Method for repairing defects of perovskite thin film

A thin film defect and perovskite technology, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of raw material residue, non-dense film, poor stability of perovskite film, etc., to improve stability, improve compactness, The effect of reducing holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Please refer to figure 2 As shown in the photo of the appearance of the perovskite film prepared on the substrate, the method of the present invention is not used for surface repair treatment, and it can be seen that there are obvious hole defects and dust impurity particles on the perovskite film.

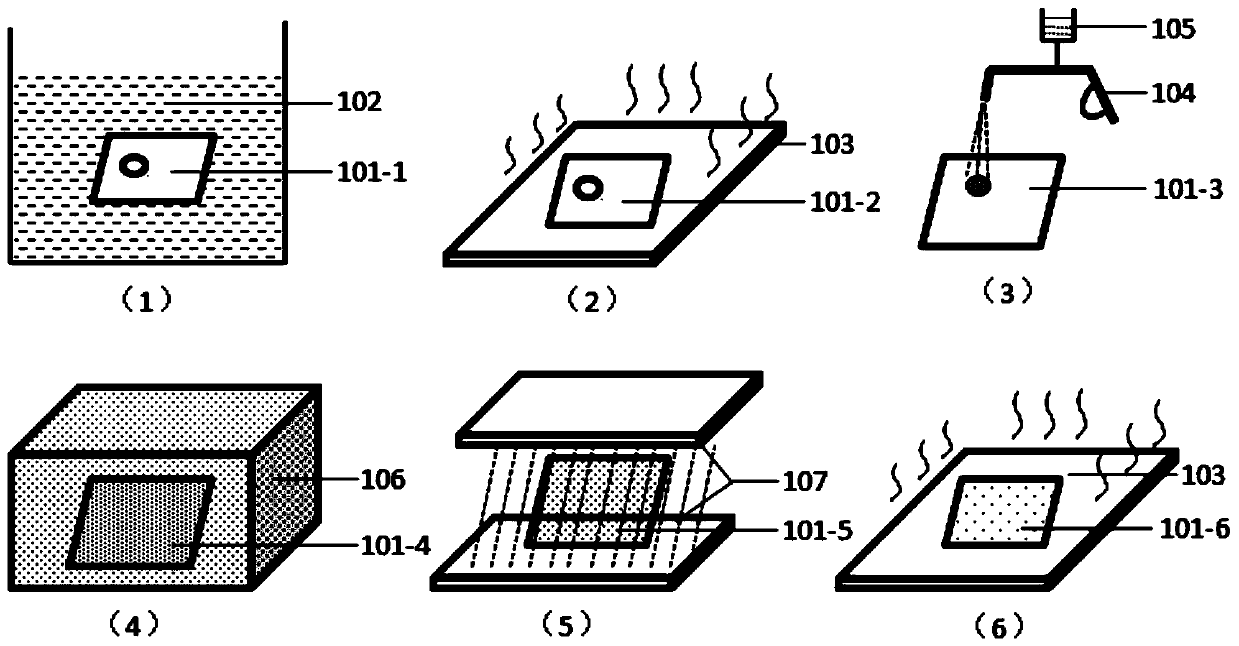

[0052] Please refer to figure 1 As shown, the above-mentioned substrate for preparing the perovskite film is repaired using a method for repairing perovskite film defects of the present invention, which specifically includes the following steps:

[0053] Step 1, such as figure 1 As shown in (1), put the prepared large-area perovskite film 101-1 into an anhydrous isopropanol solution 102 and heat it to 40°C for 30 minutes to obtain a clean perovskite film 101-1 .

[0054] Step 2, such as figure 1 As shown in (2), in a dry air environment, place the cleaned perovskite film 101 on a hot stage 103 at a temperature of 100° C. and heat for 10 minutes to obtain a dried perovs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com