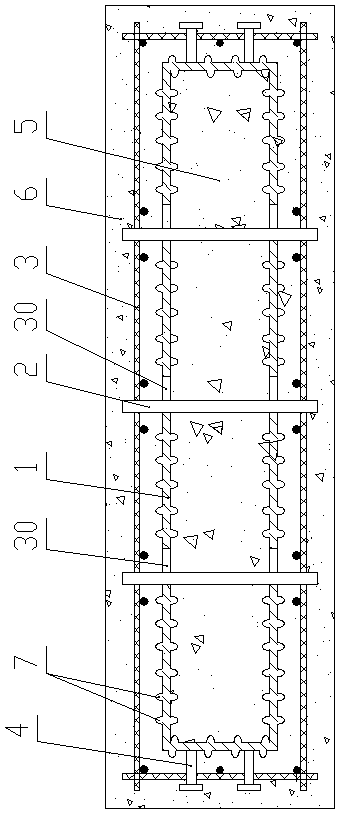

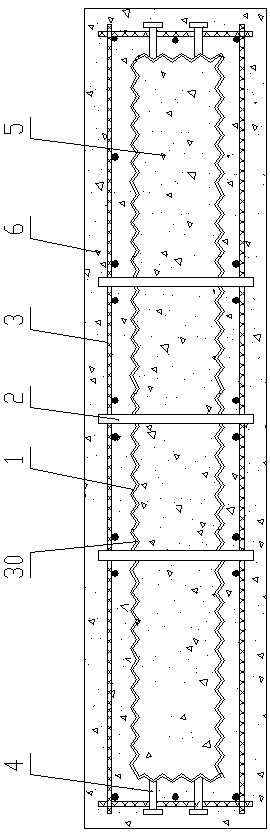

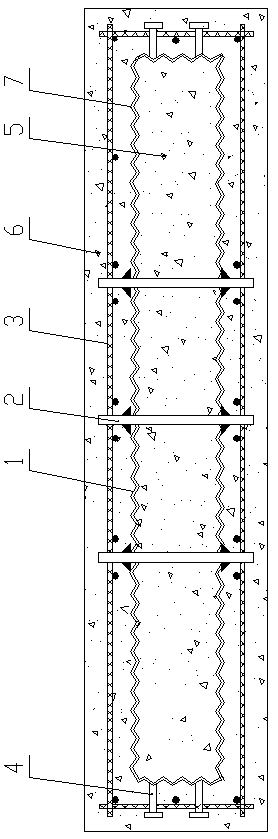

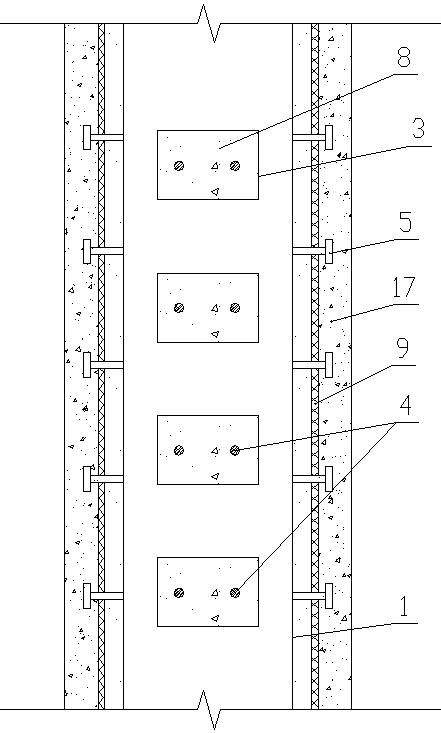

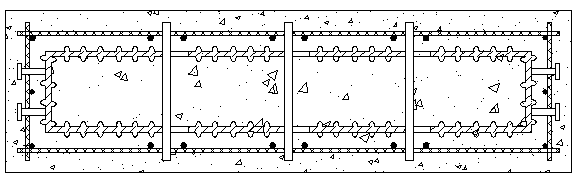

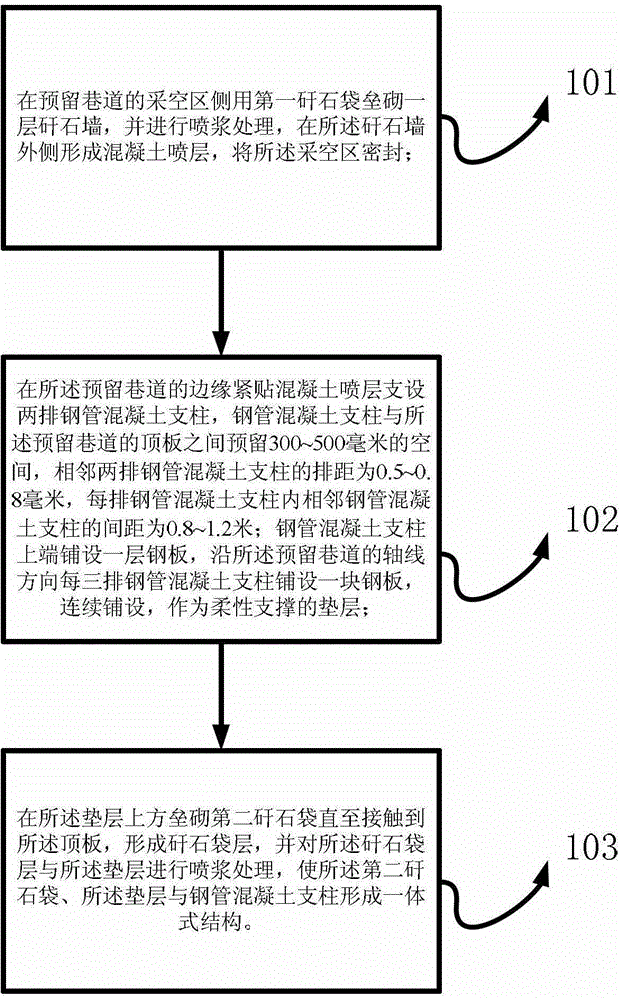

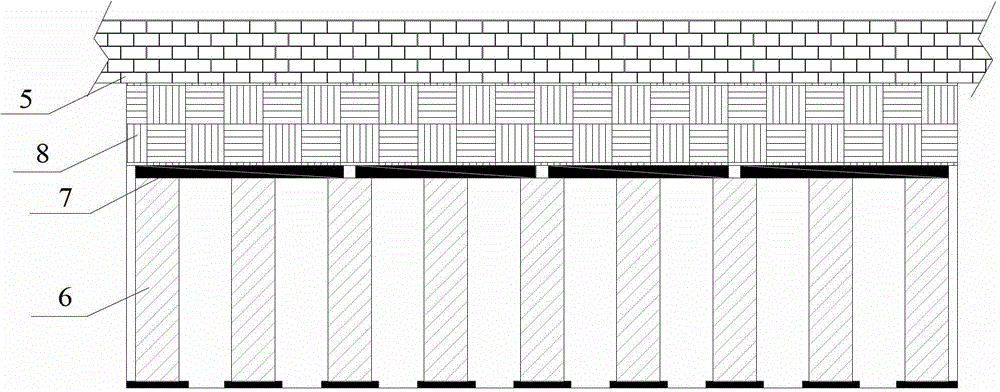

Rigid-flexible combination gob-side entry retaining method and rigid-flexible combination gob-side entry retaining device by aid of roadside supports

ActiveCN103291319AHigh compressive strengthImprove stress resistanceUnderground chambersTunnel liningSheet steelHigh intensity

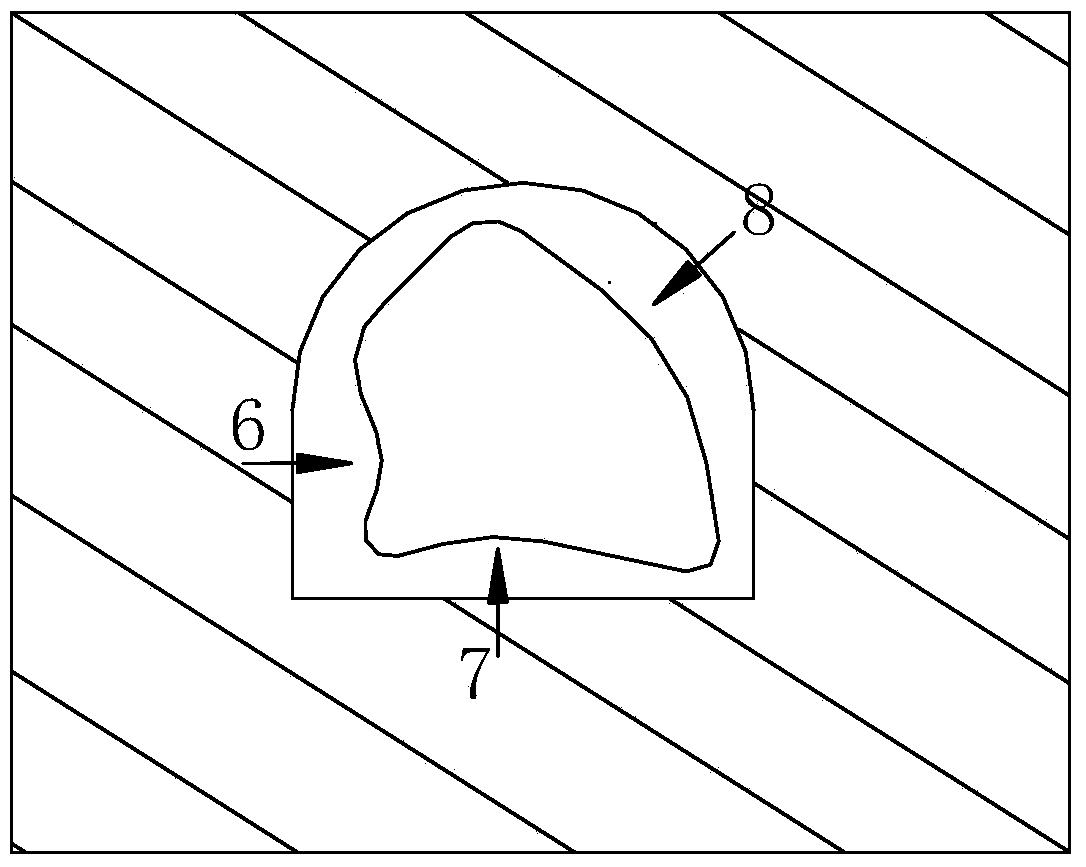

The invention discloses a rigid-flexible combination gob-side entry retaining method and a rigid-flexible combination gob-side entry retaining device by the aid of roadside supports. The rigid-flexible combination gob-side entry retaining method includes building a layer of gangue wall by first gangue bags on a gob side of a reserved roadway to seal a gob; erecting two rows of pillars made of concrete-filled steel tubes at the edge of the reserved roadway, enabling the two rows of pillars to cling to a concrete sprayed layer, laying a steel plate on each three rows of pillars made of concrete-filled steel tubes along the axial direction of the reserved roadway, and continuously laying the steel plates to form a flexible supporting cushion; laying second gangue bags on the cushion until the laid gangue bags are in contact with a top plate to form a gangue bag layer, and performing spouting on the gangue bag layer and the cushion so as to form an integral structure comprising the second gangue bags, the cushion and the pillars made of the concrete-filled steel tubes. The rigid-flexible combination gob-side entry retaining method and the rigid-flexible combination gob-side entry retaining device have the advantages that a flexible yielding effect of the gangue bags and a high-strength support effect of the pillars made of the concrete-filled steel tubes are combined with each other by the structure, accordingly, the rigid-flexible combination gob-side entry retaining method and the rigid-flexible combination gob-side entry retaining device are particularly suitable for gob-side entry retaining engineering in deep and high-stress states, a construction process of the gob-side entry retaining method is simple, the gob-side entry retaining speed can be effectively increased, and an operating environment in the roadway is improved.

Owner:SHANDONG UNIV OF SCI & TECH

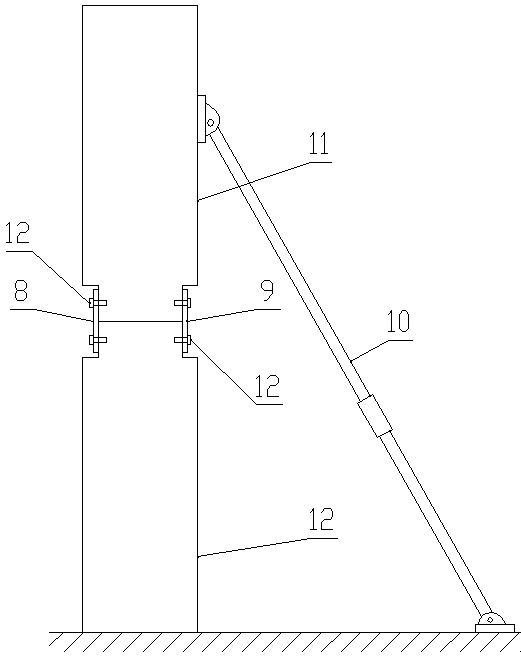

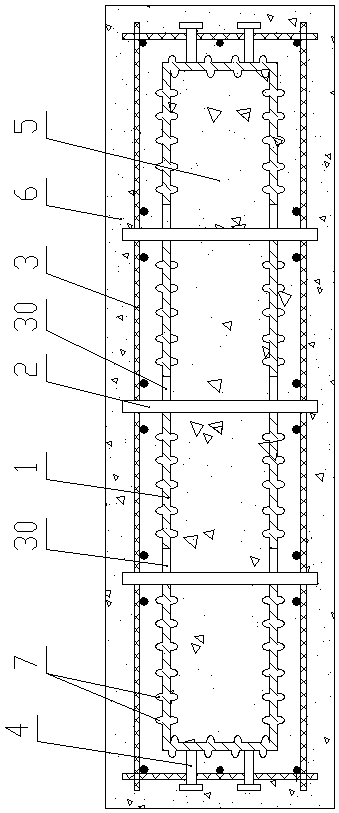

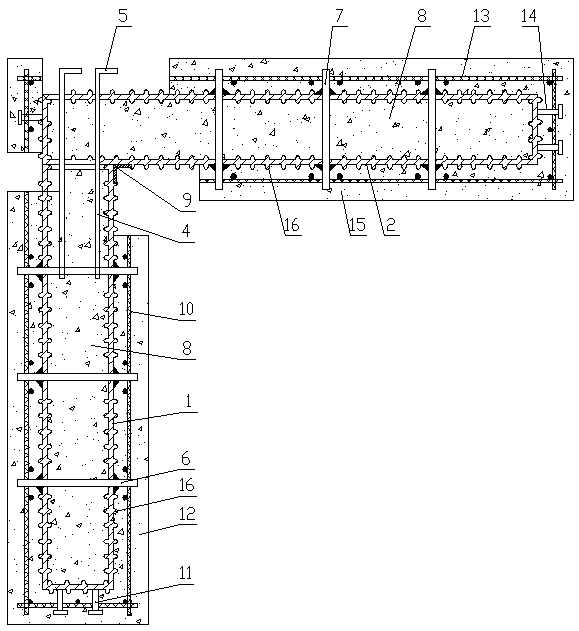

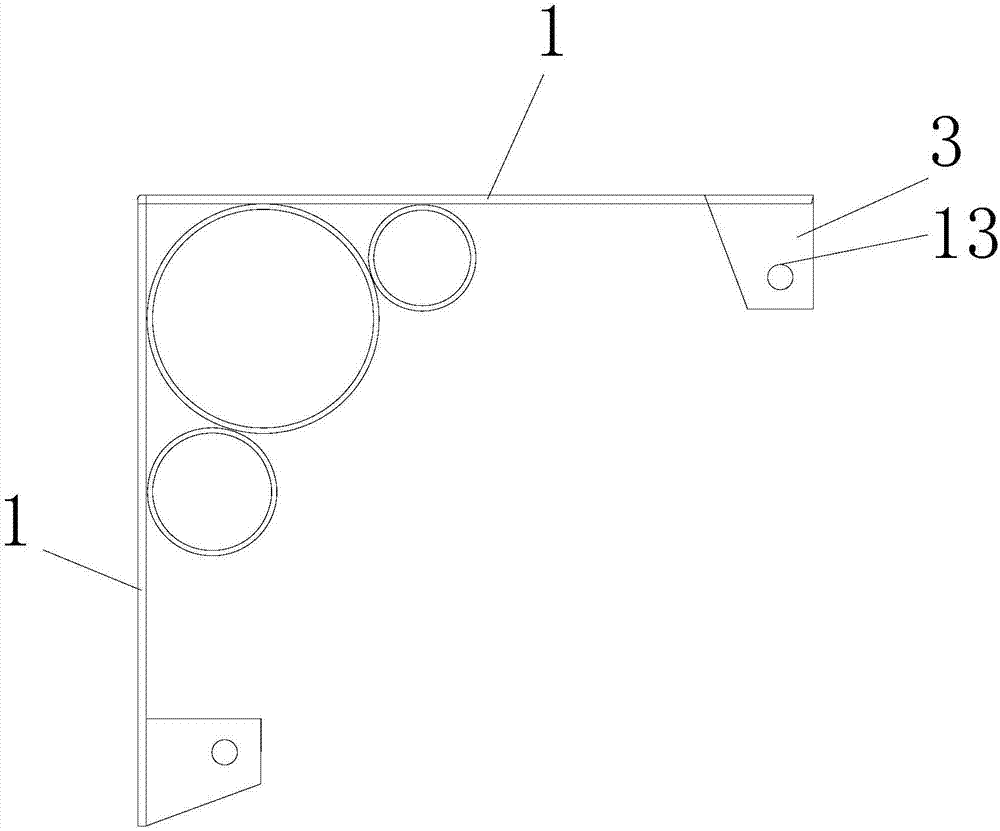

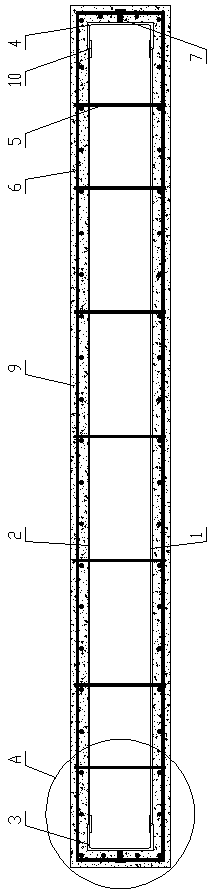

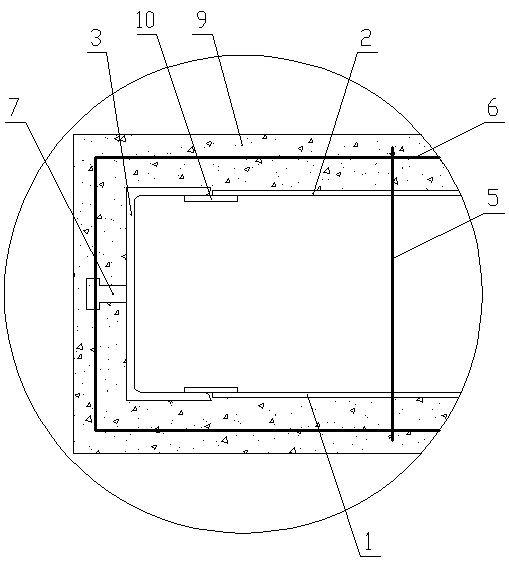

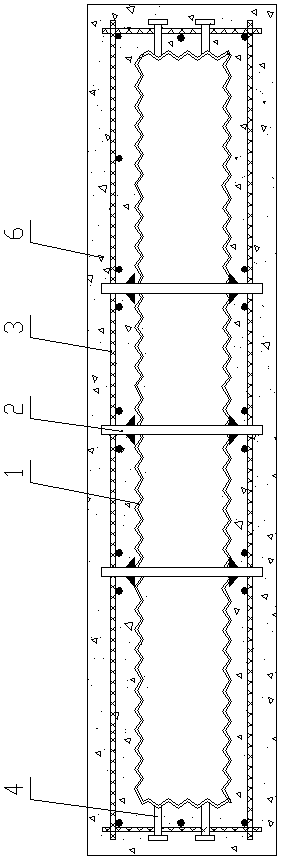

Factory-prefabricated steel concrete superposed shear wall field installation vertical connecting device

InactiveCN108505749ASimplify the construction processImprove integrityWallsBuilding material handlingCompressive strengthUltimate tensile strength

The invention discloses a factory-prefabricated steel concrete superposed shear wall field installation vertical connecting device which comprises a first connecting plate, a second connecting plate and a telescopic adjustable inclined supporting rod. Steel concrete superposed shear walls are connected by steel concrete superposed pipes with cross sections being of a rectangular structure and thenform shearing-proof wall bodies in a linear shape, a half-H shape, a reversed-L shape, a cross shape or a square shape. When two vertically adjacent steel concrete superposed shear walls are connected, the upper layer steel concrete superposed pipes are correspondingly arranged on the lower layer steel concrete superposed pipes. The telescopic adjustable inclined supporting rod is obliquely arranged, and the upper end and the lower end of the telescopic adjustable inclined supporting rod are correspondingly hinged to the outer sides of the upper layer steel concrete superposed pipes and ground of each floor. The plasticity and tenacity of the structure of an integral steel concrete superposed shear wall are greatly improved, anti-deformation capacity compression strength of the shear walls are greatly improved, components for vertical connecting are wrapped in the concrete, so that the connecting device is attractive, has high connection strength, and high stability, and is not liableto be misplaced.

