Robot additive manufacturing method based on MIG/MAG welding process

A welding process and additive manufacturing technology, applied in the field of robotic additive manufacturing based on MIG/MAG welding process, can solve problems such as difficulty in welding high-precision, high-quality metal products, complex problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0086] The additive manufacturing method of metal parts is not mature enough, and the existing slicing algorithm and path planning algorithm are not suitable for the variable welding process. In order to improve the welding quality of metal parts, it is necessary to design a special 3D printing program for a specific welding process.

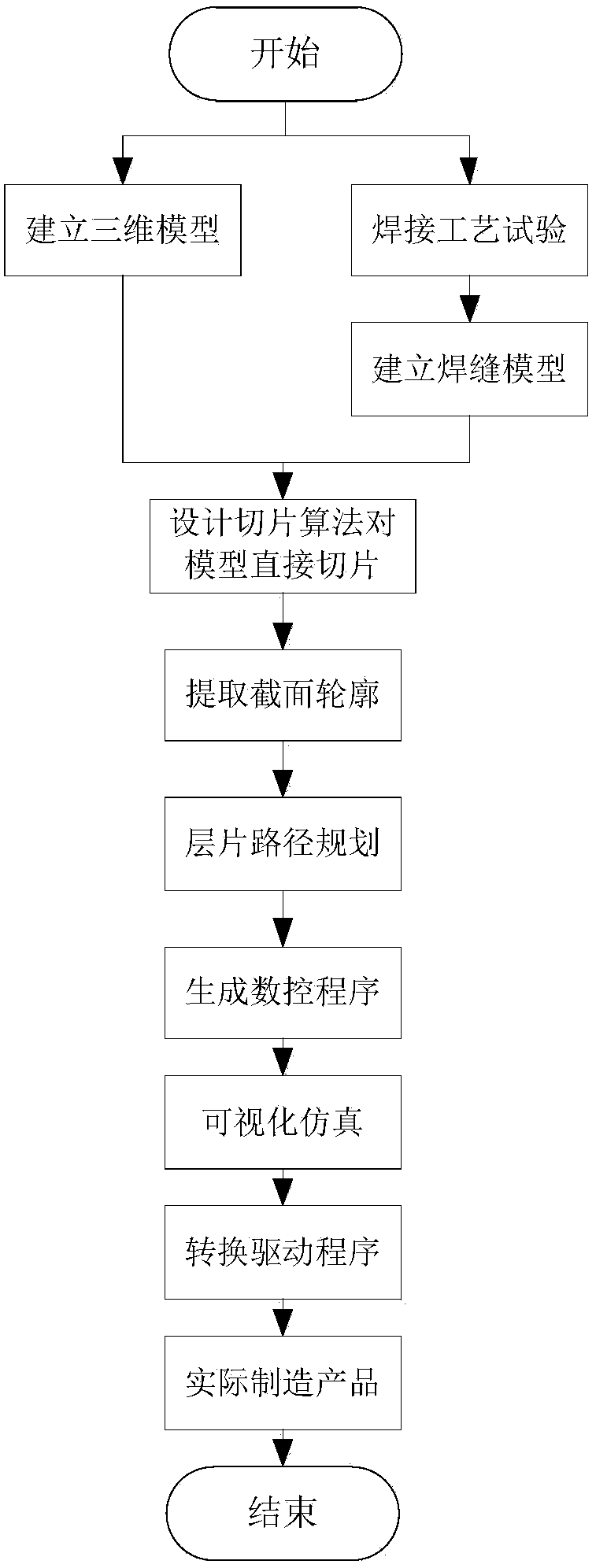

[0087] to combine figure 1 , the present invention is based on the robot additive manufacturing method of MIG / MAG welding process, comprises:

[0088] Step 1: Establish a CAD model of the metal part to be manufactured, or obtain a CAD model of the metal part to be manufactured through a laser scanner;

