System and method for testing activity of vehicle exhaust purification catalytic material

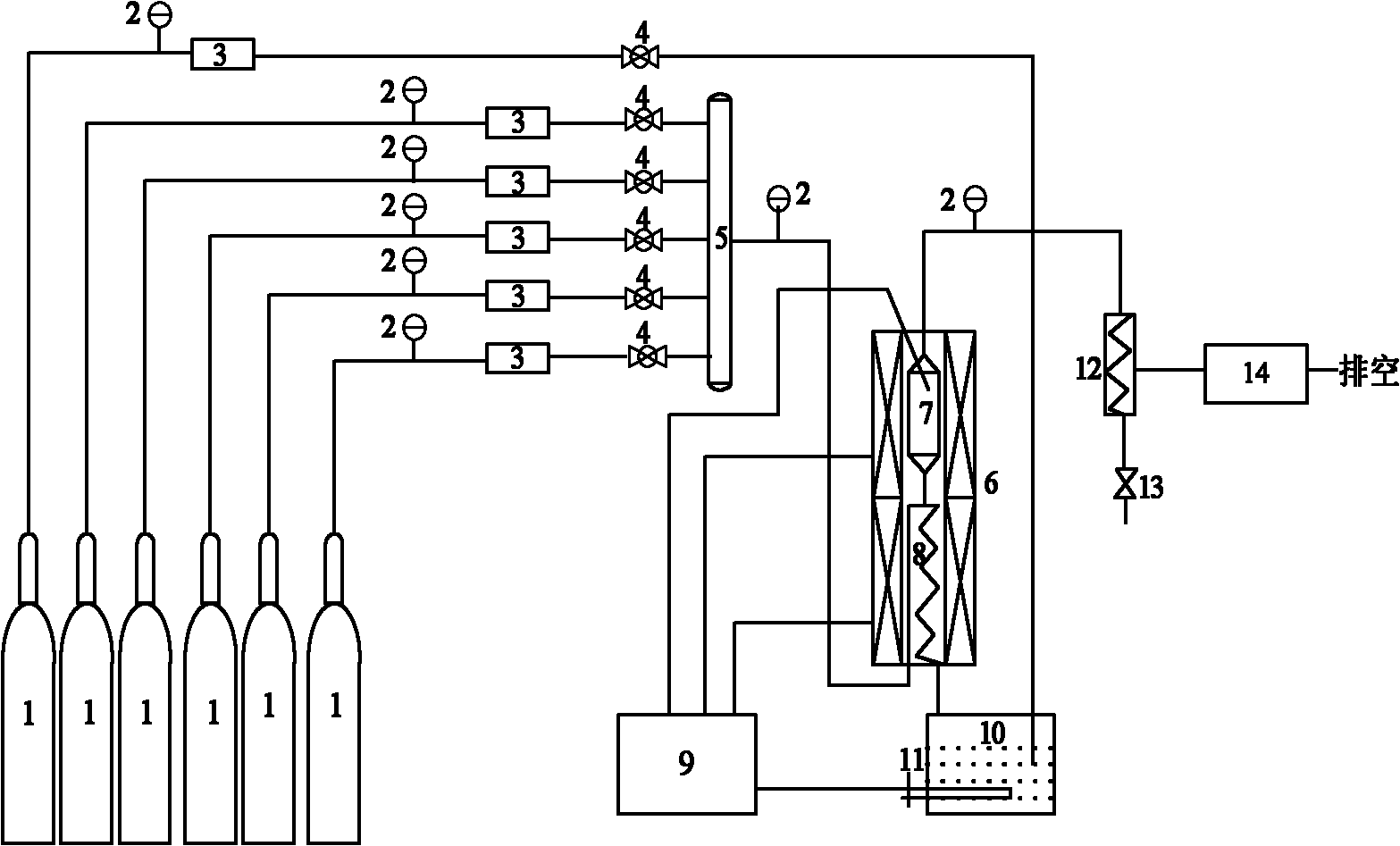

An exhaust gas purification and catalytic material technology, which is applied in the preparation of test samples and chemical analysis using catalysis, can solve the problems of complex evaluation system, inability to meet the needs of the automobile exhaust catalyst industry, lack of evaluation methods, etc., and achieve repeatability. Good performance, realization of ignition temperature characteristics, simple evaluation method and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

