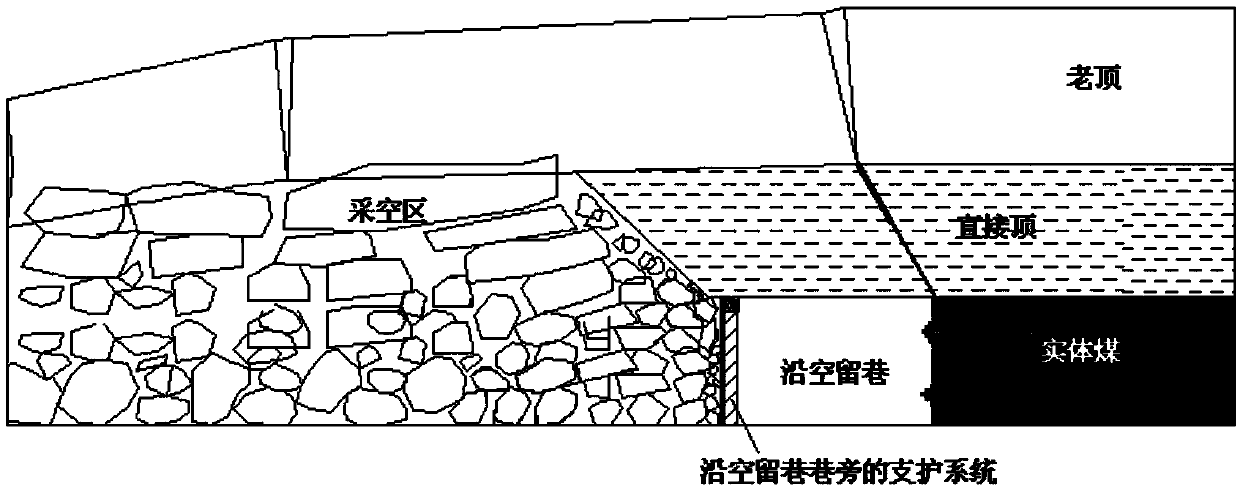

A roadside support system for gob-side entry retention and its construction method

A goaf and support device technology, which is applied in earth-moving drilling, shaft equipment, wellbore lining, etc., can solve the problems of insufficient vertical and horizontal bearing capacity of roadside support bodies and high support costs, and improve coal mining. efficiency, reduce the cost of lane retention, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 A roadside support system for gob-side entry retention