Owner:HENAN LYUJIAN BUILDING TECH CO LTD

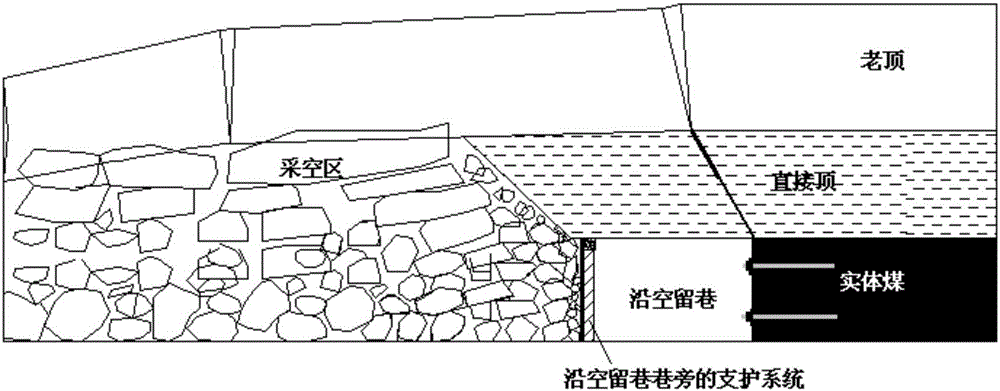

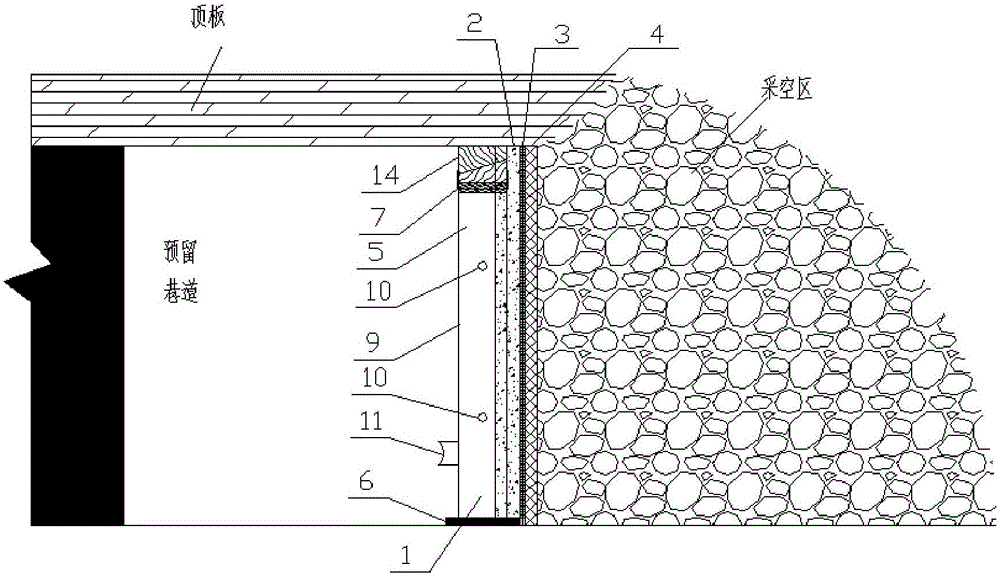

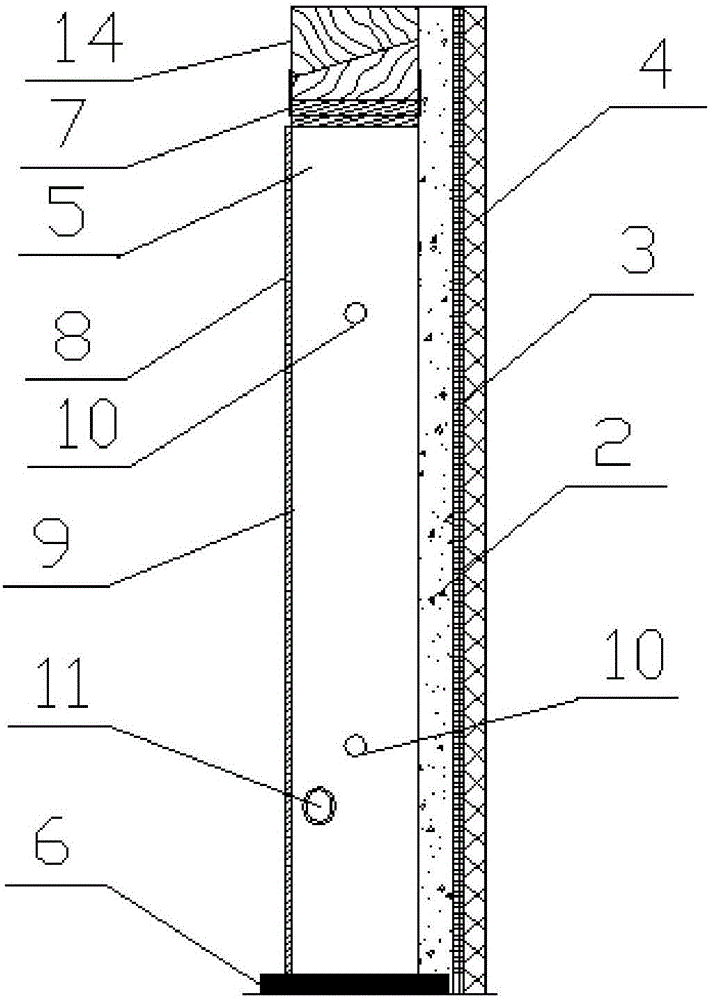

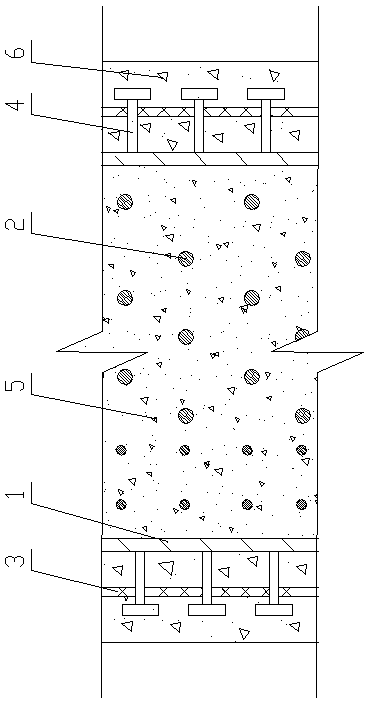

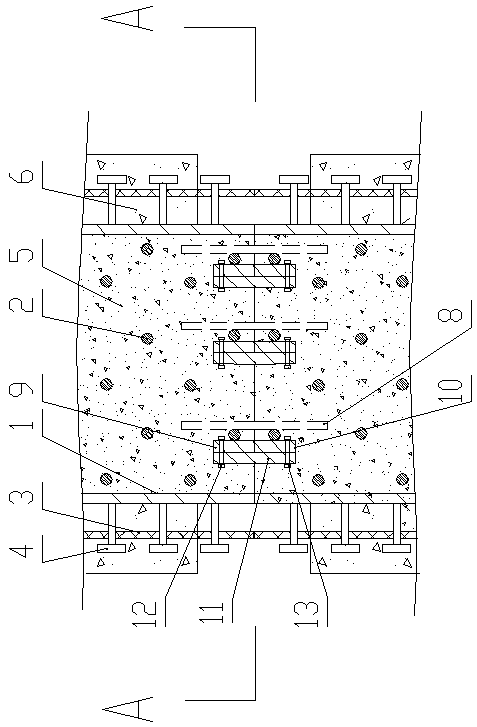

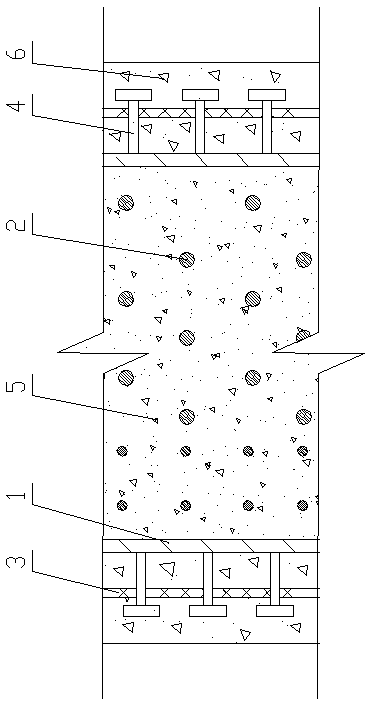

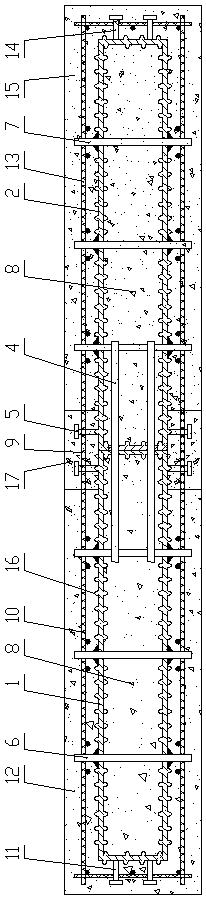

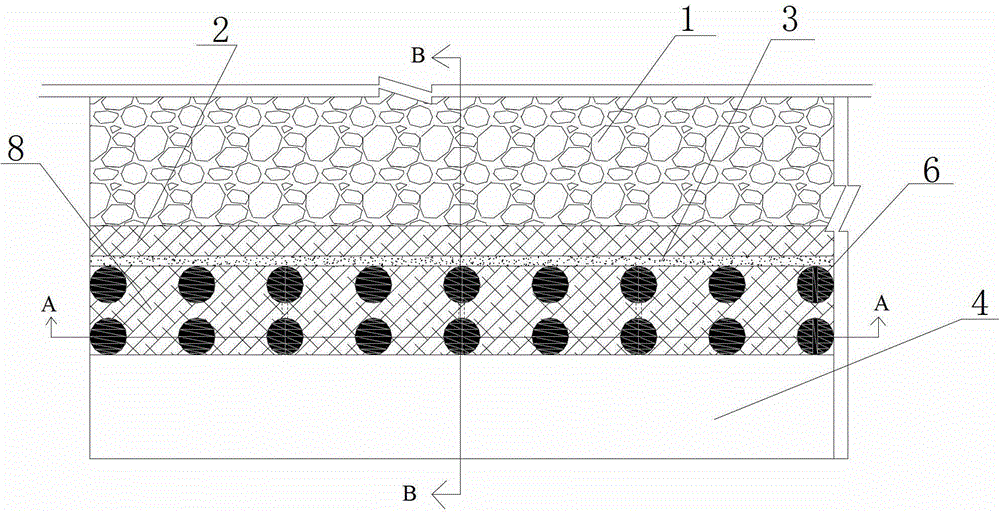

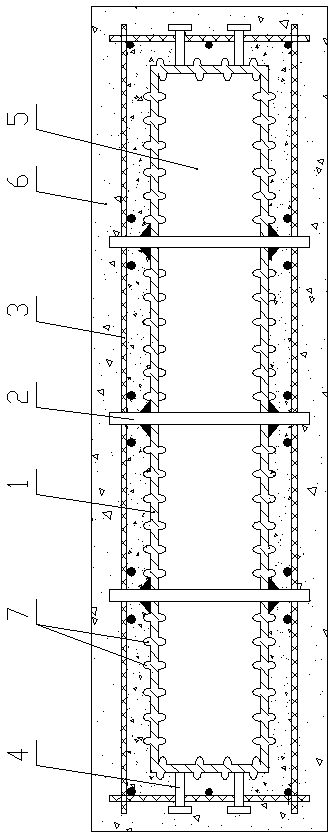

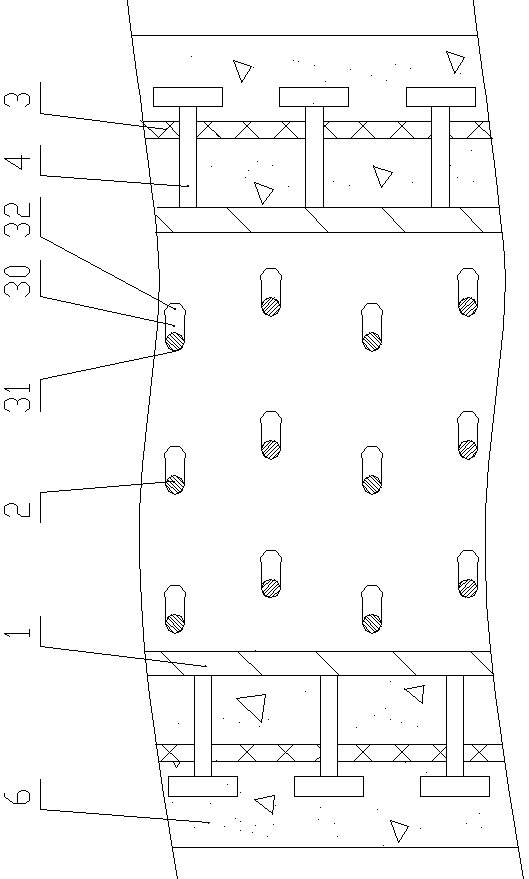

Gob-side entry retaining roadside support system and construction method thereof

ActiveCN106677804AAchieve recyclingGood removal effectUnderground chambersTunnel liningSupporting systemGeometric stability

The invention relates to a gob-side entry retaining roadside support system and a construction method thereof. A rhombic steel bar net is arranged on one side of a gob, an air drum cloth is laid on the inner side of the rhombic steel bar net, light aggregate concrete is adopted to perform guniting treatment on the air drum cloth and the rhombic steel bar net, a windtight light aggregate concrete spray layer is formed on the side of the gob, the thickness of the light aggregate concrete spray layer is 200-500 mm, and the other side of the light aggregate concrete spray layer is close to a steel tube concrete pier stud supporting device. A steel tube concrete pier stud is formed by filling an empty steel tube with concrete; through a restraint effect of a steel tube casing, internal concrete is in a three-dimensional stressed state, the geometrical stability of the steel tube wall is enhanced, and the bearing capacity of the steel tube concrete pier stud is improved. According to the gob-side entry retaining roadside support system, a top plate can be supported in high strength, coal mining efficiency is effectively improved, and an operation environment in a roadway is improved; the steel tube concrete pier stud can be recycled through a special thrust device, and the roadway retained cost is reduced.

Owner:SHANDONG JIANZHU UNIV

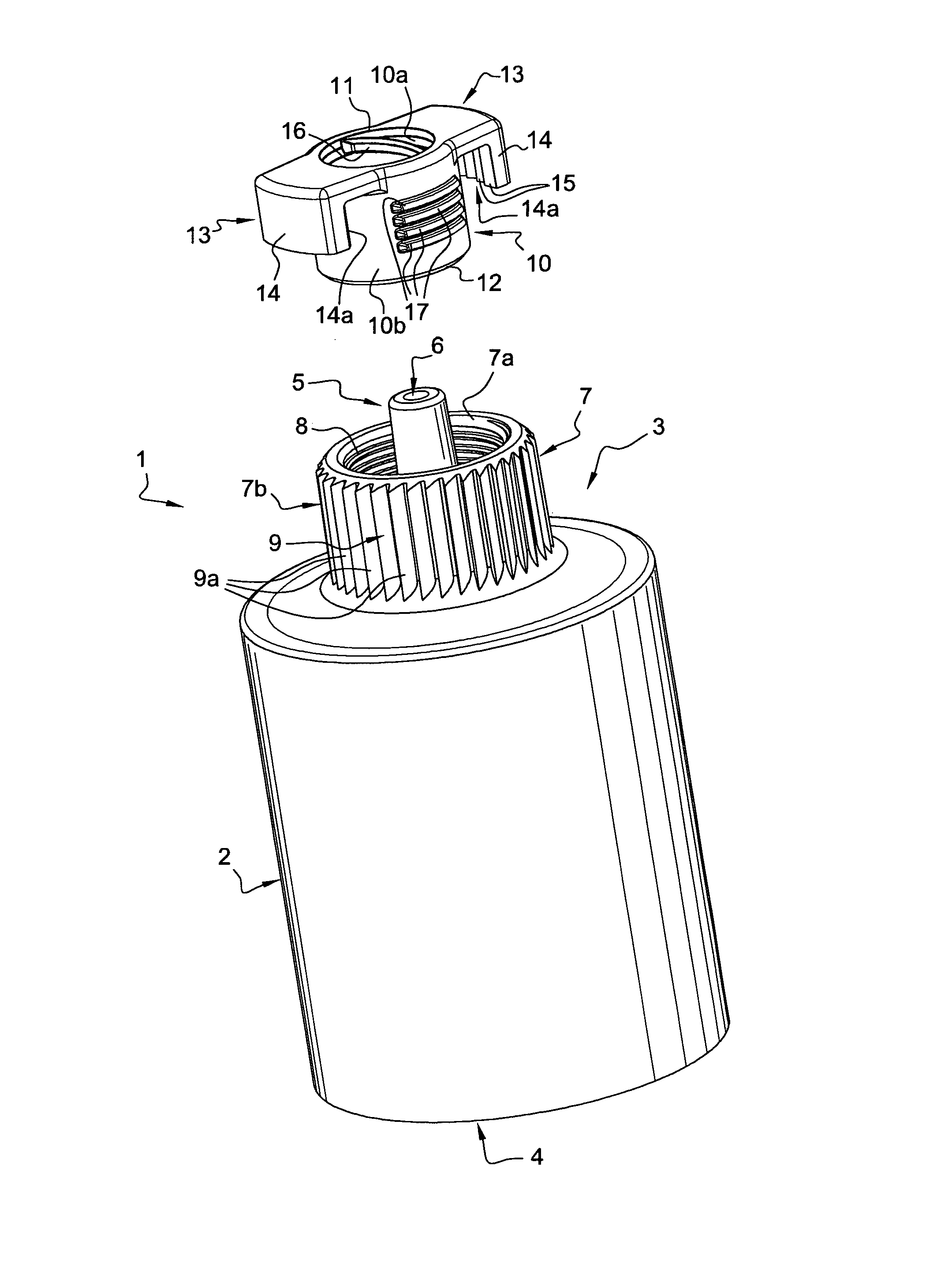

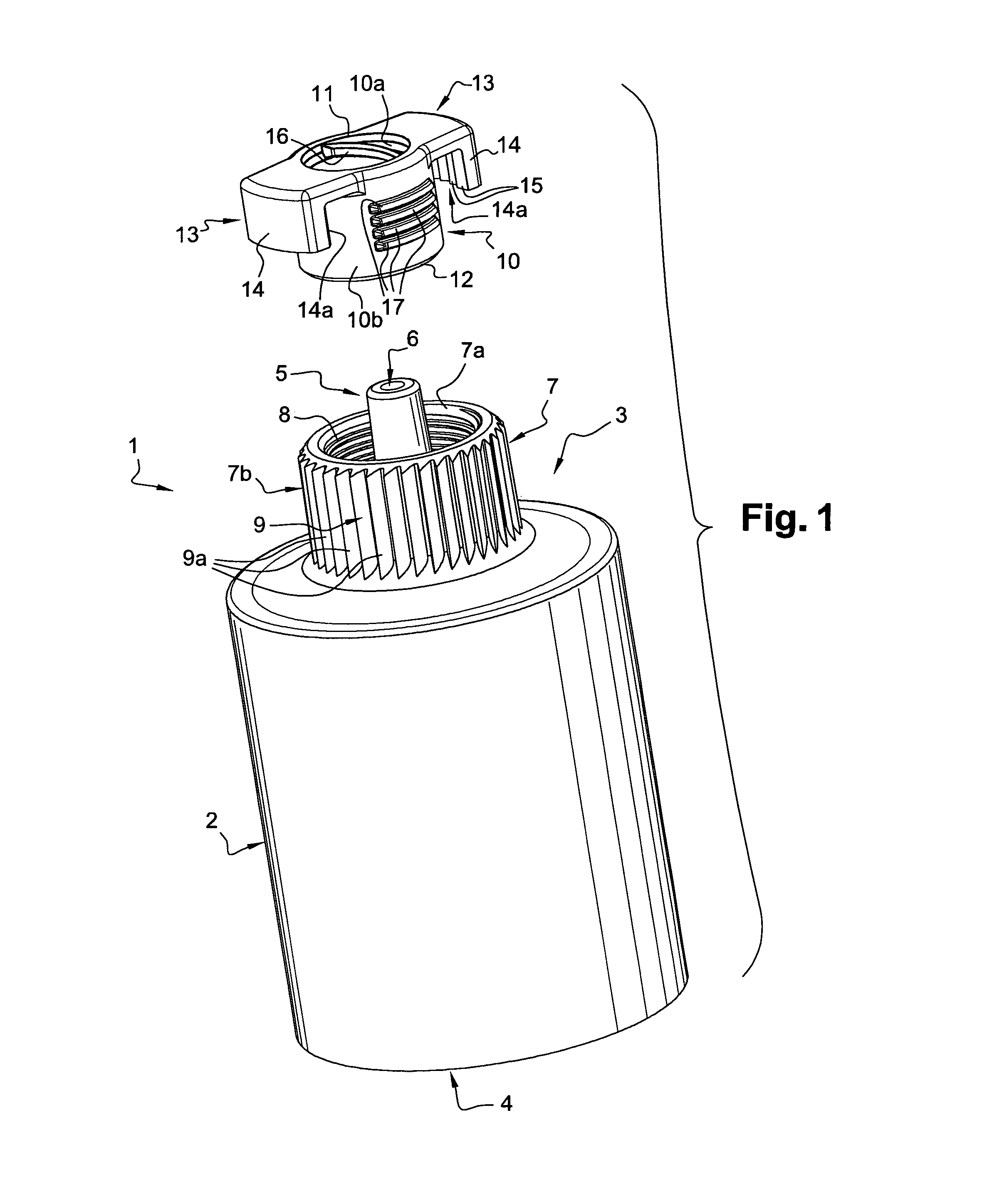

Drug delivery device with safe connection means

ActiveUS8882726B2High transparencyImprove stabilitySurgeryTube connectorsCouplingBiomedical engineering

The present invention relates to a drug delivery device defining a reservoir for containing a product, having a distal end comprising an end-piece defining a channel for the transfer of the product from the reservoir, said drug delivery device comprising means for coupling said end-piece with a connector, said coupling means comprising a collar defined around a portion of the end-piece and extending from the distal end, said coupling means comprising connection means connectable to said collar, said connection means comprising a tubular wall portion having an interface defined thereon for engagement with an internal face of said collar, and a retaining hook having engagement means engageable with at least part of an external face of said collar when said connection means is connected to said collar.

