Composite chromium plating film and sliding member having the same and method for manufacture thereof

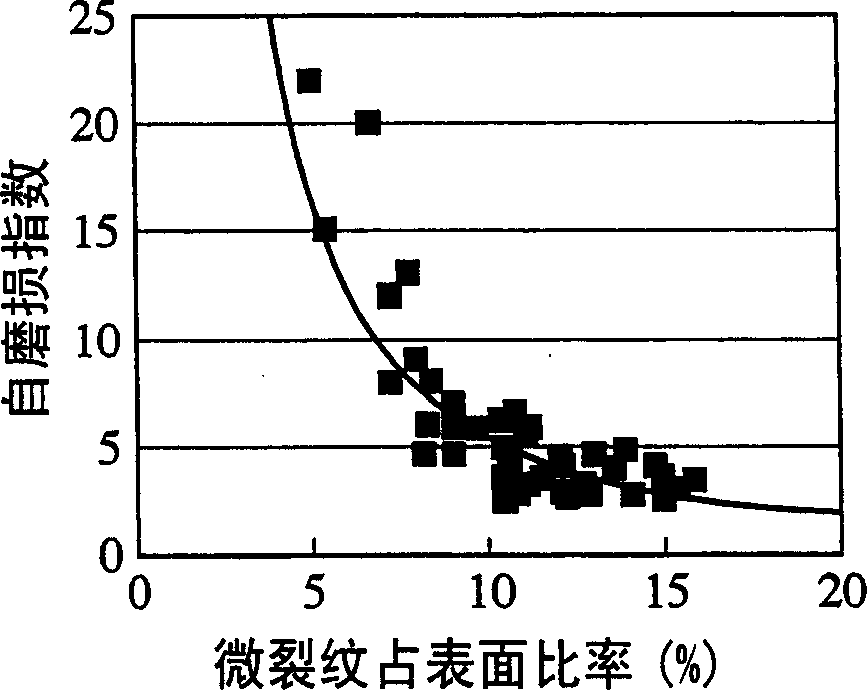

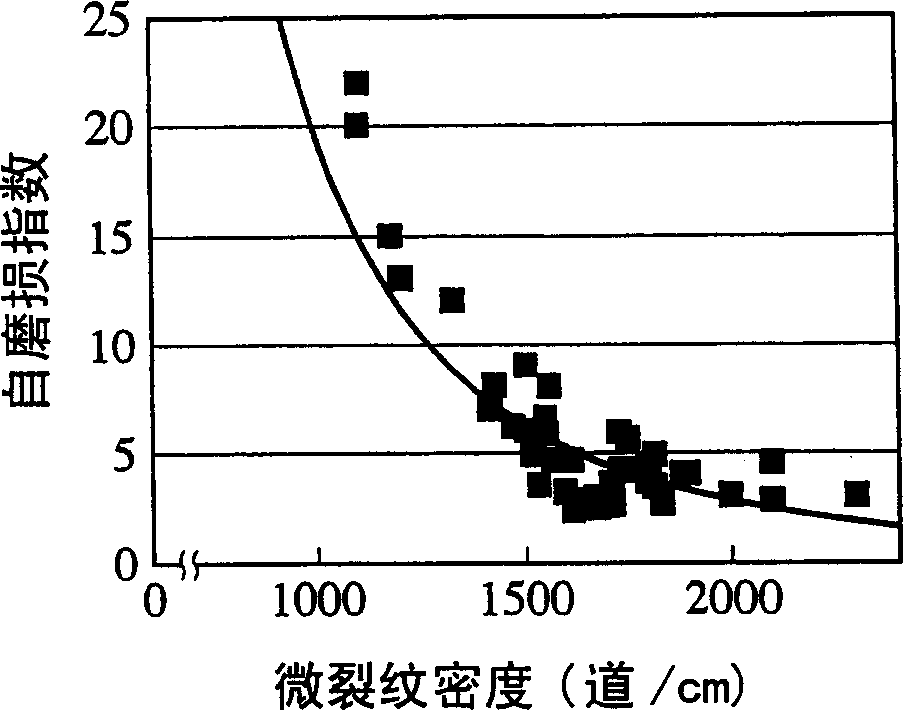

一种铬电镀、滑动件的技术,应用在发动机元件、机械设备、光学元件等方向,能够解决电镀膜低强度、低抗磨损性、电镀膜不均匀分布密度微裂纹等问题,达到油膜厚度优异、优异抗磨损性、优异润滑油保持性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 4

[0106] In the same manner as in Reference Example 1, a square cross-section bar (5 mm x 5 mm x 20 mm) made of carbon tool steel (SK-5) was polished and then degreased. The rods of these square cross-sections were subjected to pretreatment, chrome plating and counter voltage treatment in the same manner as in Example 1, except that they were immersed in a composite electroplating bath having the composition shown in Table 1, and the counter voltage treatment The current density during voltage treatment is constant 20A / dm 2 . The cycle consisting of the electroplating step and the counter voltage treatment step was repeated 12 times in total to form a 120 μm thick composite chromium electroplating film. Table 2 shows the surface ratio of microcracks, distribution density and composite ratio of hard particles in the obtained test pieces.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com