Factory prefabricated steel-concrete composite pipe site construction linear-shaped shear wall horizontal connecting structure

A technology of on-site construction and factory prefabrication, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of unguaranteed construction quality, poor durability of shear wall structures, and slow construction progress, etc., and solve the problems of fire prevention and corrosion , increase the tensile and compressive strength, and improve the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

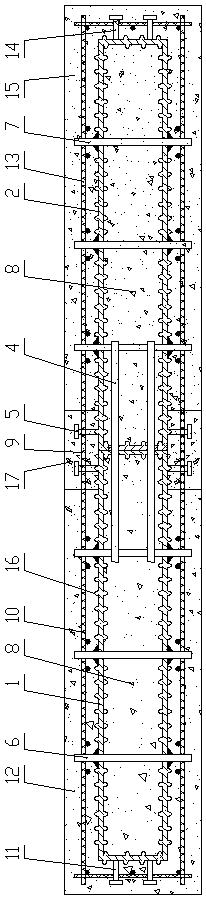

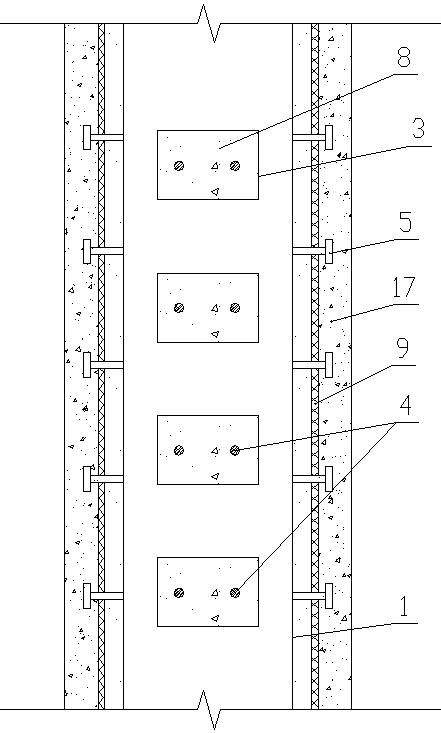

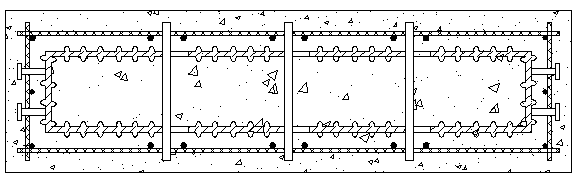

[0027] Example one: such as Figure 1-Figure 3 As shown, the in-line shear wall horizontal connection structure of the factory-prefabricated steel-concrete composite pipe of the present invention includes the first steel-concrete composite pipe and the second steel-concrete composite pipe whose horizontal cross-sections are both in the shape of "-". A steel-concrete composite pipe and a second steel-concrete composite pipe are arranged vertically. The first steel-concrete composite pipe includes a first rectangular cylindrical steel pipe 1 bent from a single piece of steel plate, and the second steel-concrete composite pipe includes a The second rectangular tubular steel pipe 2 is formed by bending the entire steel plate. The length directions of the first rectangular tubular steel pipe 1 and the second rectangular tubular steel pipe 2 are both arranged in the left and right directions. The right end surface of the first rectangular tubular steel pipe 1 In contact with the left...

Embodiment 2

[0044] Embodiment two: such as Figure 4 As shown, the difference between this embodiment and the first embodiment is that the first rectangular cylindrical steel pipe 1 and the second rectangular cylindrical steel pipe 2 are formed by bending and welding a profiled steel plate, and the cross-section of the profiled steel plate is triangular, Trapezoid, arc, wavy or broken line shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com