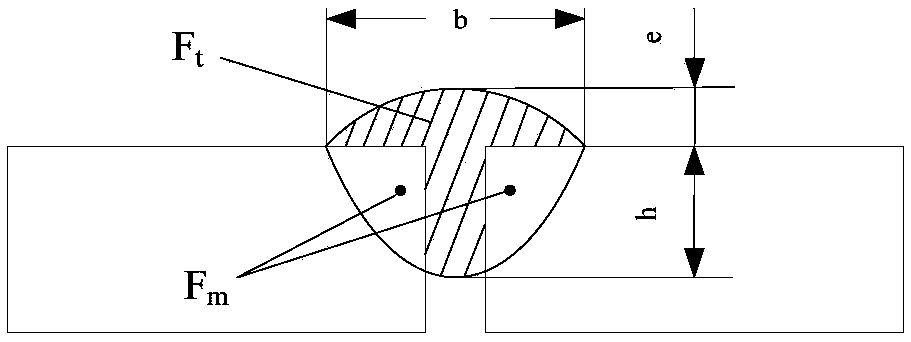

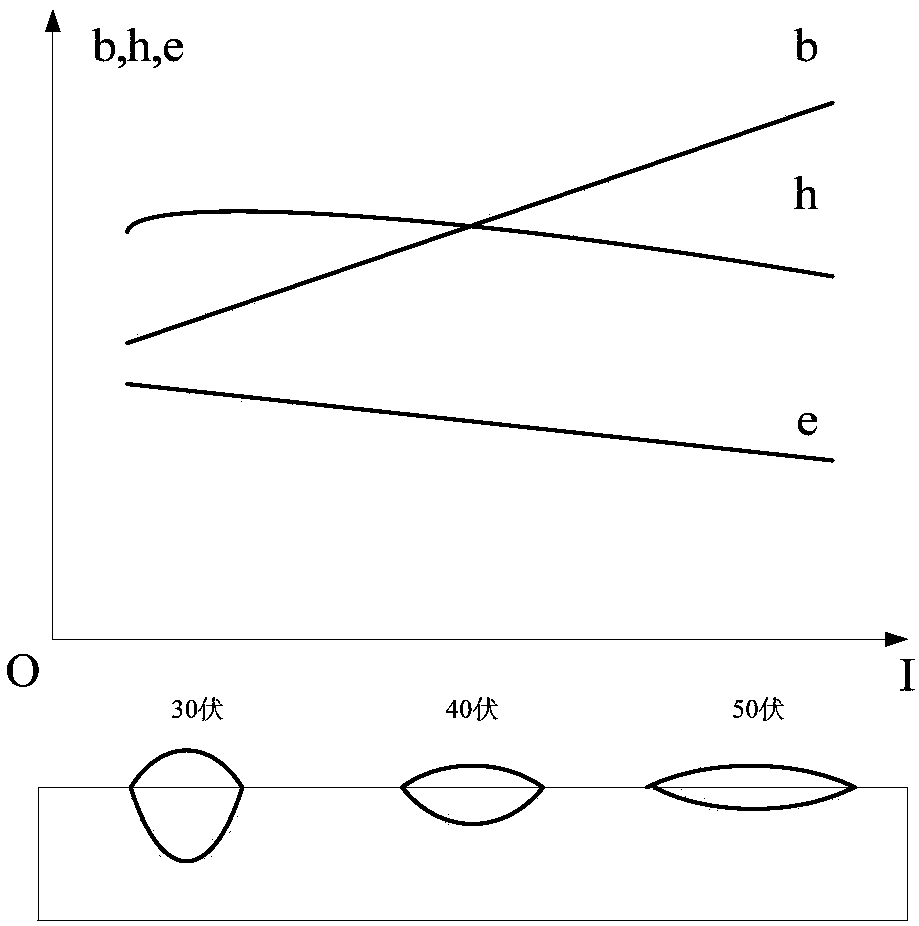

[0089] Step 2: Study the influence of the welding process parameters on the geometric features of the weld through the welding process test, and establish the mapping relationship between the welding process parameters and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com