Rigid-flexible combination gob-side entry retaining method and rigid-flexible combination gob-side entry retaining device by aid of roadside supports

A technology of roadside support and combination of rigidity and flexibility, which is used in shaft equipment, earthwork drilling, wellbore lining, etc. The effect of stability, improvement of working environment, and simplification of construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention provides a rigid-flexible roadside support method and device for gob-side entry retaining. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

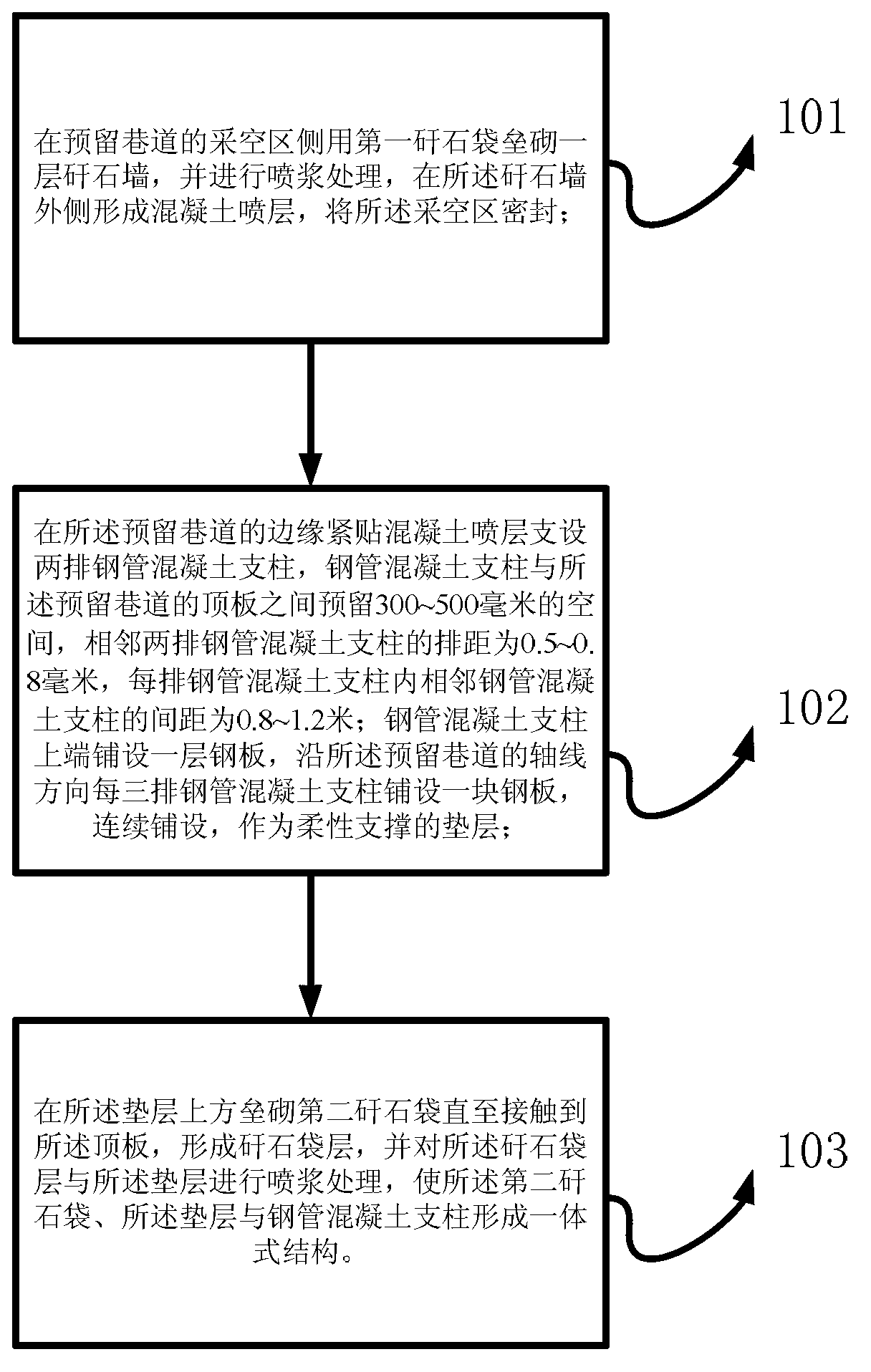

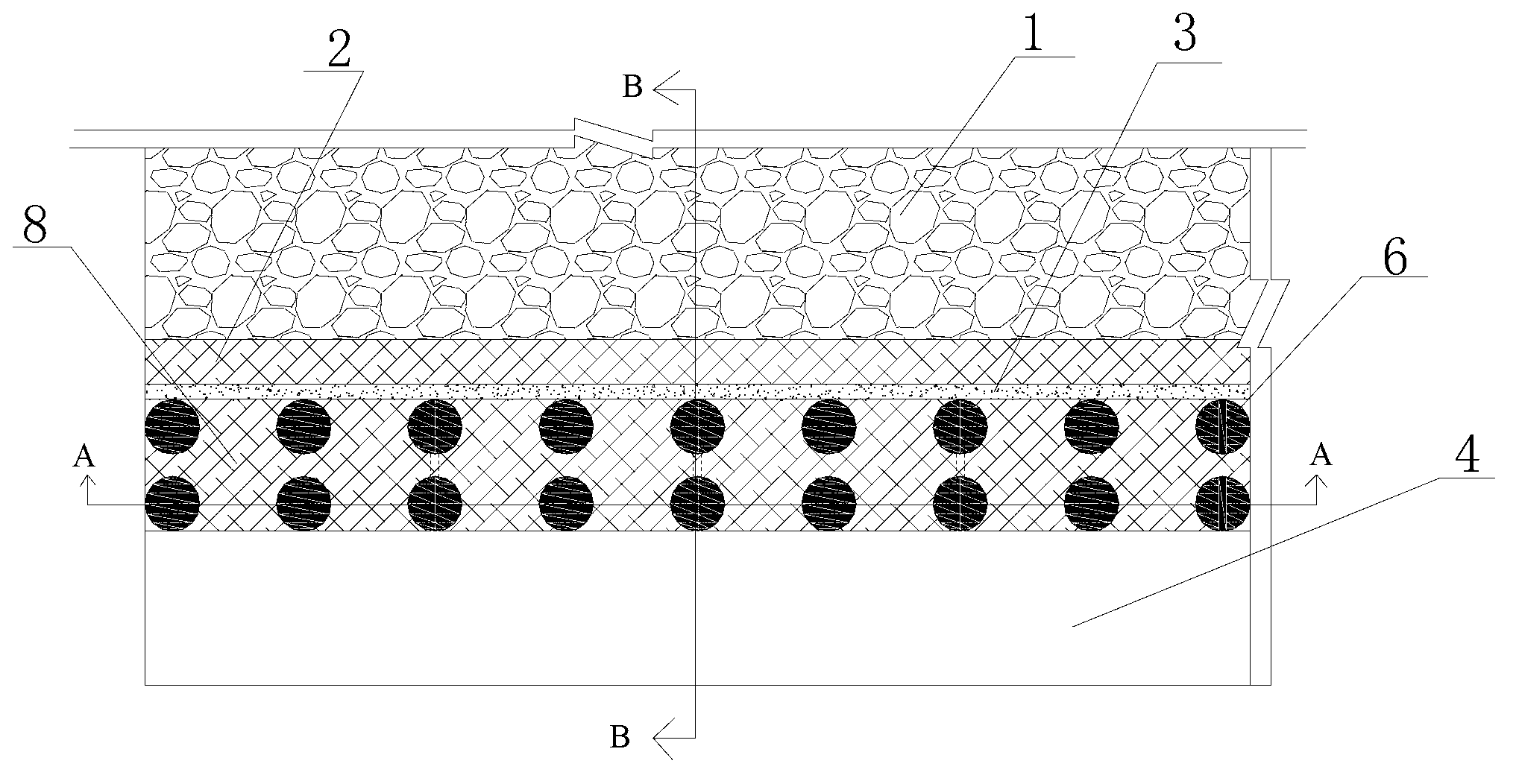

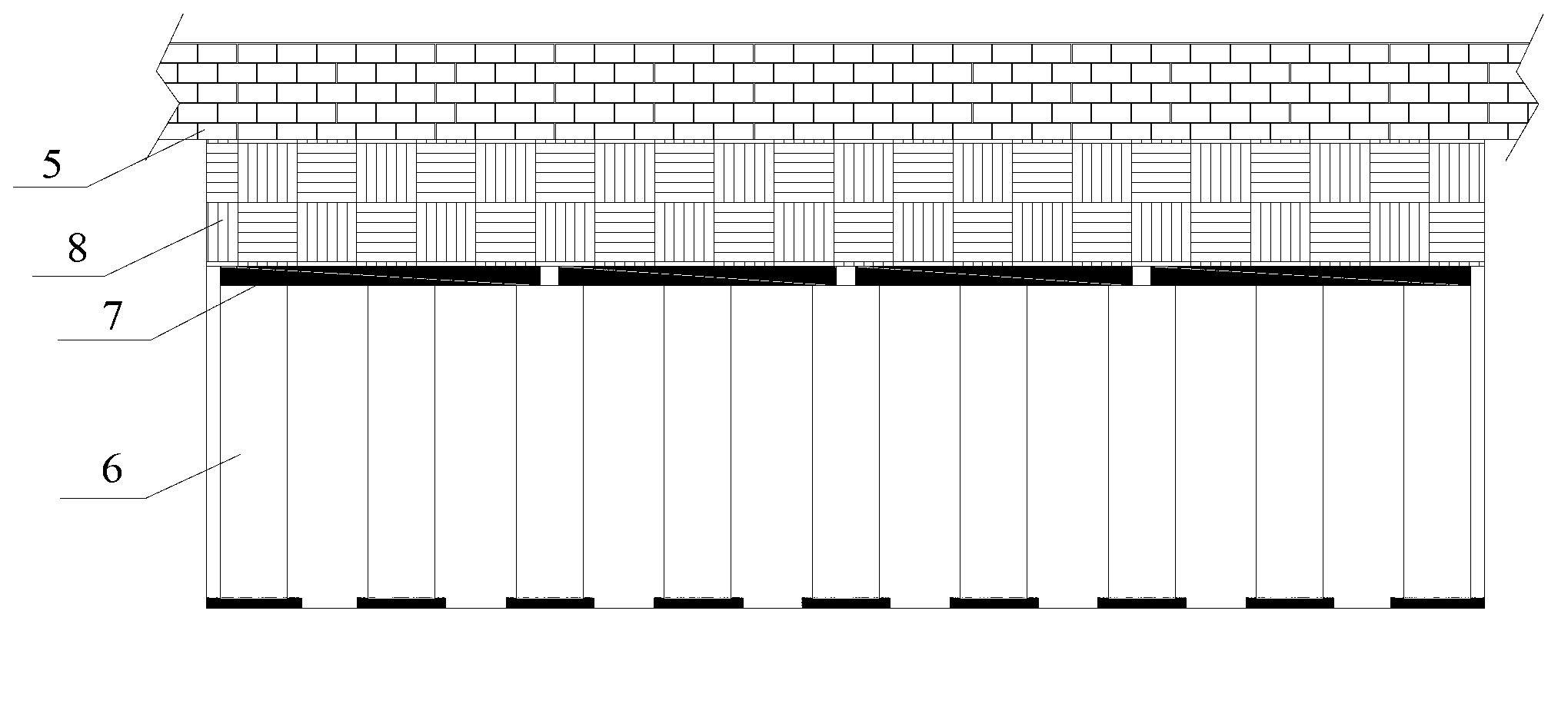

[0021] The invention provides a rigid-flexible roadside support method for gob-side entry retention, such as figure 1 As shown, it includes the following steps:

[0022] Step 101: Build a layer of gangue wall with the first gangue bag on the side of the goaf of the reserved roadway, and perform spraying treatment to form a concrete spray layer on the outside of the gangue wall, and seal the goaf;

[0023] Step 102: Set up two rows of concrete-filled steel pipe pillars close to the concrete sprayed layer on the edge of the reserved roadway...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com