Composite Cable Tray Box for Rail Transit

A cable trough box and composite material technology, applied in the field of rail transit, can solve the problems of environmental erosion and freeze-thaw damage of cement products, inconvenient maintenance and replacement of cement cable troughs, and limited use of areas, etc. Anisotropy, the effect of increasing the oxygen index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

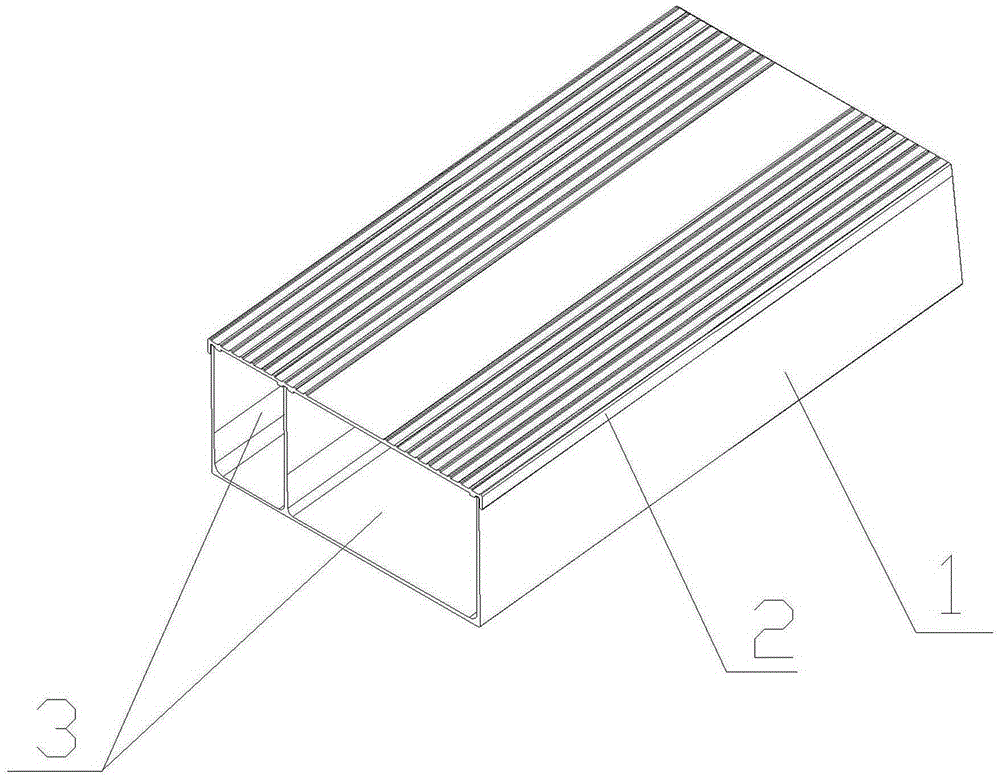

[0030] The composite cable trough box for rail transit in this embodiment includes a cable trough body 1 and a cable trough cover 2 covering the upper surface of the cable trough body 1 . Two rectangular slots 3 , one wide and one narrow, are arranged inside the cable slot body 1 along the length direction. The length of the cable groove body 1 is 3-20 meters. structured as figure 1 shown.

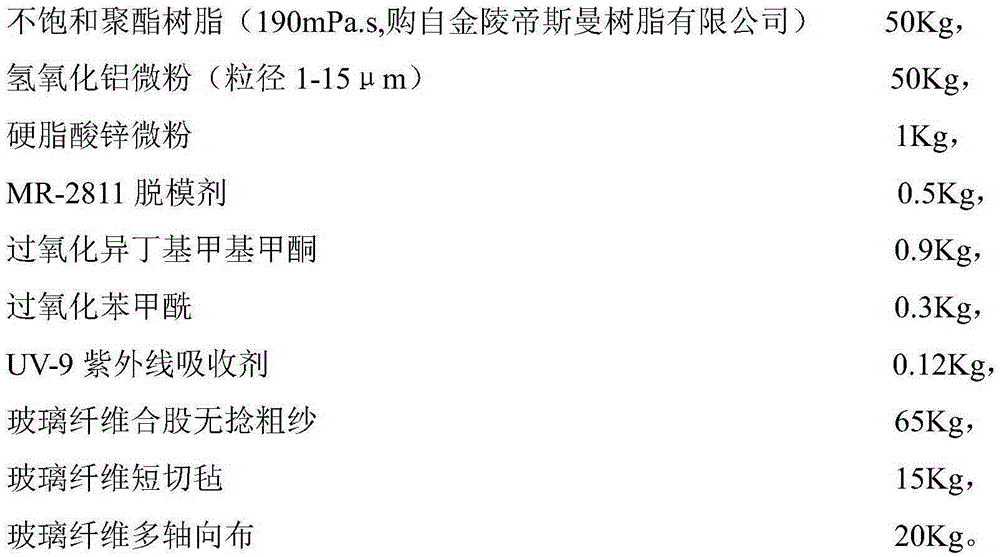

[0031] The cable trough box (including the cable trough body 1 and the cable trough cover 2) is prepared by the pultrusion process from each component with the following weight:

[0032]

[0033] The preparation method is as follows: add the release agent to the unsaturated polyester resin, stir with a high-speed disperser at a speed of 1000 rpm for 1 minute, and then add the other components in sequence. During the addition process, the high-speed dispersant should continue to disperse. And the stirring speed is kept above 1000 revolutions per minute. After all the materials are add...

Embodiment 2

[0037] The composite cable trough box for rail transit in this embodiment includes a cable trough body 1 and a cable trough cover 2 covering the upper surface of the cable trough body 1 . Two rectangular slots 3 , one wide and one narrow, are arranged inside the cable slot body 1 along the length direction. The length of the cable groove body 1 is 3-20 meters. structured as figure 1 shown.

[0038] The cable trough box is prepared by the pultrusion process from the components with the following weights:

[0039]

[0040]

[0041] The preparation method is as follows: add the release agent to the unsaturated polyester resin, stir with a high-speed disperser at a speed of 1000 rpm for 1 minute, and add the other components to the above resin in turn. During the addition process, the high-speed dispersant should be Continue to disperse, and keep the stirring speed above 1000 revolutions per minute. After all the materials are added, continue to disperse for 5 minutes to ...

Embodiment 3

[0045] The composite cable trough box for rail transit in this embodiment includes a cable trough body 1 and a cable trough cover 2 covering the upper surface of the cable trough body 1 . Two rectangular slots 3 , one wide and one narrow, are arranged inside the cable slot body 1 along the length direction. The length of the cable groove body 1 is 3-20 meters. structured asfigure 1 shown.

[0046] The cable trough is prepared by pultrusion from the following components by weight percentage:

[0047]

[0048]

[0049] The preparation method is as follows: add the release agent to the unsaturated polyester resin, stir with a high-speed disperser at a speed of 1000 rpm for 1 minute, and add the other components to the above resin in turn. During the addition process, the high-speed dispersant should be Continue to disperse, and keep the stirring speed above 1000 revolutions per minute. After all the materials are added, continue to disperse for 5 minutes to obtain an unsa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com