Owner:BECTON DICKINSON FRANCE

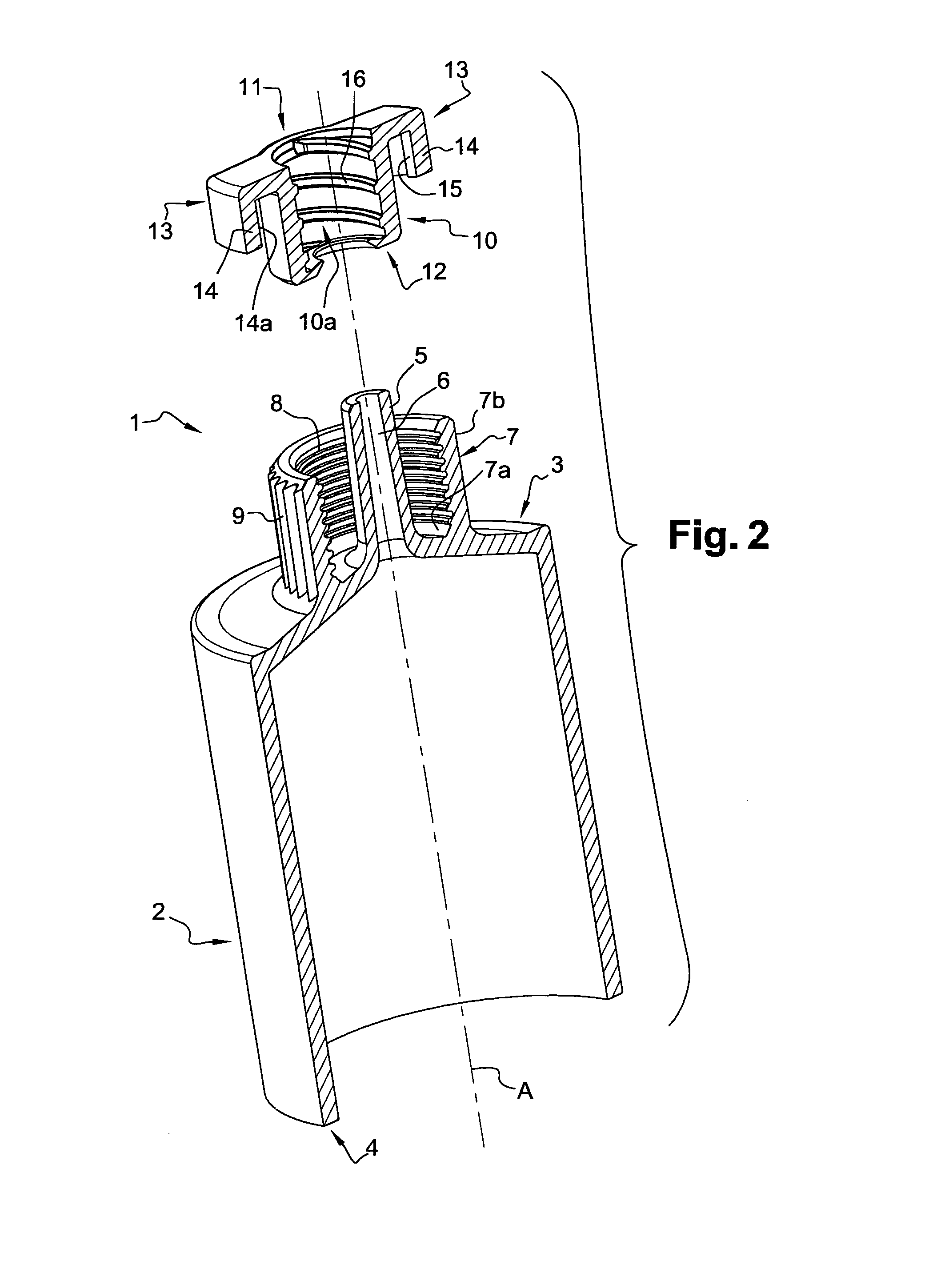

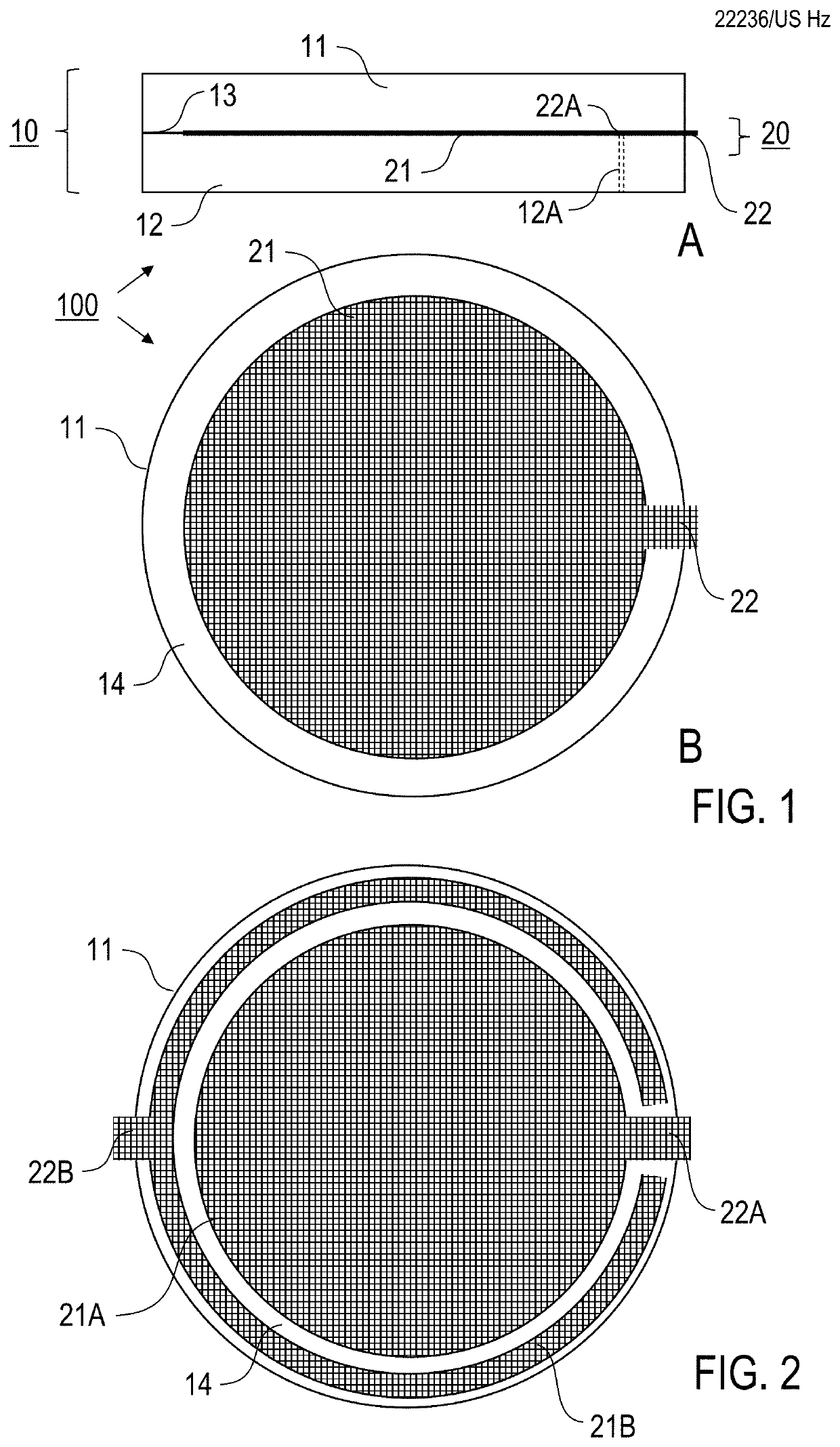

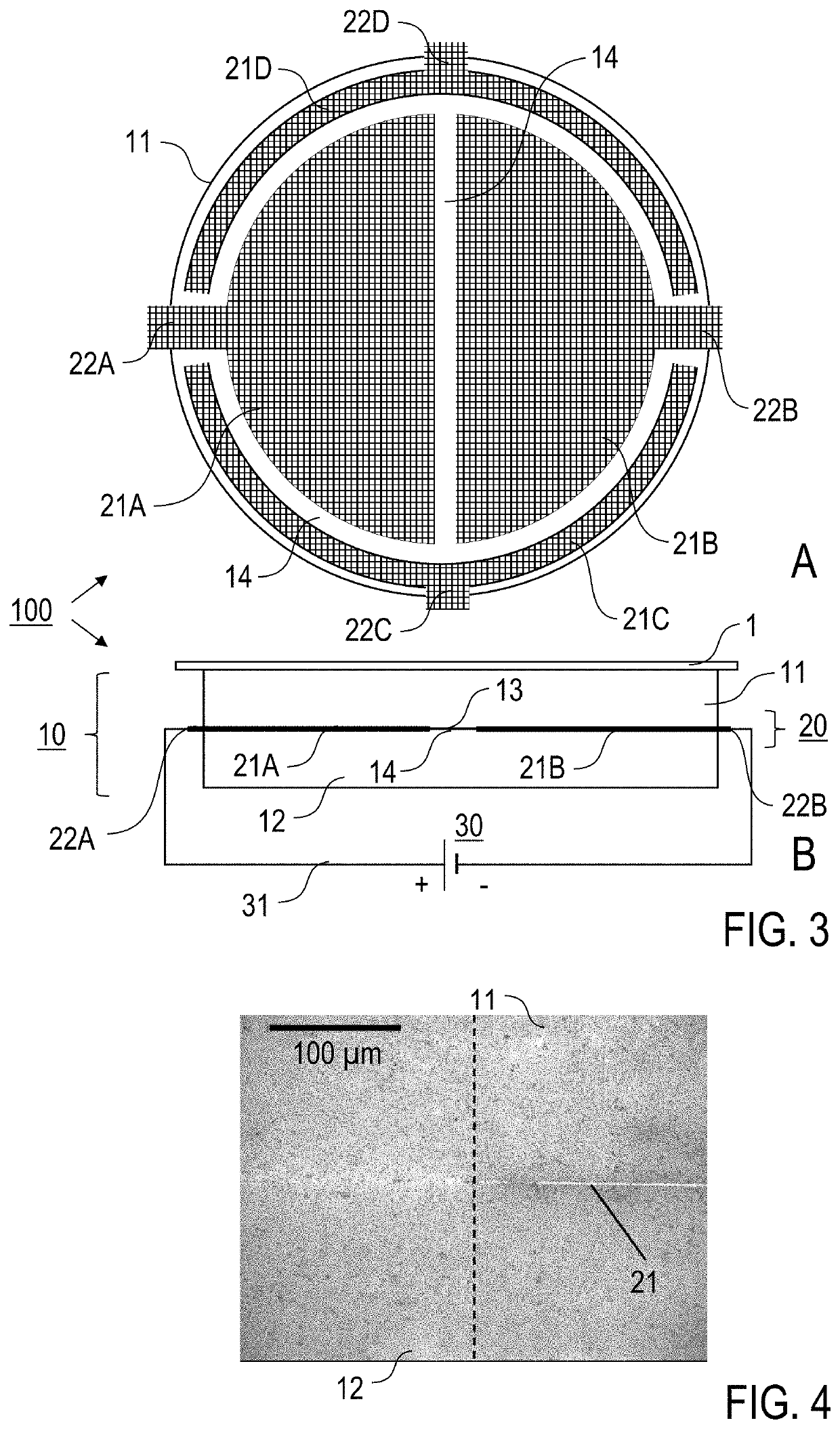

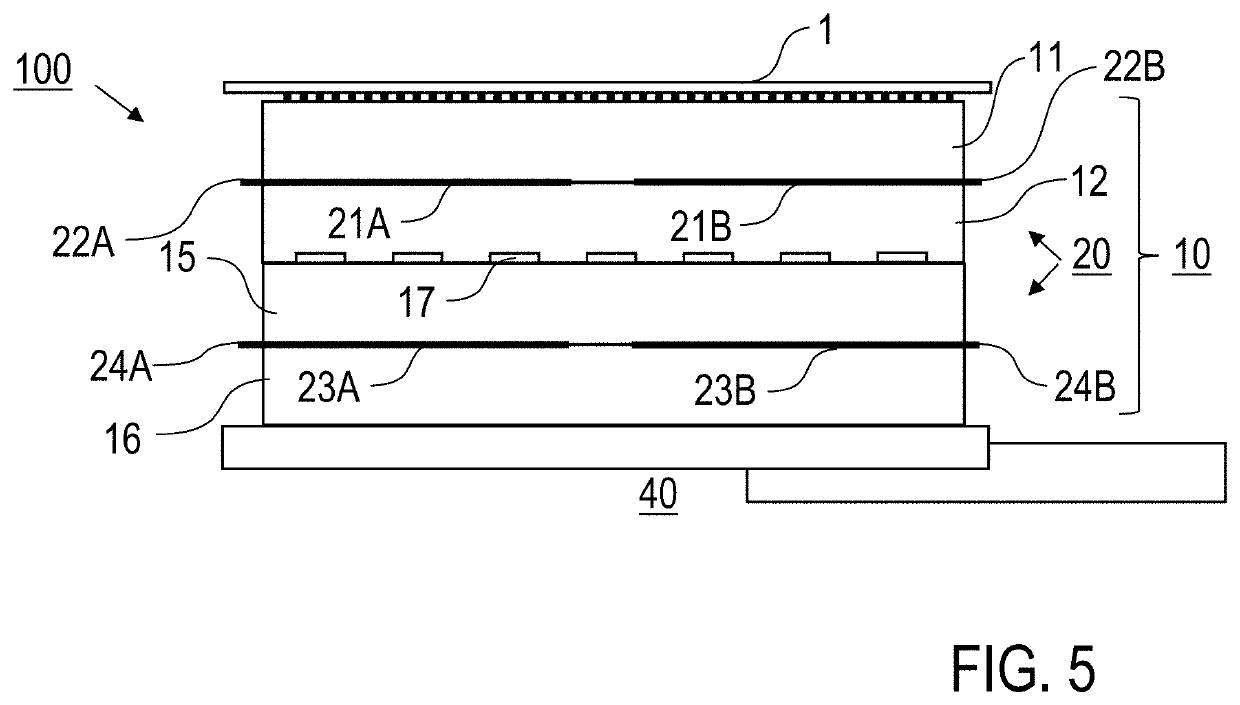

Holding apparatus for electrostatically holding a component, including a base body joined by diffusion bonding, and process for its manufacture

ActiveUS20200234992A1Enhanced geometric stabilityImprove thermal stabilitySemiconductor/solid-state device manufacturingWaferingEngineering

A holding apparatus, which is adapted for electrostatically holding a component, in particular a wafer, comprises an electrically insulating base body, which comprises a first pair of base body plates, which are connected to one another in a planar manner via a joint connection, and an electrode device with at least one electrode layer, which is arranged to generate an electrostatic holding force and extends parallel to the extension of the base body plates along the joining connection, wherein the joining connection comprises a diffusion bond connection, wherein the at least one electrode layer is connected in a planar manner to the respectively adjacent base body plate, and the at least one electrode layer has a contact section, which is arranged for electrically contacting the at least one electrode layer. Methods for manufacturing the holding apparatus are also described.

