Steel belt lead-bath quenching and backfire product line decarburization technique and device thereof

A lead bath quenching and production line technology, applied in quenching devices, heat treatment equipment, heat treatment baths, etc., can solve problems such as fracture, the surface hardness of steel strips should not be too high, and cracks are prone to occur, and achieve toughness enhancement, surface hardness reduction, and improvement plastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

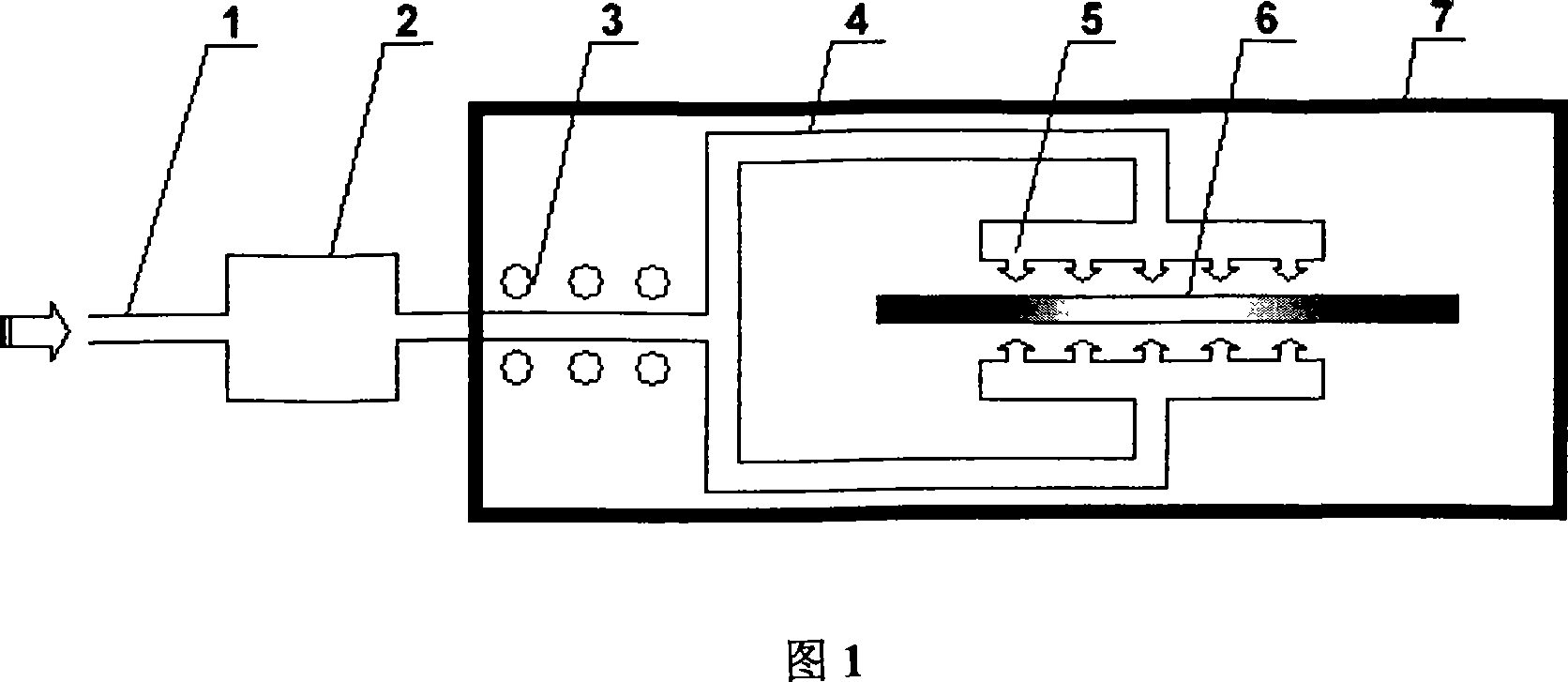

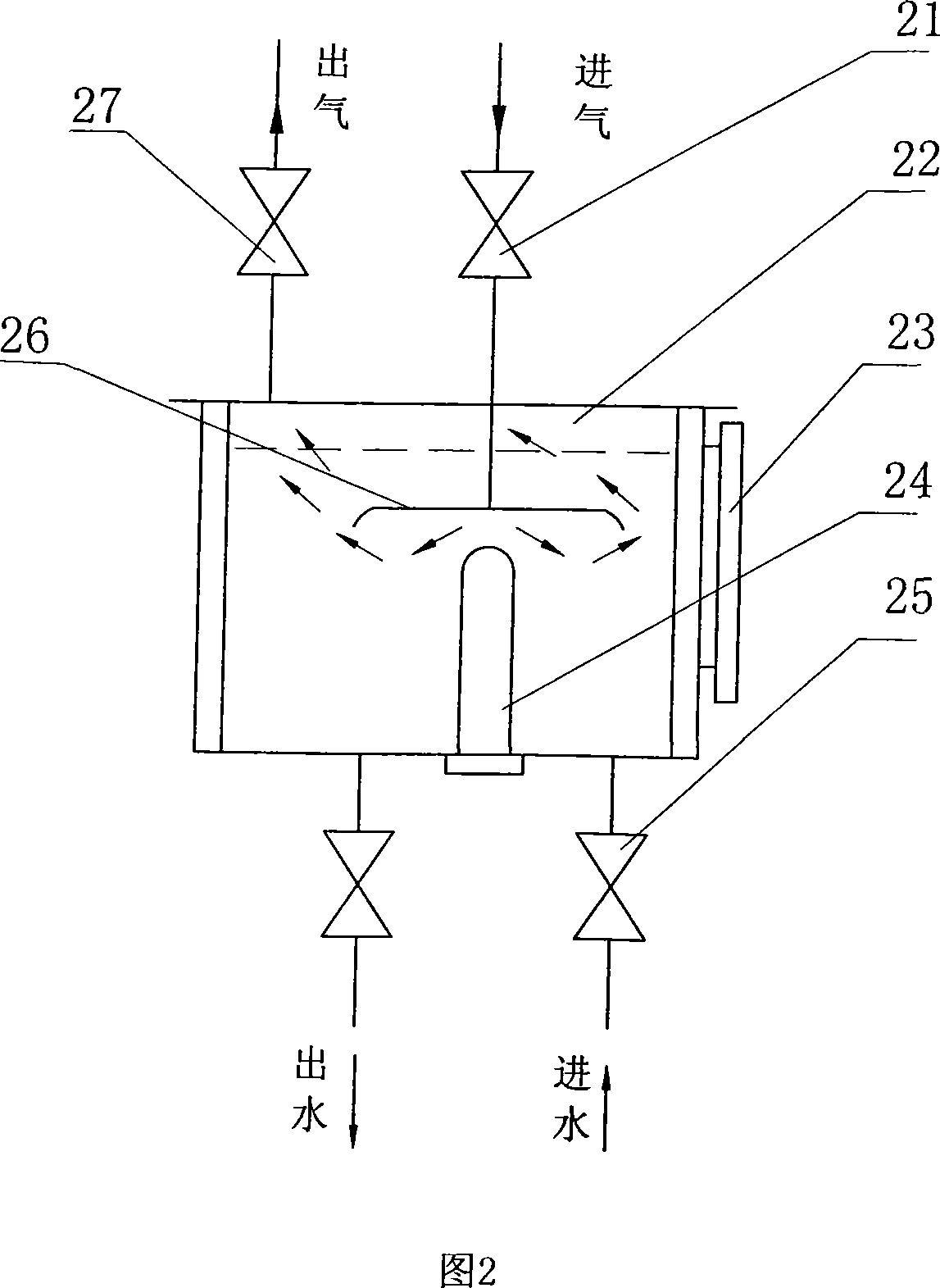

[0022] The 2 mm thick and 24 mm wide 30CrMo steel strip used to make shoe knives is subjected to continuous decarburization treatment on a continuous lead bath quenching and tempering heat treatment production line, and the steel strip moves at a speed of 1.5 to 2.0 meters per minute. The composition content of the mixed protective gas is (75%H 2 +25%N 2 ) 0.9 (H 2 O) 0.1 . The protective gas mixed with water vapor is further heated to 860-880°C in the pipeline, and then sprayed to the upper and lower surfaces of the steel strip through the nozzle at a flow rate of 800 ml per minute. The decarburization time of the moving steel strip surface is 2-3 minute. After the above decarburization process, the surface decarburization layer is about 5 microns thick, and the decarburization amount is about 40%. The hardness of the steel strip surface is obviously lower than that of the undecarburized steel strip, and the plasticity is obviously improved. The steel strip does not bre...

Embodiment 2

[0024] The 4mm thick and 80mm wide 40CrMo steel strip, which is also used to make shoe knives, is subjected to continuous decarburization treatment on a continuous lead bath quenching and tempering heat treatment production line, and the steel strip moves at a speed of 1.0 to 1.5 meters per minute. The composition content of the mixed protective gas is (75%H 2 +25%N 2 ) 0.8 (H 2 O) 0.2 . The protective gas mixed with water vapor is heated to 880-900 degrees in the pipeline, and sprayed to the upper and lower surfaces of the steel strip through the nozzle at a flow rate of 1000 ml per minute. The decarburization time of the moving steel strip surface is about 1 to 2 minutes . After the steel strip treated by the above decarburization process, the surface decarburization layer is about 4 to 5 microns thick, and the decarburization amount is about 30 to 40%. cracking.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com