Rapid differential-temperature flat plate hot embossing process for polymer micro-nano structure

A micro-nano structure, flat plate hot pressing technology, applied in the field of polymer micro-nano structure differential temperature flat plate hot imprinting process, can solve the problems of serious time-consuming, demolding defects, prolonging the flat plate hot imprinting process cycle, etc. The effect of small mold defects, low imprinting temperature, and shortening of flat plate hot imprinting cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

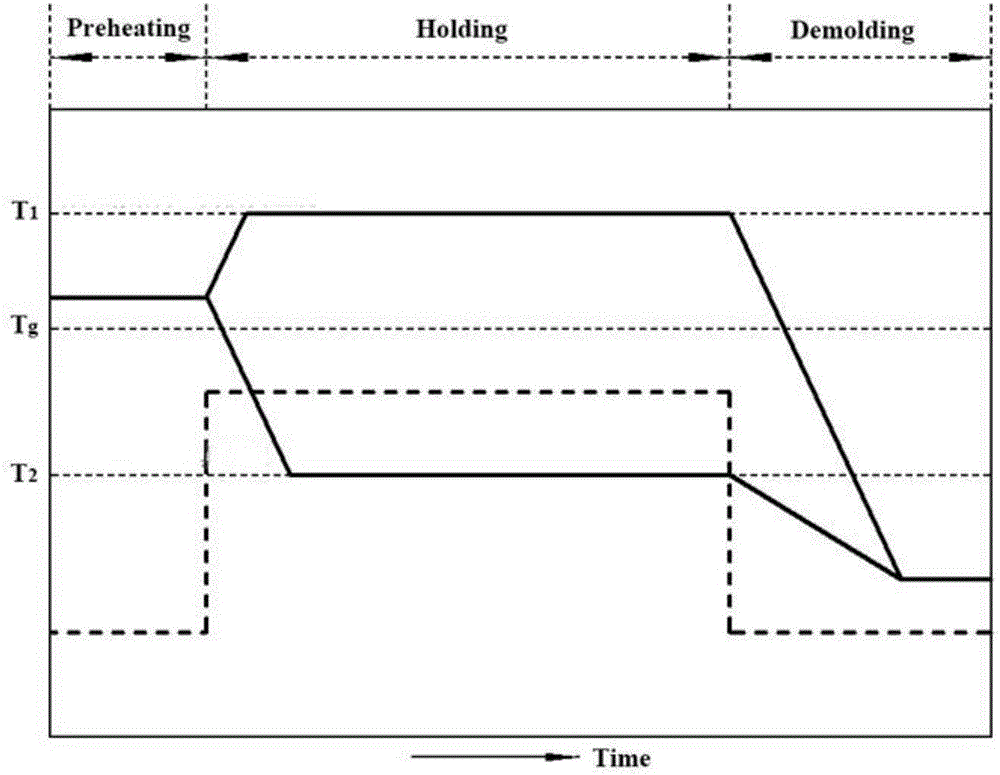

[0033] The present embodiment provides with 1mm thickness PMMA (T g =105°C) thin plate is the micro-nano structure thermal embossing method of substrate, the surface of the micro-nano structure mold used is a V-Cut structure with a characteristic size of 25 μm, comprising the following steps:

[0034] (1) Preheating: The PMMA substrate is preheated to 110°C, and the preheating process ensures that the temperature distribution of the polymer pressure surface is even;

[0035] (2) Embossing: The mold temperature on the side with V-Cut structure is set to 120°C, and the mold temperature on the side without structure is set to 100°C to ensure uniform temperature distribution on the mold surface. The material is embossed, the embossing pressure is set to 4Mpa, and the embossing time is set to 30s;

[0036] (3) Demoulding: After the thermal embossing micro-nano structure is filled, the mold temperature remains unchanged, and the mold is directly demoulded to obtain a polymer device...