Owner:ASML NETHERLANDS BV

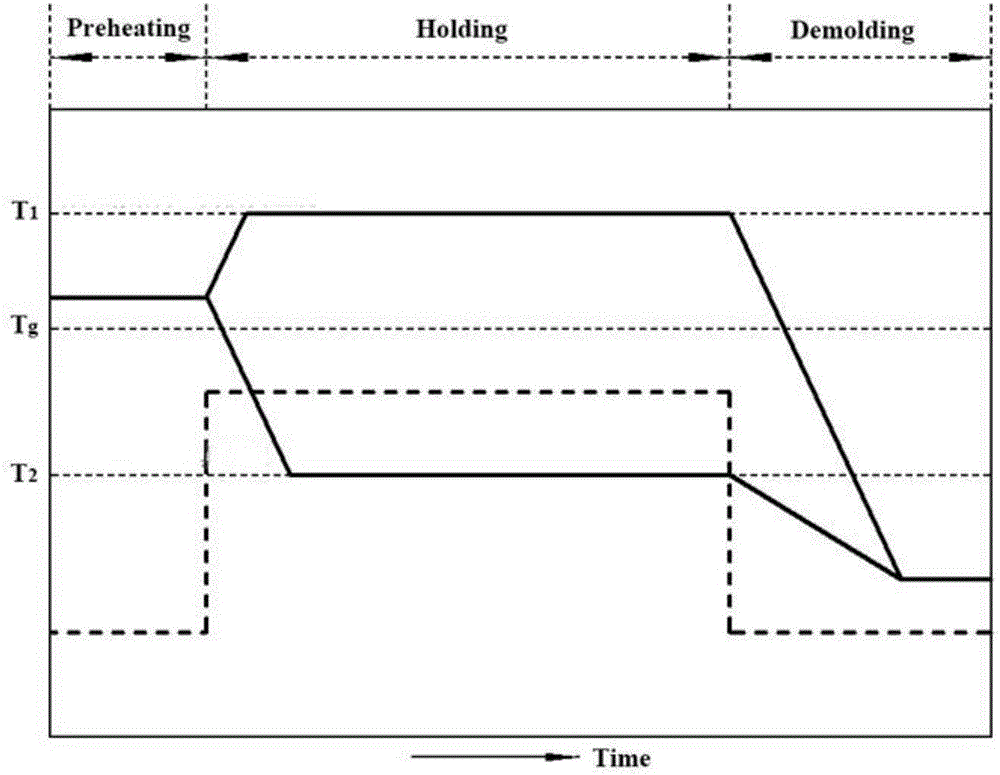

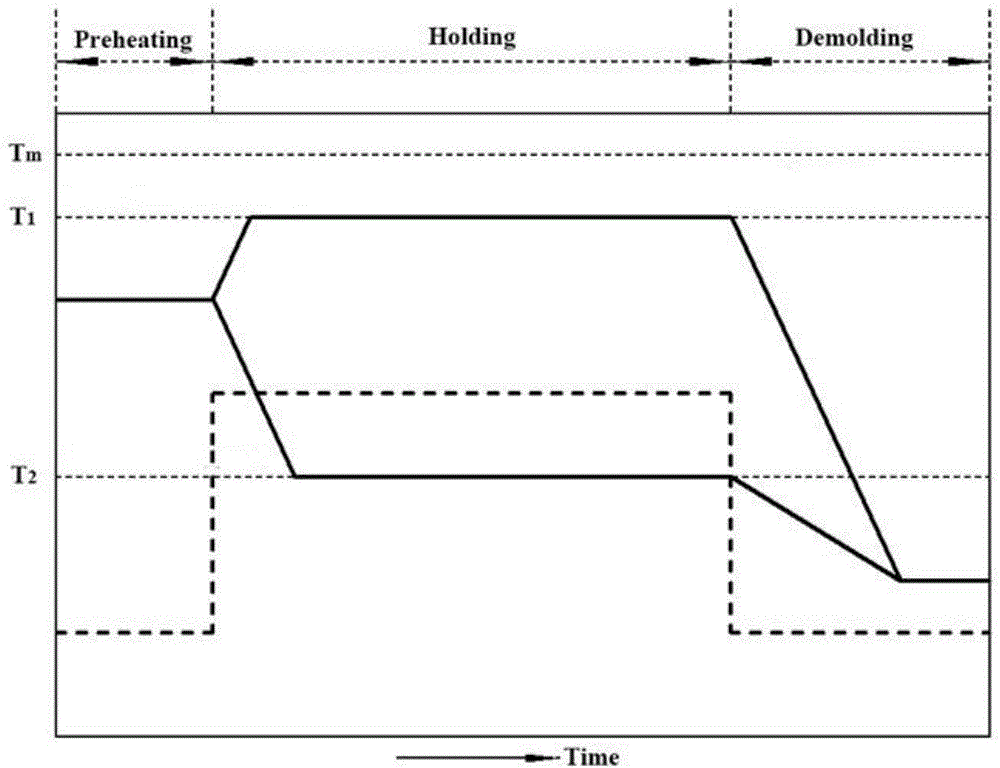

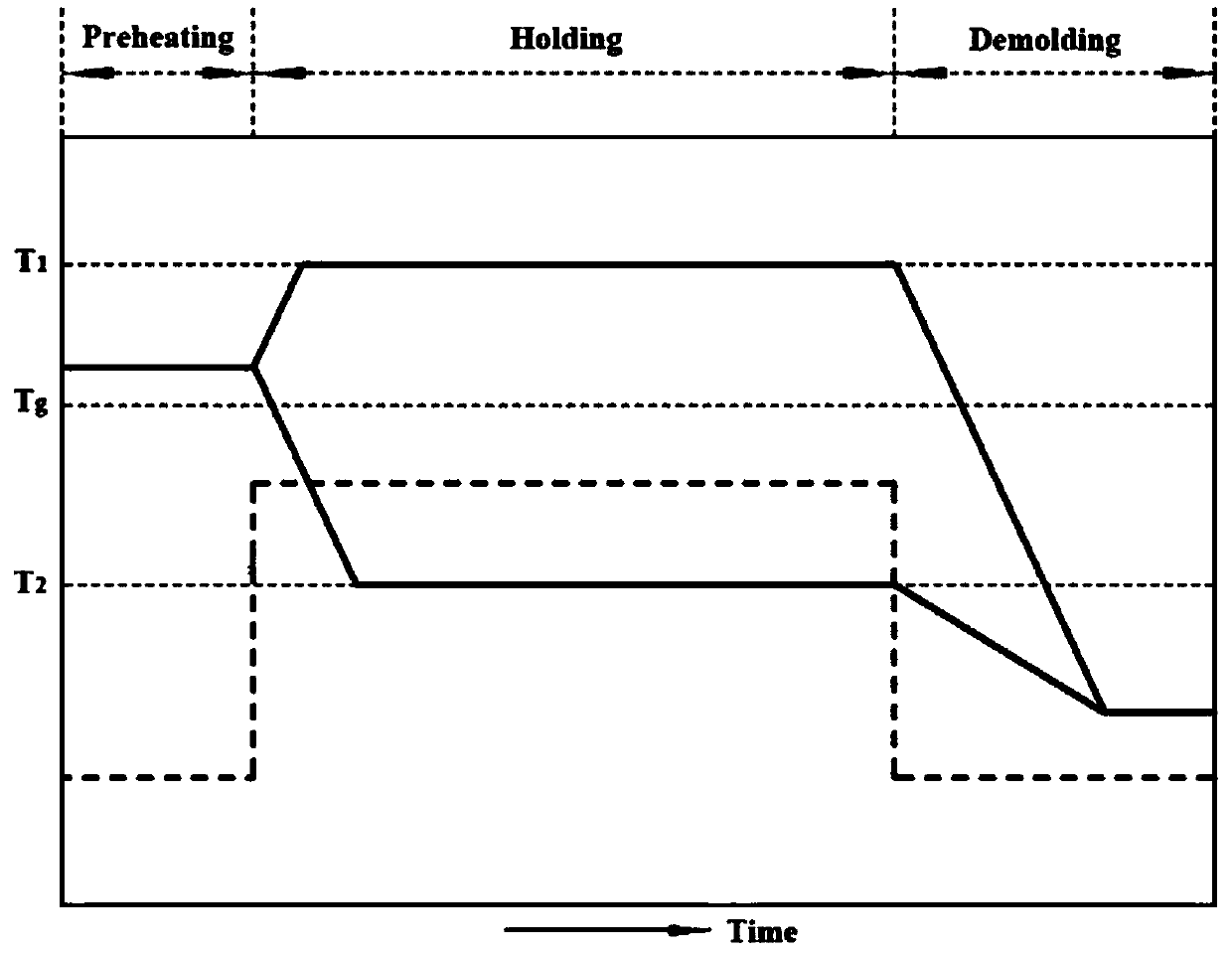

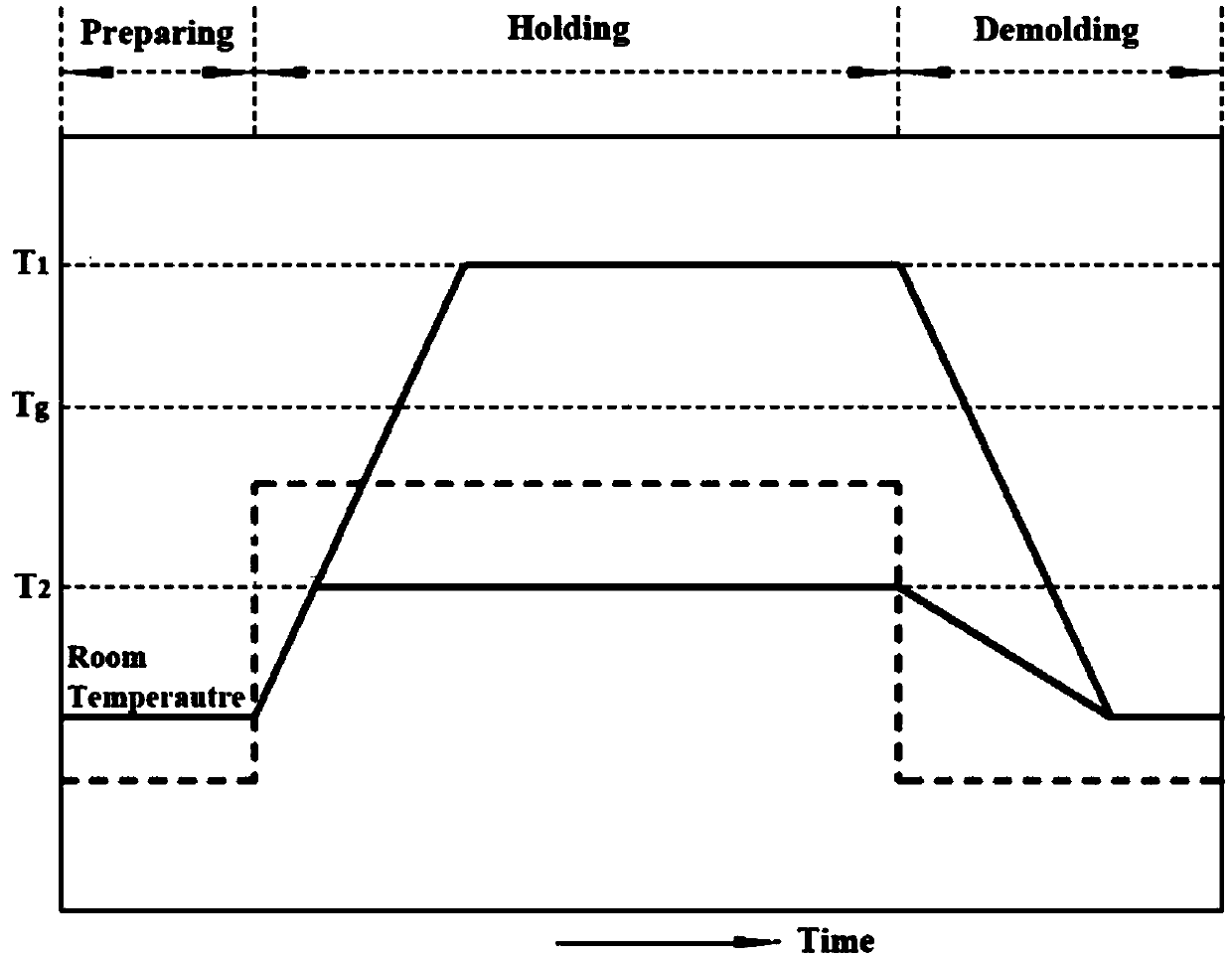

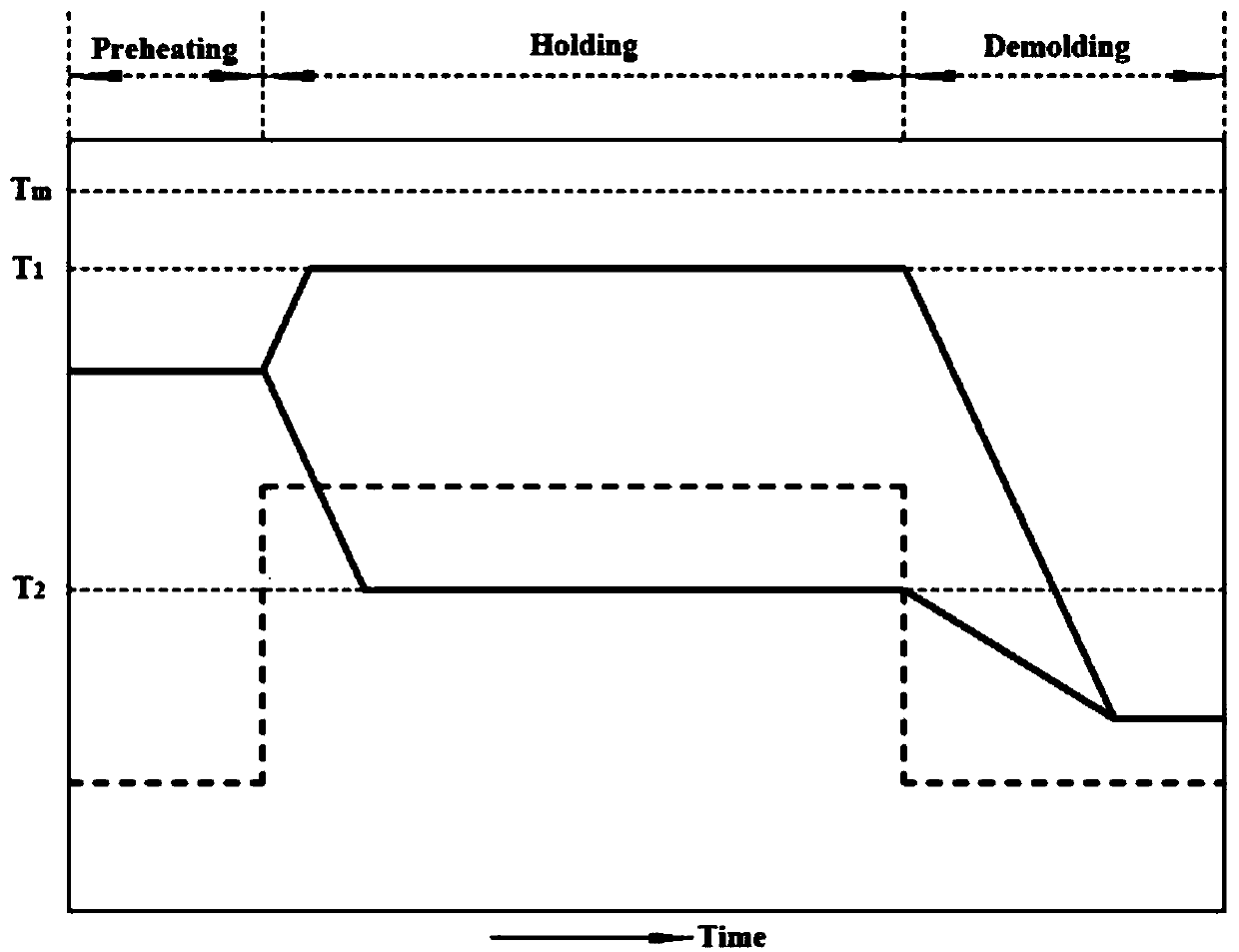

Rapid differential-temperature flat plate hot embossing process for polymer micro-nano structure

The invention discloses a rapid differential-temperature flat plate hot embossing process for a polymer micro-nano structure. The rapid differential-temperature flat plate hot embossing process is characterized in that temperature of a hot embossing mold is kept consistent in the whole embossing period, set temperatures of an upper half mold and a lower half mold are different, the aims of smooth mold filling and mold release of the micro-nano structure are achieved through the differential-temperature mode, and the rapid differential-temperature flat plate hot embossing process is particularly suitable for rapid hot embossing of a polymer product with the single-face micro-nano structure. The temperature of the side, provided with the micro-nano structure, of the mold is set as a higher value, and the side, not provided with the micro-nano structure, of the mold is set as a lower value. At the initial stage of hot embossing, the temperature of a polymer substrate making contact with the high-temperature half mold rapidly rises to a high temperature, and mold filing is completed; and at the pressure maintaining stage, the polymer substrate is cooled through the low-temperature half mold, the formed micro-nano structure is shaped, and demolding is facilitated. By means of the process, it is avoided that because the mold is repeatedly heated and cooled, energy is consumed, and meanwhile the forming period of hot embossing is remarkably shortened; controllability of the forming process is high, the forming precision is high, and the overall consistency is good; and the mold sticking phenomenon of the polymer product is obviously improved, and demolding defects are effectively avoided.

Owner:BEIJING UNIV OF CHEM TECH

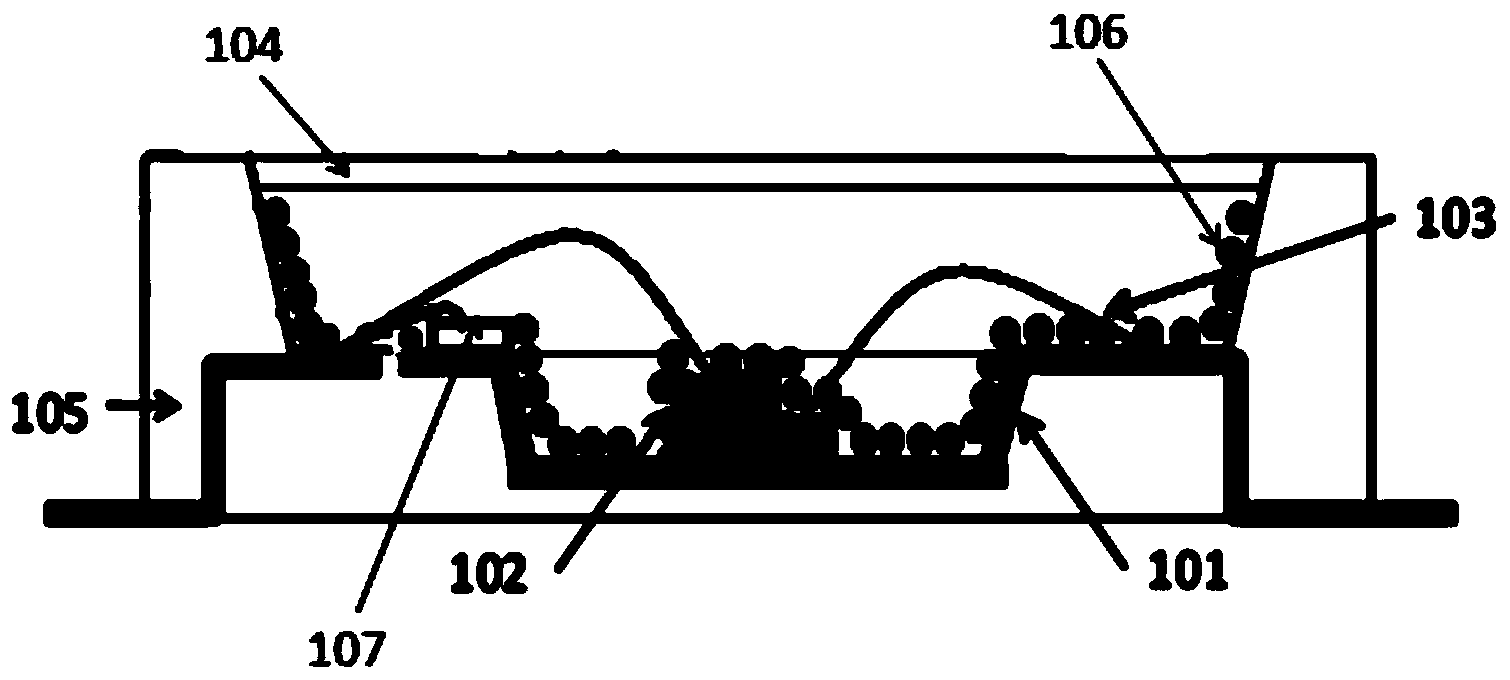

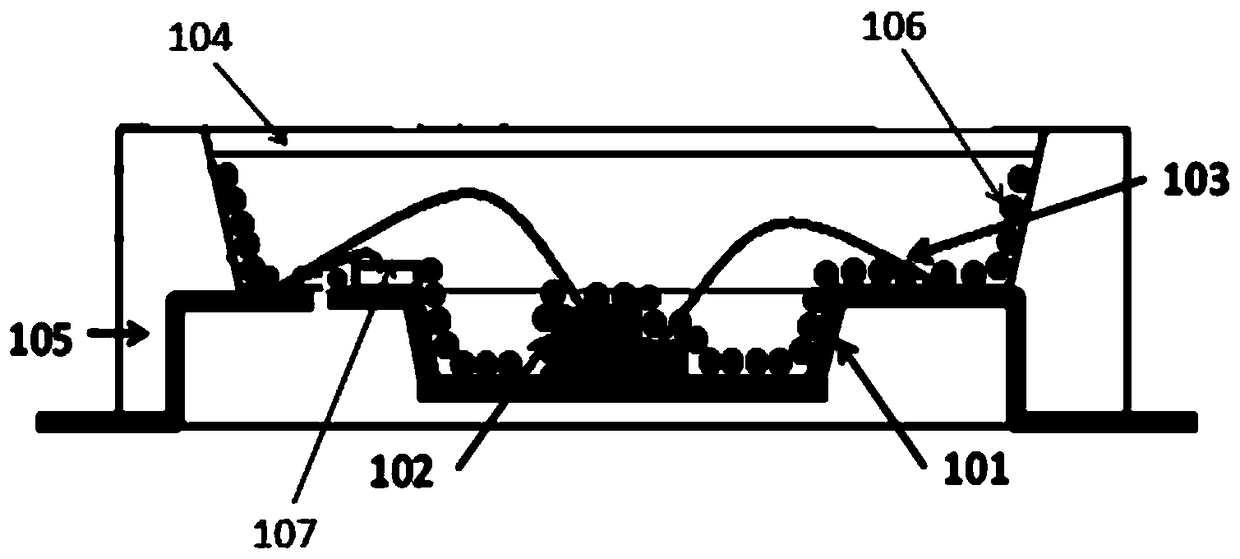

Light-emitting Element

InactiveCN104253192AEnhanced geometric stabilityImprove luminous efficiencySolid-state devicesSemiconductor devicesPhotonic crystalZener diode

A light-emitting element provided by the present invention comprises a light source body, a conducting wire rack, LED grains, a Zener diode, a light transmission layer and a photonic crystal film. The conducting wire rack is arranged at the bottom of the light source body, the LED grains are arranged above the conducting wire rack, and the light transmission layer is arranged above the light source body. At least one conducting wire is connected with the LED grains and the Zener diode electrically, the photonic crystal film is arranged on the surfaces of the LED grains and the inner surface of the light source body, and the luminous efficiency is increased by utilizing the characteristics of the photonic crystal film.

Owner:FENG CHIA UNIVERSITY

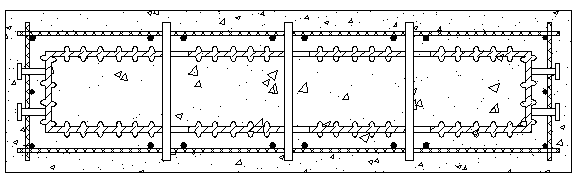

Horizontal connection structure of site-construction L-shaped shear wall with steel concrete combined pipes prefabricated in factory

InactiveCN108487478AHigh strengthImprove deformation resistanceWallsBuilding insulationsBarrel ShapedFireproofing

The invention provides a horizontal connection structure of a site-construction L-shaped shear wall with steel concrete combined pipes prefabricated in a factory. The horizontal connection structure comprises a first steel concrete combined pipe with the linear horizontal section and a second steel concrete combined pipe with the linear horizontal section. Multiple pouring penetrating holes are uniformly formed in the rear end face of a first rectangular barrel-shaped steel pipe and the front side face of the left end of a second rectangular barrel-shaped steel pipe from top to bottom. At least two penetrating reinforced holes corresponding to each pouring penetrating hole in a front and rear mode are formed in the rear side of the second rectangular barrel-shaped steel pipe. Site horizontal anchor ribs penetrate through the inside of the penetrating reinforced holes. The front ends of the site horizontal anchor ribs penetrate forward through the pouring penetrating holes and stretch into the first rectangular barrel-shaped steel pipe. The ductility and compressive strength of concrete are greatly improved, the plasticity and toughness properties of the whole steel concrete overlapped shear wall structure are greatly improved, and the non-deformability and compressive strength of the shear wall are greatly improved; meanwhile, the rectangular barrel-shaped steel pipes are package in the concrete so that the problems of fireproofing and corrosion protection of steel structure buildings are effectively solved.

Owner:HENAN LYUJIAN BUILDING TECH CO LTD

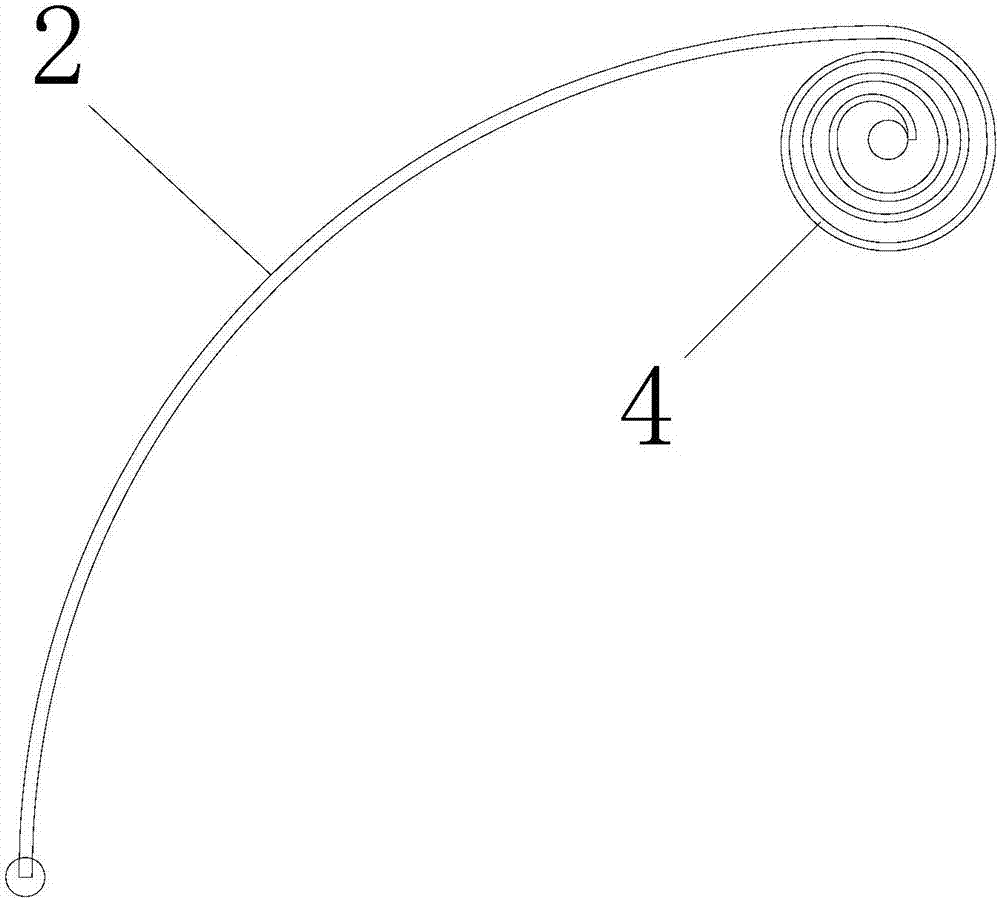

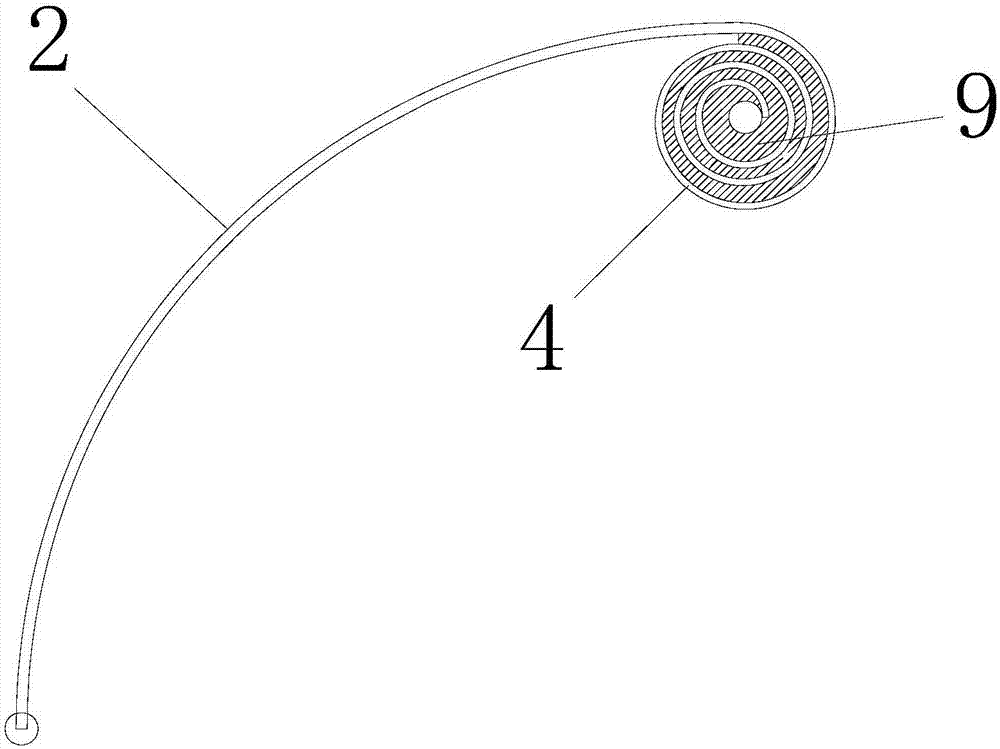

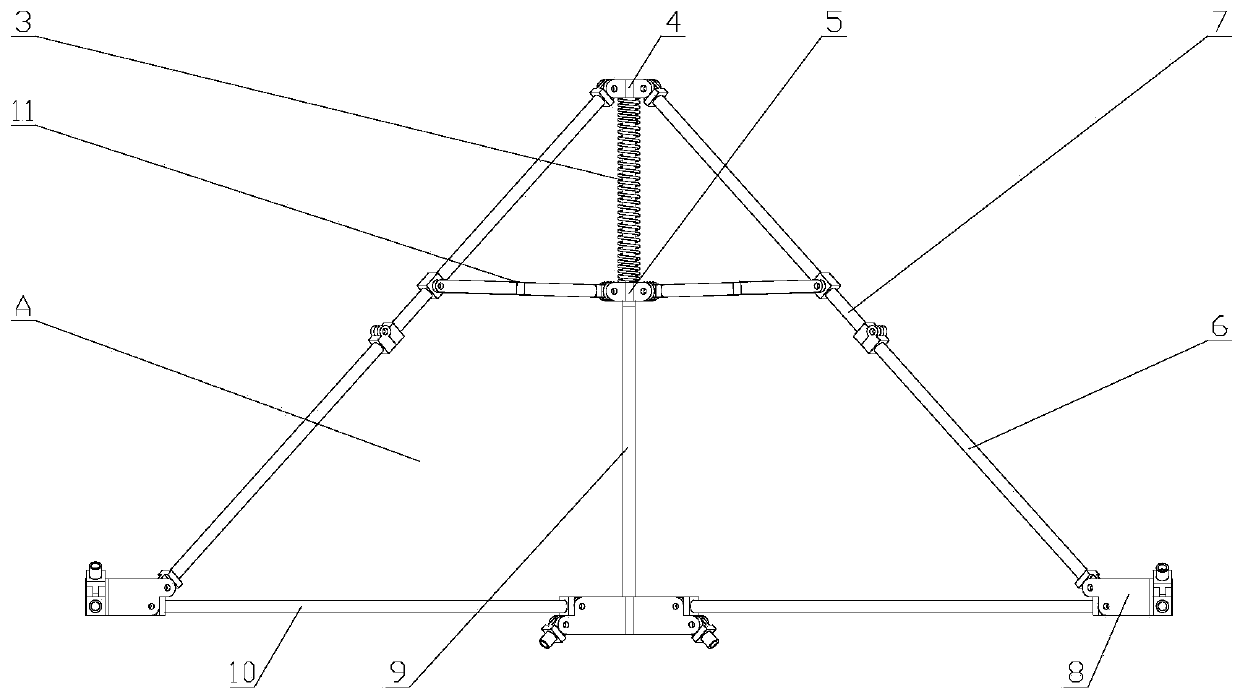

Sparrow brace imitating reinforcing structure for reinforcing wood structure joint and manufacturing method thereof