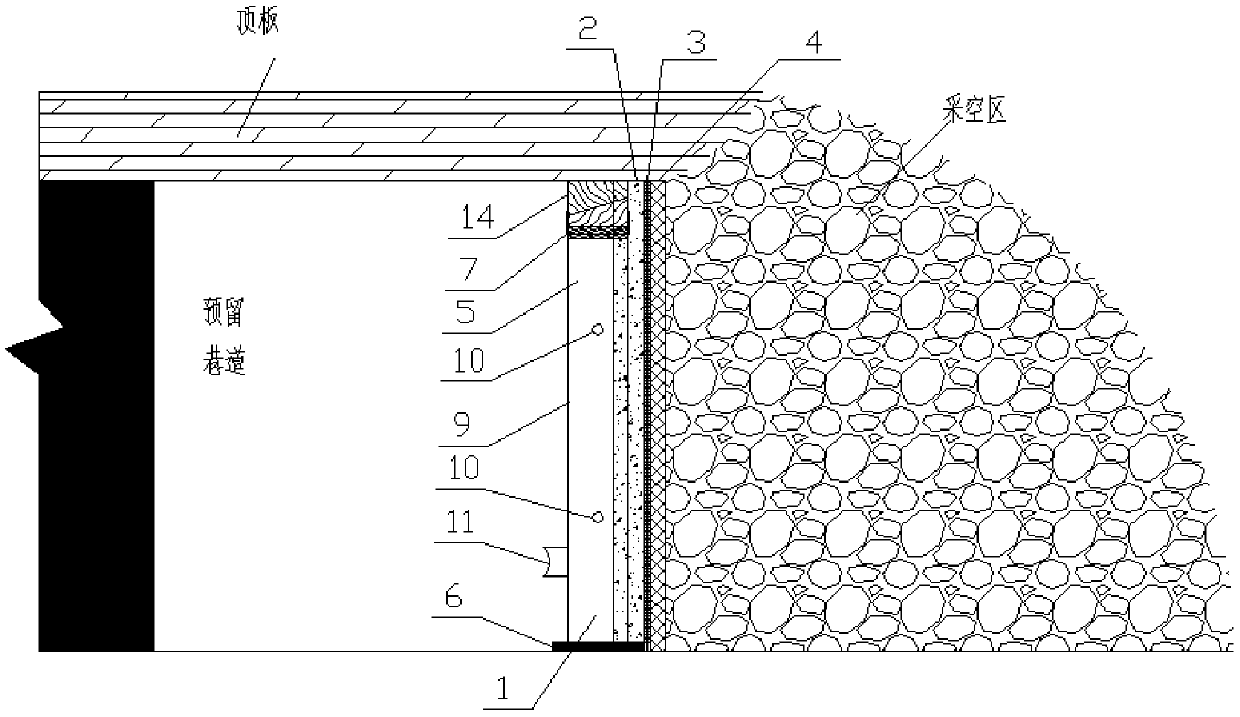

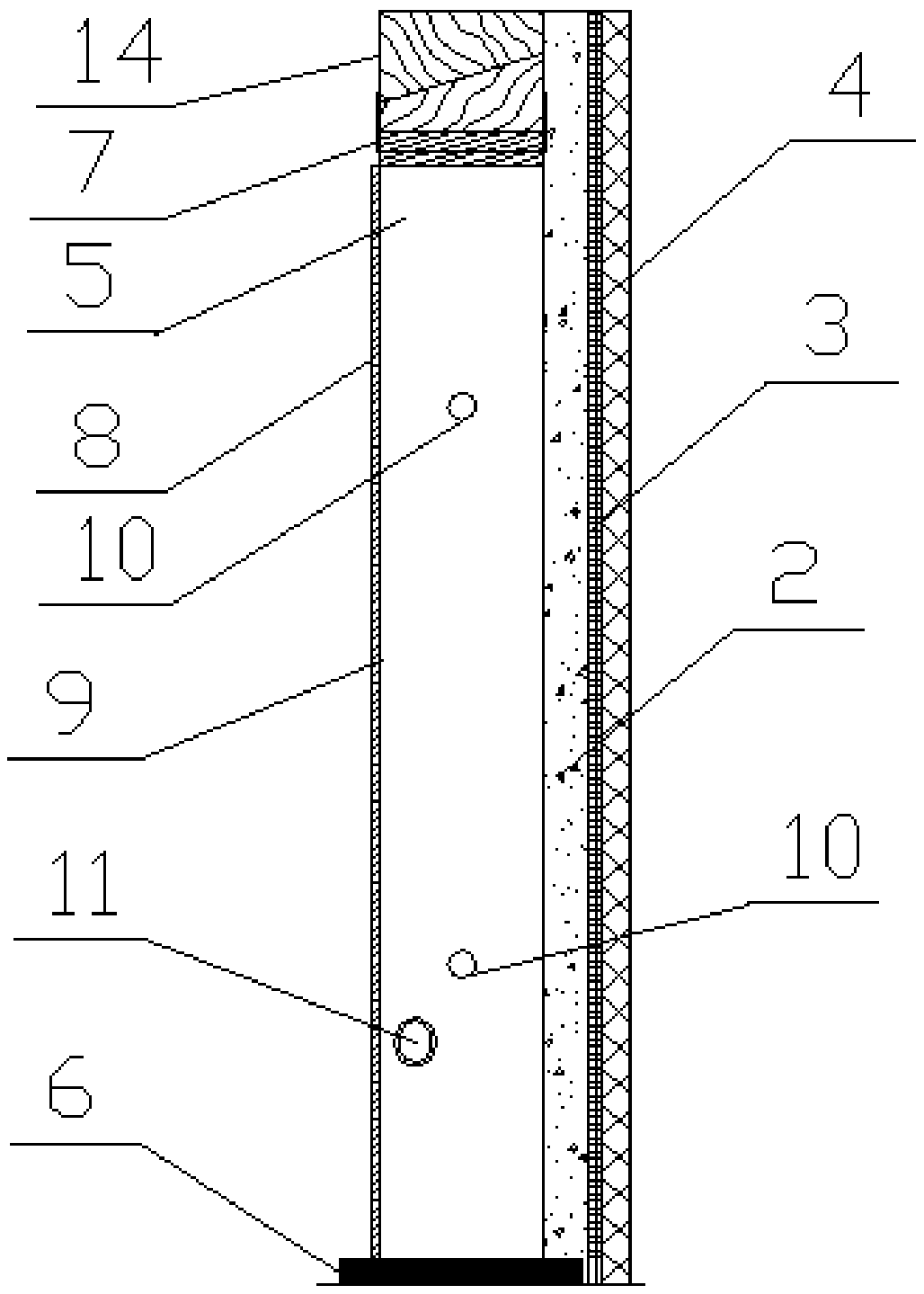

[0054] like Figure 1-Figure 8 As shown, the support system for gob-side entry retaining includes steel pipe concrete pier supporting device 1, light aggregate flexible concrete spray layer 2, air duct cloth 3 and diamond-shaped steel mesh 4, and diamond-shaped steel mesh 4 is set along one side of the gob. Air duct cloth 3 is laid on the inner side of diamond-shaped steel mesh 4, and light aggregate concrete is used for spraying treatment on air duct cloth 3 and diamond-shaped steel mesh 4, and an airtight light aggregate concrete spray layer 2 is formed on the side of the gob. The thickness of the concrete sprayed layer 2 is 200mm-500mm, and the other side of the light aggregate concrete sprayed layer 2 is close to the steel pipe concrete pier supporting device 1;

[0055] The concrete-filled steel pipe pier supporting device 1 includes a concrete-filled steel pipe pier 5, a pier shoe plate 6, a pi...

Embodiment 2

[0061] The composition of embodiment 2 light aggregate concrete

[0062] The composition of light aggregate concrete is (kg / m 3 ): cement 450, ceramsite 650, sand 650, mineral powder 50, water 125, water reducing agent 3; the strength grade of light aggregate concrete is CL50, and the apparent density is 800-1000kg / m 3 .

Embodiment 3

[0063] Embodiment 3 Construction method of roadside support system for gob-side entry retention

[0064] Specific steps are as follows:

[0065] (1) First, the empty steel pipe pier column body, pier top cap and pier shoe plate are processed on the ground, the outer side of the steel pipe concrete pier top is processed into a threaded opening, the lower part is provided with a grouting port, and one side of the steel pipe concrete pier Spot welding of bending-resistant round steel;

[0066] (2) Suspend diamond-shaped steel mesh and air duct cloth at the edge of the goaf side of the reserved roadway, and use light aggregate concrete for spraying treatment to form airtight light aggregate concrete on the gob side spraying layer, sealing the goaf, and the thickness of the light aggregate concrete spraying layer is 200mm-500mm;

[0067] (3) Empty steel pipe piers are erected on the side of the goaf of the reserved roadway close to the light aggregate concrete sprayed layer. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com