Embodiment 2

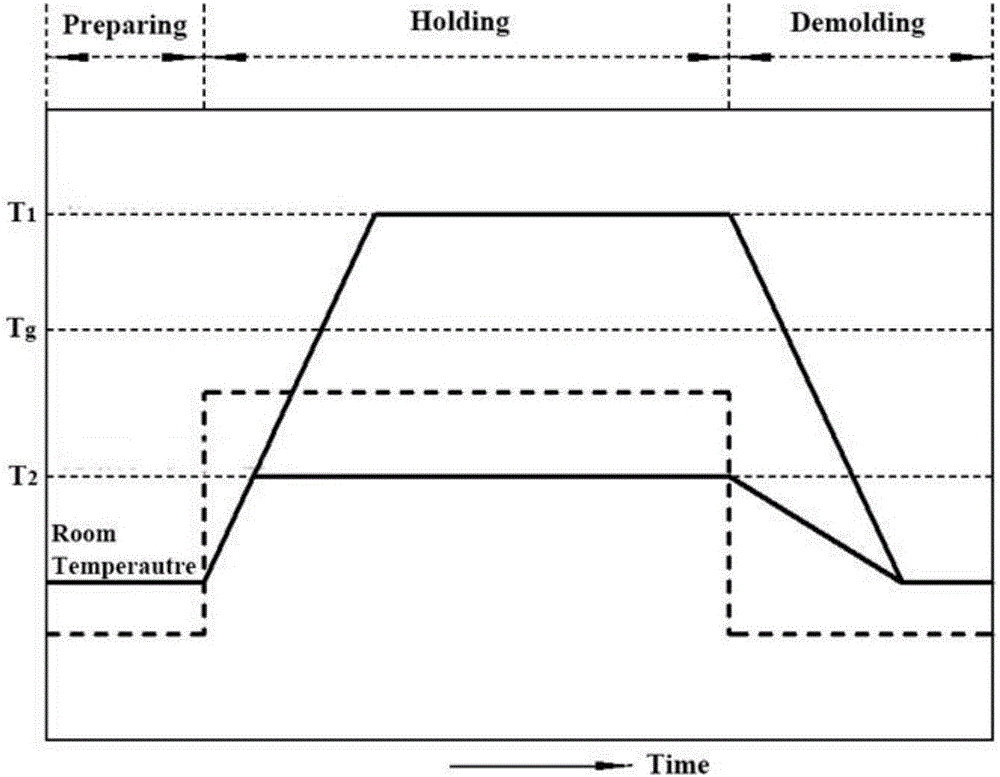

[0038] The present embodiment provides with 0.25mm thickness PC (T g =150°C) sheet is the micro-nano structure heat embossing method of base material, and the surface of the micro-nano structure mold used is a hemispherical structure with a diameter of 40 μm, comprising the following steps:

[0039] (1) Embossing: The temperature of the mold on the side with the hemispherical structure is set to 160°C, and the temperature of the mold on the side without the structure is set to 140°C to ensure uniform temperature distribution on the surface of the mold, and the mold directly performs thermal embossing on the PC substrate at room temperature , the embossing pressure is set to 8Mpa, and the embossing time is set to 60s;

[0040] (2) Demoulding: After the hot embossing is completed, the mold temperature is kept constant, and the mold is directly demoulded to obtain a polymer device with a hemispherical microstructure on the surface.

Embodiment 3

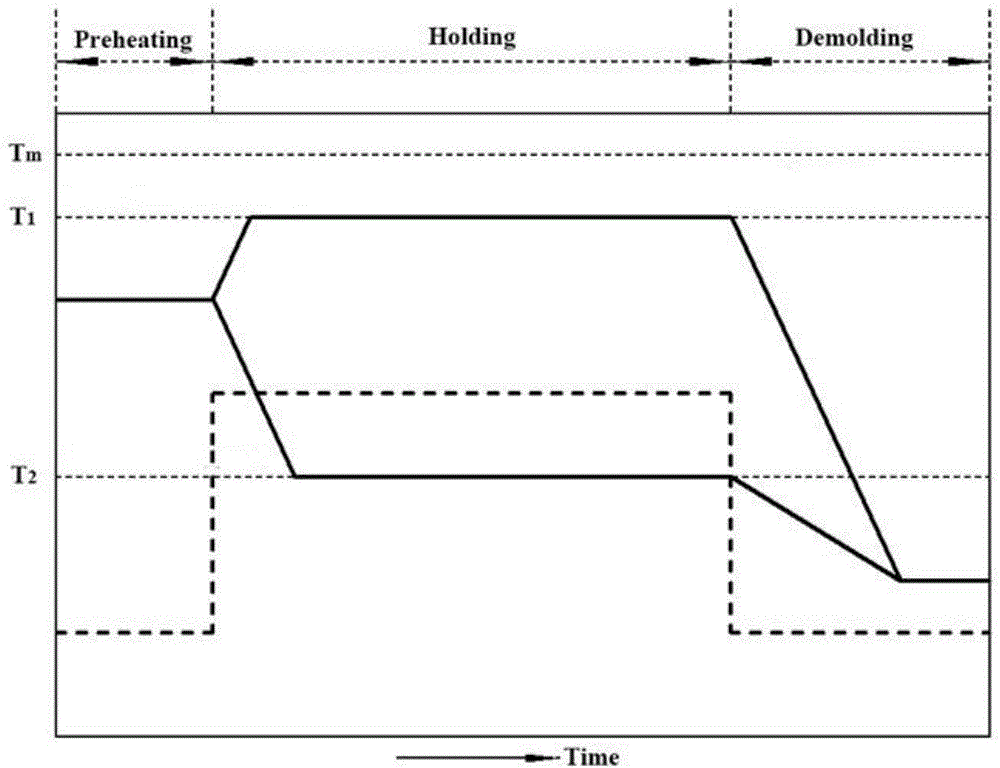

[0042] The present embodiment provides with 1mm thickness PMMA (T g =105 DEG C) thin plate is the micro-nano structure thermal embossing method of base material, and the micro-nano structure mold surface used is the nano cylinder structure that characteristic size is 200nm, comprises the following steps:

[0043] (1) Preheating: The PMMA substrate is preheated to 110°C, and the preheating process ensures that the temperature distribution of the polymer pressure surface is even;

[0044](2) Embossing: The temperature of the mold on the side with the nano-cylindrical structure is set to 125°C, and the mold temperature on the side without the structure is set to 95°C to ensure uniform temperature distribution on the surface of the mold, and the mold is directly hot-pressed on the PMMA substrate at room temperature Printing, the printing pressure is set to 10Mpa, and the printing time is set to 90s;

[0045] (3) Demoulding: After the thermal embossing micro-nano structure is fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com