Cable duct box device for rail transportation

A cable trough box and rail transit technology, applied in the field of rail transit, can solve the problems of environmental erosion and freeze-thaw damage of cement products, inconvenient maintenance and replacement of cement cable troughs, and limited use of regions, etc. Anisotropy, the effect of increasing the oxygen index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

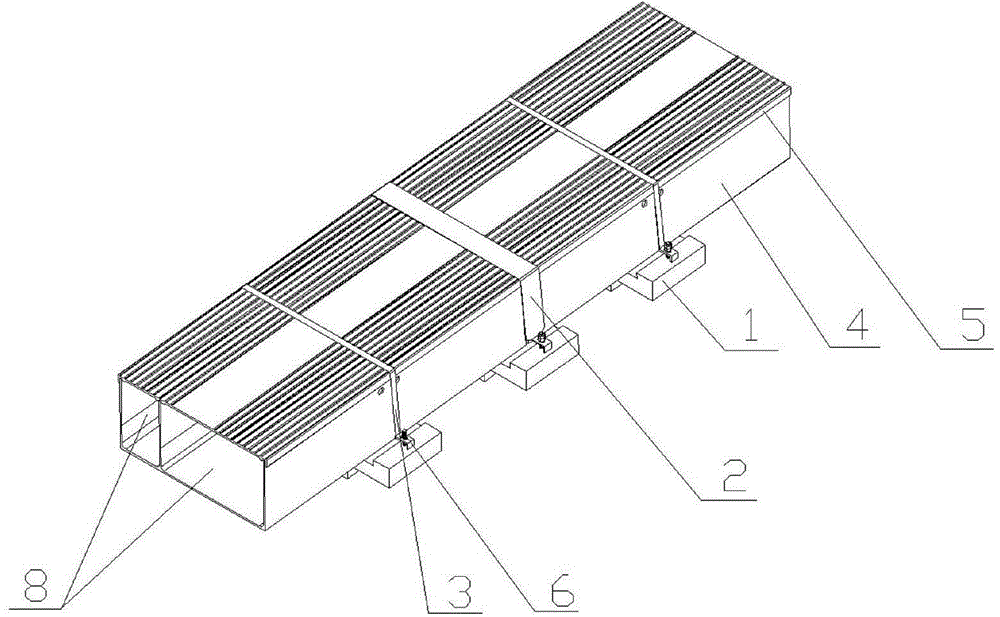

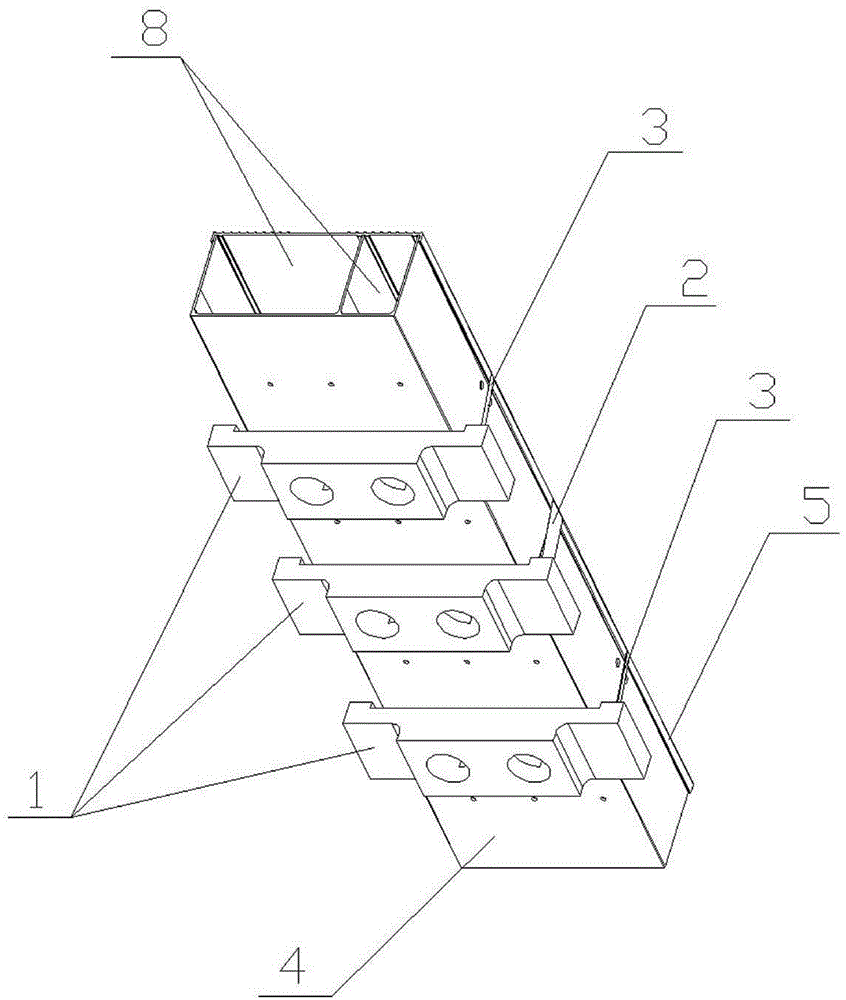

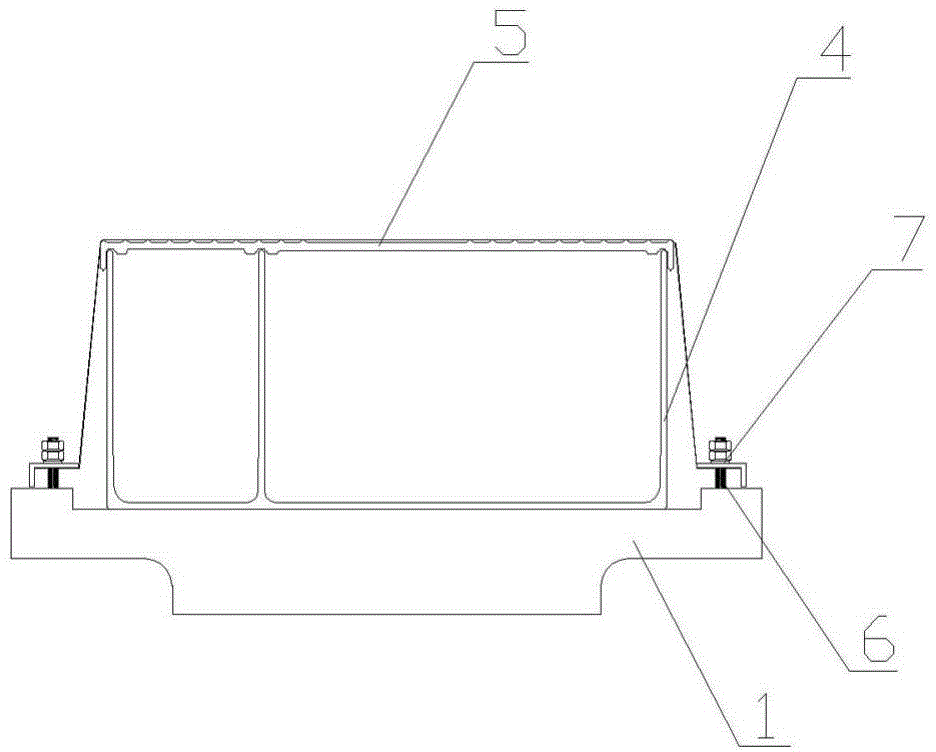

[0033] The cable trough box device for rail transit in this embodiment includes a plurality of cable trough box units made of composite materials connected end to end in sequence, a sealing component and a load-bearing component arranged at the joints of the cable trough box units. The sealing assembly includes a sealing bead 2 and a spacer 1, wherein the spacer 1 is arranged at the bottom of the junction of the unit body of the cable groove box, and the sealing bead 2 is sealed and pressed on the upper surface and the side of the junction of the unit body of the cable groove box, There is a detachable connection between the sealing bead 2 and the spacer 1 . The load-bearing assembly includes a fixed bead 3 and a pad 1, the pad 1 is arranged at the bottom of the middle part of the cable groove box unit body, the fixed bead 3 is pressed on the upper surface and the side of the cable groove box unit body, the fixed bead 3 and The pads 1 are detachably connected. The fixed bead ...

Embodiment 2

[0044] The new composite material cable duct for rail transit in this embodiment includes a cable duct box unit body, a spacer 1 , a sealing bead 2 and a fixing bead 3 . The specific structure is the same as in Embodiment 1, and will not be described in detail here.