ActiveCN106948609AIncrease stiffnessImprove carrying capacityBuilding repairsEarthquake resistanceIndustrial engineering

The invention discloses a sparrow brace imitating reinforcing structure for reinforcing a wood structure joint and a manufacturing method thereof. The sparrow brace imitating reinforcing structure for reinforcing the wood structure joint comprises angle arm steel plates, a reinforcing connector and arc-shaped arch steel. The number of the angle arm steel plates is two. One ends of the two angle arm steel plates are hinged, and connecting lug plates are arranged at the other ends of the two angle arm steel plates correspondingly. The two angle arm steel plates are further provided with external connectors connected with the wood structure joint. A spiral-shaped spring portion is arranged at one end of the arc-shaped arch steel, and the spring portion and the other end of the arc-shaped arch steel are connected to the connecting lug plates of the two angle arm steel plates correspondingly. A reinforcing area is formed among the two angle arm steel plates and the arc-shaped arch steel. The reinforcing connector is located in the reinforcing area and fixedly connected with the two angle arm steel plates. The sparrow brace imitating reinforcing structure greatly improves the rigidity, bearing capacity and deformability of the wood structure joint and enhances the energy-dissipating capacity of the wood structure joint, thereby greatly improving the anti-seismic property of the wood structure joint.

Owner:SOUTH CHINA UNIV OF TECH

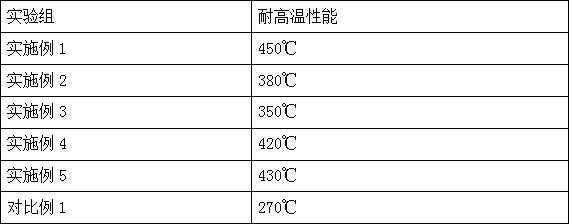

High-temperature-resistant release ink

InactiveCN110760216ANarrow particle size distributionSmall specific surface areaInksPolymer sciencePolymer chemistry

The invention provides high-temperature-resistant release ink. The high-temperature-resistant release ink is characterized by comprising the following components in parts by weight: 40 to 58 parts ofresin, 15 to 27 parts of solvent, 5 to 10 parts of curing agent, 3 to 5 parts of assistant and 12 to 33 parts of functional filler. The invention provides the ink which can resist to a high temperature and be easy to release in the forming process in the manufacture procedure of a mobile phone back cover. The high-temperature-resistant release ink can resist to a high temperature of over 300 DEG C, and is superior to existing similar products in the market.

Owner:惠州市韵点新材料科技股份有限公司

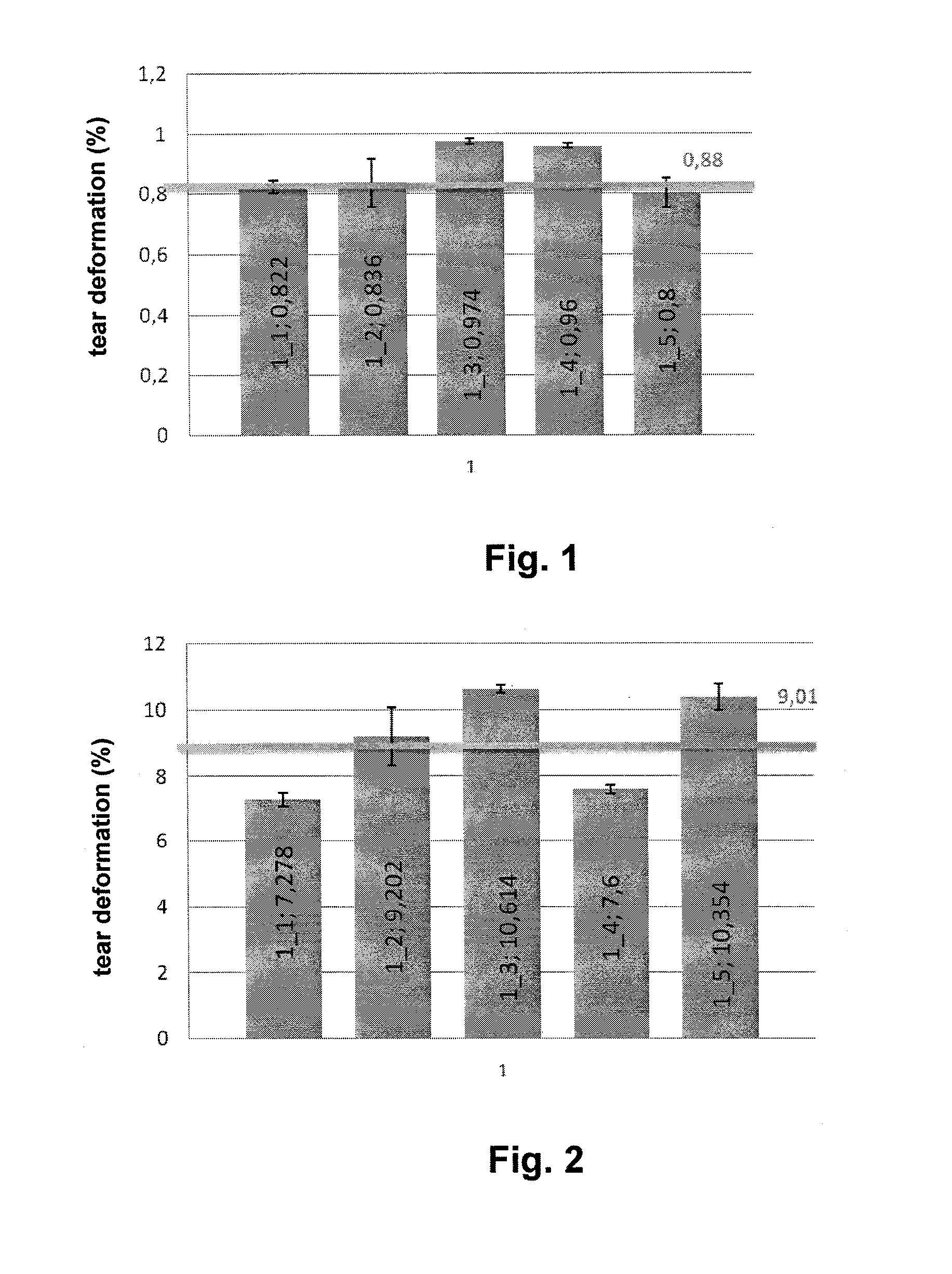

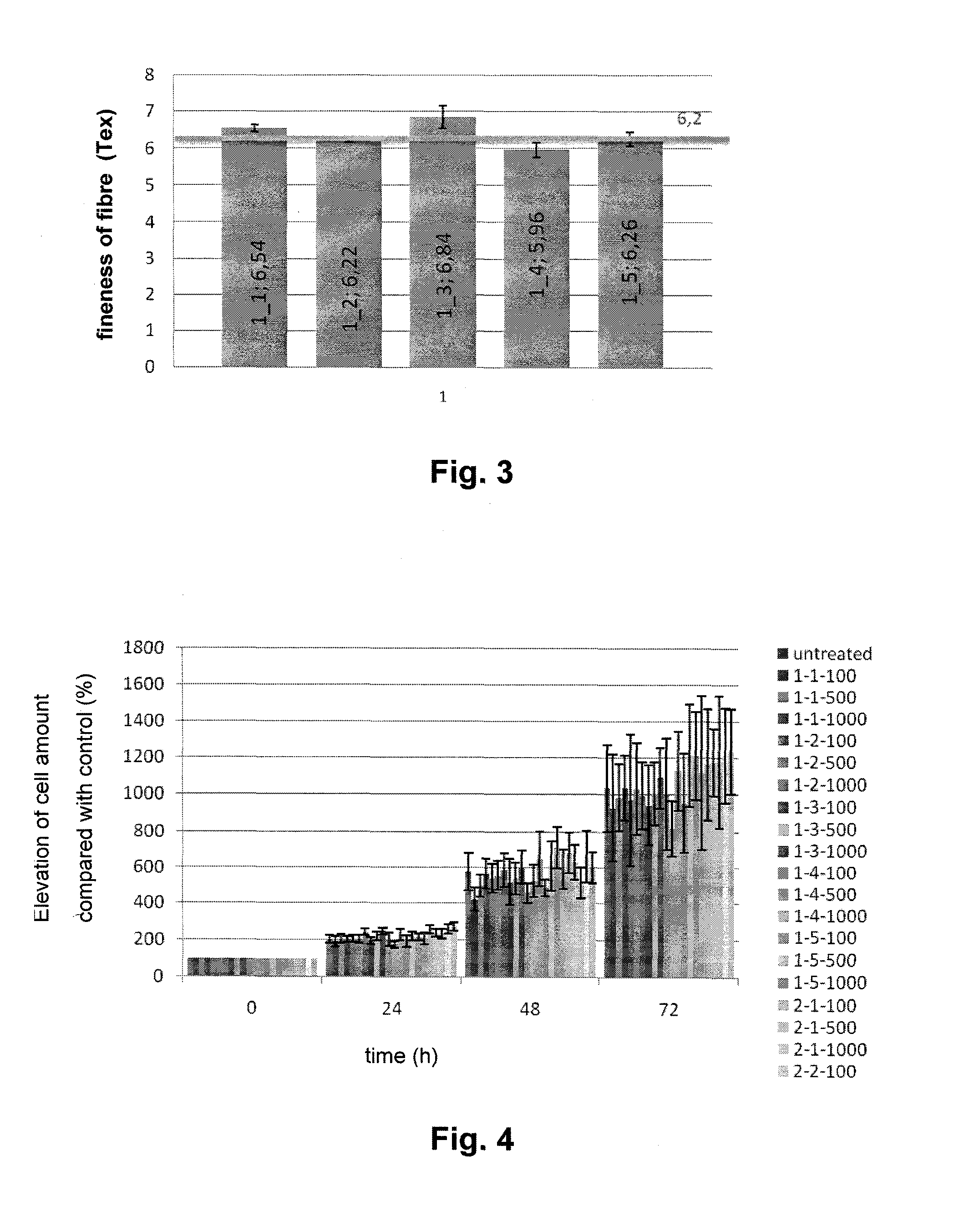

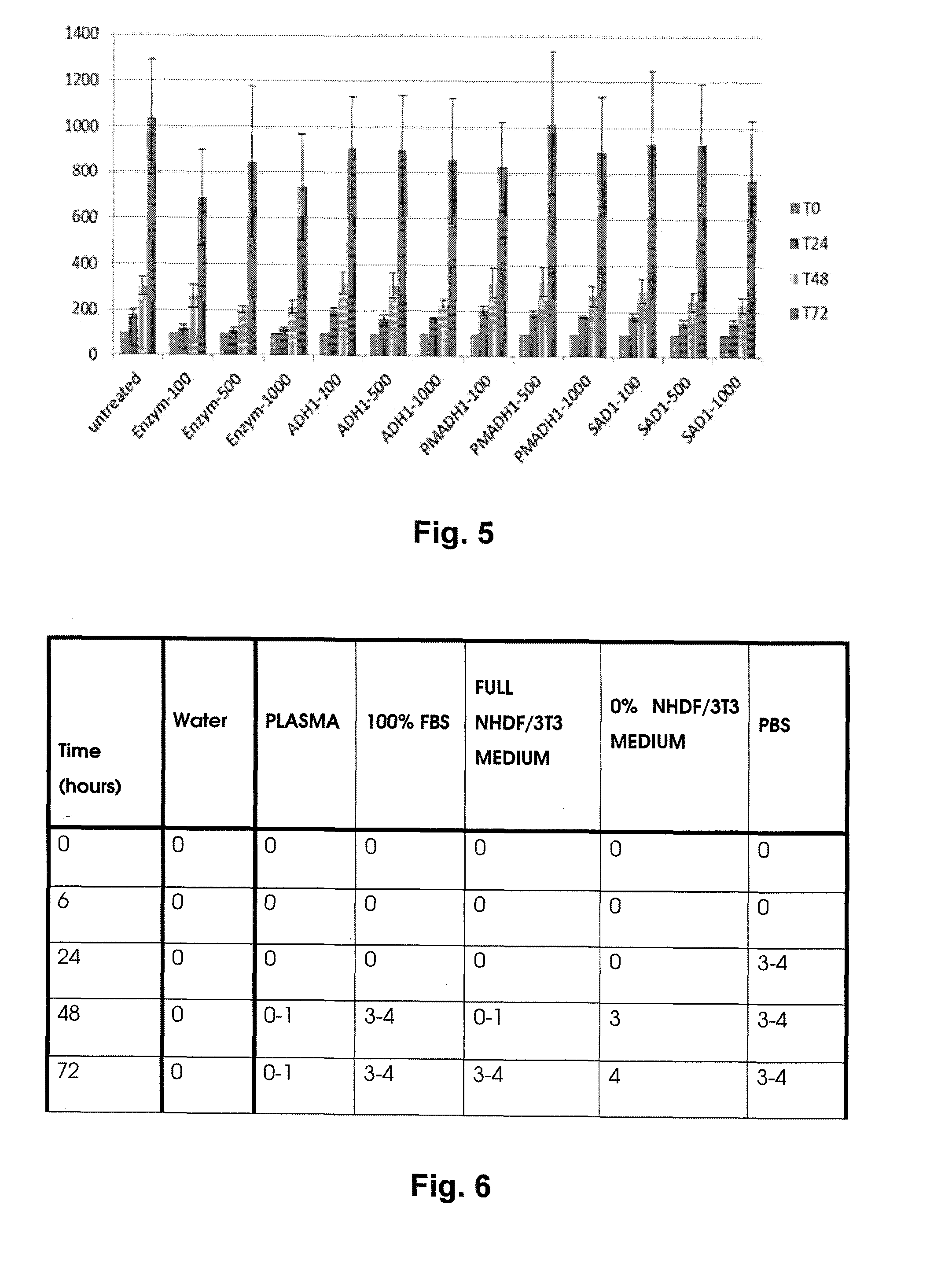

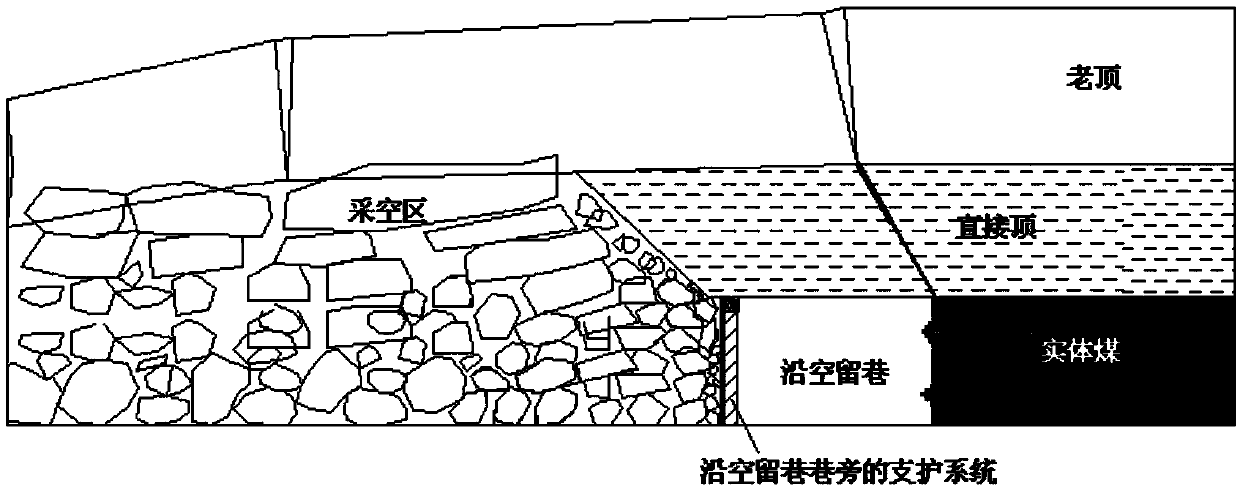

Endless Fibres on the Basis of Hyaluronan Selectively Oxidized in the Position 6 of the N-Acetyl-D-Glucosamine Group, Preparation and Use Thereof, Threads, Staples, Yarns, Fabrics Made Thereof and Method for Modifying the Same

InactiveUS20150299911A1Reduce adhesionExtended maintenance periodLayered productsWarp knittingFiberYarn

The present invention relates to the preparation of textile processable endless monofilaments and multifilaments on the basis of hyaluronan which has been selectively oxidized to aldehyde in the position 6 of its / V-acetyl-D-glucosamine group and to the subsequent modification of such filaments with low molecular dihydrazides. The fibres as well as the fabrics, which are subsequently prepared from the former, exhibit a time-varying solubility in saline depending on the external modification of the fibres. After having been externally modified, the fibres as well as the fabrics exhibit a prolong period of transition into an evenly distributed gel layer. The externally modified fibrous materials retain their full biocompatibility.

