Factory prefabricated steel concrete combination pipe making technology

A technology of factory prefabrication and manufacturing process, which is applied to structural elements, building components, and elongated structural components for load-bearing, etc. It can solve the problems of poor durability of shear wall structures, poor corrosion resistance, and insufficient strength of steel plates Achieve the effect of increasing tensile and compressive strength, reducing weight, and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

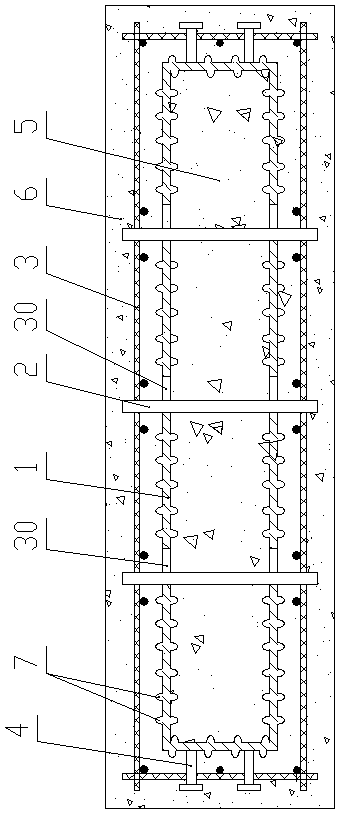

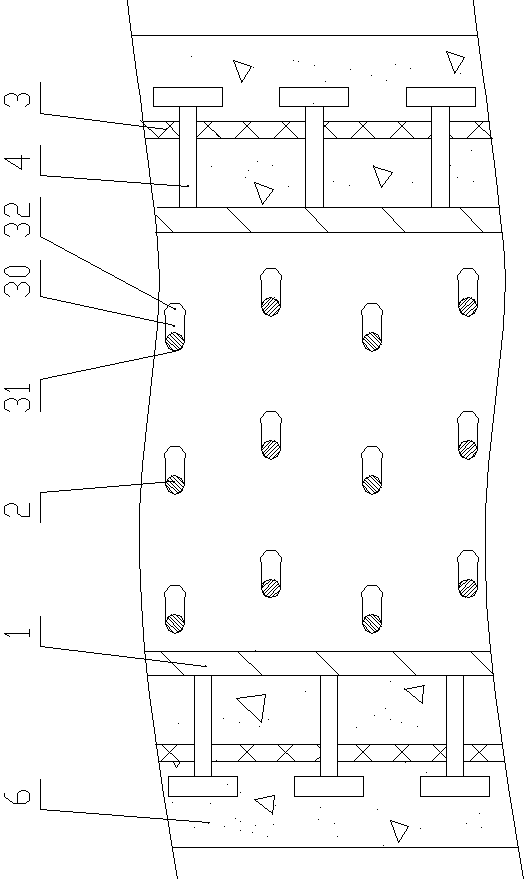

[0033] Embodiment one: if figure 1 and image 3 As shown, the manufacturing process of the factory prefabricated steel-concrete composite pipe of the present invention comprises the following steps:

[0034] (1) According to the requirements of the construction drawings, the number and related dimensions of several sections of steel-concrete composite pipes with a rectangular cross-section are designed;

[0035](2) According to the requirements of the drawing, prefabricate the steel-concrete composite pipe in sections in the factory; the concrete composite pipe includes a bent rectangular cylindrical structural steel plate 1, and the two long sides of the steel-concrete composite pipe with a rectangular structure are respectively rectangular The inner side and the outer side of the cylindrical structural steel plate 1, and the two short sides of the steel-concrete composite pipe in a rectangular structure are respectively the left side and the right side of the rectangular cy...

Embodiment 2

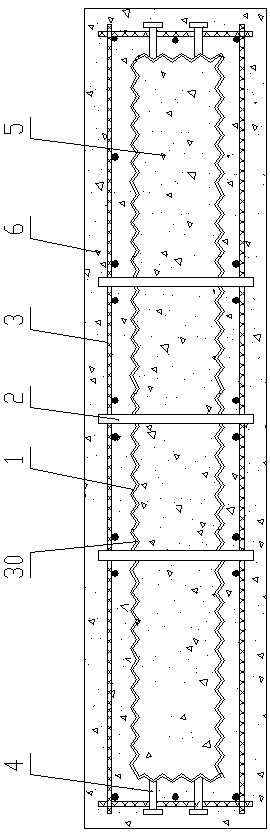

[0053] Embodiment two: if figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the rectangular cylindrical structural steel plate 1 is formed by bending and welding a profiled steel plate, and the cross-section of the profiled steel plate is triangular, trapezoidal, arc-shaped, wavy or folded. Linear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com