Fabricated concrete-filled steel tube double-layer gate-type pier structure

A concrete-filled steel tube and prefabricated technology, applied to bridge parts, bridges, buildings, etc., can solve problems such as short construction period, long construction period, and potential safety hazards, so as to reduce the cost of the whole life, reduce the construction time, and improve the use efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

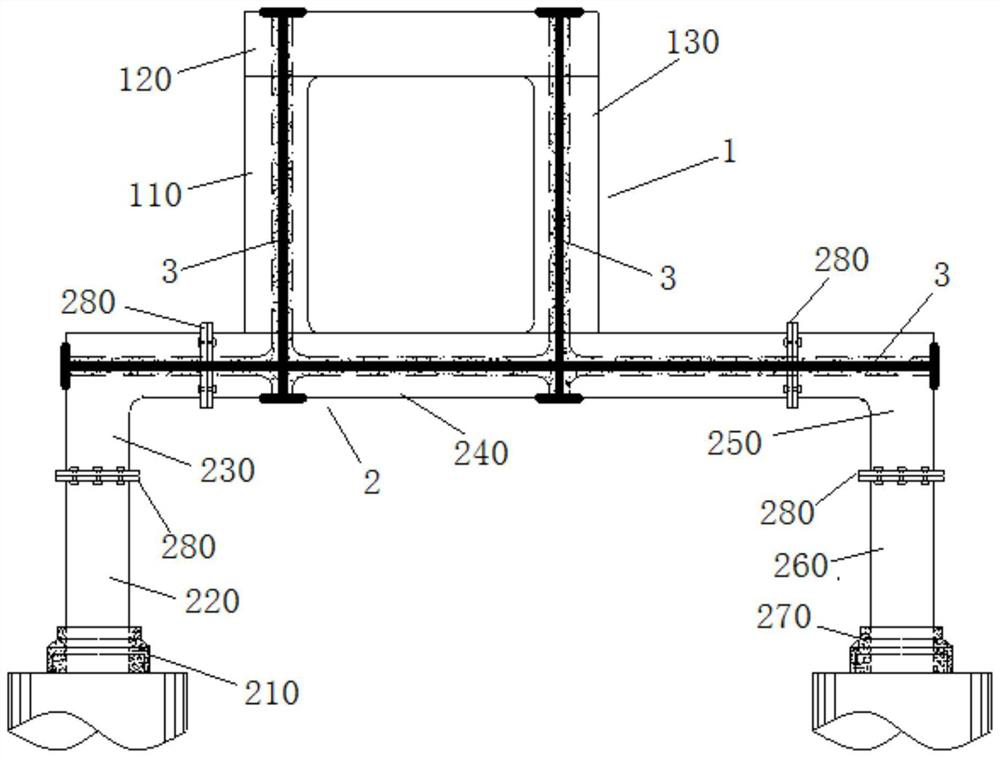

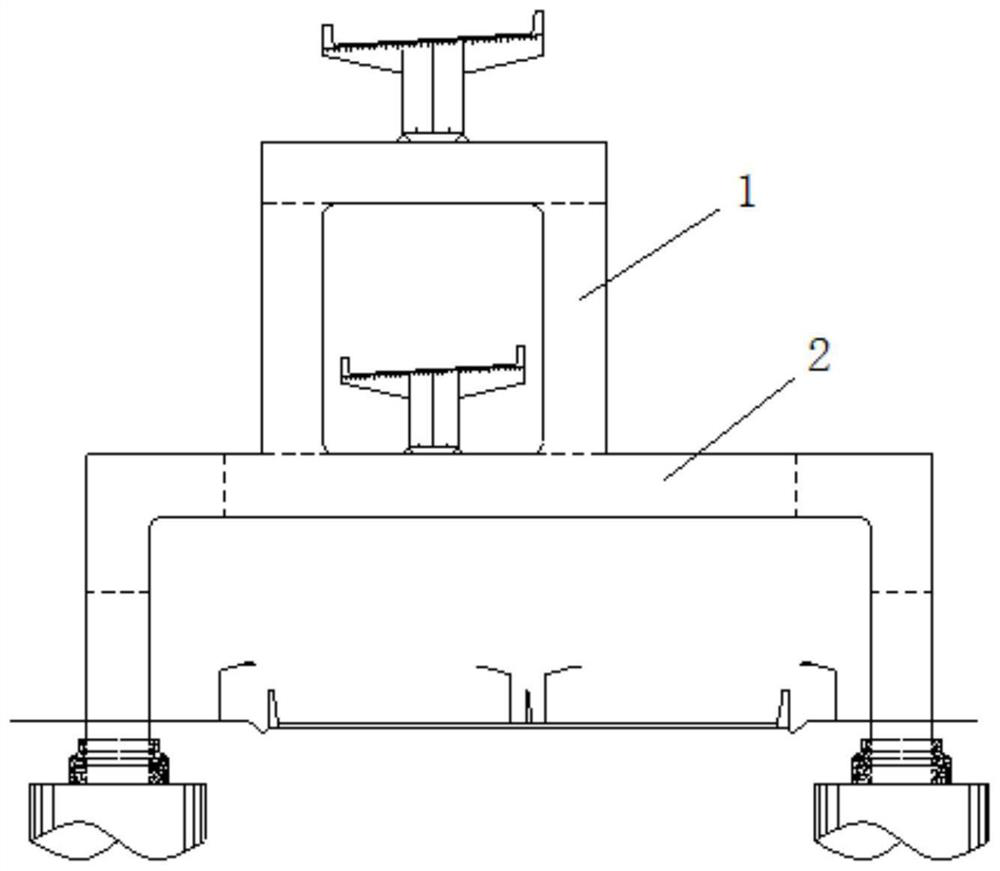

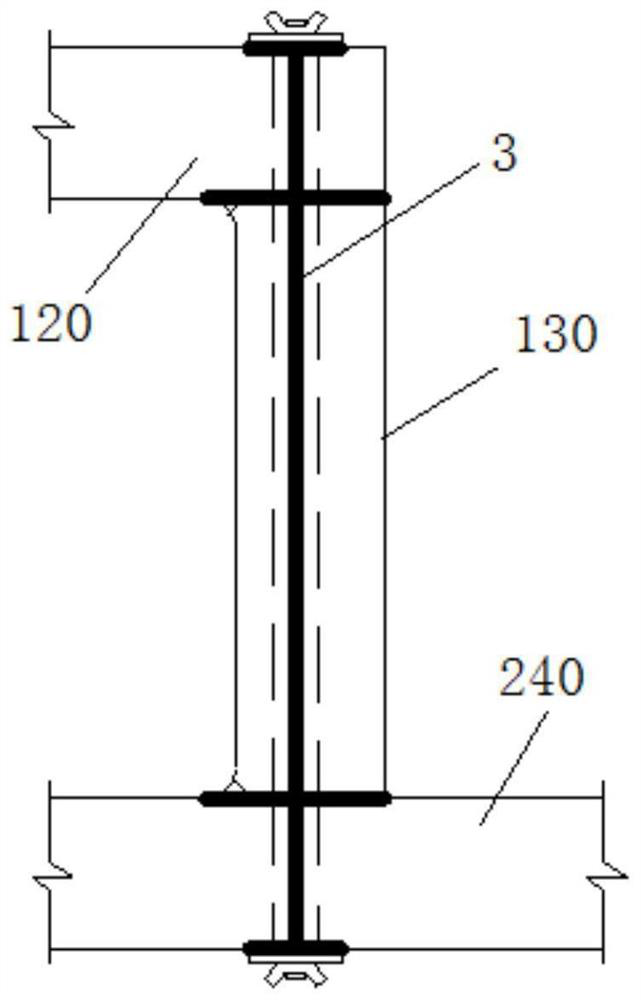

[0025] Such as Figure 1 ~ Figure 3 As shown, a prefabricated steel pipe concrete double-layer portal pier structure includes an upper portal pier 1 and a lower portal pier 2, and the upper portal pier 1 and the lower portal pier 2 are prestressed by welding and post-tensioning Rebar 3 composite connection.

Embodiment 2

[0027] Such as Figure 1 ~ Figure 3 As shown, the present embodiment is a further optimization carried out on the basis of embodiment 1, which is specifically as follows:

[0028] The upper gantry pier 1 includes a left upper column 110, an upper cover beam 1220 and a right upper column 130, and the left upper column 110 and the right upper column 130 are respectively arranged below the two ends of the upper cover beam 1220; the upper cover beam 1220, the left upper column 110 and the lower gantry Pier 2 is compositely connected by welding and post-tensioned prestressed steel bar 3; the upper cover beam 1220, right upper column 130 and lower door-type pier 2 are compositely connected by welding and post-tensioned prestressed steel bar 3, construction of post-tensioned prestressed steel bar The process belongs to the prior art, and will not be described in detail here.

Embodiment 3

[0030] Such as Figure 1 ~ Figure 3 As shown, the present embodiment is a further optimization carried out on the basis of embodiment 2, which is specifically as follows:

[0031] The upper left column 110, the upper cover beam 1220 and the upper right column 130 are all filled with concrete filled steel tubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com