Owner:CONTIPRO AS

A roadside support system for gob-side entry retention and its construction method

ActiveCN106677804BHigh compressive strengthEnhanced geometric stabilityUnderground chambersTunnel liningSupporting systemGeometric stability

Owner:SHANDONG JIANZHU UNIV

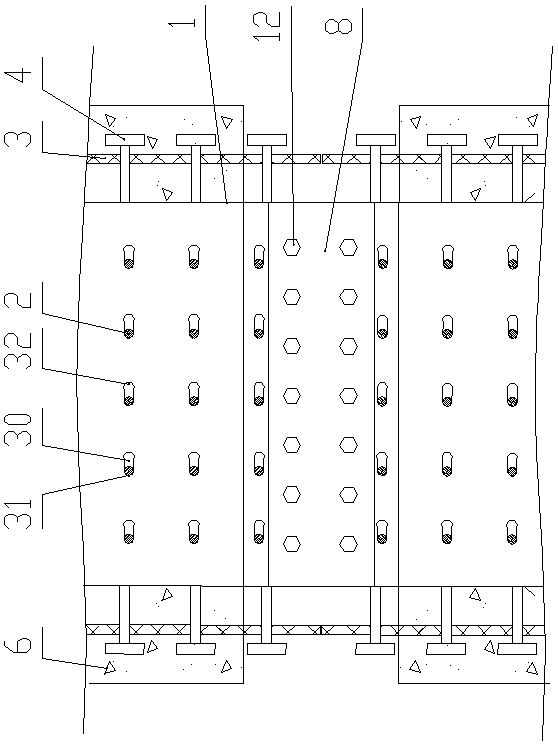

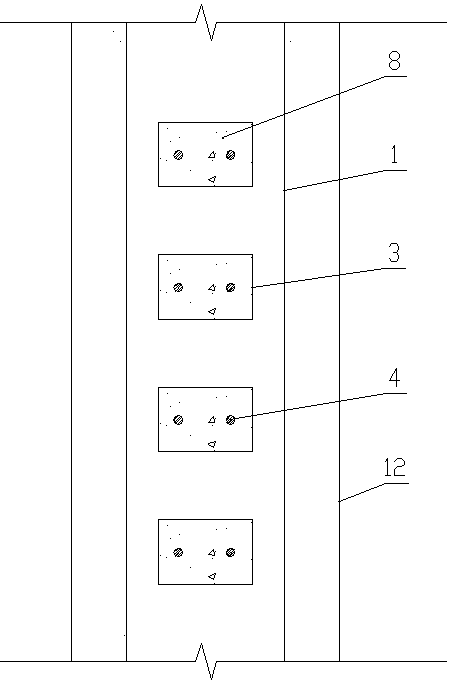

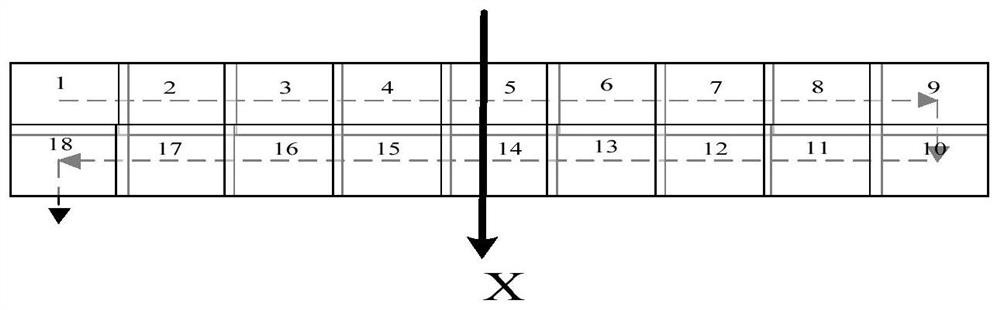

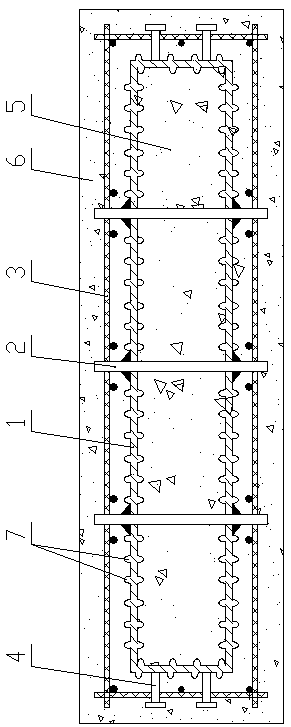

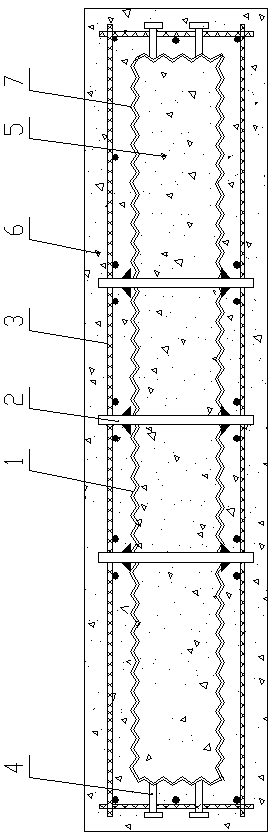

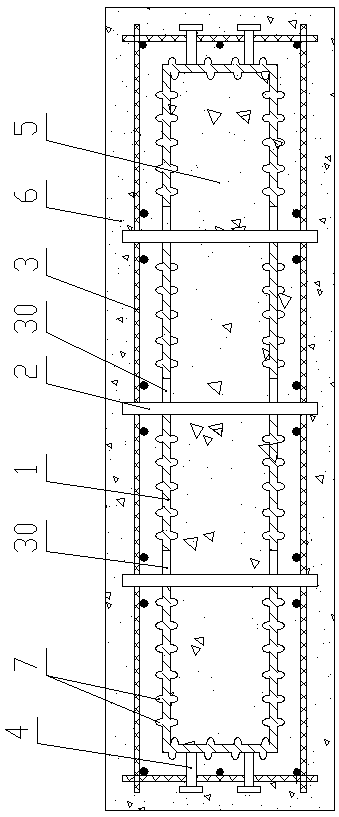

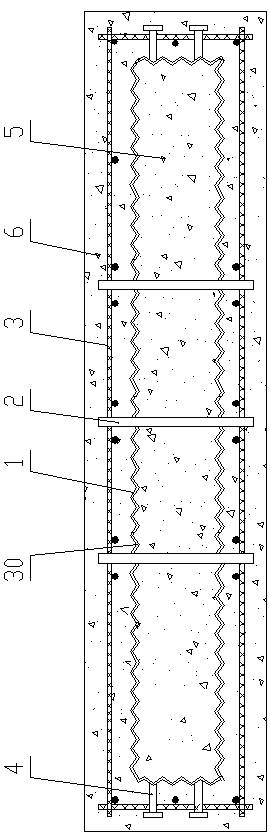

Factory prefabricated steel concrete combination pipe making technology

ActiveCN108466018AHigh tensile strengthHigh compressive strengthLoad-supporting elementsRebarMouth shape

The invention discloses a factory prefabricated steel concrete combination pipe making technology. The technology comprises following steps: firstly, according to the construction drawing need, the number and the related sizes of steel concrete combination pipes with multiple cross sections of the rectangular structures are designed; secondly, according to the drawing need, the steel concrete combination pipes are prefabricated in the factory in a segmented manner; thirdly, the steel concrete combination pipes are connected to form straight-line-shaped, the leftwards-rotated-T-shaped, an inverted-L-shaped, crossed or mouth-shaped structures. Inner concrete, outer concrete and reinforcing meshes are combined with a steel plate with the inner side with ribs to form a whole steel concrete combination shear wall through binding bars, joint work is achieved, ductility and compressive strength of the concrete are greatly improved, plasticity and toughness of the whole steel concrete combinedshear wall structure are greatly improved, the anti-deforming capacity and the anti-pressing strength of the shear wall are greatly improved, and meanwhile, due to the fact that the steel plate withthe ribs is wrapped by the concrete, the fireproof anti-corrosion aims of the steel structure building can be effectively achieved.

Owner:HENAN LYUJIAN BUILDING TECH CO LTD

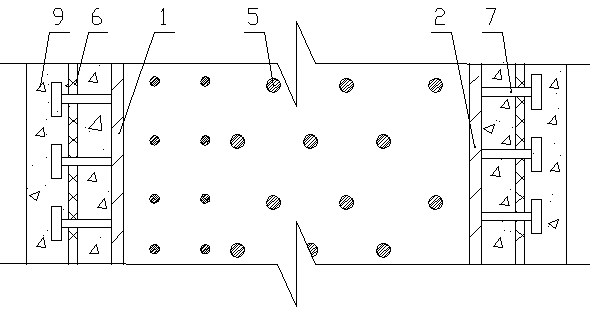

End reinforcing type steel-concrete composite pipe

InactiveCN108487545AHigh tensile strengthHigh compressive strengthWallsLoad-supporting elementsSheet steelRebar

An end reinforcing type steel-concrete composite pipe comprises an up-down through rectangular cylindrical structure which is defined by inner side steel plates, outer side steel plates, left reinforcing profile steel and right reinforcing profile steel. A plurality of tie bars are arranged between the inner side steel plates and the outer side steel plates, the inner ends and the outer ends of the tie bars extend out of the inner side steel plates and the outer side steel plates towards the two sides correspondingly, a steel bar skeleton with the cross section being of a rectangular structureis arranged on the periphery of the outer portion of the rectangular cylindrical structure, gaps are formed between the steel bar skeleton and the rectangular cylindrical structure, concrete is poured on the periphery of the outer portion of the rectangular cylindrical structure, and thus the steel bar skeleton is coagulated. According to the end reinforcing type steel-concrete composite pipe, the construction efficiency is improved, the ductility and compressive strength of the concrete are greatly improved, the plasticity and toughness performance of a whole steel-concrete composite shear wall structure is greatly improved, the anti-deformation ability and compressive strength of a shear wall are greatly improved, and the fireproof and anticorrosion problems are also solved effectively.

Owner:HENAN LYUJIAN BUILDING TECH CO LTD

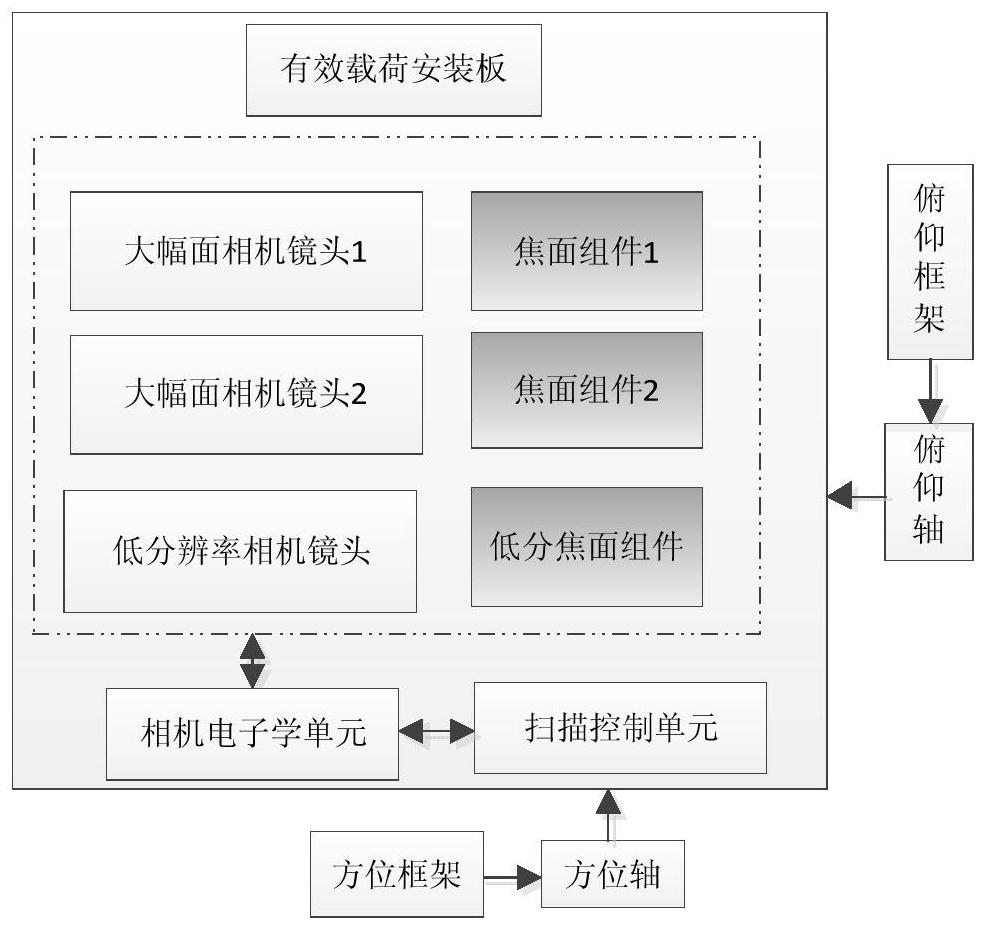

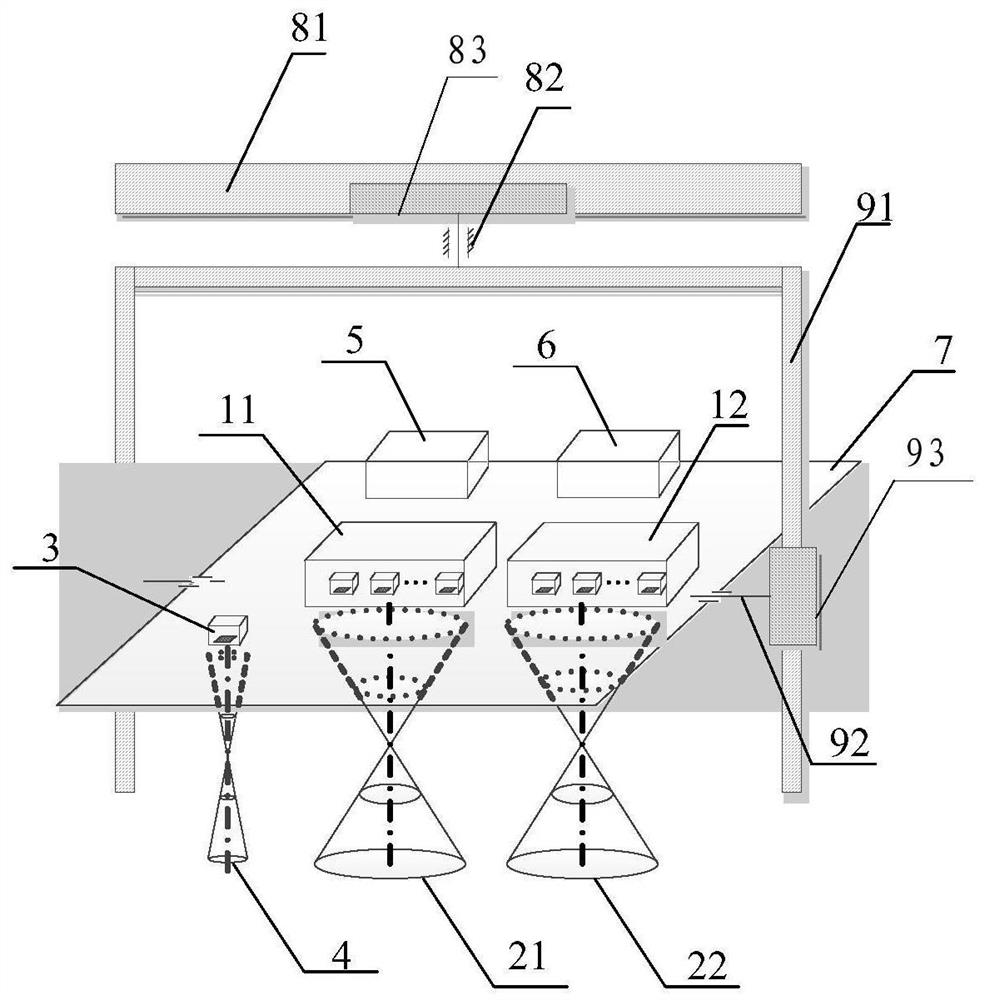

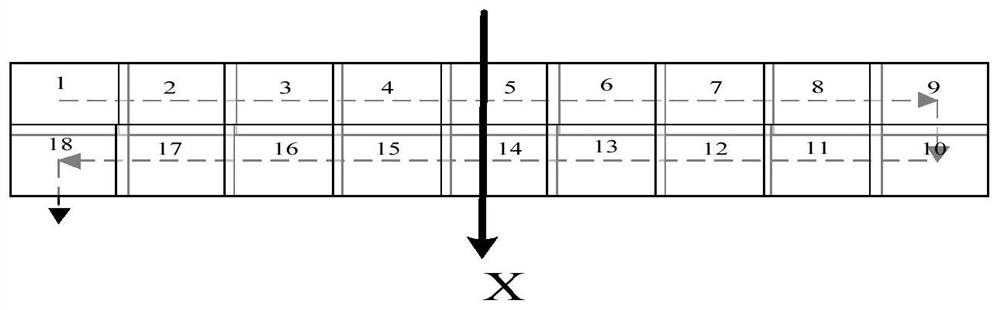

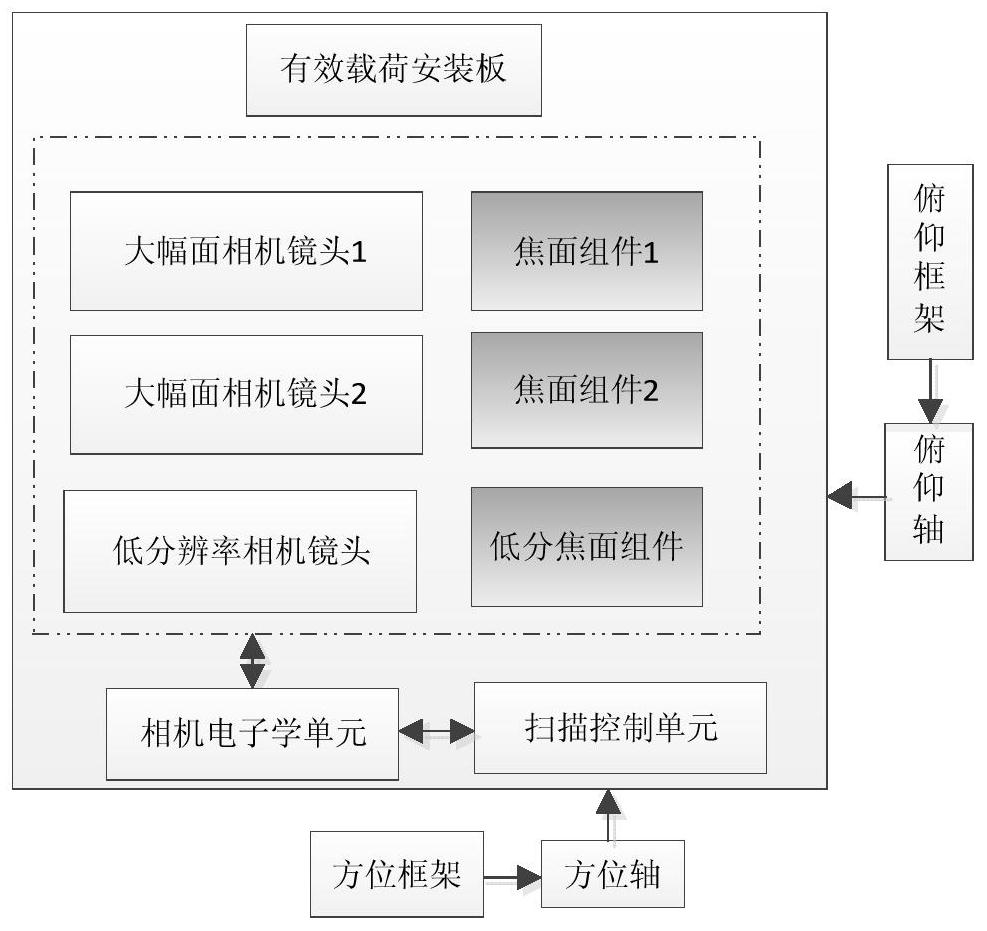

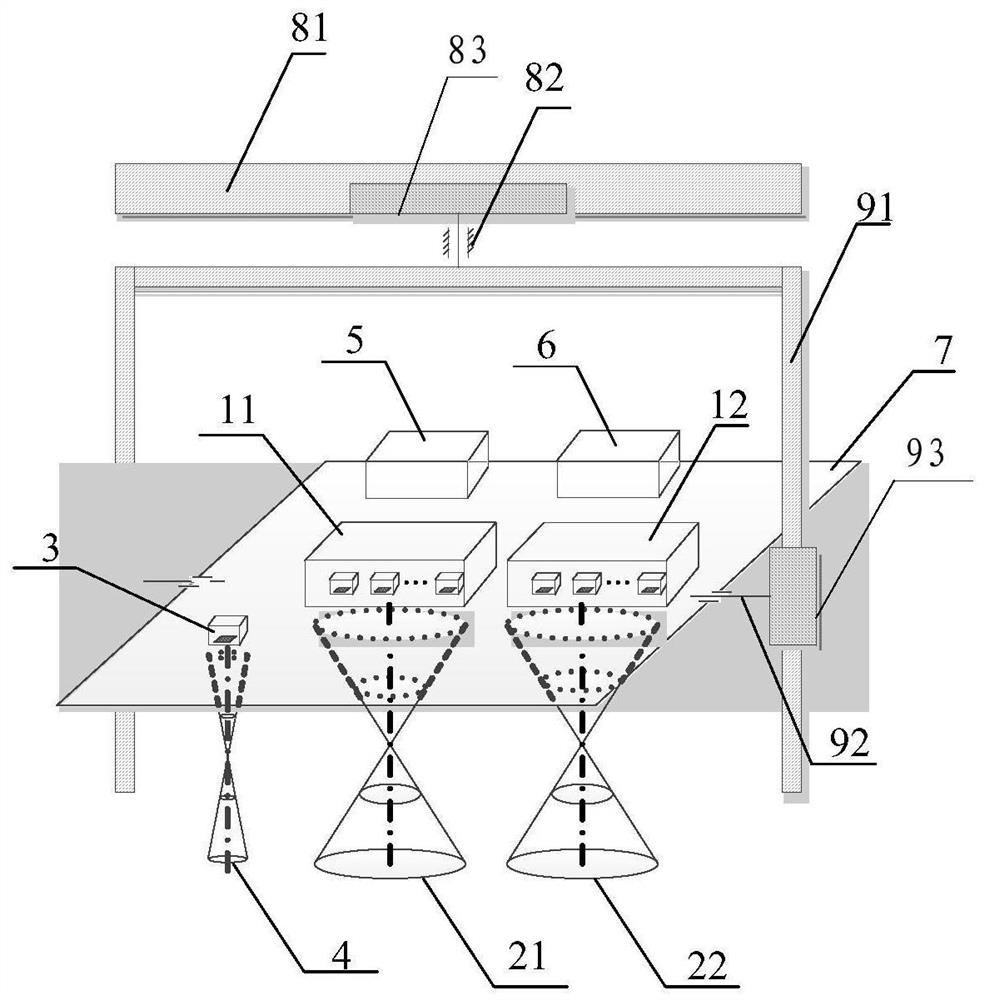

Field-of-view spliced large-format camera system

ActiveCN112040097ALarge side view angleImprove work efficiencyTelevision system detailsColor television detailsCamera lensComputer graphics (images)

The invention discloses a field-of-view spliced large-format camera system. The system comprises a first focal plane assembly, a second focal plane assembly, a first large-format camera lens, a secondlarge-format camera lens, a low-resolution camera focal plane assembly, a low-resolution camera lens, a camera electronics unit, a scanning control unit, a payload mounting plate, an azimuth frame, an azimuth driving mechanism, an azimuth axis, a pitching frame, a pitching driving mechanism and a pitching axis. In the invention, an external view field splicing mode and a two-dimensional scanningmechanism are combined to realize large-format imaging.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Manufacturing method of factory prefabricated steel-concrete combined pipes

ActiveCN108466016AHigh strengthImprove deformation resistanceLoad-supporting elementsRebarCompressive strength

A manufacturing method of factory prefabricated steel-concrete combined pipes comprises the following steps that (1) the number and relevant sizes of multiple steel-concrete combined pipes with crosssections of rectangular structures are designed according to the requirements of a construction drawing; (2) the steel-concrete combined pipes are prefabricated in a factory in a segmented manner according to the drawing requirements; and (3) after the steel-concrete combined pipes are connected, I-shaped structures or T-shaped structures or L-shaped structures or cross-shaped structures or squarestructures are formed. In the manufacturing method, inner concrete, outer concrete, steel bar net pieces and steel plates with ribs on the inner sides form an overall steel-concrete combined shear wall through tie bars to work together, and therefore the ductility and compressive strength of the concrete are greatly improved, the practicality and toughness properties of the structure of the overall steel-concrete combined shear wall are greatly improved, and the anti-deformation capacity and compressive strength of the shear wall are greatly improved; and meanwhile, due to the fact that the steel plates with the ribs are wrapped in the concrete, the problems of fire prevention and corrosion prevention of a steel structure building are effectively solved.