[0045] The unit body of the cable trough box is prepared by the pultrusion process of each component with the following weight:

[0046]

[0047] The preparation method is as follows: add the release agent to the unsaturated polyester resin, stir with a high-speed disperser at a speed of 1000 rpm for 1 minute, and add the other components to the above resin in turn. During the addition process, the high-speed dispersant should be Continue to disperse, and keep the stirring speed above 1000 revolutions per minute. After all the materials are added, continue to disperse for 5 minutes to obtain an unsaturated polyester resin paste; use glass fiber ply roving to fully soak in the above mixture. Some pultrusion mo...

Embodiment 3

[0051] The new composite material cable duct for rail transit in this embodiment includes a cable duct box unit body, a spacer 1 , a sealing bead 2 and a fixing bead 3 . Concrete structure is with embodiment 1.

[0052] The unit body of the cable trough box is prepared by the pultrusion process of each component with the following weight:

[0053]

[0054] The preparation method is as follows: add the release agent to the unsaturated polyester resin, stir with a high-speed disperser at a speed of 1000 rpm for 1 minute, and add the other components to the above resin in turn. During the addition process, the high-speed dispersant should be Continue to disperse, and keep the stirring speed above 1000 revolutions per minute. After all the materials are added, continue to disperse for 5 minutes to obtain an unsaturated polyester resin paste; use glass fiber ply roving to fully soak in the above mixture. Some pultrusion molding techniques make glass fiber plied roving, chopped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com