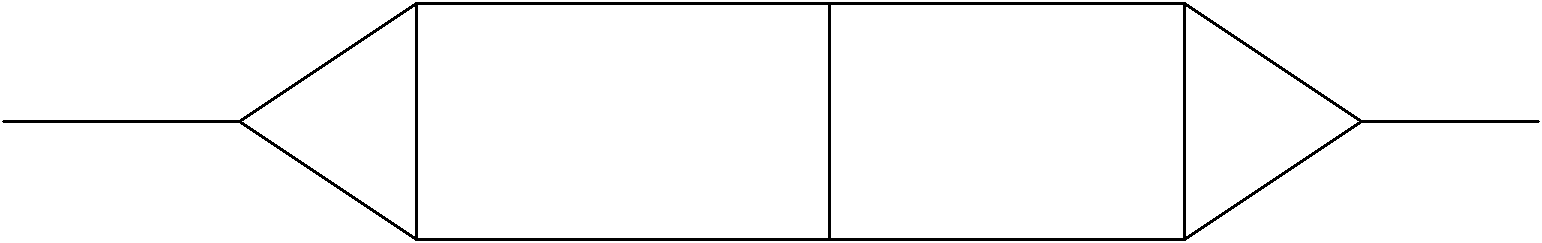

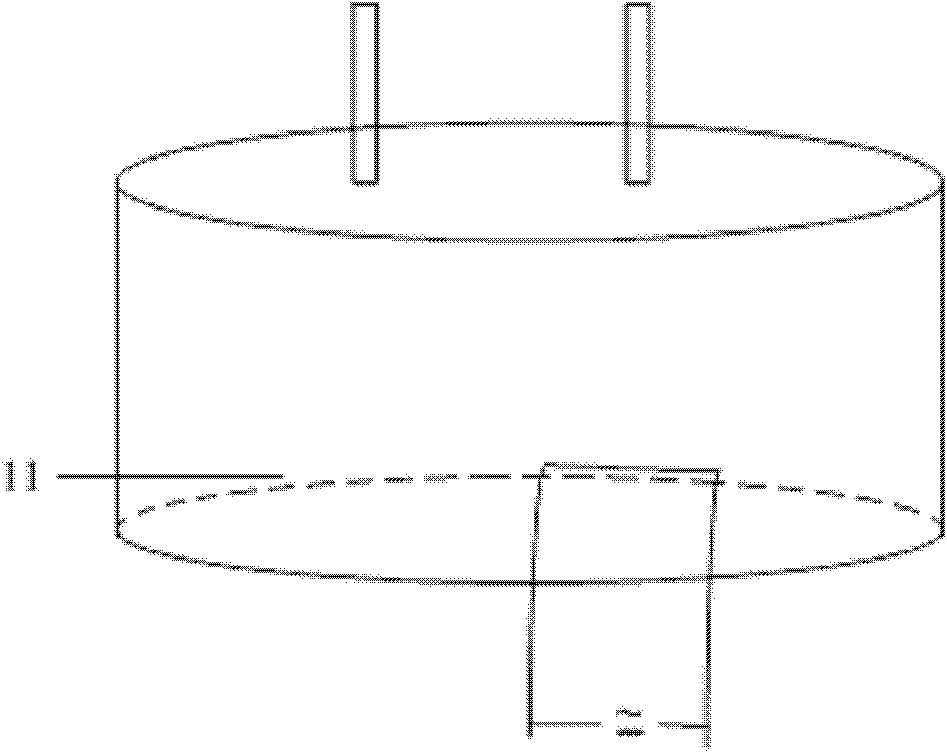

[0032] Mix the three-way catalyst powder sample (600mg) with a certain amount of quartz sand evenly and put it into the reactor, and place the reactor in the heating furnace along the axial direction; set the temperature of the water vapor generator to 80°C, so that the water vapor volume concentration is 10% ;Simulated gasoline vehicle exhaust gas atmosphere: 2%CO+0.1%NO+0.1%C 3 h 8 +12%CO 2 +1.5%O 2 +N 2 (Balance gas) and the water vapor sent by the water gas generator are sent to the preheating tube in the heating furnace to preheat to 40°C; the simulated automobile exhaust and water vapor after preheating by the preheating tube (the total gas flow rate is 1.5L, the space velocity 50,000h -1) into the reactor, and the temperature in the reactor is raised at a rate of 10°C / min to increase the temperature in the reactor from 40°C to 700°C. React at a temperature of 700°C, and use an analyzer to continuously collect data online. Analyzer (NDIR) online detection reactor o...

Embodiment 2

[0034] three-way catalyst The monolithic honeycomb catalyst sample is loaded into the reactor, and the reactor is placed in the heating furnace along the axial direction; the temperature of the water vapor generator is set at 100°C, so that the water vapor volume concentration is 12%; the atmosphere of simulated gasoline vehicle exhaust: 2.2% CO+ 0.1%NO+0.1%C 3 h 8 +10%CO 2 +O 2 +N 2 (Balance gas) and water vapor sent by the water gas generator are sent to the preheating tube in the heating furnace to preheat to 100°C; the simulated automobile exhaust and water vapor after preheating by the preheating tube (the total gas flow rate is 1.5L, the air velocity 50,000h -1 ) into the reactor through the catalyst at a temperature of 500 ° C for 20 minutes of mixed reaction, and then use the analyzer to collect data. Adjust the lambda value by changing the oxygen flow, while adjusting the N 2 The flow rate keeps the total flow rate of the reaction gas constant at 1.5L, and the...

Embodiment 3

[0036] Take the SCR catalyst The monolithic honeycomb catalyst sample is loaded into the reactor, and the reactor is placed in the heating furnace in the axial direction; the temperature of the water vapor generator is set at 10°C, so that the water vapor volume concentration is 5%; the simulated diesel vehicle exhaust atmosphere: 0.035% NO+ 0.035%NH 3 +5%CO 2 +14%O2+0.01%8O 2 +N 2 (Balance gas) and the water vapor sent by the water gas generator are sent to the preheating tube in the heating furnace to preheat to 150 °C, and the simulated automobile exhaust and water vapor (with an air velocity of 50000h-1) after being preheated by the preheating tube are sent to the In the reactor, the temperature in the reactor is raised at a rate of 8°C / min to make the temperature in the reactor rise from 150°C to 550°C. React at a certain temperature, and use an analyzer (FTIR) to detect NO at the reactor outlet online x Concentration, calculated NO x Conversion rate, get SCR catal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com