Owner:HENAN LYUJIAN BUILDING TECH CO LTD

Factory prefabricated steel-concrete composite shear wall field installation vertical connection structure

InactiveCN108487475ASimplify the construction processImprove integrityWallsBuilding insulationsEngineeringUltimate tensile strength

The invention discloses a factory prefabricated steel-concrete composite shear wall field installation vertical connection structure. The factory prefabricated steel-concrete composite shear wall field installation vertical connection structure comprises a plurality of vertical post-insertion anchoring ribs, a plurality of upper welding anchorage plates, a plurality of lower welding anchorage plates and a plurality of connecting anchorage plates. The upper portions of the connecting anchorage plates are connected with the upper welding anchorage plates through upper connecting bolts in a fastening mode, the lower portions of the connecting anchorage plates are connected with the lower welding anchorage plates through lower connecting bolts in a fastening mode, and the vertical post-insertion anchoring ribs are vertically arranged in a steel-concrete composite pipe. The factory prefabricated steel-concrete composite shear wall field installation vertical connection structure greatly improves the plasticity and toughness of the overall steel-concrete composite shear structure, greatly improves the deformation resistance and compressive strength of the shear wall, and the vertical joint structure is wrapped in concrete, attractiveness is achieved, connection strength is high, stability is high, and dislocation is not prone to being generated.

Owner:HENAN LYUJIAN BUILDING TECH CO LTD

Manufacturing method of factory prefabricated steel concrete composite pipe

ActiveCN108466016BHigh strengthImprove deformation resistanceLoad-supporting elementsRebarFire prevention

A manufacturing method of factory prefabricated steel-concrete combined pipes comprises the following steps that (1) the number and relevant sizes of multiple steel-concrete combined pipes with crosssections of rectangular structures are designed according to the requirements of a construction drawing; (2) the steel-concrete combined pipes are prefabricated in a factory in a segmented manner according to the drawing requirements; and (3) after the steel-concrete combined pipes are connected, I-shaped structures or T-shaped structures or L-shaped structures or cross-shaped structures or squarestructures are formed. In the manufacturing method, inner concrete, outer concrete, steel bar net pieces and steel plates with ribs on the inner sides form an overall steel-concrete combined shear wall through tie bars to work together, and therefore the ductility and compressive strength of the concrete are greatly improved, the practicality and toughness properties of the structure of the overall steel-concrete combined shear wall are greatly improved, and the anti-deformation capacity and compressive strength of the shear wall are greatly improved; and meanwhile, due to the fact that the steel plates with the ribs are wrapped in the concrete, the problems of fire prevention and corrosion prevention of a steel structure building are effectively solved.

Owner:HENAN LYUJIAN BUILDING TECH CO LTD

Light emitting element

InactiveCN104253192BEnhanced geometric stabilityImprove luminous efficiencySolid-state devicesSemiconductor devicesPhotonic crystalZener diode

The invention provides a light-emitting element, comprising: a light source body, a lead frame, an LED crystal grain, a Zener diode, a light-transmitting layer, and a photonic crystal film. The lead frame is placed at the bottom of the light source body, the LED die is placed above the lead frame, the light-transmitting layer is placed above the light source body, and at least one wire is electrically connected to the LED die and the Zener diode , The photonic crystal film is placed on the surface of the LED die and the inner surface of the light source body, and the characteristics of the photonic crystal film are used to increase the luminous efficiency.

Owner:FENG CHIA UNIVERSITY

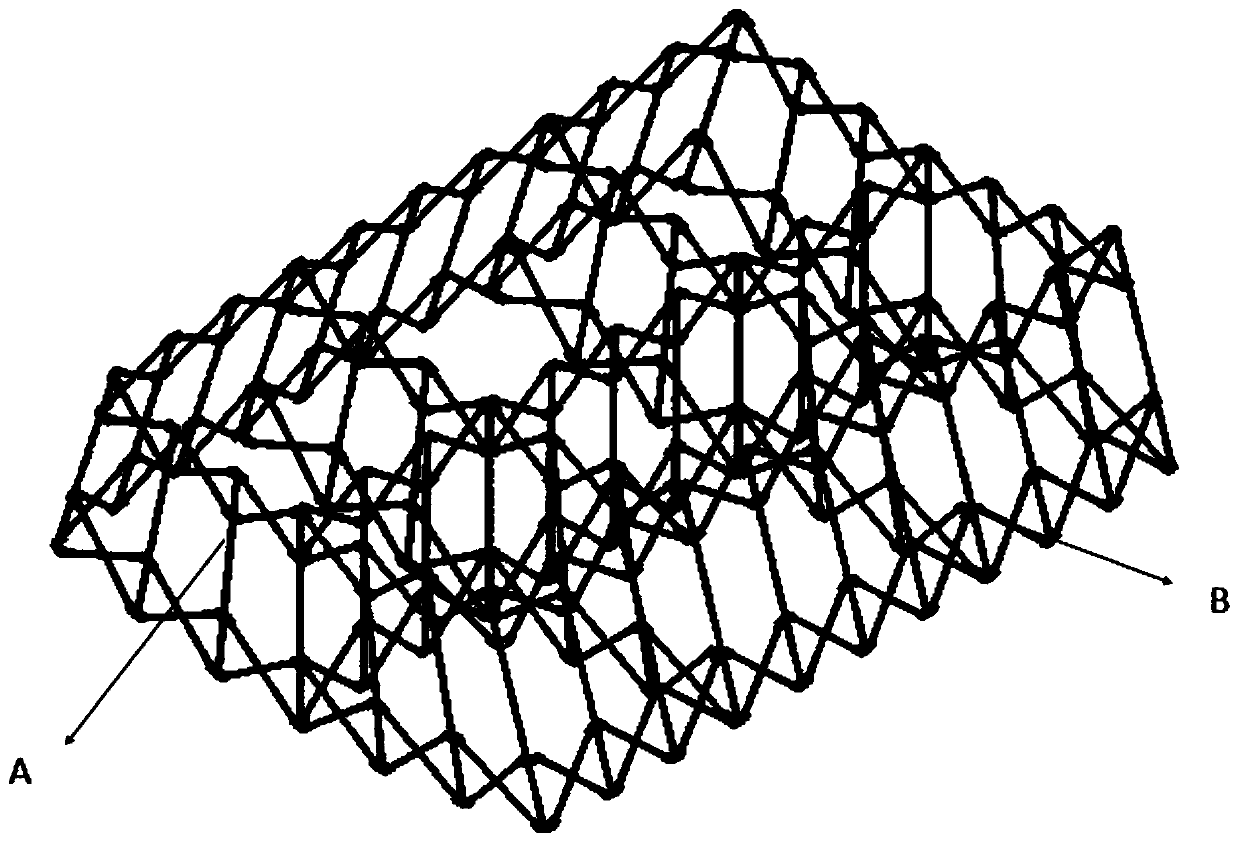

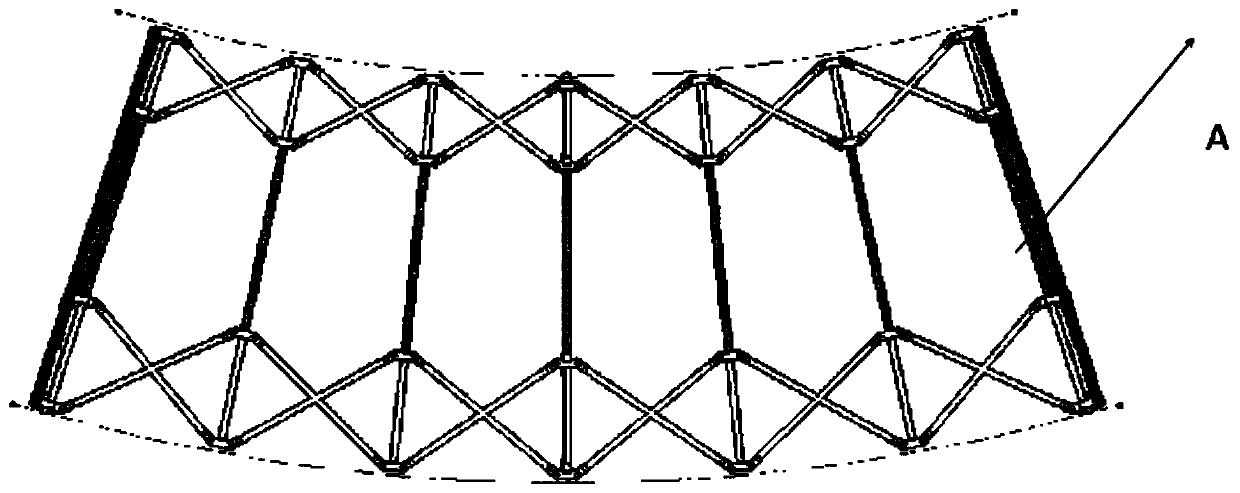

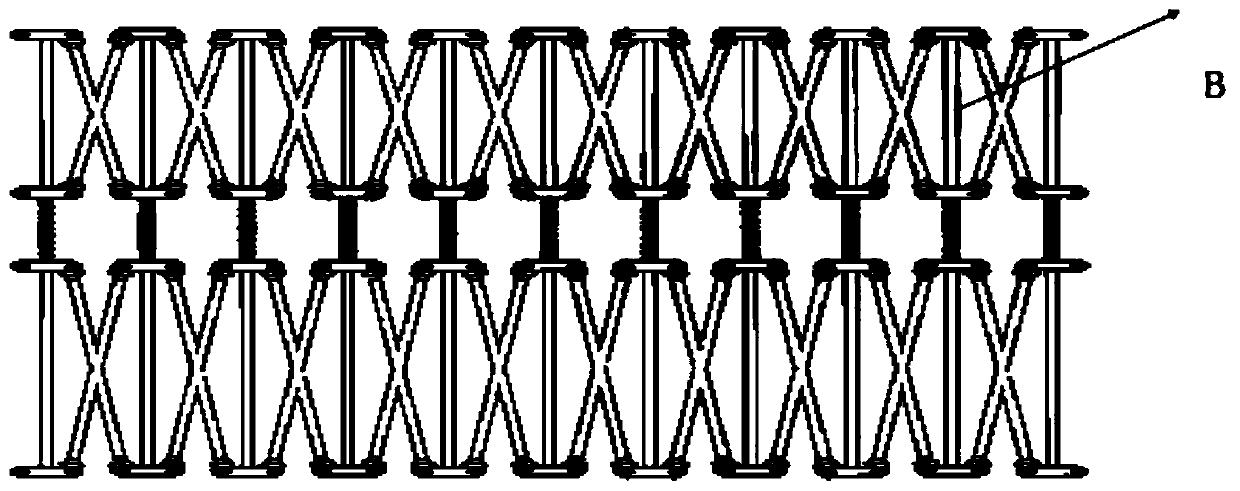

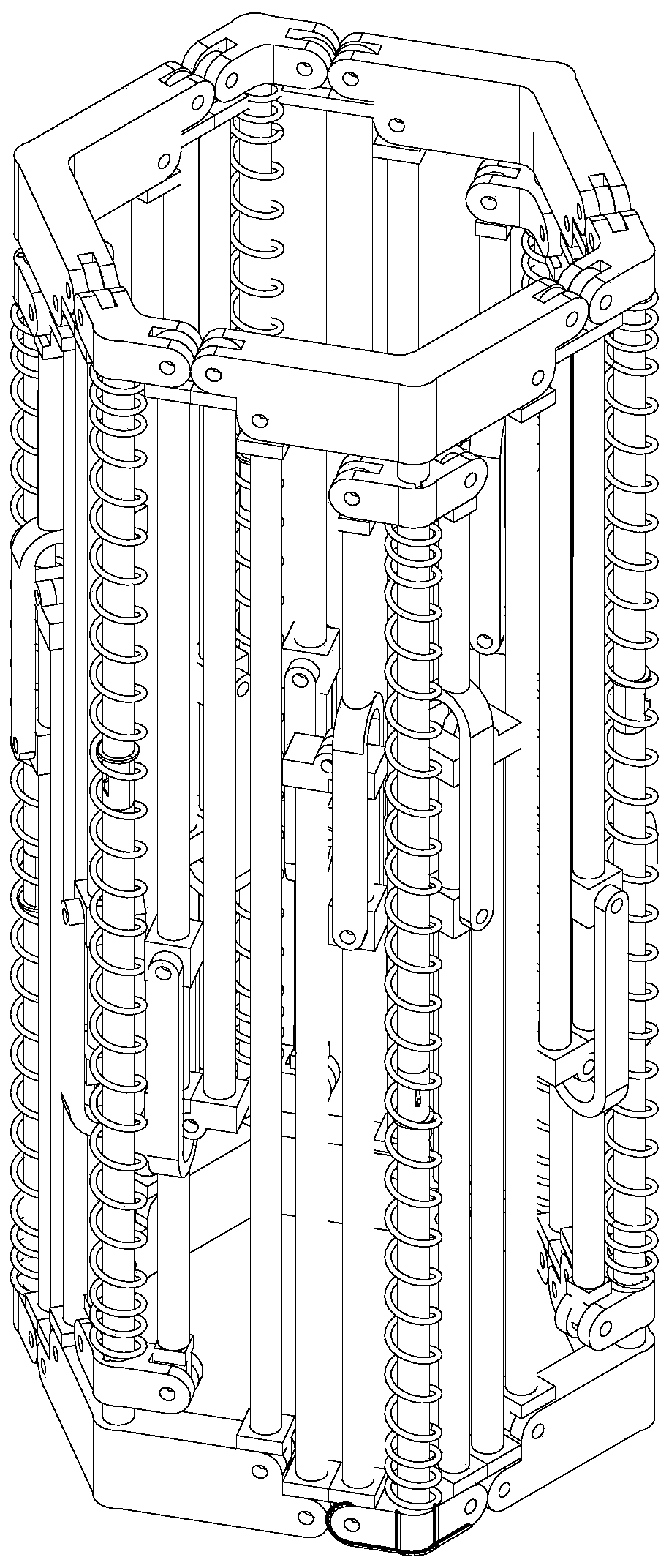

A Double Layer Scissor Parabolic Cylindrical Deployable Truss Antenna Device

ActiveCN108649314BMeet the use requirementsSimple structureCollapsable antennas meansAntenna adaptation in movable bodiesControl systemStructural engineering

Owner:XIDIAN UNIV +1

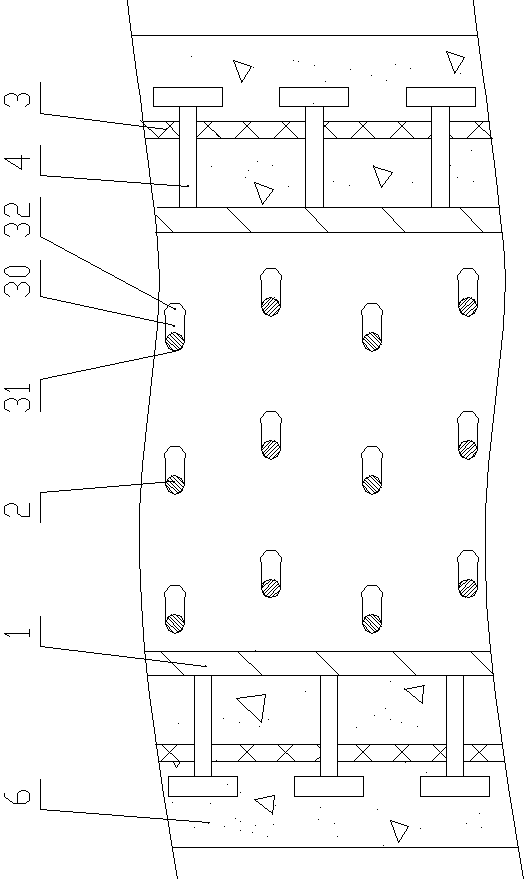

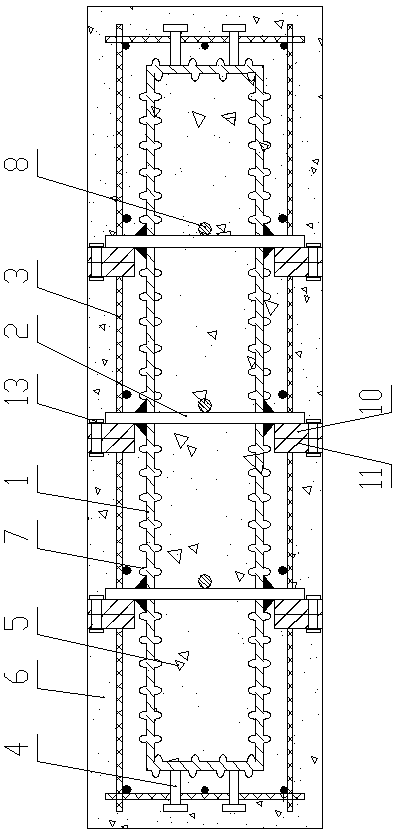

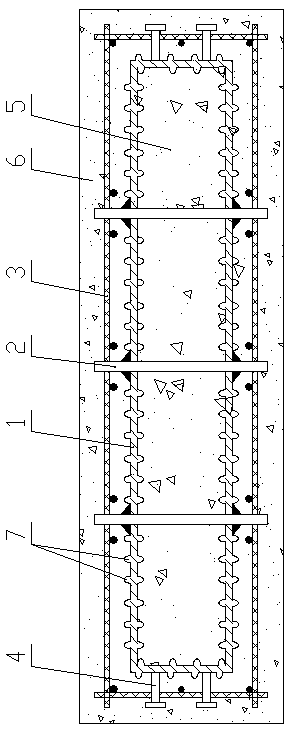

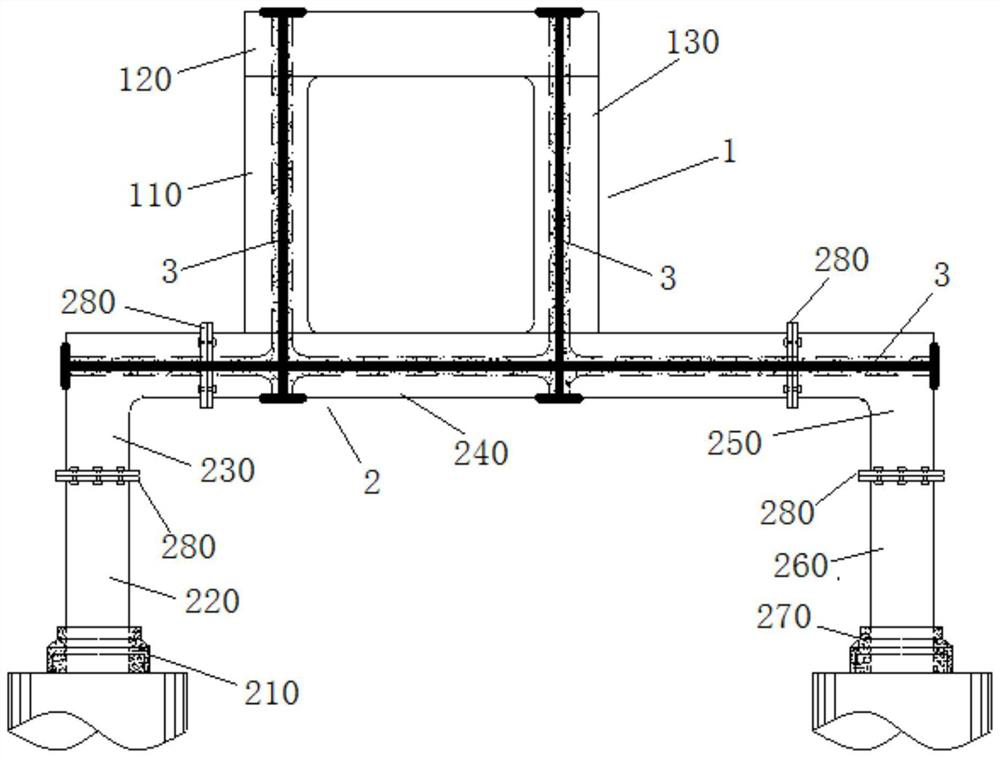

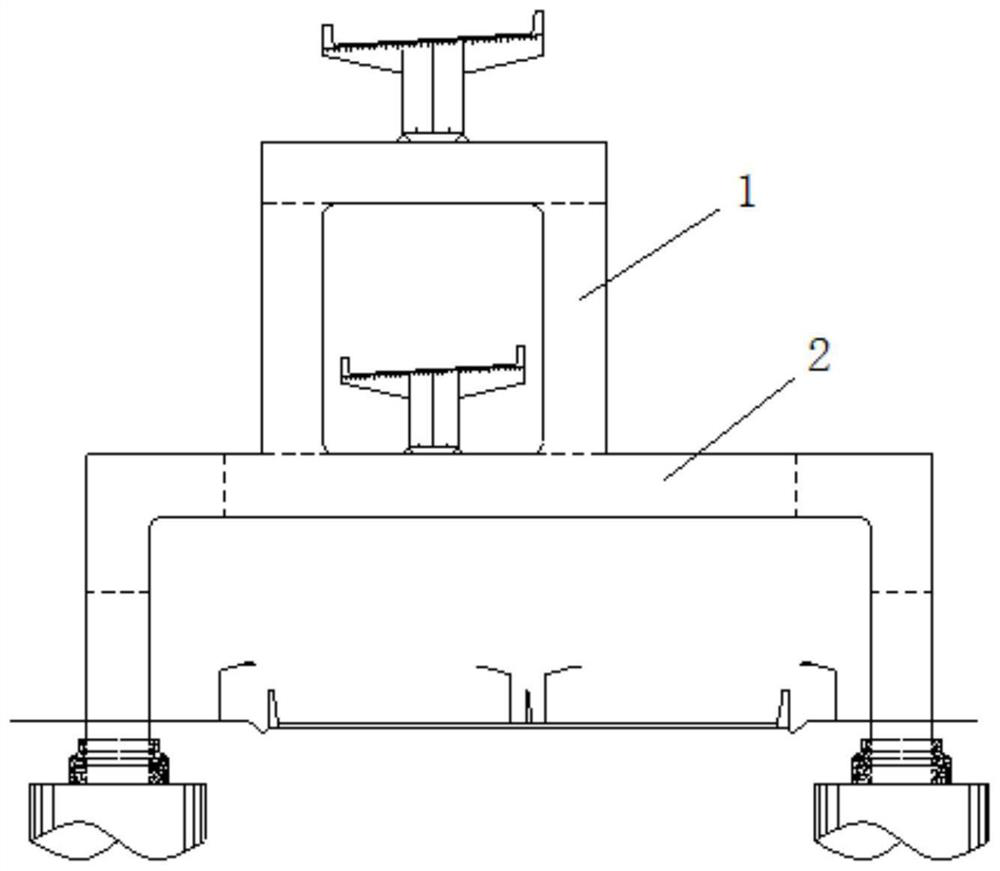

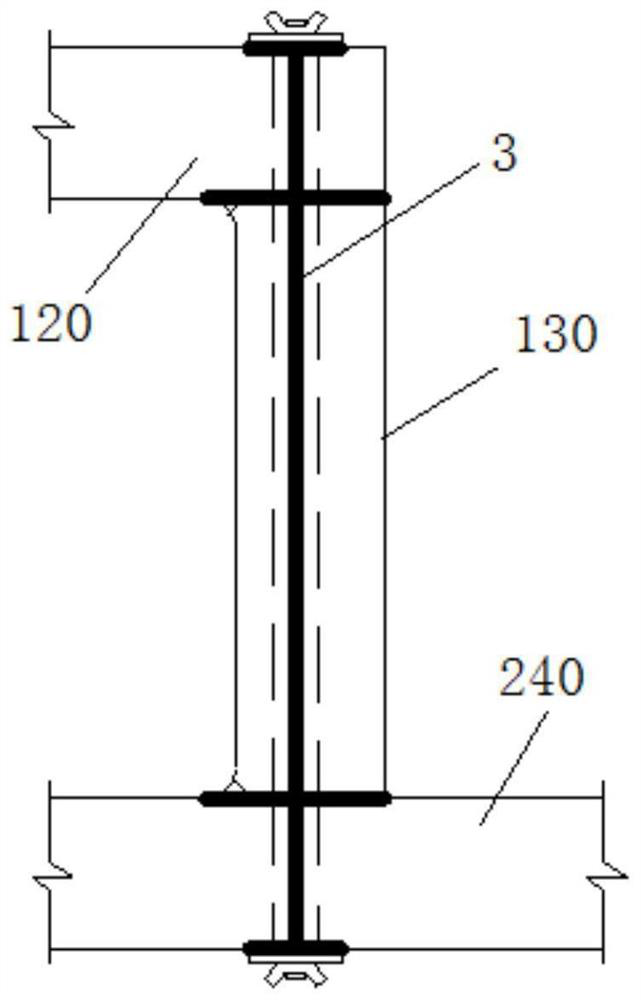

Fabricated concrete-filled steel tube double-layer gate-type pier structure

ActiveCN113356024AImprove efficiencyLower Lifetime CostsBridge structural detailsPre stressArchitectural engineering

The invention relates to a fabricated concrete-filled steel tube double-layer gate-type pier structure which comprises an upper-layer gate-type pier and a lower-layer gate-type pier, and the upper-layer gate-type pier and the lower-layer gate-type pier are compositely connected through welding and post-tensioned prestressed reinforcements. The fabricated concrete-filled steel tube double-layer gate-type pier structure has the advantages that the double-layer gate-type pier is a structure which is composed of the double-layer stand columns and the cover beams, loads are transmitted to a foundation, under the background that urban land is increasingly strained, the double-layer gate-type pier provides a mode for building a double-layer bridge, the requirements for the line shape and the gradient in road design can be effectively met, the use efficiency of urban traffic is improved as much as possible in a limited urban space, the contradiction between urban land resources and traffic construction is relieved, and the method becomes the trend of urban bridge development.

