Light emitting element

A technology of light-emitting components and light sources, applied in electrical components, semiconductor devices, electric solid-state devices, etc., can solve the problems of low efficiency and the luminous efficiency of white LEDs cannot exceed 150lm/W.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

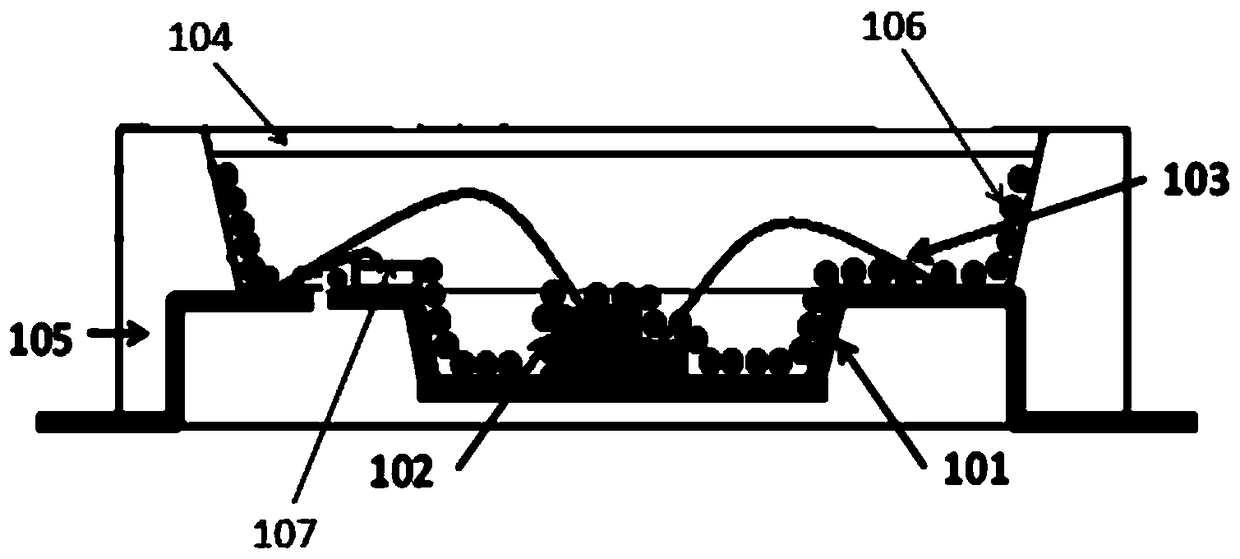

[0026] Such as figure 1 As shown, the present invention provides a light-emitting element, including a light source body 105, a lead frame 101, at least one wire 103, an LED chip 102, a Zener diode 107, a photonic crystal film 106 and a light-transmitting layer 104, Its relative position is that the lead frame 101 is placed on the bottom of the light source body 105, the LED die 102 is placed above the lead frame 101, and the photonic crystal film 106 is coated on at least a part of the surface of the LED die 102 and the light source. At least a part of the inner surface of the body 105 , the lead frame 101 including the at least one wire 103 are electrically connected to the LED die 102 and the Zener diode 107 .

[0027] The material for making the lead frame 101 needs to consider its electrical conductivity, thermal conductivity, mechanical strength, weldability and corrosion resistance. Commonly used materials are copper alloy, 42 alloy (nickel: 42%, iron: 58%), Kovar allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com