Powder metallurgy preparation method of high-thermal-conductivity Cu-Invar bimetal-based composite material

A composite material and powder metallurgy technology, which is applied in the field of powder metallurgy preparation of Cu-Invar bimetal matrix composite materials, can solve the problems that have not been published, and achieve the effect of zero performance, excellent comprehensive performance and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

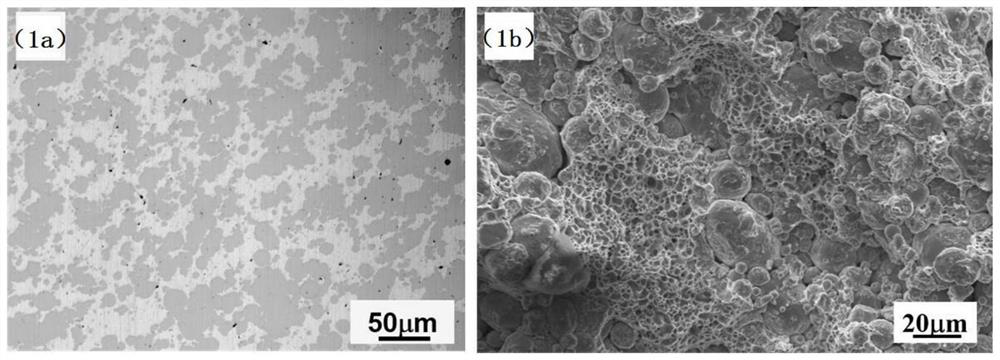

[0025] Example 1: 50wt% Cu-Invar composite material sintered by SPS at 700°C using Invar alloy powder with a particle size of -400 mesh (<37 μm)

[0026] (1) Material selection: select the average particle diameter D50 of 25-100 μm, spherical gas-atomized Invar alloy powder and the average particle diameter D50 of gas-atomized Cu powder of 20-40 μm as raw materials for preparing the composite material;

[0027](2) Sieving: Weigh 100g of Invar alloy powder and place it in a vibrating sieving apparatus. The sieve is 400 mesh, the vibration frequency is 3000 times / min, the sieving time is 5min, and the particle size is -400 mesh (<37μm). Invar powder;

[0028] (3) Mixing: Weigh 10g of Invar powder with a particle size of -400 mesh (<37μm) and 10g of Cu powder into a nylon tank, and add zinc stearate with a mass fraction of 0.5wt% as a lubricant. After sealing, put it on the tank mill for mixing with two-axis rollers, the roller speed is 500r / min, and the mixing time is 10h;

[...

Embodiment 2

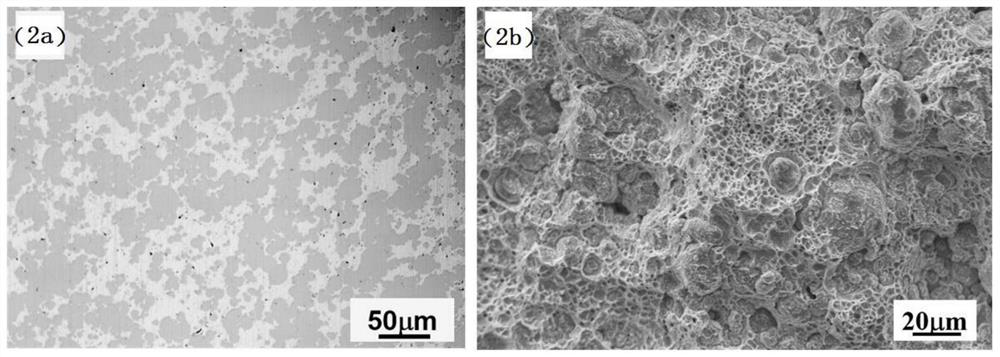

[0031] Example 2: Using Invar alloy powder with a particle size of -400 mesh (<37 μm), 50wt% Cu-Invar composite material sintered by SPS at 800 ° C. The preparation process of this example is the same as that of Example 1, except that the step (5 ) The sintering temperature is 800°C, and other processes and parameters remain unchanged.

Embodiment 3

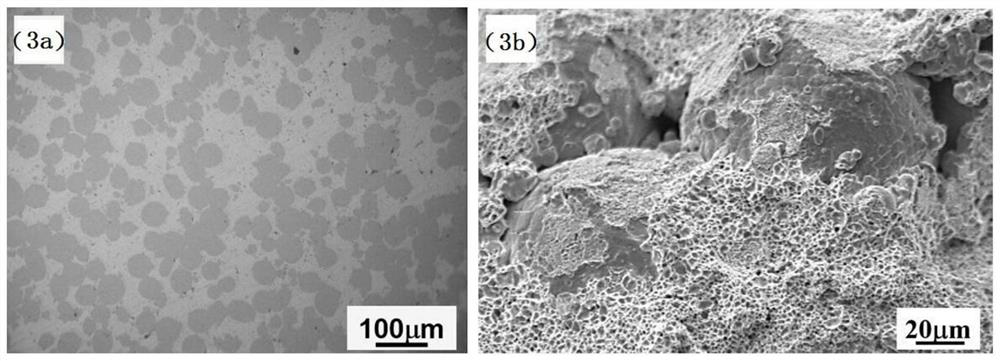

[0032] Example 3: Using Invar alloy powder with a particle size of +200 mesh (>74 μm), 50wt% Cu-Invar composite material sintered by SPS at 700 ° C. The preparation process of this example is the same as that of Example 1, except that the step (2 ) obtained in the Invar alloy particle size is +200 mesh (>74μm), other processes and parameters remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com