Owner:WUHAN UNIV OF TECH

Factory prefabricated steel-concrete composite pipe site construction linear-shaped shear wall horizontal connecting structure

InactiveCN108487477AHigh strengthImprove deformation resistanceWallsBuilding insulationsEngineeringUltimate tensile strength

A factory prefabricated steel-concrete composite pipe site construction linear-shaped shear wall horizontal connecting structure is characterized in that the factory prefabricated steel-concrete composite pipe site construction linear-shaped shear wall horizontal connecting structure comprises a first rectangular cylindrical steel pipe and a second rectangular cylindrical steel pipe, wherein the horizontal sections of both the first rectangular cylindrical steel pipe and the second rectangular cylindrical steel pipe are each in a linear shape; the length directions of both the first rectangular cylindrical steel pipe and the second rectangular cylindrical steel pipe are arranged in the left-right direction; the left ends and the right ends of site horizontal anchorage ribs are welded to orbound with first prefabricated tie bars and second prefabricated tie bars into wholes correspondingly; and inner concrete is poured into the first rectangular cylindrical steel pipe and the second rectangular cylindrical steel pipe. The factory prefabricated steel-concrete composite pipe site construction linear-shaped shear wall horizontal connecting structure is prefabricated in a factory and mounted on site, the convenient and fast effects are achieved, the ductility and compressive strength of the concrete are greatly improved, the plasticity and toughness properties of a whole steel-concrete laminated shear wall structure are greatly improved, the anti-deformation ability and compressive strength of a shear wall are greatly improved, and meanwhile, due to the fact that rectangular cylindrical steel plates are wrapped with the concrete, the fireproof and anticorrosion problems of a steel structure building are also effectively solved.

Owner:HENAN LYUJIAN BUILDING TECH CO LTD

Rigid-flexible combination gob-side entry retaining method and rigid-flexible combination gob-side entry retaining device by aid of roadside supports

ActiveCN103291319BHigh compressive strengthImprove stress resistanceUnderground chambersTunnel liningMechanical engineeringIndustrial engineering

Owner:SHANDONG UNIV OF SCI & TECH

A Large Format Camera System with Field of View Stitching

ActiveCN112040097BLarge side view angleImprove work efficiencyTelevision system detailsColor television detailsCamera lensImage resolution

The invention discloses a large-format camera system with field-of-view splicing, comprising: a first focal plane component, a second focal plane component, a first large-format camera lens, a second large-format camera lens, and a low-resolution camera focal plane component , low resolution camera lens, camera electronics unit, scan control unit, payload mounting plate, azimuth frame, azimuth drive mechanism, azimuth axis, pitch frame, pitch drive mechanism and pitch axis. The present invention realizes large-format imaging by combining the external field of view splicing method and the two-dimensional scanning mechanism.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

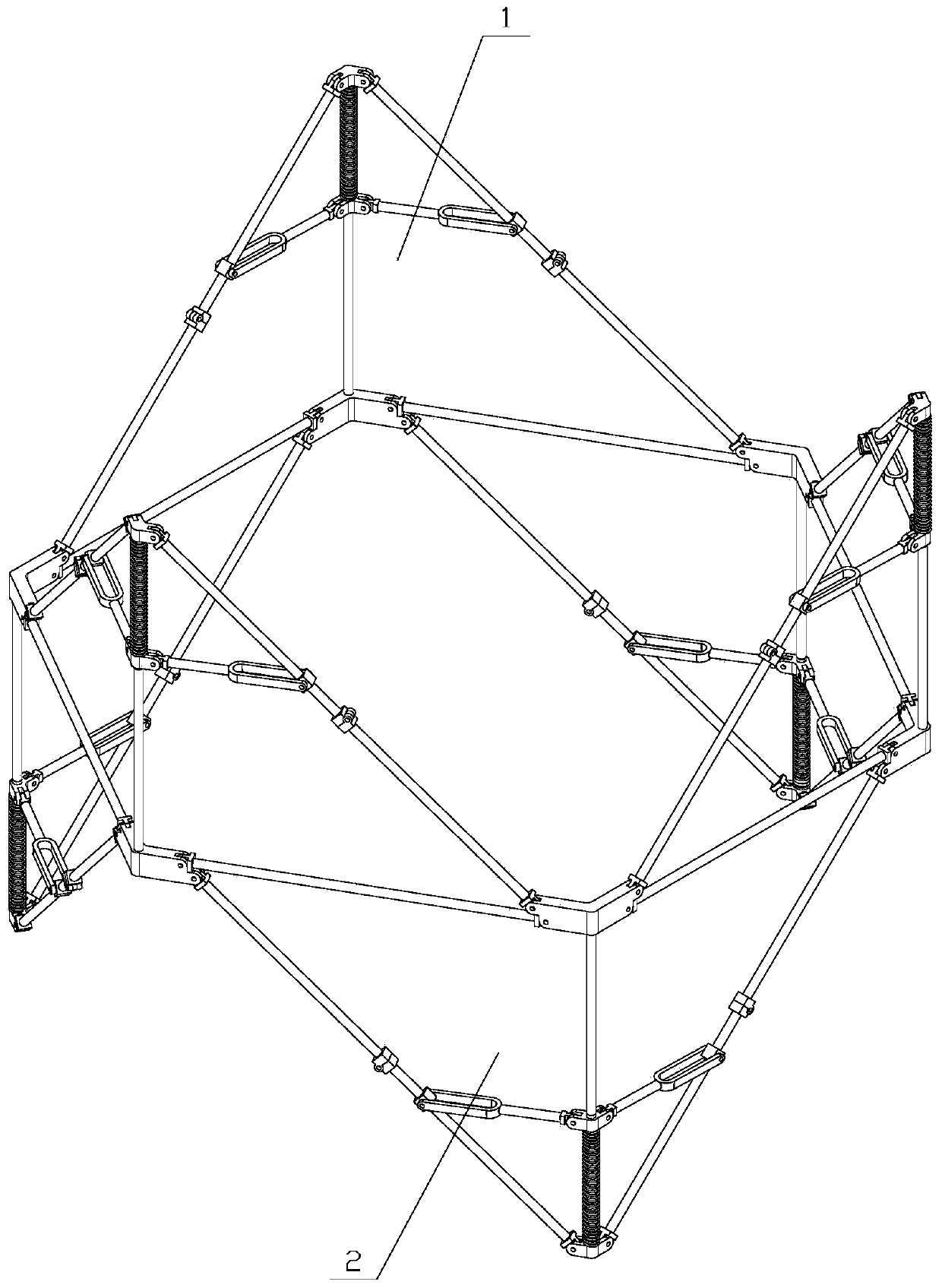

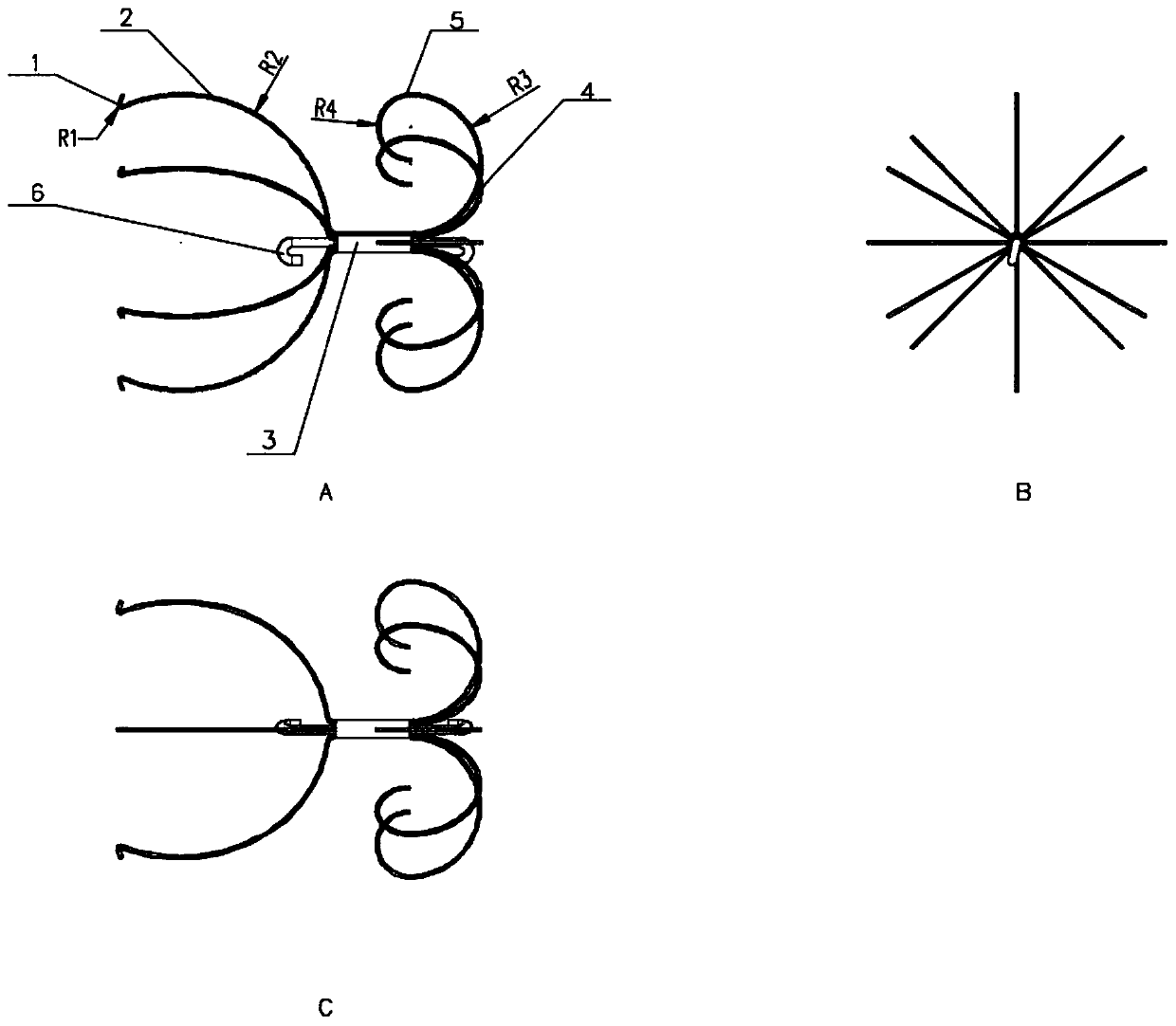

A spring-driven spatially expandable loop antenna device

ActiveCN107394407BMeet the use requirementsEnhanced geometric stabilityCollapsible/retractable loop antennasExtensibilityRight triangle

The invention discloses a spring-driven space deployable annular antenna device. The spring-driven space deployable annular antenna device comprises n sets of triangular deployable assemblies and an equilateral right triangle deployable unit A; the equilateral right triangle deployable unit A is composed of n sets of triangular deployable cooperative assemblies connected below the n sets of adjacent triangular deployable assemblies; n is greater than or equal to 2; the n sets of triangular deployable assemblies are connected end to end through four-head hinges; the n sets of triangular deployable cooperative assemblies and the n sets of triangular deployable assemblies share the same set of transverse rods connected through the four-head hinges; the n sets of triangular deployable assemblies and the n sets of triangular deployable cooperative assemblies are connected end to end; and, under the action of the elasticity of a spring, folding or unfolding is carried out, so that the deployable annular antenna device is formed. The device has relatively high geometric stability; a motion mechanism and a control system are simple; after being folded, the device is small in volume and high in accepting rate; an active driving device is unnecessary; the module extensibility is high; accessories are simple; and use requirements of large-aperture space antennas, such as communication satellites and space exploration, can be satisfied.

Owner:XIDIAN UNIV

Factory prefabricated steel-concrete composite pipe

InactiveCN108487543AHigh strengthImprove deformation resistanceWallsLoad-supporting elementsRebarUltimate tensile strength

A factory prefabricated steel-concrete composite pipe comprises a rectangular cylindrical structure made of steel plates and / profile steel. Tie bars are arranged between the inner side face and the outer side face of the rectangular cylindrical structure, the inner ends and the outer ends of the tie bars extend out of the rectangular cylindrical structure towards the two sides correspondingly, anda steel bar skeleton is arranged on the periphery of the outer portion of the rectangular cylindrical structure; gaps are formed between the steel bar skeleton and the rectangular cylindrical structure, the inner side face and the outer side face of the steel bar skeleton are fixedly connected to the inner ends and the outer ends of the tie bars correspondingly, and the left side face and the right side face of the steel bar skeleton are fixedly connected with the rectangular cylindrical structure through studs correspondingly; and concrete is poured on the periphery of the outer portion of the rectangular cylindrical structure, and thus the steel bar skeleton is coagulated. According to the factory prefabricated steel-concrete composite pipe, the building construction efficiency is improved, the ductility and compressive strength of the concrete are greatly improved, the plasticity and toughness performance of a whole steel-concrete composite shear wall structure is greatly improved,and the fireproof and anticorrosion problems of steel structure buildings are also solved effectively.

Owner:HENAN LYUJIAN BUILDING TECH CO LTD

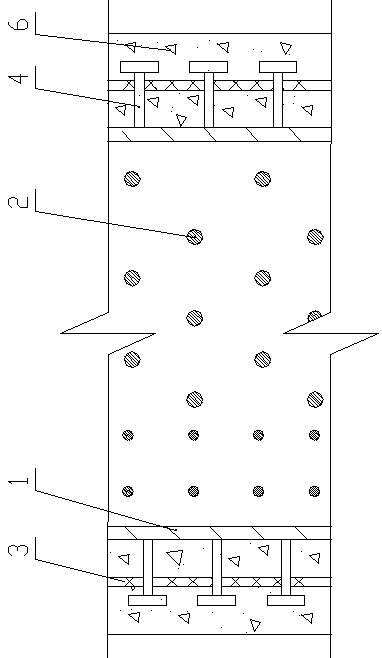

Recyclable vena cava filter

The invention discloses a recyclable vena cava filter comprising a filtering part for filtering thrombus and a supporting part for fixing the filter. The filtering part includes a first filtering partbody and a second filtering part body that are arranged along the vein, wherein the first filtering part body and the second filtering part body have central symmetry structures respectively; and thefirst filtering part body and the second filtering part body are connected through a connecting part. The supporting part includes a first supporting part and a second supporting part; the first supporting part is arranged at the tail end of the first filtering part body; and the second supporting part is arranged at the middle section part of the second filtering part body. The recyclable vena cava filter has high geometric stability and a long recovery period and is capable of carrying out oriented recovering or releasing. The geometric stability of the filter is improved while the thrombusfiltering effect is improved and inclination and displacement of the filter are reduced. Since the filtering parts on the two sides employ an asymmetric design, the thrombus filtering effect is enhanced; and all filtering parts employ curling and arc-shaped fixing anchor designs, so that the damage of the instrument to the blood vessel wall is reduced.

Owner:成都迈德克科技有限公司

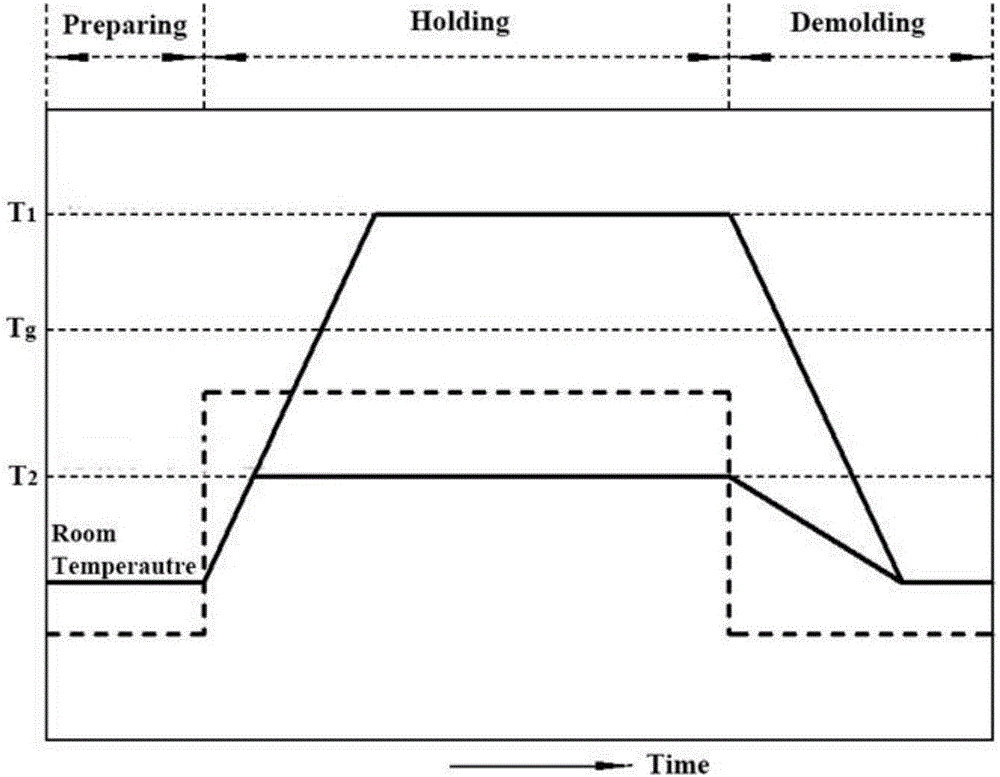

A fast thermal embossing process of polymer micro-nano structure differential temperature flat plate

The invention discloses a rapid differential-temperature flat plate hot embossing process for a polymer micro-nano structure. The rapid differential-temperature flat plate hot embossing process is characterized in that temperature of a hot embossing mold is kept consistent in the whole embossing period, set temperatures of an upper half mold and a lower half mold are different, the aims of smooth mold filling and mold release of the micro-nano structure are achieved through the differential-temperature mode, and the rapid differential-temperature flat plate hot embossing process is particularly suitable for rapid hot embossing of a polymer product with the single-face micro-nano structure. The temperature of the side, provided with the micro-nano structure, of the mold is set as a higher value, and the side, not provided with the micro-nano structure, of the mold is set as a lower value. At the initial stage of hot embossing, the temperature of a polymer substrate making contact with the high-temperature half mold rapidly rises to a high temperature, and mold filing is completed; and at the pressure maintaining stage, the polymer substrate is cooled through the low-temperature half mold, the formed micro-nano structure is shaped, and demolding is facilitated. By means of the process, it is avoided that because the mold is repeatedly heated and cooled, energy is consumed, and meanwhile the forming period of hot embossing is remarkably shortened; controllability of the forming process is high, the forming precision is high, and the overall consistency is good; and the mold sticking phenomenon of the polymer product is obviously improved, and demolding defects are effectively avoided.

Owner:BEIJING UNIV OF CHEM TECH

Manufacture process of factory prefabricated steel concrete composite pipe

ActiveCN108466018BHigh strengthImprove deformation resistanceLoad-supporting elementsRebarMouth shape

The invention discloses a factory prefabricated steel concrete combination pipe making technology. The technology comprises following steps: firstly, according to the construction drawing need, the number and the related sizes of steel concrete combination pipes with multiple cross sections of the rectangular structures are designed; secondly, according to the drawing need, the steel concrete combination pipes are prefabricated in the factory in a segmented manner; thirdly, the steel concrete combination pipes are connected to form straight-line-shaped, the leftwards-rotated-T-shaped, an inverted-L-shaped, crossed or mouth-shaped structures. Inner concrete, outer concrete and reinforcing meshes are combined with a steel plate with the inner side with ribs to form a whole steel concrete combination shear wall through binding bars, joint work is achieved, ductility and compressive strength of the concrete are greatly improved, plasticity and toughness of the whole steel concrete combinedshear wall structure are greatly improved, the anti-deforming capacity and the anti-pressing strength of the shear wall are greatly improved, and meanwhile, due to the fact that the steel plate withthe ribs is wrapped by the concrete, the fireproof anti-corrosion aims of the steel structure building can be effectively achieved.

Owner:HENAN LYUJIAN BUILDING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com